Polymer latex agglomerated particles and preparation method thereof

A technology of polymer glue and condensed particles, which is applied in the field of polymer latex condensed particles and its preparation, can solve the problems of low curing molding rate and poor quality of polymer latex condensed particles, and reduce the residue of coagulant and the amount of coagulant and the amount of steam, the effect of reducing the amount of fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

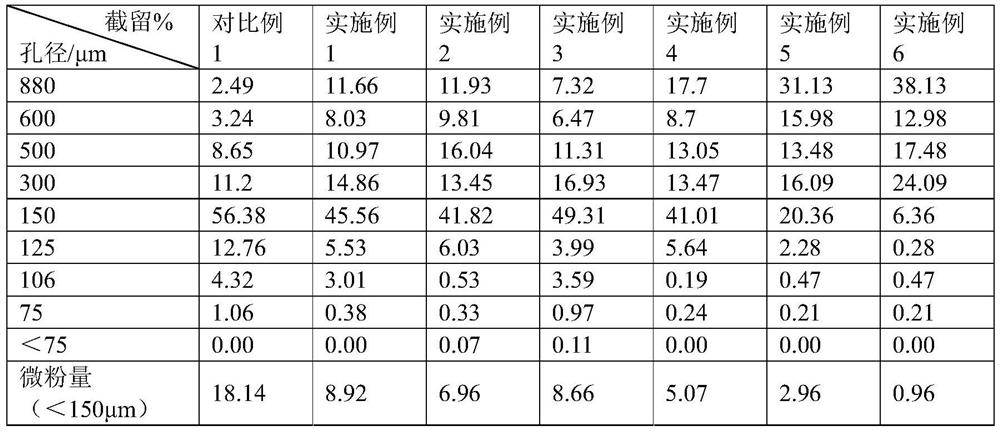

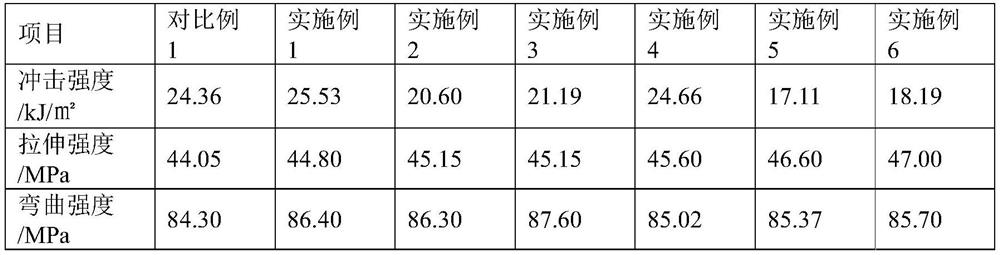

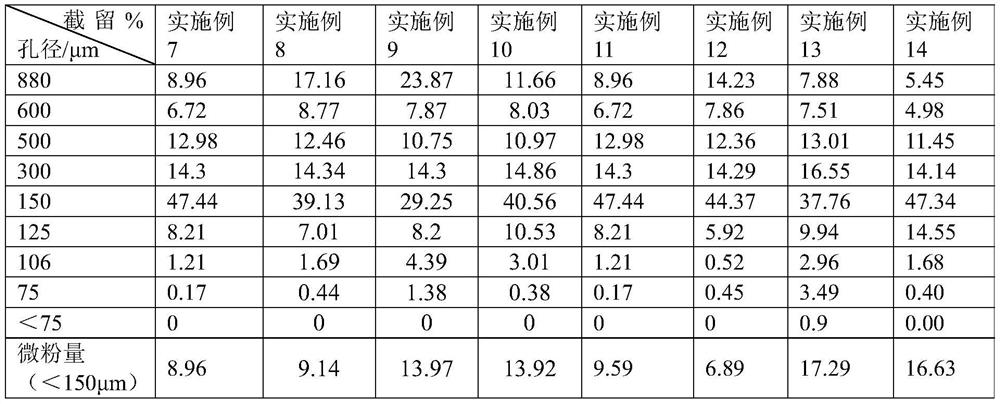

Examples

preparation example Construction

[0019] In a typical implementation of the present application, a method for preparing polymer latex aggregated particles is provided, the method comprising: step S1: preparing the first latex with a core-first polymer shell structure; A latex is added with a polymerized monomer to react to obtain a second latex with a core-first polymer shell-second polymer shell structure, wherein the glass transition temperature of the second polymer is higher than the glass transition temperature of the first polymer Lower 5-20°C; step S3: make the second latex coagulate, ripen and then dehydrate to obtain polymer latex coagulated particles.

[0020] In the above method of the present application, the process of preparing the first latex in step S1 and the coagulation and dehydration process after aging in step S3 are well known to those skilled in the art. The first latex prepared in step S1 includes but not limited to ABS grafted latex such as polybutadiene latex grafted with acrylonitril...

Embodiment 1

[0036] (1) Use polybutadiene (PB) latex with a total solid content (TSC) of 57.5 to 58.5% to carry out ABS graft polymerization, the amount of PB latex is 1135kg, and the amount of incremental monomer composed of acrylonitrile and styrene is 440kg , wherein the weight percent of acrylonitrile is 25wt%. The graft polymerization reaction is carried out by adding incremental monomer step by step. First, 110kg incremental monomer and 0.75kg cumene hydroperoxide are added to start the first stage reaction. The temperature of the reactor jacket is set at 50°C. After the reaction was carried out for 60 minutes, the remaining incremental monomer and cumene hydroperoxide were added dropwise for 100 minutes to obtain the first latex with the core-first polymer shell structure. After the completion, the temperature of the jacket was raised to 65° C., and 55 kg of styrene and 0.25 kg of cumene hydroperoxide were added dropwise into the reactor, and the dropwise addition time was 20 minute...

Embodiment 2

[0040] Except that 55kg of styrene is added at one time, the process of embodiment 2 is all the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com