Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce the amount of fine powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

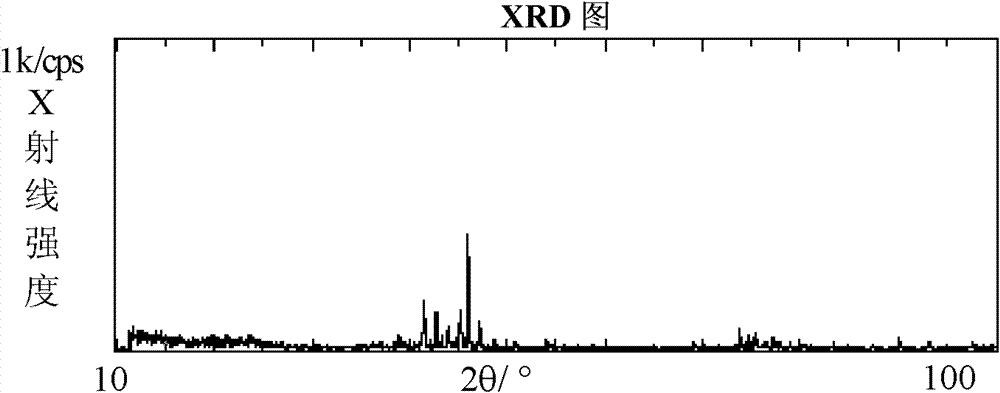

Catalyst component, catalyst, preparation method and its application

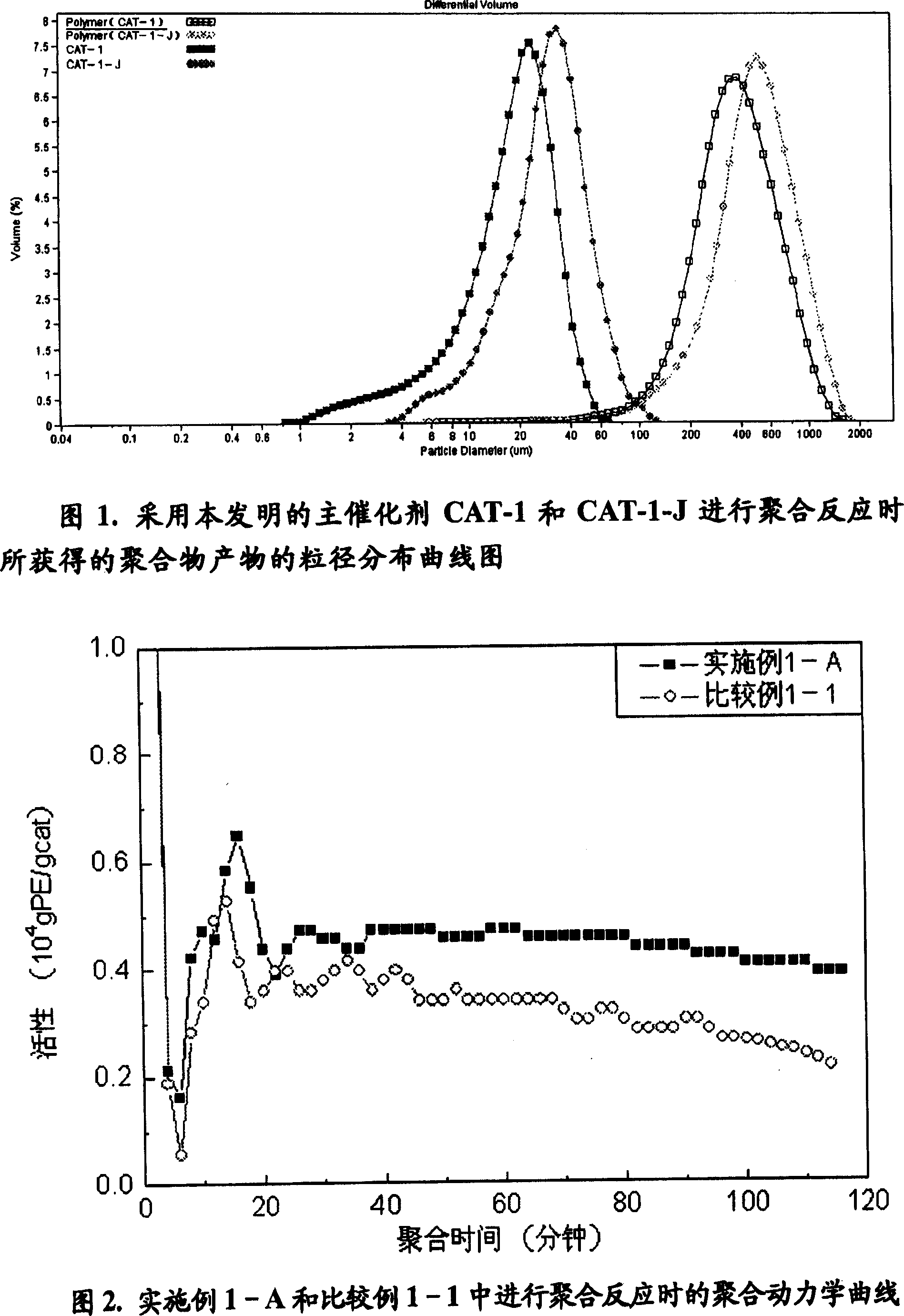

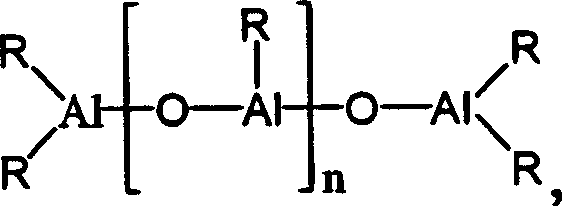

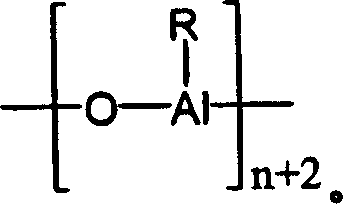

The invention relates to supported Ziegler-Natta catalyst components based on water-bearing silica gel (water content 0.5-8.0wt percent), which comprises the supported Ziegler-Natta catalyst and catalyst components of the supported Ziegler-Natta catalyst components, and a preparation method of the catalyst. The supported Ziegler-Natta catalyst is applied to homopolymerization of catalytic olefin and copolymerization of two or more than two different olefins. The supported Ziegler-Natta catalyst of the invention has low production cost, stable and easily controllable kinetic curve when being used in homopolymerization and copolymerization of catalytic olefin and stable active release; besides, polymers produced by the invention have low contend of fine powder and oligomer of the polymer and narrow particle size distribution of the polymer.

Owner:SINOPEC YANGZI PETROCHEM

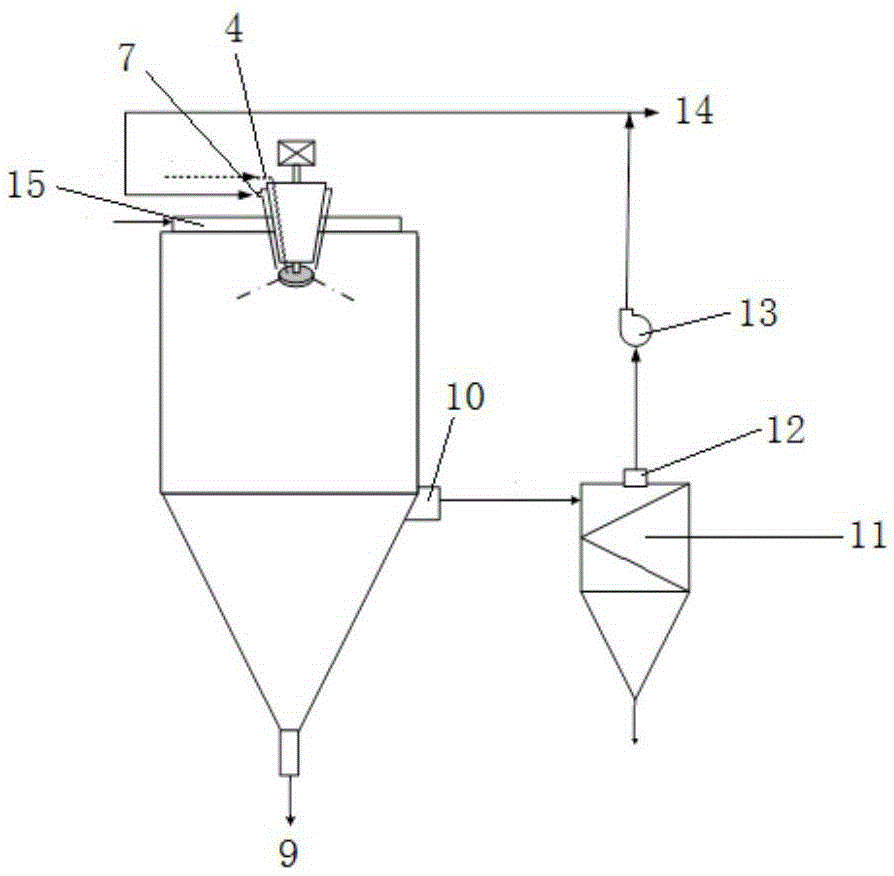

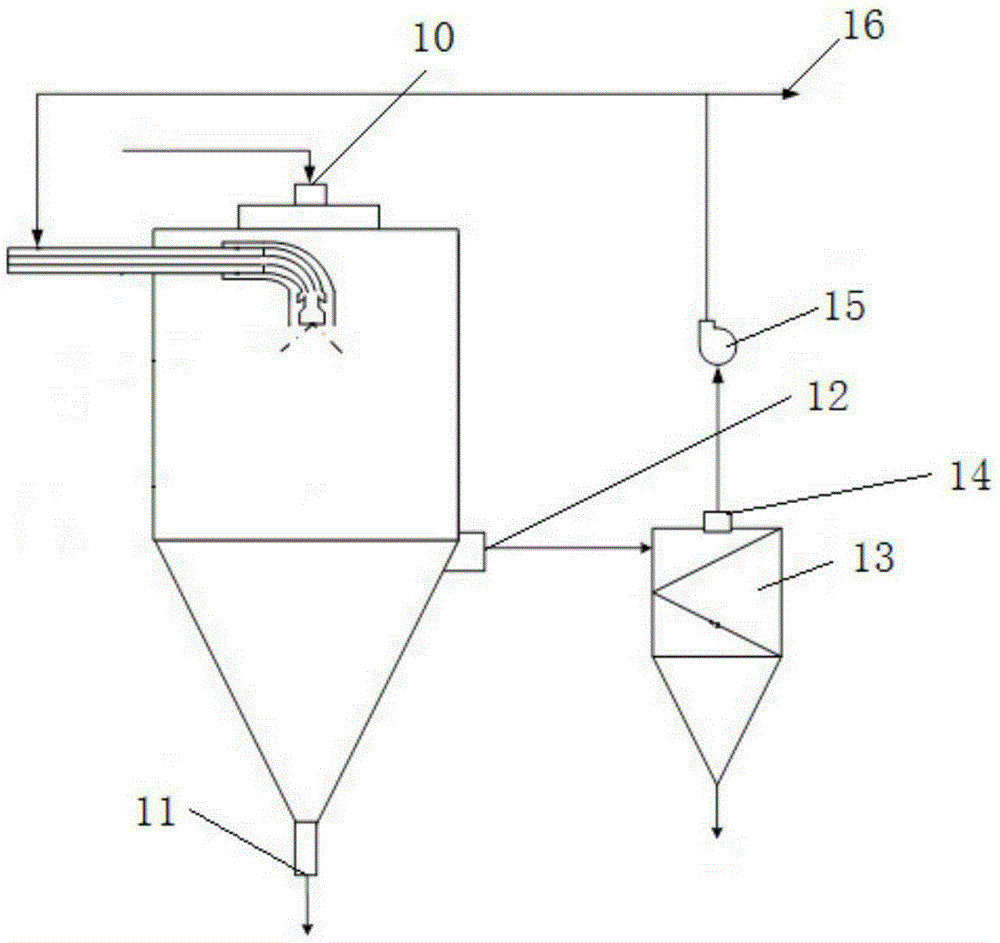

Centrifugal atomizing nozzle and spray dryer

InactiveCN106607197AReduce the chance of breakageAvoid direct contactSpray nozzlesEvaporation by sprayingNebulizerMicrosphere

The invention relates to the field of spray dryers and discloses a centrifugal atomizing nozzle and a spray dryer comprising the same. The centrifugal atomizing nozzle comprises a centrifugal atomizer and a protection wind guide pipe, wherein the centrifugal atomizer is internally provided with an atomizing disc which is used for spraying materials into fog drips and provided with atomizing holes, and a material guide pipe connected with the atomizing disc and a material inlet; and the protection wind guide pipe is provided with a protection wind inlet and a protection wind spraying opening. The protection wind guide pipe is arranged around the centrifugal atomizer, so that protection wind sprayed by the protection wind spraying opening surrounds the fog-drip-shaped materials sprayed by the atomizing holes. When spray drying is conducted by adopting the dryer comprising the centrifugal atomizing nozzle, the problems that microspheres are burst, abnormal shapes and fine powder are produced in the drying process can be solved, and the sphericity of obtained dried particles can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

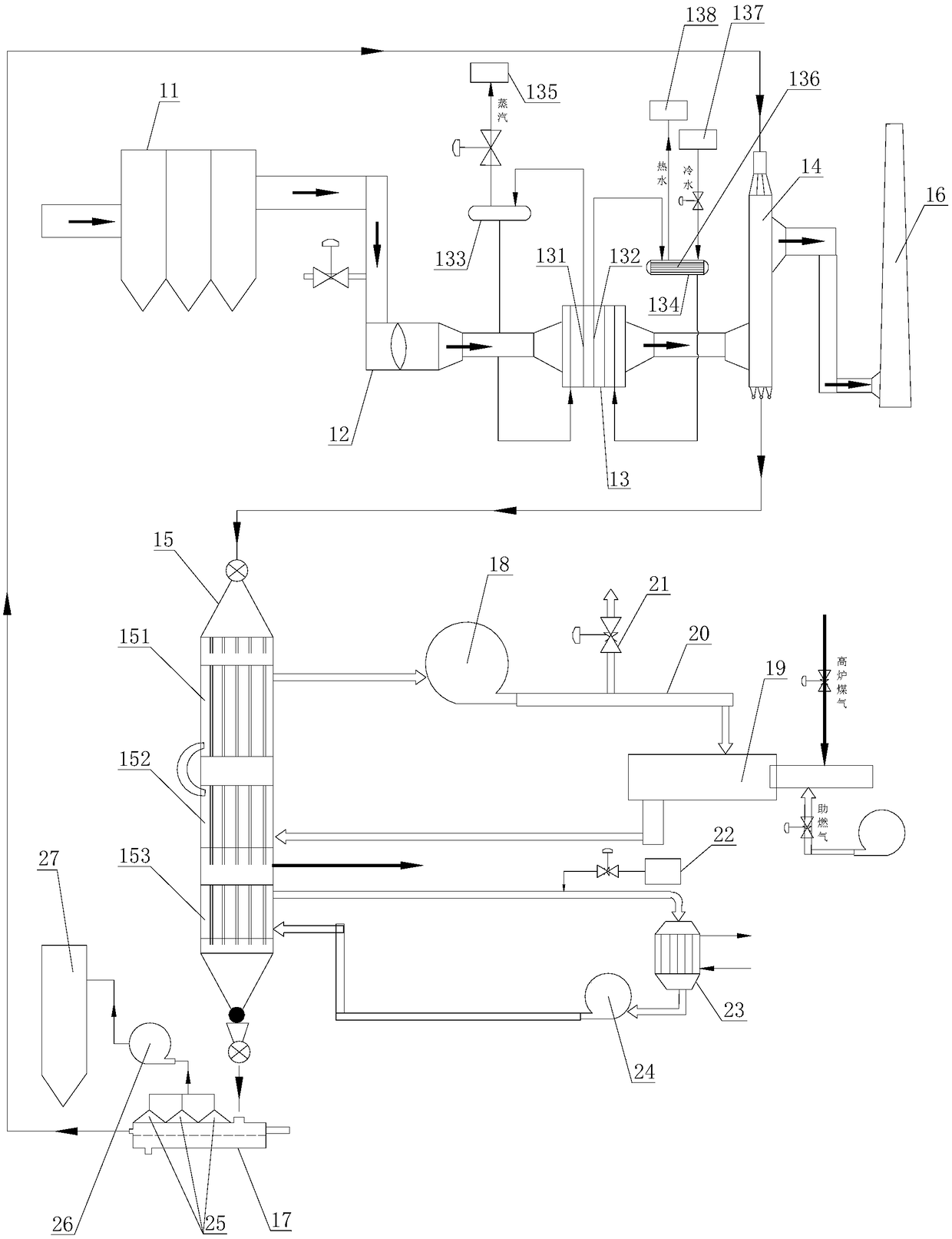

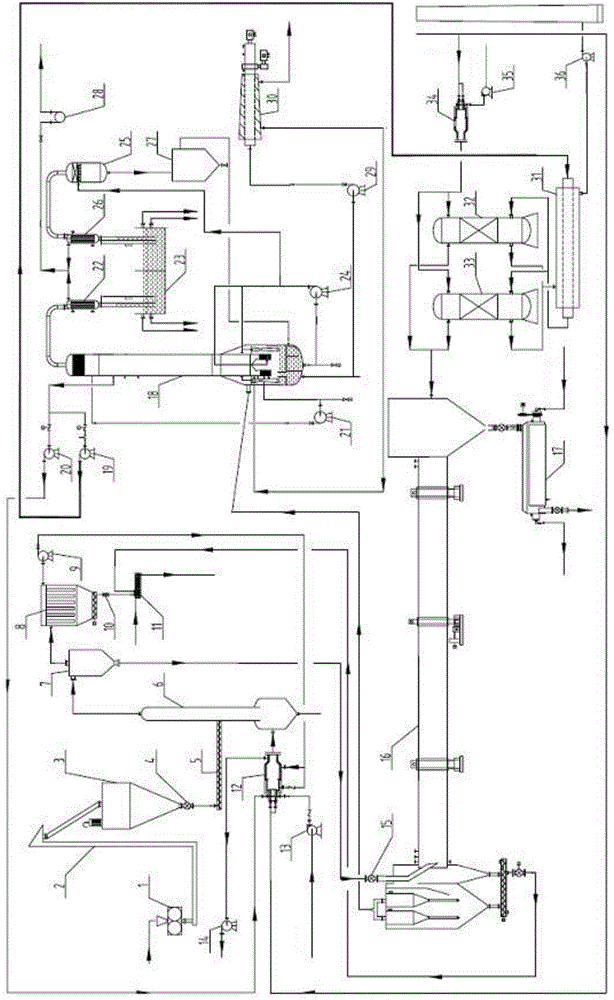

Flue gas desulfurization and denitration system

PendingCN109173570ATower resistance does not riseWill not cause forced production cutsGas treatmentDispersed particle filtrationBaghouseProcess engineering

The invention discloses a flue gas desulfurization and denitration system. The system comprises a bag deduster, a booster fan, a waste heat boiler, an adsorption tower and a regeneration tower, the outlet of the bag deduster is communicated with the flue gas inlet of the waste heat boiler through the booster fan, the flue gas outlet of the waste heat boiler is communicated with the flue gas inletof the adsorption tower, the flue gas outlet of the adsorption tower is communicated with the chimney, a material outlet at the bottom of the adsorption tower is communicated with a material inlet atthe top of the regeneration tower, a material outlet at the bottom of the regeneration tower is communicated with a material inlet of a vibrating screen, and the oversize product outlet of the vibrating screen is communicated with a material inlet at the top of the adsorption tower. The system has the advantages of high long-term running stability, high safety, high desulfurization and denitrationefficiency, and realization of safe and ultralow emission of the flue gas.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

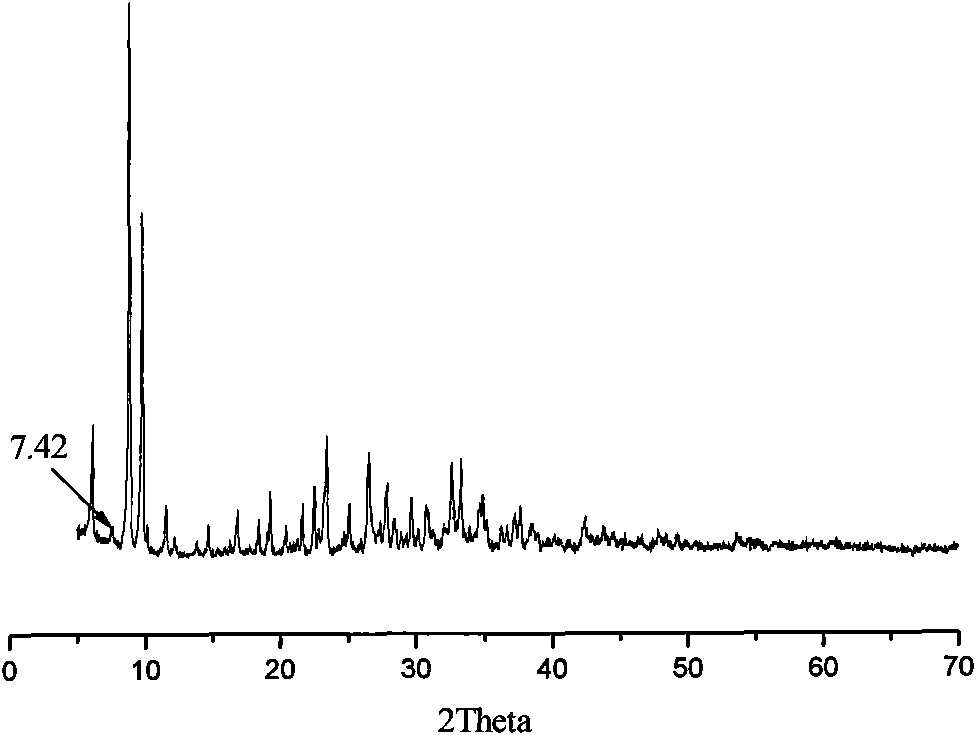

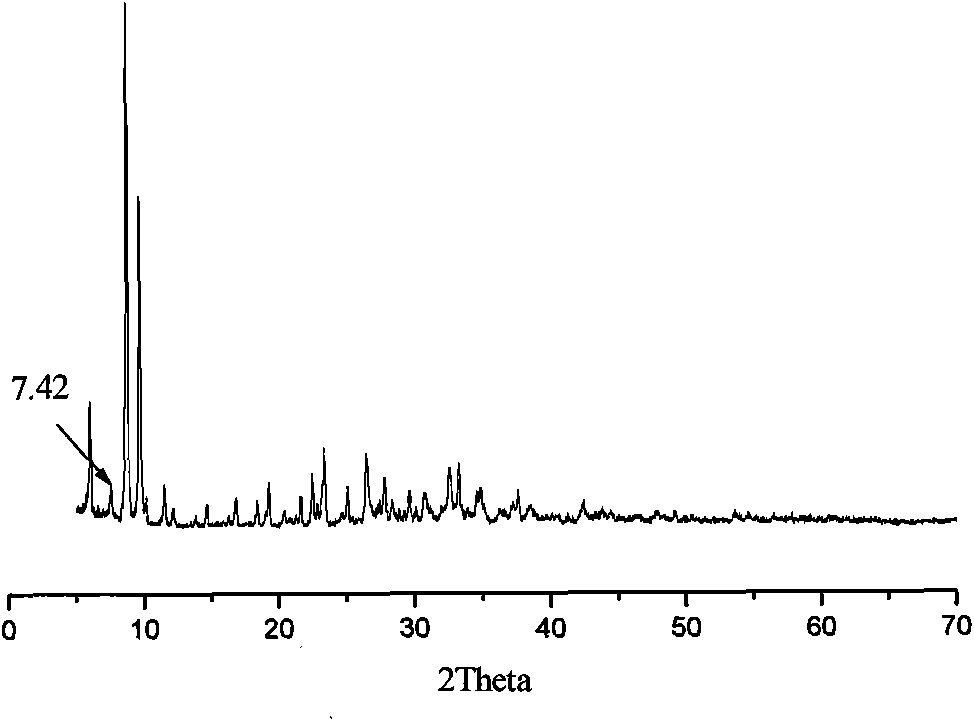

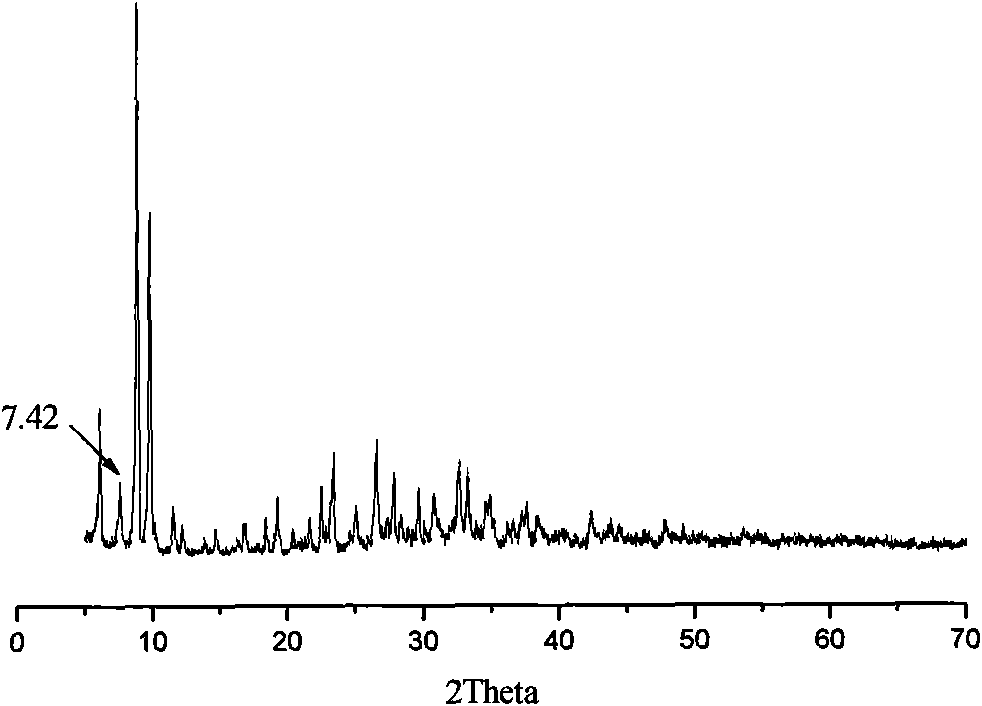

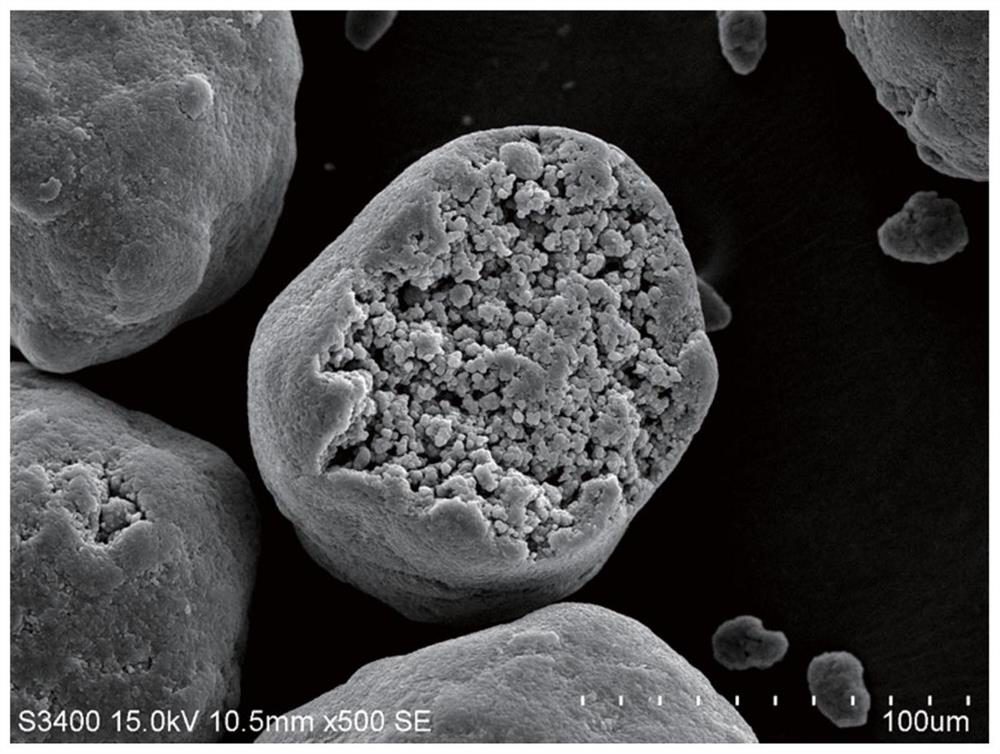

Method for preparing spherical magnesium chloride carrier

The invention discloses a method for preparing a spherical magnesium chloride carrier. The method comprises the following steps of: performing alcohol combination reaction on magnesium chloride and fatty alcohol (ROH), dispersing, quenching, solidifying and drying to obtain a carrier precursor, performing primary alcohol removal on the carrier precursor in inert airflow at the temperature of between 30 and 40 DEG C, heating to the temperature of between 41 and 55 EG C, performing secondary alcohol removal, and thus obtaining the spherical magnesium chloride and alcohol carrier. An olefin polymerization catalyst prepared from the carrier obtained after alcohol removal by the method has high catalytic activity, the granular size of the olefin polymerization catalyst is increased, and the fine powder quantity of the olefin polymerization catalyst is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

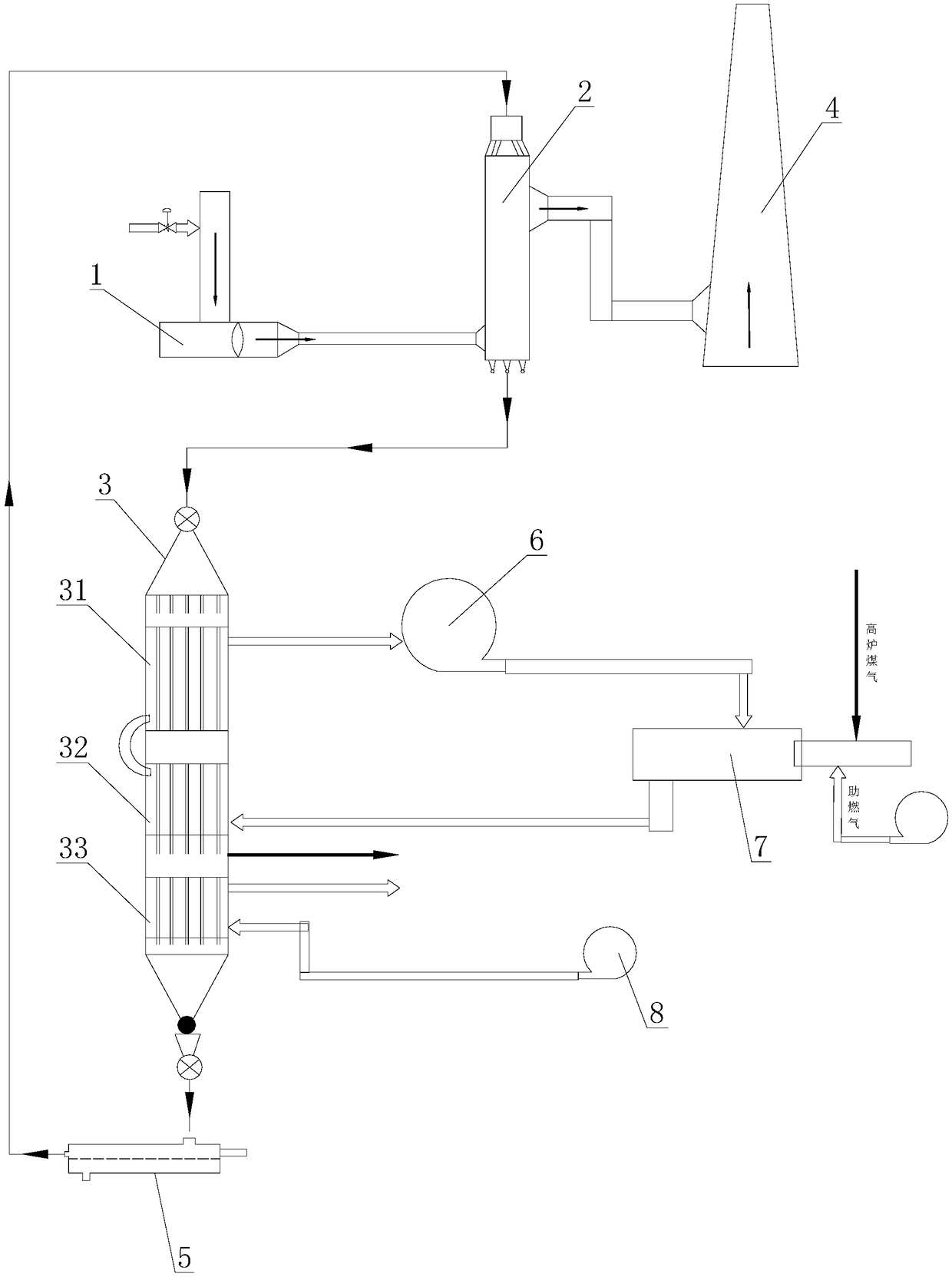

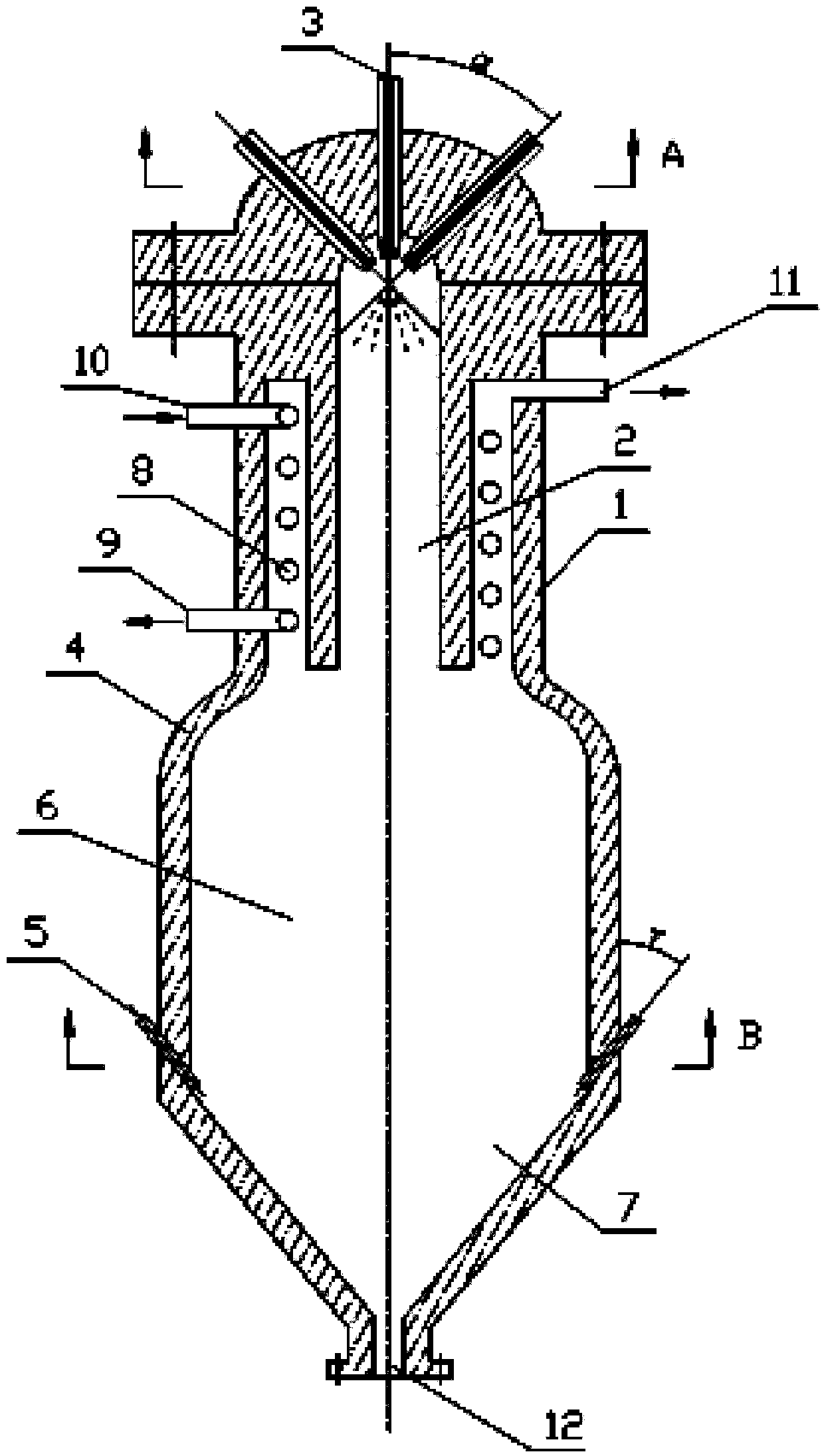

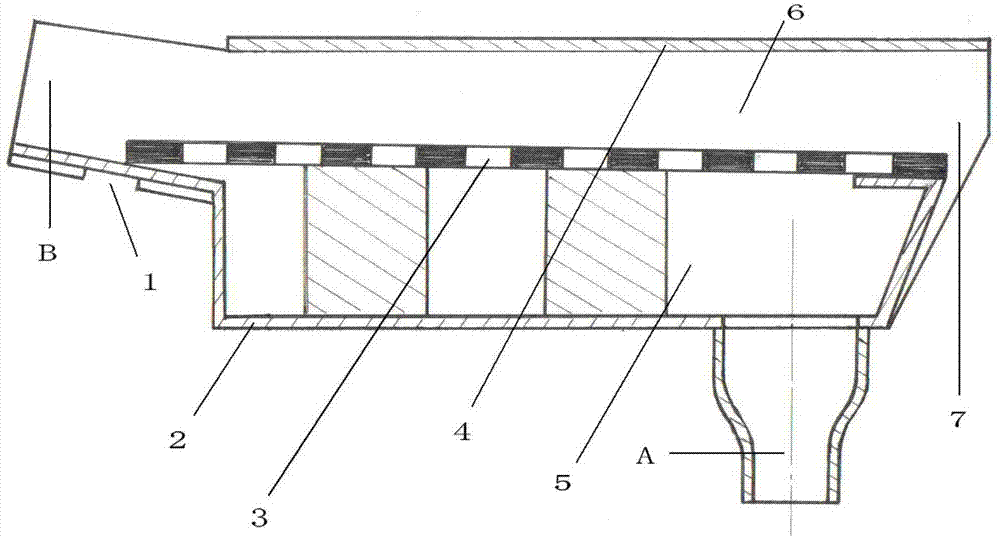

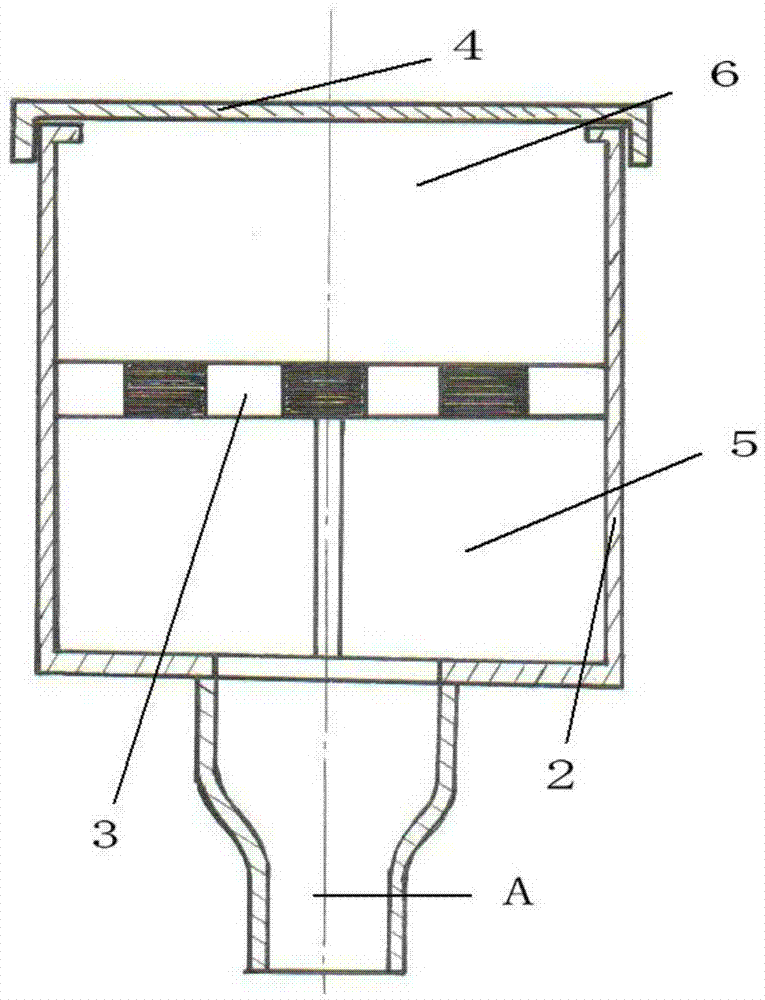

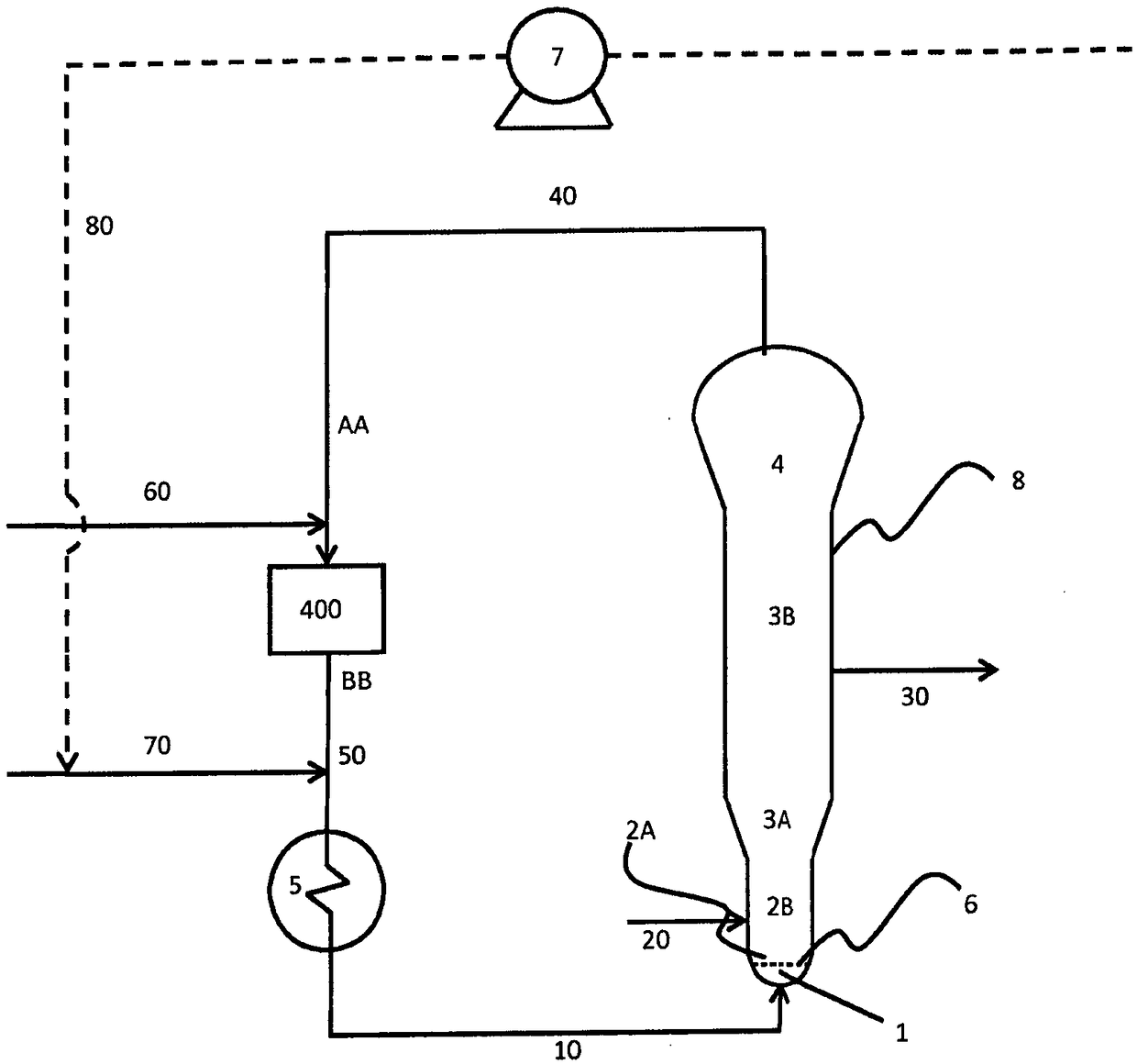

Entrained-flow bed gasification furnace for coal hydrogenation

InactiveCN103666577AIncrease temperatureReduce the amount of fine powderGranular/pulverulent flues gasificationProcess engineeringCoal

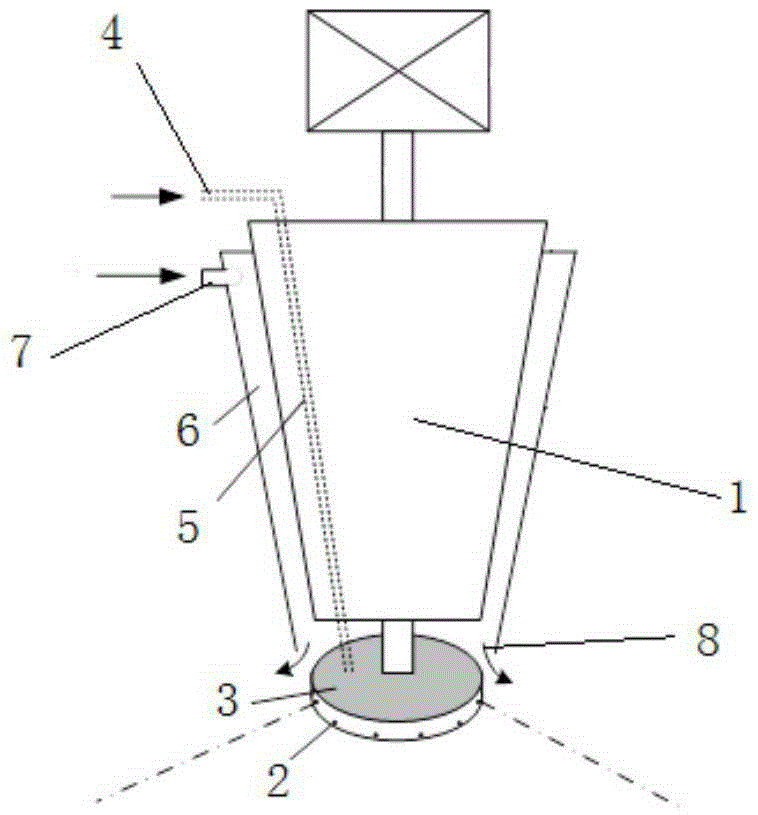

The invention discloses an entrained-flow bed gasification furnace for coal hydrogenation, which consists of a furnace body (1), a feed nozzle (3), a gasification chamber (2) and a semi-coke collection tank (7) and is characterized in that the furnace body (1) is divided into an upper part, a middle part and a lower part; the upper part of the furnace body (1) is a vertical section; the middle part of the furnace body (1) is an expansion section (6); the V-shaped semi-coke collection tank (7) is arranged at the lower part of the furnace body (1); the gasification chamber (2) is arranged at the upper part of the furnace body (1); the feed nozzle (3) is positioned at the top end of the gasification chamber (2); a coil heat exchanger (8) for preheating the feed gas is arranged between the gasification chamber (2) and the upper part of the furnace body (1); a product gas outlet (11) is formed in the furnace body (1) above the coil heat exchanger (8); a high-pressure gas spray pipe (5) is arranged at the lower part of the expansion section (6) of the furnace body (1); a discharge port (12) is formed at the bottom of the semi-coke collection tank (7). The entrained-flow bed gasification furnace disclosed by the invention has the advantages of low energy consumption, low hydrogen consumption and light dedusting load.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

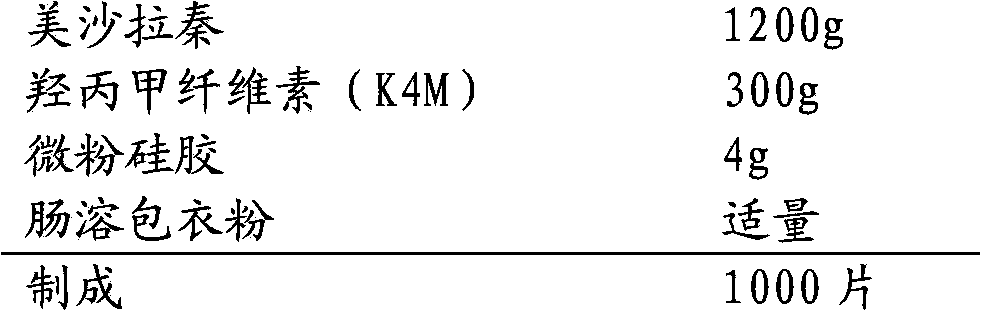

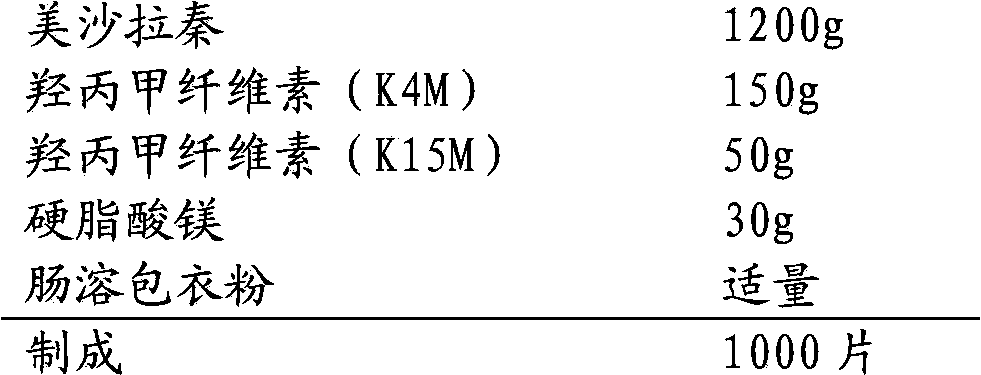

Mesalazine enteric-coated sustained release tablet

InactiveCN103565766AImprove uniformityEasy to prepareOrganic active ingredientsDigestive systemSustained Release TabletIntestinal fluid

The invention discloses a mesalazine enteric-coated sustained release tablet. The mesalazine enteric-coated sustained release tablet is characterized by consisting of the following components in a unit dose: 1.2g of mesalazine, 0.1-0.3g of a sustained release material, 0.004.0.03g of a lubricant and 0.02-0.1g of enteric-coated powder. The release of the mesalazine enteric-coated sustained release tablet in one hour in simulated intestinal fluid of which the pH value is 7.2 is less than 30%, the release in four hours is not more than 70%, and the release in eight hours exceeds 80%.

Owner:四川健能制药有限公司

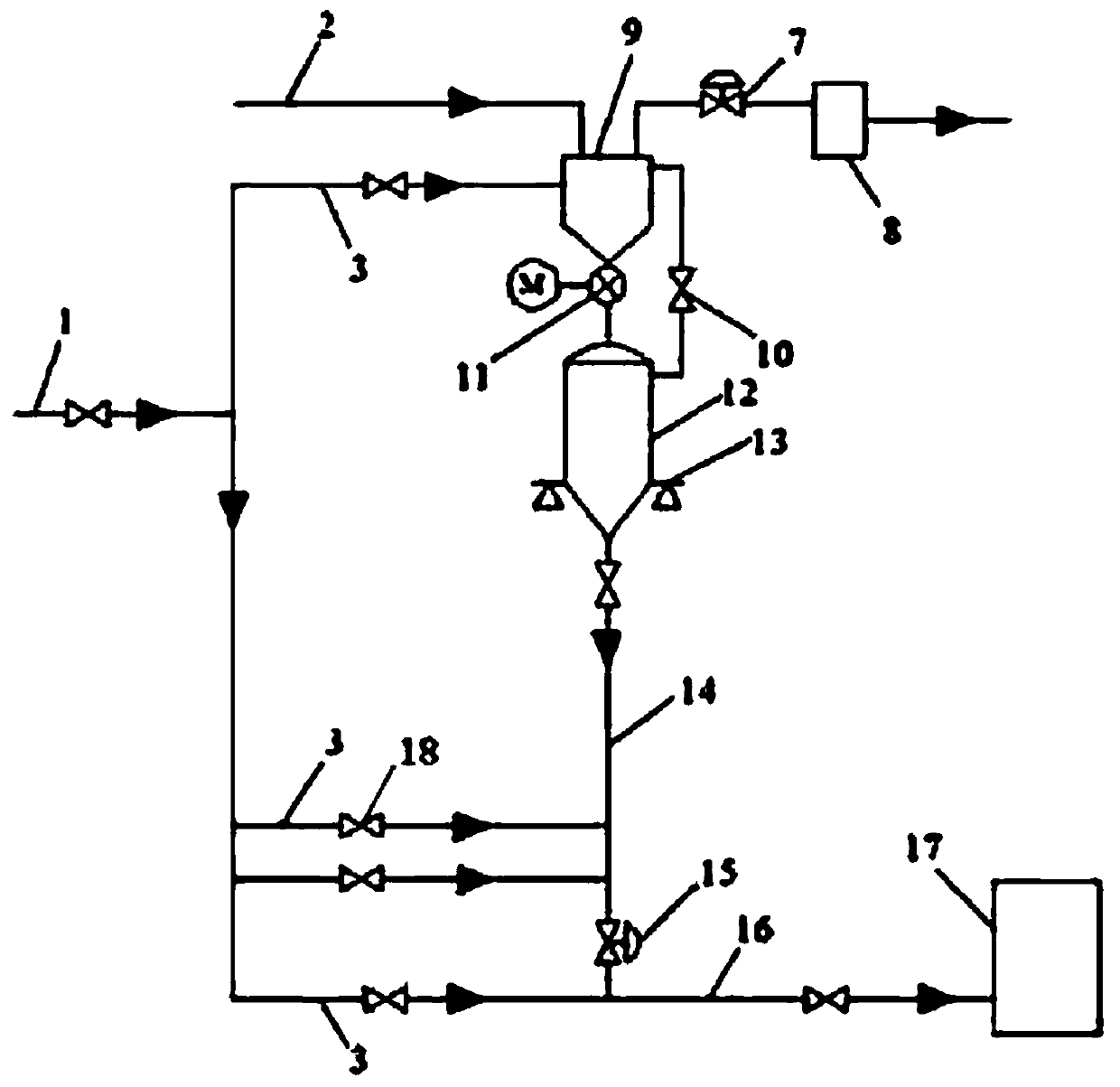

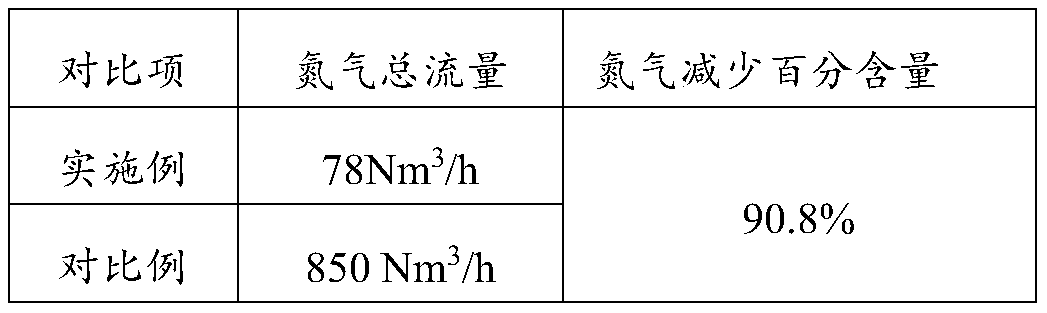

Continuous vertical feeding system and method for fluidized bed reactor

PendingCN111495283AAvoid wear and tearPrevent backflowDispersed particle filtrationChemical/physical processesGas solidFluidized bed

The invention discloses a continuous vertical feeding system and method for a fluidized bed reactor. The feeding system comprises a supply system, a vertical discharging section, a horizontal conveying section, a gas conveying system and a pressure adjusting assembly which are connected in sequence. The other end of the horizontal conveying section is connected with a fluidized bed reactor, and the pressure adjusting assembly is connected with the supply system and the gas conveying system. The self-weight of a solid particle reaction material and the effect of an input gas are used to make particle materials uniformly fluidized and transferred to the vertical discharging section from the supply system, then transferred to the horizontal conveying section and continuously uniformly conveyed into a fluidized bed reactor, so the particle material abrasion caused by mechanical feeding is avoided, the fine powder amount is reduced, the entrainment loss of gas-solid reaction is further reduced, the gas amount introduced by pneumatic feeding is greatly reduced, and great benefits are brought to chlorination production.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

Method for manufacturing moisture-free granular flavoring

ActiveCN101669610APrevent moisture absorptionHigh viscosityFood preparationMoisture resistanceMoisture

The invention discloses a method for manufacturing a moisture-free granular flavoring, which comprises the following steps of suspension preparation, mixing, granulation, drying, cooling and screening. The method overcomes the defects of the prior granular flavoring manufacturing method by improving the mixing process of the granular flavoring, and can produce the granular flavoring with good moisture resistance and avoid the problem that the granular flavoring absorbs moisture during use in a kitchen.

Owner:上海佳格食品有限公司

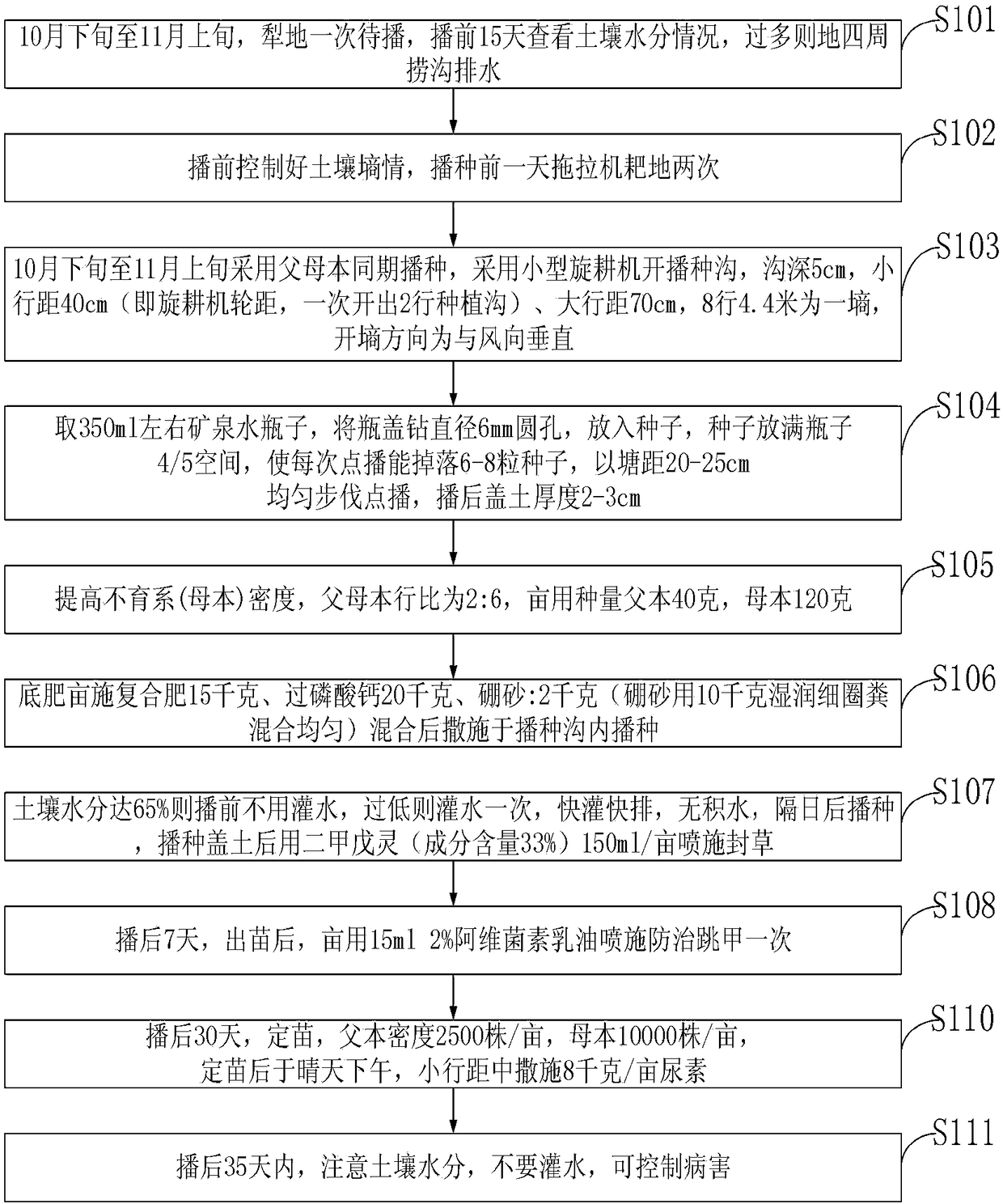

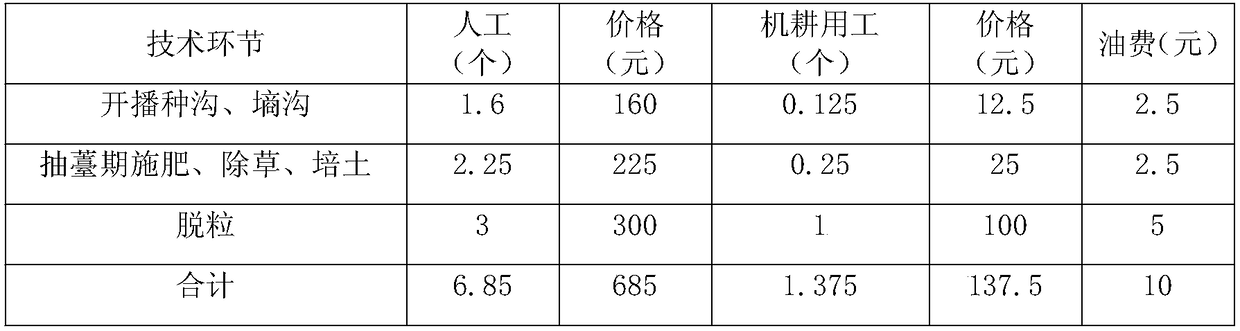

Three-line hybrid rape seed production method

InactiveCN108207615ATechnology is easy to masterSeed quality controllablePlant genotype modificationWeedFlowering time

Owner:德宏州农业技术推广中心

Novel crank pull rod type vibration fluid bed drying machine

InactiveCN103344094AEven by forceConsistent heating timeDrying solid materials with heatHearth type furnacesPhysicsElectric machinery

The invention relates to a novel crank pull rod type vibration fluid bed drying machine which comprises a machine body. A sieve plate is arranged inside the machine body, a vibration cross beam which supports the machine body is arranged on the lower portion of the machine body, and the vibration cross beam is connected with a driving motor through a linkage mechanism. The vibration cross beam rotates under the driving of linking rods, so that the machine body moves up and down and front and back. The novel crank pull rod type vibration fluid bed drying machine is wide in application range, good in drying quality and high in efficiency.

Owner:PENGFEI CHEM EQUIPS FACTORY JIANGDU CITY +2

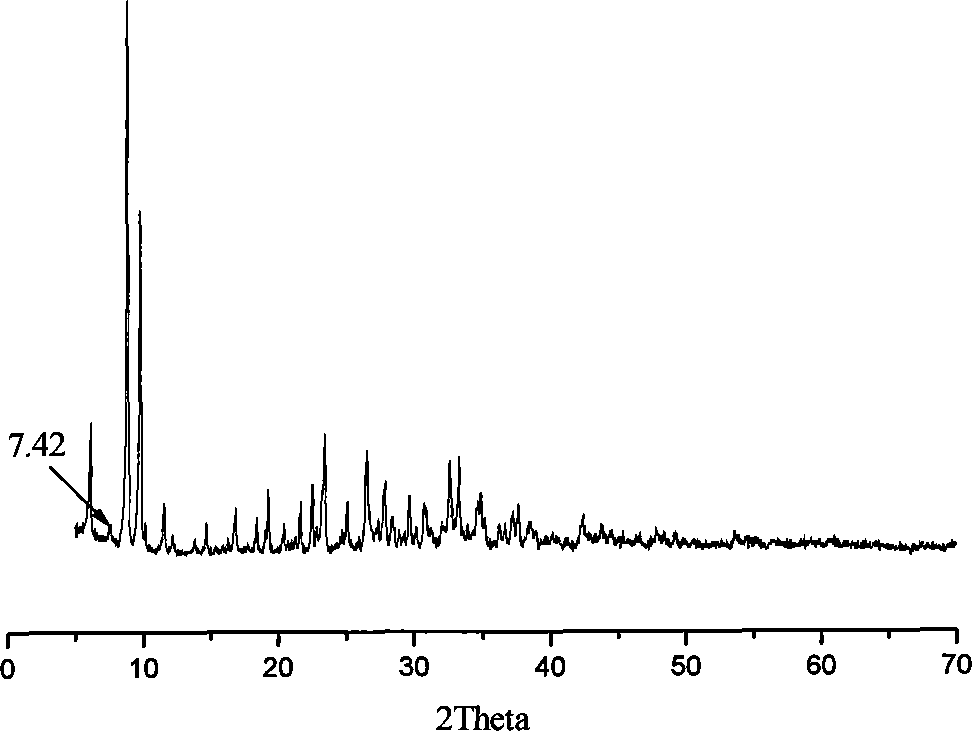

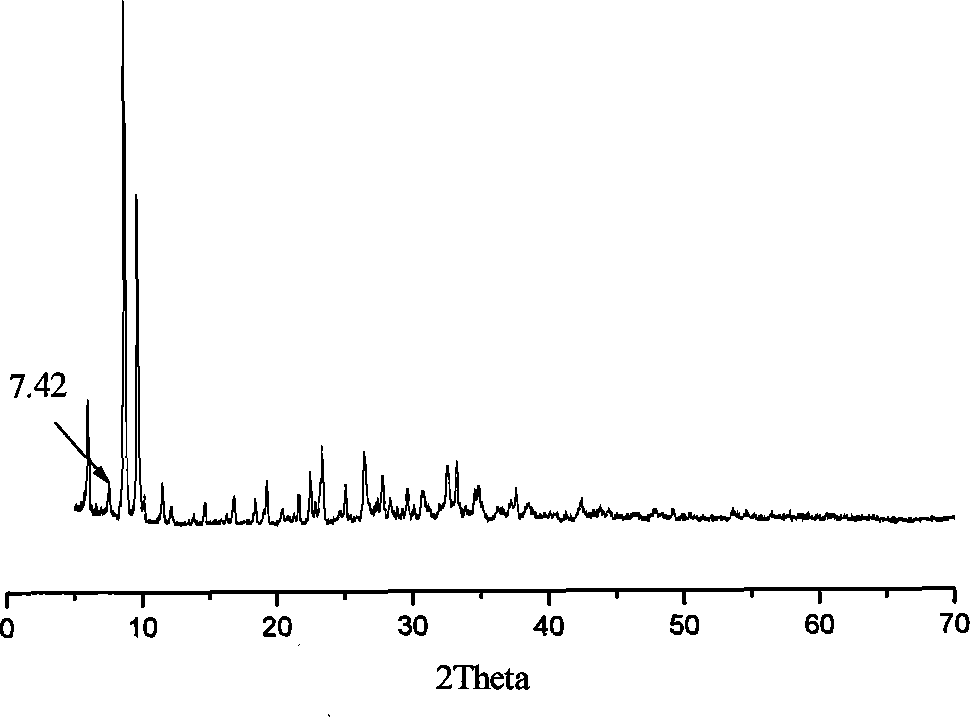

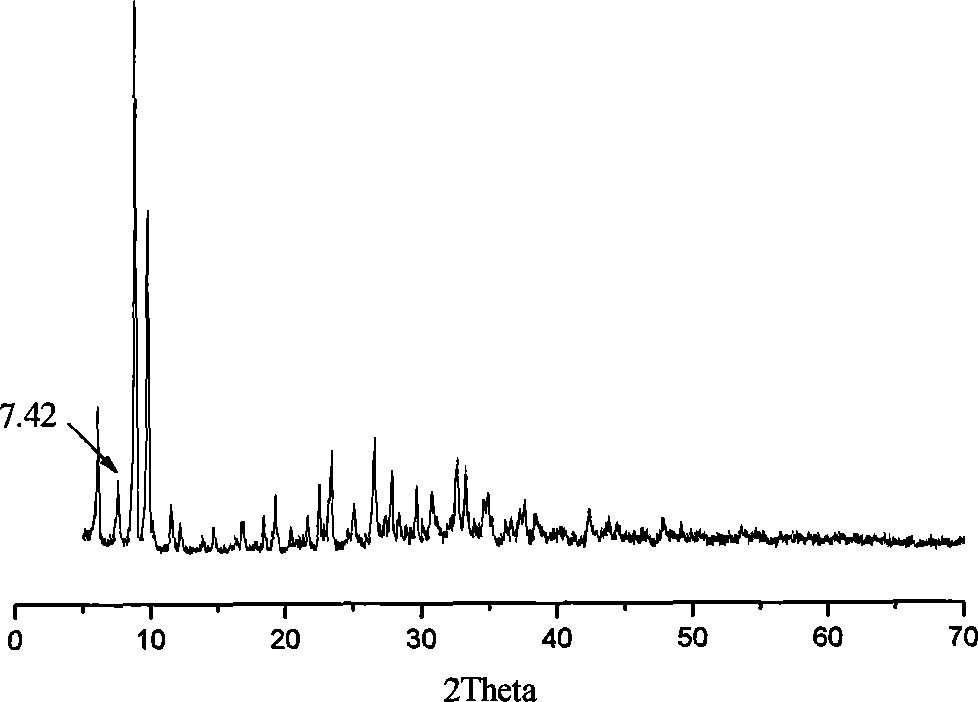

Preparation method for solid catalyst component for olefin polymerization

ActiveCN1621420AParticles in good shapeNarrow particle size distributionSolid componentElectron donor

The preparation process of the solid component of olefin polymerizing catalyst includes first reaction of C2-C8 alcohol and magnesium powder in the molar ratio of 2.0-4.0 in the presence of methane halide to form homogeneous magnesium ligand solution; subsequent addition of electron donor compound to form homogeneous solution and the reaction between the solution with titanium compound to form Mg-Ti ligand solution; the contact reaction between the solution with inorganic oxide carrier to prepare solid catalyst precursor; and final activation of the precursor with alkyl aluminum chloride to obtain the solid catalyst. The solid component of catalyst of the present invention is matched with alkyl aluminum for the polymerization of ethylene and has high catalytic activity and polymer prepared with very small amount of fine powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for removing dust in tablets of tablet press

InactiveCN103879019AComply with GMP requirementsMeet environmental protection requirementsSievingScreeningEngineeringTABLET CUTTER

The invention relates to a device for removing dust in tablets of a tablet press. An interlayer is arranged in the middle of a rectangular tank body formed by stainless steel plates and divides the rectangular tank body into an upper cavity and a lower cavity. The interlayer is a 12-mesh stainless steel screen, and a detachable stainless steel cover is arranged on the upper cavity of the rectangular tank body. A bevel is arranged at the front end of the upper cavity, and the front end of the upper cavity is manufactured into a connector connected with the press, the rear end of the rectangular tank body is provided with a bevel, the upper cavity of the rectangular tank body is longer than the lower cavity, a stainless steel connector is welded and fixed to the lower portion of the rear end of the lower cavity, and the connector is used for being connected with a tablet press dust collector. The device has a good dust moving effect and is low in noise, low in cost, free of occupied area and low in fault rate, pollution caused by dust to air is effectively controlled, and cross contamination between medicines is effectively controlled.

Owner:哈药集团三精制药四厂有限公司

Impact crusher

PendingCN112808388AAvoid Repeated FragmentationIncrease average rateGrain treatmentsStructural engineeringCrusher

The invention discloses an impact crusher. The impact crusher comprises a lower shell, a rack, a transmission device, a rotor, an upper shell, an impact plate, an adjusting device and the like, wherein a pre-screening channel is formed in the lower shell, a pre-screening device is arranged at a feeding port formed by the upper shell and the lower shell and used for pre-screening materials at the feeding port, fine materials subjected to pre-screening enter the pre-screening channel and then are output through a discharging port. After the materials are sorted by the pre-screening device, fine materials enter the pre-screening channel and then are discharged out of the crusher, unqualified coarse materials fall into the rotor working area, the transmission device drives the rotor to rotate to hit the materials onto the impact plate to be subjected to impact crushing, and therefore the materials with qualified particle sizes are obtained. The particle size difference rate of output materials is reduced, the fine powder amount of finished product granules is reduced, the uniformity rate of the materials with the finished product particle size is improved, the beating frequency is reduced, and the efficiency is improved.

Owner:山东博研粉体技术装备有限公司

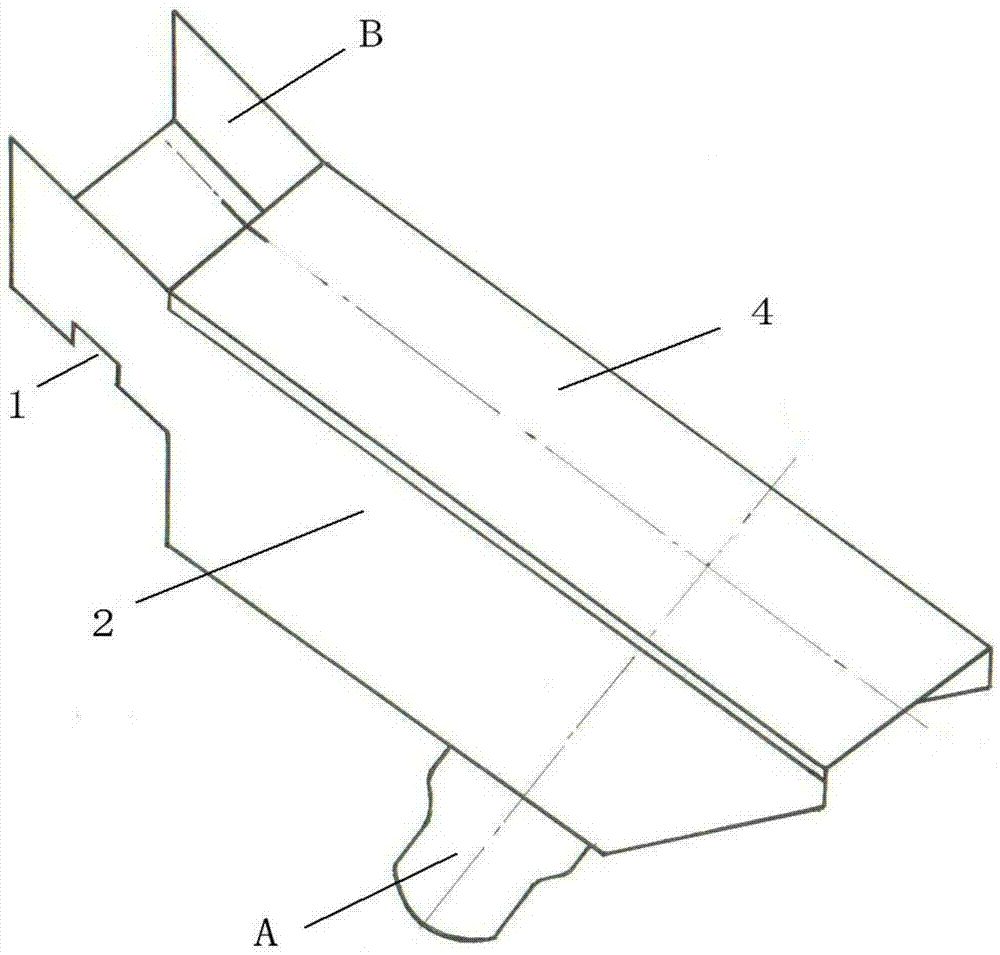

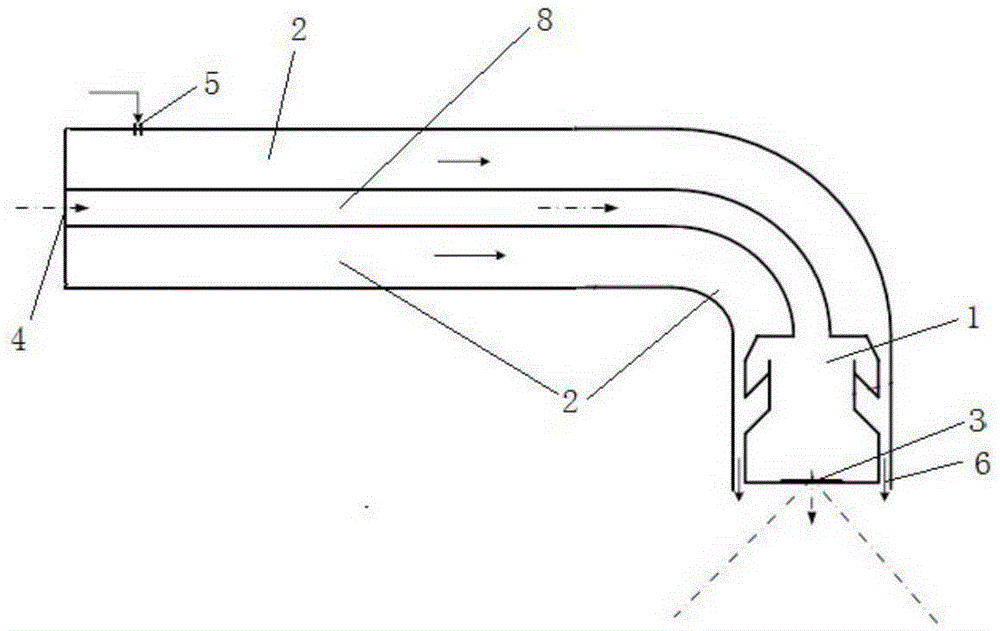

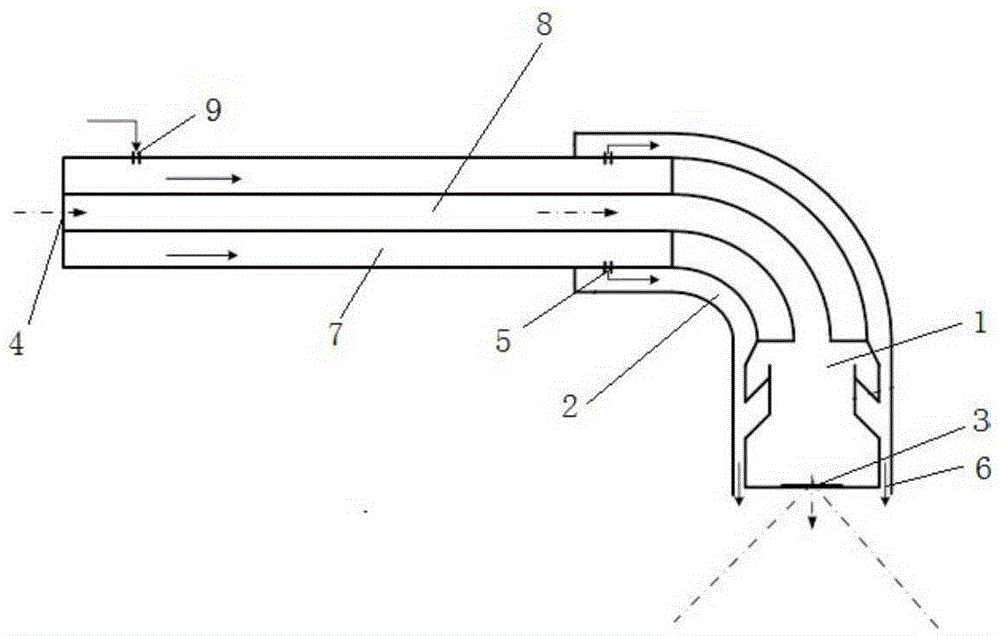

Nozzle for spray dryer and spray dryer with nozzle

InactiveCN106606994AHigh sphericityReduce fines problemsGranulation by liquid drop formationInjection portMicrosphere

The invention relates to the field of a spray dryer and discloses a nozzle for a spray dryer and a spray dryer with the nozzle. The nozzle comprises a nozzle main body which is provided with a nozzle head for injecting a material to form droplets, a material inlet communicated with the nozzle head and a material cavity connecting the nozzle head and the material inlet, and a protective air guide pipe which is provided with a protective air distribution port and a protective air injection port communicated with the protective air distribution port and is provided around the nozzle main body so that the protective air injected by the protective air injection port surrounds the droplet-like material ejected from a material injection port of the nozzle head. The nozzle can reduce the problem that fine powder is generated by fast heating-caused bursting of the microspheres during the spray drying process, realizes concentrated particle size distribution, reduces production of special-shaped particles and improves the sphericity of the finished particles.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of anti-degradation cationic polyacrylamide

InactiveCN112979871AReasonable structureClear principleWater/sewage treatment by flocculation/precipitationInorganic saltsMeth-

The invention belongs to the technical field of polyacrylamide, and particularly relates to a synthesis method of anti-degradation cationic polyacrylamide, which comprises the following steps: adding an inorganic salt auxiliary agent, acrylamide and acryloyloxyethyl trimethyl ammonium chloride into deionized water according to the mass percent of dry substances, dissolving and mixing to obtain a material solution with a certain mass concentration; and pumping the solution into a polymerization kettle, introducing nitrogen for 40 minutes; then adding a composite initiator, continuing introducing nitrogen for 3 minutes, thickening the feed liquid; then carrying out pressure building polymerization for 3 hours, and carrying out granulation, drying, grinding and other processes on the colloid to obtain a particle product, namely the anti-degradation cationic polyacrylamide. A composite initiation system and free radical aqueous solution polymerization are adopted, so that the viscosity and charge binding force of the product are improved, and the degradation resistance of the product is improved; the product yield is improved, the yield and the quality are improved, the production cost and the use cost are reduced, and the cost performance is higher.

Owner:DONGYING BAOMO ENVIRONMENT ENG CO LTD

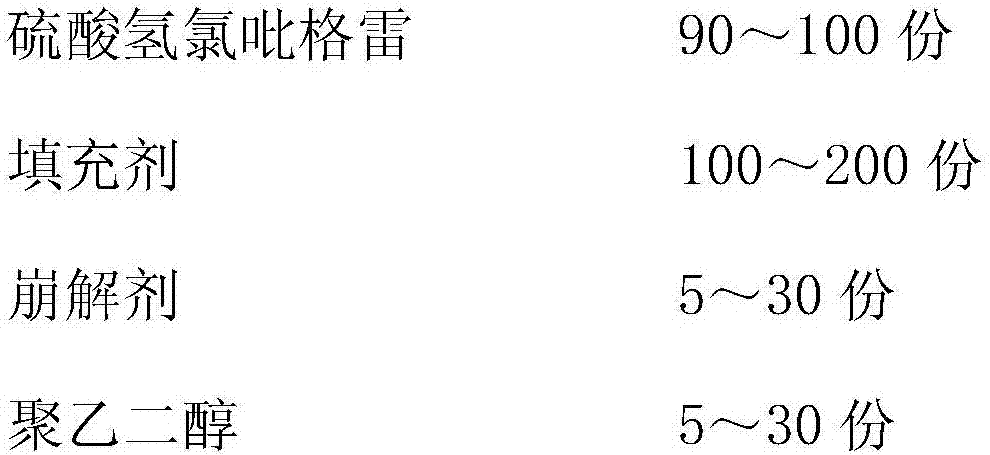

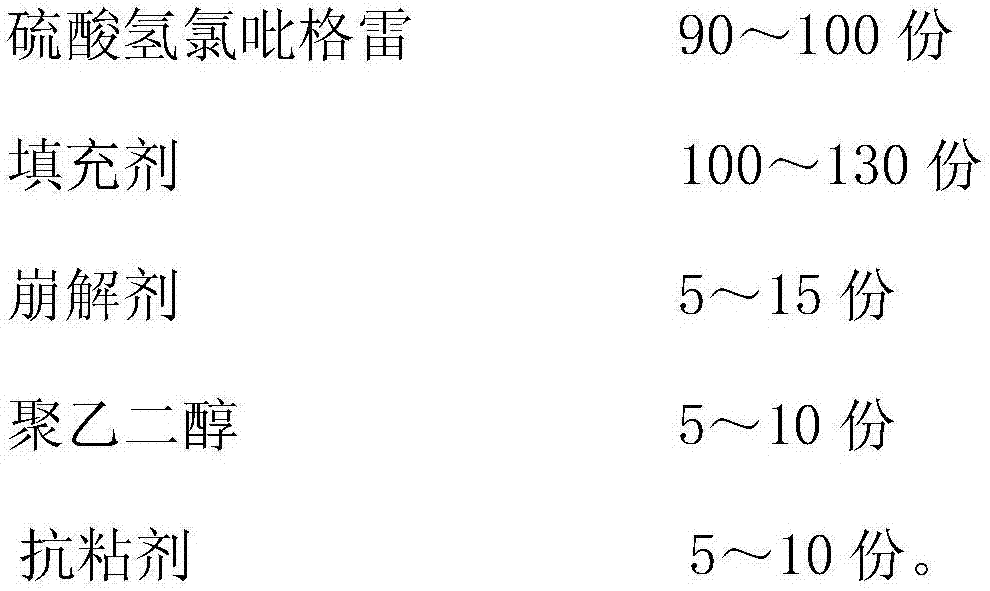

Clopidogrel hydrogen sulfate tablet as well as preparation method and use

InactiveCN107951847AImprove liquidityReduce the amount of fine powderOrganic active ingredientsPharmaceutical non-active ingredientsDiseasePolyethylene glycol

The invention discloses a clopidogrel hydrogen sulfate tablet as well as a preparation method and use thereof. The clopidogrel hydrogen sulfate tablet is prepared from the following raw materials in parts by weight: 90 to 100 parts of clopidogrel hydrogen sulfate, 100 to 200 parts of filling agent, 5 to 30 parts of disintegrating agent, 5 to 30 parts of polyethylene glycol, and 5 to 30 parts of anti-sticking agent. The preparation method comprises the following steps: S1: preparing a polyethylene glycol solution; S2: uniformly mixing the clopidogrel hydrogen sulfate, the filling agent and thedisintegrating agent, adding the polyethylene glycol solution, preparing a soft material, then granulating, drying, and shaping; S3: adding the anti-sticking agent, mixing, tabletting, coating, thus obtaining the clopidogrel hydrogen sulfate tablet. The use of the clopidogrel hydrogen sulfate tablet can prevent and treat cerebral-cardio diseases and other artery circulatory disturbance diseases caused by the high clustering degree of blood platelets. The clopidogrel hydrogen sulfate tablet and the preparation method thereof have the advantages that the sticking in the tabletting process and the slow disintegration of the tablet can be effectively reduced, the tabletting process is ensured to be smooth, a main drug is ensured to dissolve out rapidly, and the bioavailability of the drug canbe improved.

Owner:湖南天济草堂制药股份有限公司

Preparation method for solid catalyst component for olefin polymerization

ActiveCN1281636CParticles in good shapeNarrow particle size distributionTitaniumOlefin polymerization

A kind of preparation method of olefin polymerization catalyst solid component, comprises in the presence of halide methane, make C 2 -C 8 Alcohol and magnesium powder react at 20-200°C at a molar ratio of 2.0-4.0:1 to form a uniform magnesium complex solution, then add an electron donor compound to form a uniform solution, and then contact this solution with a titanium compound to form The Mg-Ti complex solution is used to fully contact and react with the inorganic oxide carrier to obtain a solid catalyst precursor, and then the precursor is activated with an alkylaluminum halide to obtain a solid catalyst. The solid component of the catalyst prepared by the method of the invention is used in the polymerization of ethylene in combination with the alkylaluminum, has high catalytic activity, and the amount of fine polymer powder produced is very small.

Owner:CHINA PETROLEUM & CHEM CORP +1

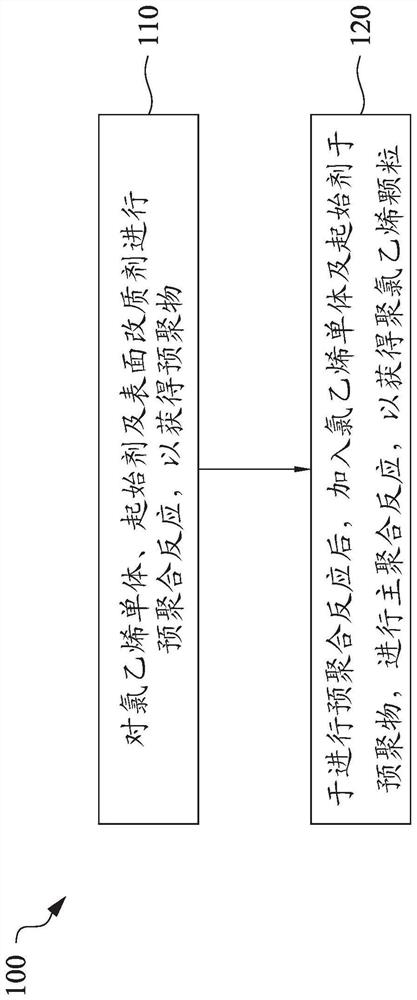

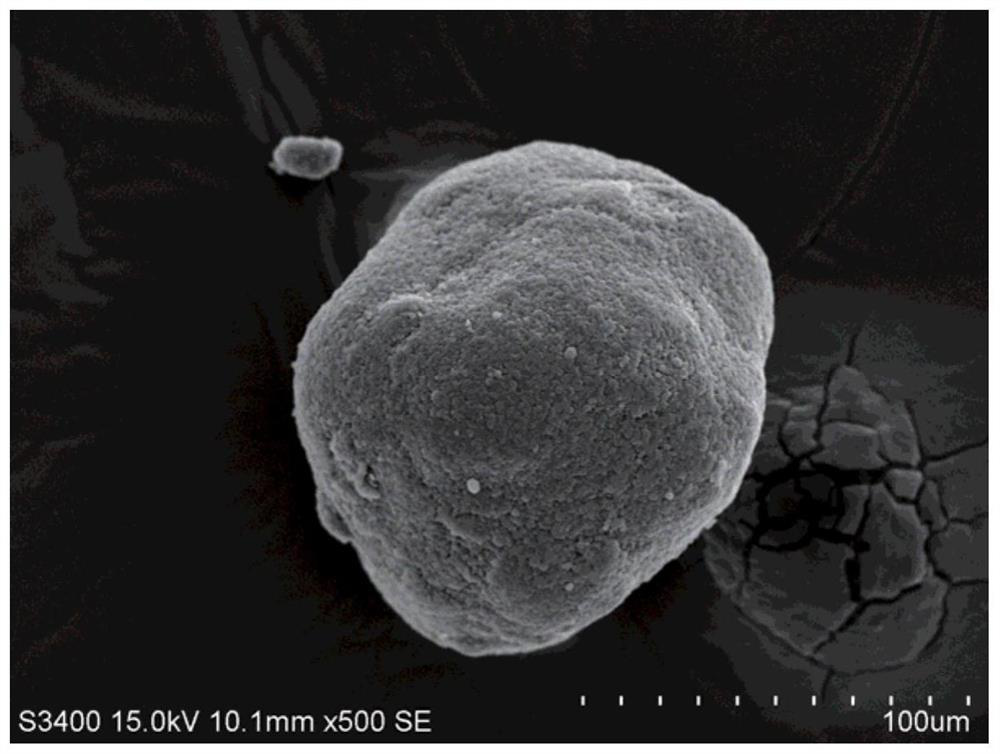

Polyvinyl chloride and method for producing same

PendingCN114437267AReduce surface roughnessReduce the amount of fine powderPolymer chemistryPolymerization

The invention relates to polyvinyl chloride and a manufacturing method thereof. The manufacturing method comprises a prepolymerization reaction and a main polymerization reaction. The prepolymerized particles generated by the prepolymerization reaction and the main polymerized particles generated by the main polymerization reaction are bonded with each other to form polyvinyl chloride particles. The surface modifier which is added in the prepolymerization reaction and / or the main polymerization reaction and has a specific hydrophilic-lipophilic balance value is beneficial to bonding of the prepolymerization particles and the main polymerization particles, so that the surface roughness of the polyvinyl chloride particles is reduced, and the amount of fine powder generated by friction between the polyvinyl chloride particles is reduced; under the condition that the oil absorption amount of the polyvinyl chloride particles is not changed, the apparent specific gravity of the polyvinyl chloride particles is improved.

Owner:FORMOSA PLASTICS CORP

Method for preparing spherical magnesium chloride carrier

The invention discloses a method for preparing a spherical magnesium chloride carrier. The method comprises the following steps of: performing alcohol combination reaction on magnesium chloride and fatty alcohol (ROH), dispersing, quenching, solidifying and drying to obtain a carrier precursor, performing primary alcohol removal on the carrier precursor in inert airflow at the temperature of between 30 and 40 DEG C, heating to the temperature of between 41 and 55 EG C, performing secondary alcohol removal, and thus obtaining the spherical magnesium chloride and alcohol carrier. An olefin polymerization catalyst prepared from the carrier obtained after alcohol removal by the method has high catalytic activity, the granular size of the olefin polymerization catalyst is increased, and the fine powder quantity of the olefin polymerization catalyst is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

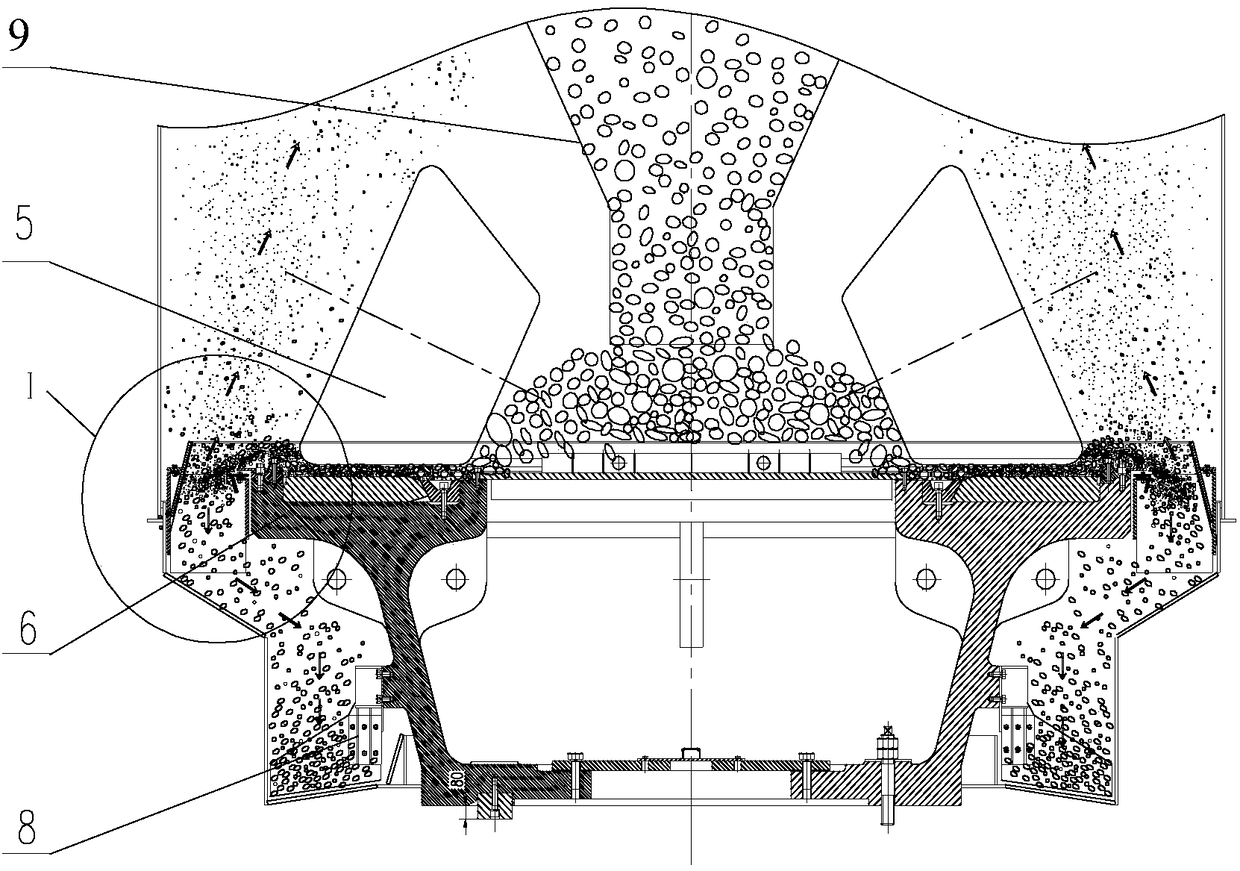

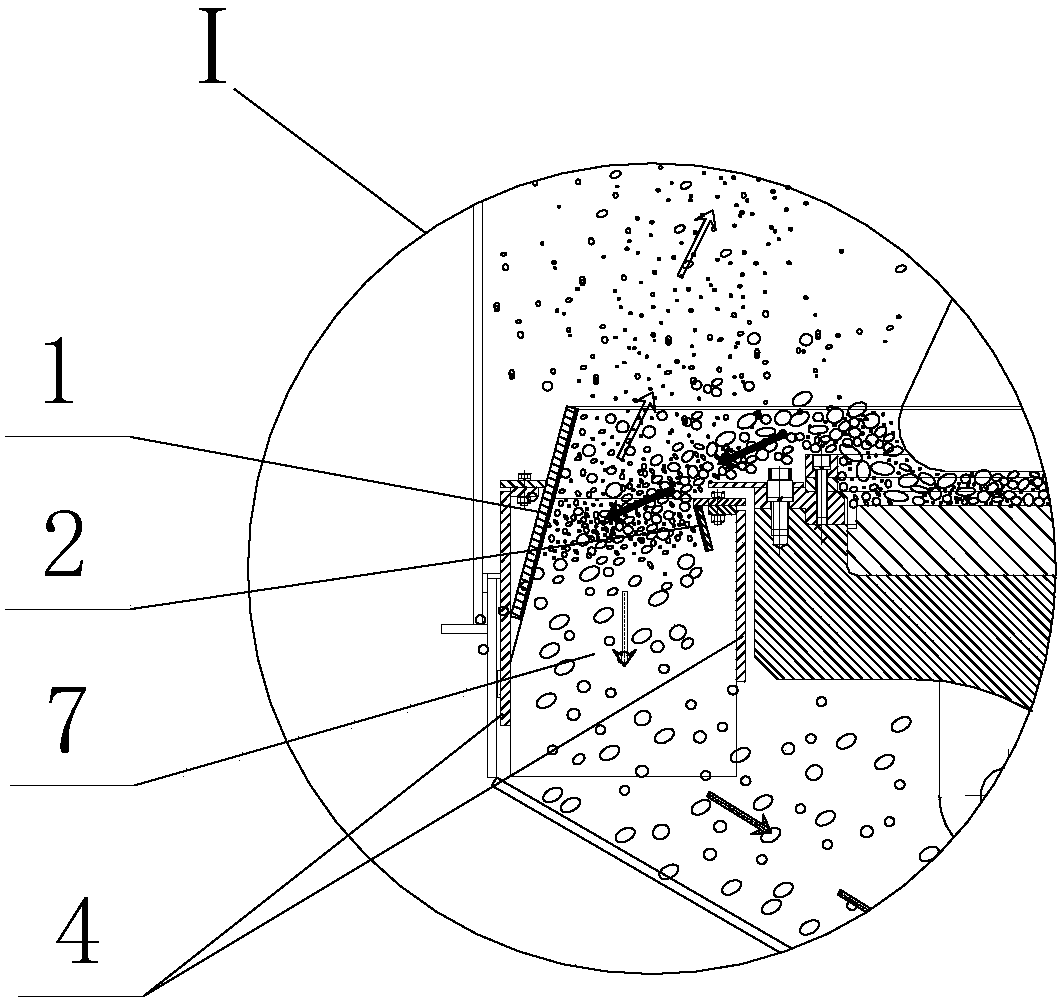

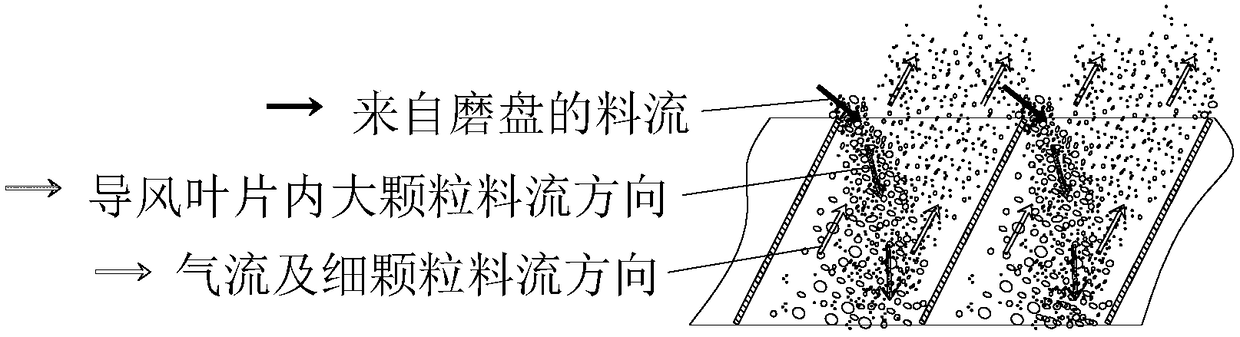

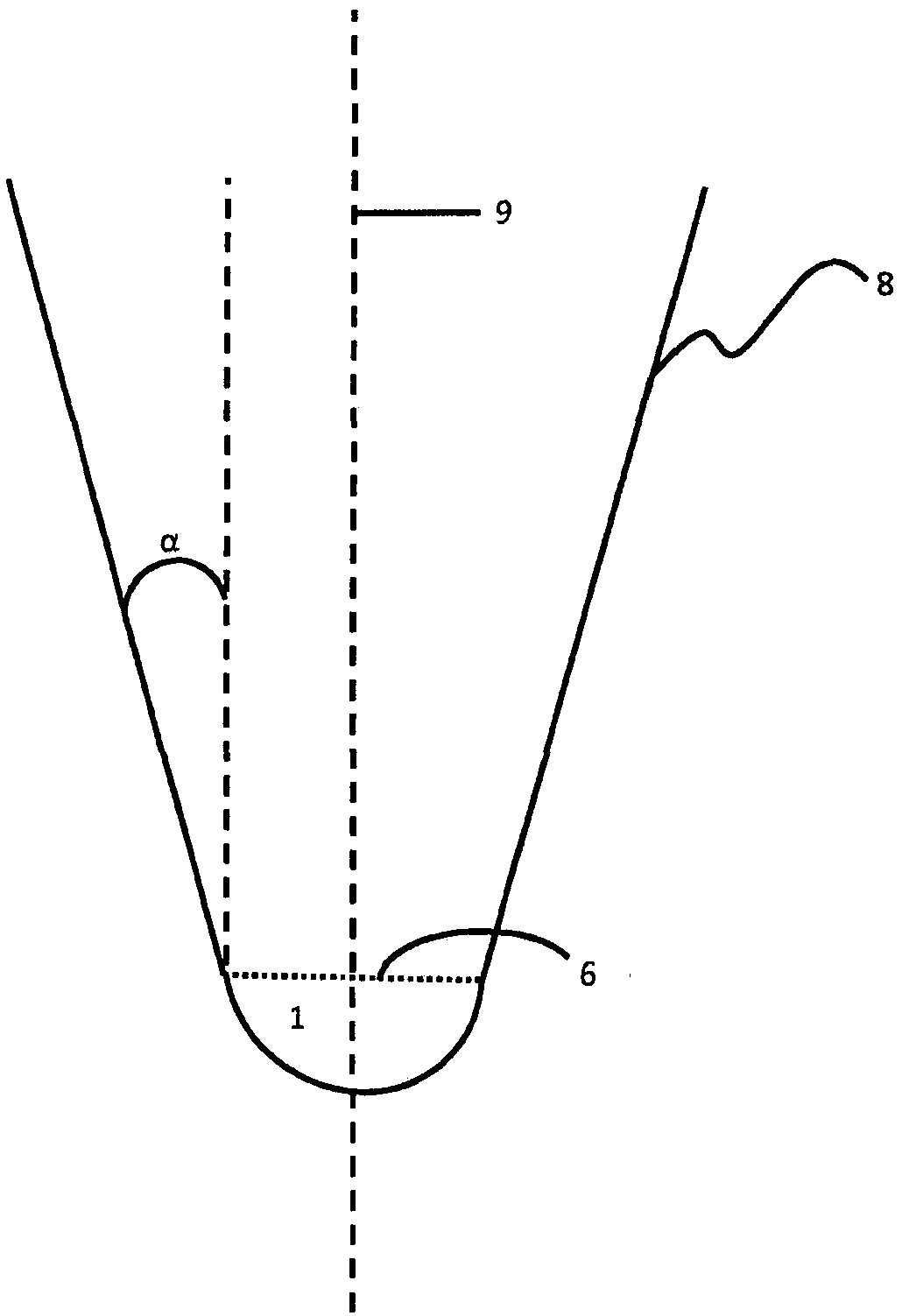

Air ring structure of a vertical roller mill

The invention relates to a wind ring structure of a vertical roller mill. The wind ring structure comprises a wing ring outer ring, a wind ring inner ring and wind guide bodies; and multiple wind guide bodies are fixed between the wind ring outer ring and the wind ring inner ring. The wind ring structure is characterized in that the wind guide bodies consist of horizontal cover plates, first wind guide plates and second wind guide plates; and the horizontal cover plates, the first wind guide plates and the second wind guide plates are connected end to end in sequence to form the air guide bodies with triangular cross sections. The wind ring can perform two times of impact dispersion for materials to improve the material layer stability and the powder milling efficiency, reduces the wind ring design wind speed requirements, improves the powder selection efficiency, reduces the quantity of fine powder returned to a grinding disc, improves the material layer stability, and improves the powder milling efficiency.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Method for preparing sigma-phase FeV50

The invention belongs to the field of metallurgy and relates to a method for preparing sigma-phase FeV50. The technical problem to the solved of the invention is to provide a method for preparing the sigma-phase FeV50 which has good apparent mass and is easy to break. In the adopted technical scheme, the sigma-phase FeV50 is obtained by uniformly mixing vanadium oxide, aluminum, iron and lime serving as raw materials, feeding the mixture into a furnace and smelting the mixture in an electric arc furnace by an electro-aluminothermic process. The method comprises the following steps of: a, adding excess aluminum into the raw materials while proportioning so as to reduce the vanadium oxide, melting a furnace charge down, depleting slag until vanadium content is low and removing lean slag; and b, adding an appropriate amount of vanadium oxide into alloy liquor from which the slag is removed to remove the excess aluminum, discharging and casting when the temperature and aluminum content ofthe alloy liquor meet requirements and cooling so as to obtain a product, namely, the sigma-phase FeV50. The crush strength of the sigma-phase FeV50 produced by the process is less than 510 MPa and convenience can be brought to vanadium iron manufacturers and customers in the crushing, sampling and using processes of vanadium iron.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Polymer latex agglomerated particles and preparation method thereof

The invention provides polymer latex agglomerated particles and a preparation method thereof. The method comprises the following steps: S1, preparing first latex with a core-first polymer shell structure; S2, adding a polymeric monomer into the first latex for a reaction, and obtaining second latex of a core-first polymer shell-second polymer shell structure, wherein the glass transition temperature of a second polymer is 5-20 DEG C lower than that of the first polymer; and S3, condensing the second latex, curing, and dehydrating to obtain polymer latex agglomerated particles. By applying the method, on the premise of not changing coagulation conditions, the curing forming rate of polymer particles is increased, the particle size of powder is increased, the micro powder amount in the powder is reduced, and the operation stability of a dehydration and drying system is improved.

Owner:PETROCHINA CO LTD

Preparation method of olefine polymerization catalyst solid component

A solid catalyst component for preparing alpha-olefin homopolymer or copolymer with high catalytic activity is prepared through reacting between C2-C4 alcohol and Mg powder under existance of halomethane to obtain Mg matches solution, reacting on inorganic carrier, drying to obtain Mg carrier, and reacting on Ti(OR)nCl4-n in inertial hydrocarbon solvent, where R is C2-C8 alkyl and n=0-4.

Owner:CHINA PETROLEUM & CHEM CORP +1

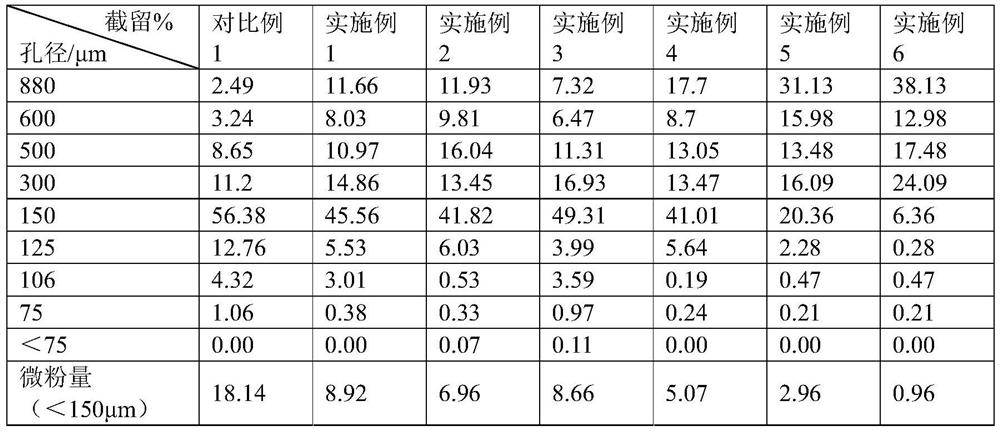

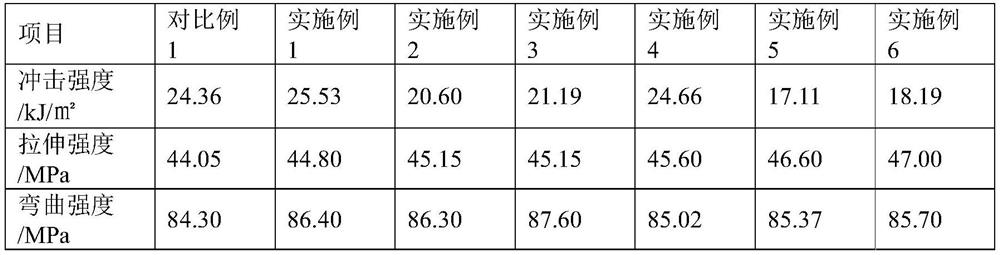

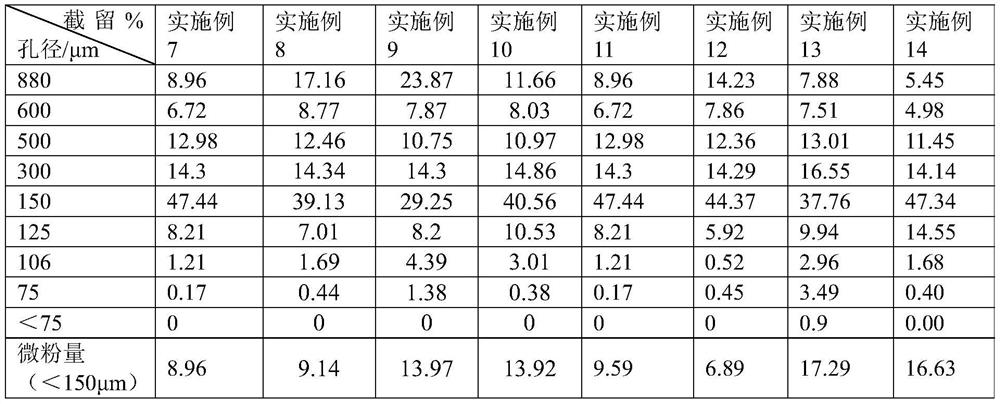

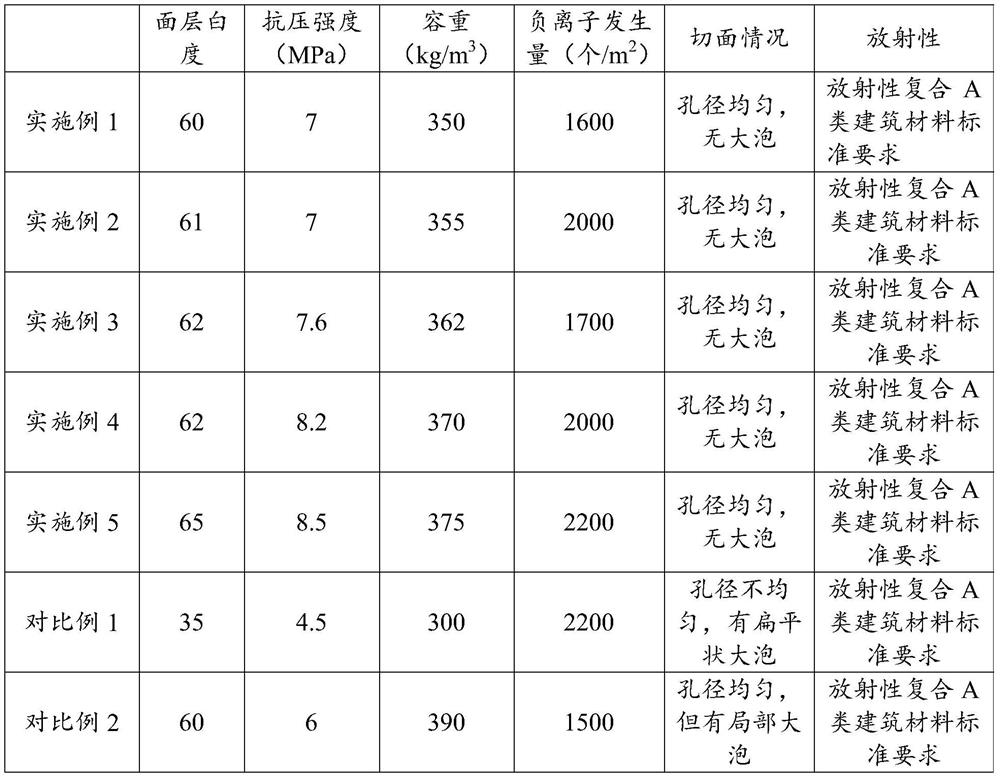

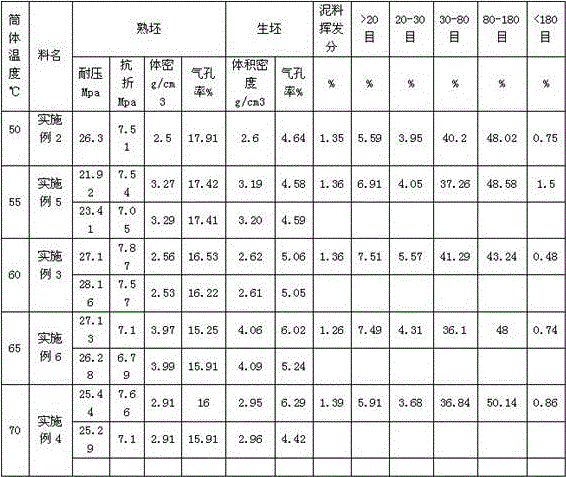

A kind of lightweight negative ion foamed ceramics and preparation method thereof

ActiveCN109265193BImprove utilization efficiencyReduce usageCeramic materials productionCeramicwareCeramicCeramic materials

The invention discloses a light-weight anion foamed ceramic. The light-weight anion foamed ceramic with a double-layer structure is formed by using basic foaming powder and anion foaming powder; correspondingly, the invention also discloses a kind of the above-mentioned A method for preparing lightweight negative ion foamed ceramics; the invention effectively improves the utilization efficiency of negative ion materials and reduces the usage amount of negative ion materials by setting layered design and adding negative ion materials only in the surface layer. At the same time, through the combination of formula structure and preparation process, a foamed ceramic with fine and uniform pore size and high strength is prepared.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

Coal low temperature dry distillation method

InactiveCN104017594BHigh calorific valueAvoid cloggingSpecial form destructive distillationGas purification by liquid washingOil sludgeHeating furnace

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

A kind of crystallization method of large particle dicumyl peroxide

InactiveCN108069888BInhibitionPromote growthOrganic compound preparationPeroxy compound preparationPhysical chemistryCrystal growth

The invention especially relates to a crystallization method for large-particle dicumyl peroxide, belonging to the technical field of crystallization of dicumyl peroxide. The crystallization method comprises the following steps: 1) uniformly mixing dicumyl peroxide liquid with an alcoholic solvent so as to obtain a mixed solution; and 2) adding a dicumyl peroxide seed crystal and fine dicumyl peroxide powder into the mixed solution obtained in the step 1), and carrying out cooling crystallization to obtain large-particle dicumyl peroxide. According to the preparation method, the addition of the dicumyl peroxide seed crystal and the fine dicumyl peroxide powder is beneficial for crystal growth and effective inhibition of the generation of fine powder; and the yield of large-particle dicumylperoxide in a prepared dicumyl peroxide product is as high as 95% or above.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of crystallization method of large particle dicumyl peroxide

ActiveCN109867615BInhibitionPromote growthOrganic compound preparationPeroxy compound preparationAlcoholPhysical chemistry

The invention relates to the technical field of crystallization of dicumyl peroxide, in particular to a crystallization method of large particle dicumyl peroxide. The crystallization method comprises the following steps: 1) uniformly mixing dicumyl peroxide liquid and alcohol solvent to obtain a mixed solution; 2) adding water and dicumyl peroxide seed crystals to the mixed solution obtained in step 1) and dicumyl peroxide fine powder, crystallized by cooling to obtain the large particle dicumyl peroxide. The preparation method of the present invention adds water, dicumyl peroxide seed crystals and dicumyl peroxide fine powder, which is beneficial to crystal growth and effectively inhibits the generation of fine powder, and large particles in the prepared dicumyl peroxide product The yield of dicumyl peroxide is high, and the yield in industrial production can reach more than 85%.

Owner:CHINA PETROLEUM & CHEM CORP

Method for manufacturing moisture-free granular flavoring

ActiveCN101669610BPrevent moisture absorptionHigh viscosityFood preparationMoisture resistanceMoisture

The invention discloses a method for manufacturing a moisture-free granular flavoring, which comprises the following steps of suspension preparation, mixing, granulation, drying, cooling and screening. The method overcomes the defects of the prior granular flavoring manufacturing method by improving the mixing process of the granular flavoring, and can produce the granular flavoring with good moisture resistance and avoid the problem that the granular flavoring absorbs moisture during use in a kitchen.

Owner:上海佳格食品有限公司

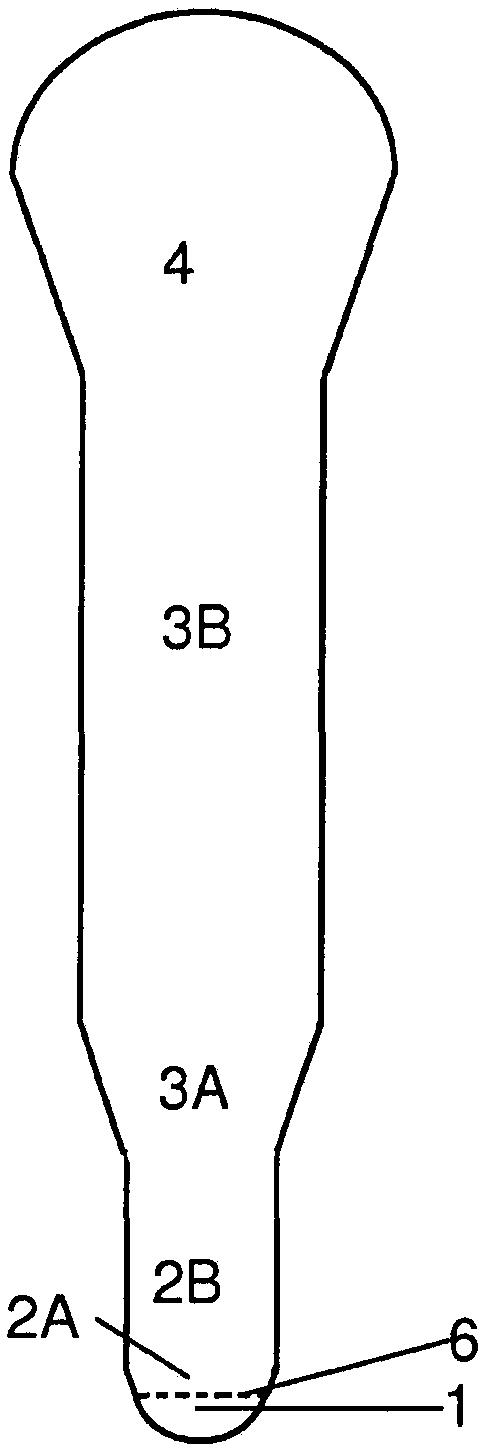

Multi-zone reactor for continuous polymerization of alpha-olefin monomers

ActiveCN105916890BRun fastDoes not cause instabilityChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsMaximum diameterFluidized bed

The present invention relates to a multi-zone reactor suitable for the continuous fluidized bed polymerization of one or more alpha-olefin monomers, at least one of which is ethylene or propylene, which multi-zone reactor can be used in Operating in condensation mode, the multi-section reactor includes a first section, a second section, a third section, a fourth section and a distribution plate, wherein the first section and the second section separated by the distribution plate, wherein the multi-zone reactor extends vertically, wherein the second zone of the multi-zone reactor is located above the first zone, and wherein the said third section of said multi-zone reactor is located above said second section, and wherein said fourth section of said multi-zone reactor is located above said third section, wherein The second section comprises an inner wall, wherein at least a portion of the inner wall of the second section is in the form of a progressively increasing inner diameter or a continuously open cone, wherein the diameter or the opening is directed towards the A vertically increasing top of a multi-zone reactor, wherein the third zone comprises an inner wall, wherein at least a portion of the inner wall of the third zone is in the form of a progressively increasing inner diameter or a continuous open cone body, wherein said diameter or said opening increases vertically towards the top of said multi-zone reactor, wherein said inner wall of said third zone has a maximum diameter greater than that of said second zone The maximum diameter of the inner wall.

Owner:SAUDI BASIC IND CORP SA +1

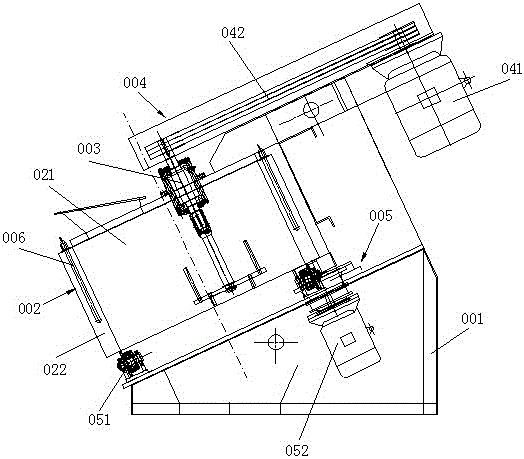

A high-temperature granulation machine for resin bonded products and a high-temperature granulation method thereof

ActiveCN103977741BGuaranteed wettingLow viscosityGranulation in rotating drumsPorosityRoom temperature

The invention relates to a resin binding product high temperature high temperature granulator and a high temperature granulation method, the method comprises the following steps: heating a rotating cylinder to the temperature of 40-120 DEG C, adding a granulation raw material in the rotating cylinder for mixing, wherein the rotating speed of the rotating cylinder is 5-30rpm, performing high speed intense agitation through a high speed stirring rotor (the speed is 1000-2000rpm) over the rotating cylinder for stirring for 10-60 minutes, finally discharging, and cooling to the room temperature to prepare the finished product mud material. The mud material has stable grain composition and low fine powder quantity, so that the product appears very excellent porosity, volume density and stable strength property, is directly and rapidly dried at anaphase of granulation, and the drying equipment is not required for being added. The technology appears flexible, and the land occupation is small. The technology is not influenced by harsh environment, and has little influence by change of environment, even has no influence by change of environment. According to the high temperature granulation technology, the production cost appears very excellent, compared with a traditional normal temperature granulation technology, the comprehensive cost can be saved by more than 50%.

Owner:宜兴市得力陶瓷科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com