Graphene UV pressure-sensitive adhesive and preparation method thereof

A technology of graphene and pressure-sensitive adhesives, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of poor adhesion between porous and cured layers and substrates, uneven curing, compression and Reduced fatigue resistance and other issues, to achieve excellent mechanical strength and reliable stability, good curing rate and curing degree, appropriate weight ratio and volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: A kind of graphene UV pressure sensitive adhesive and preparation method

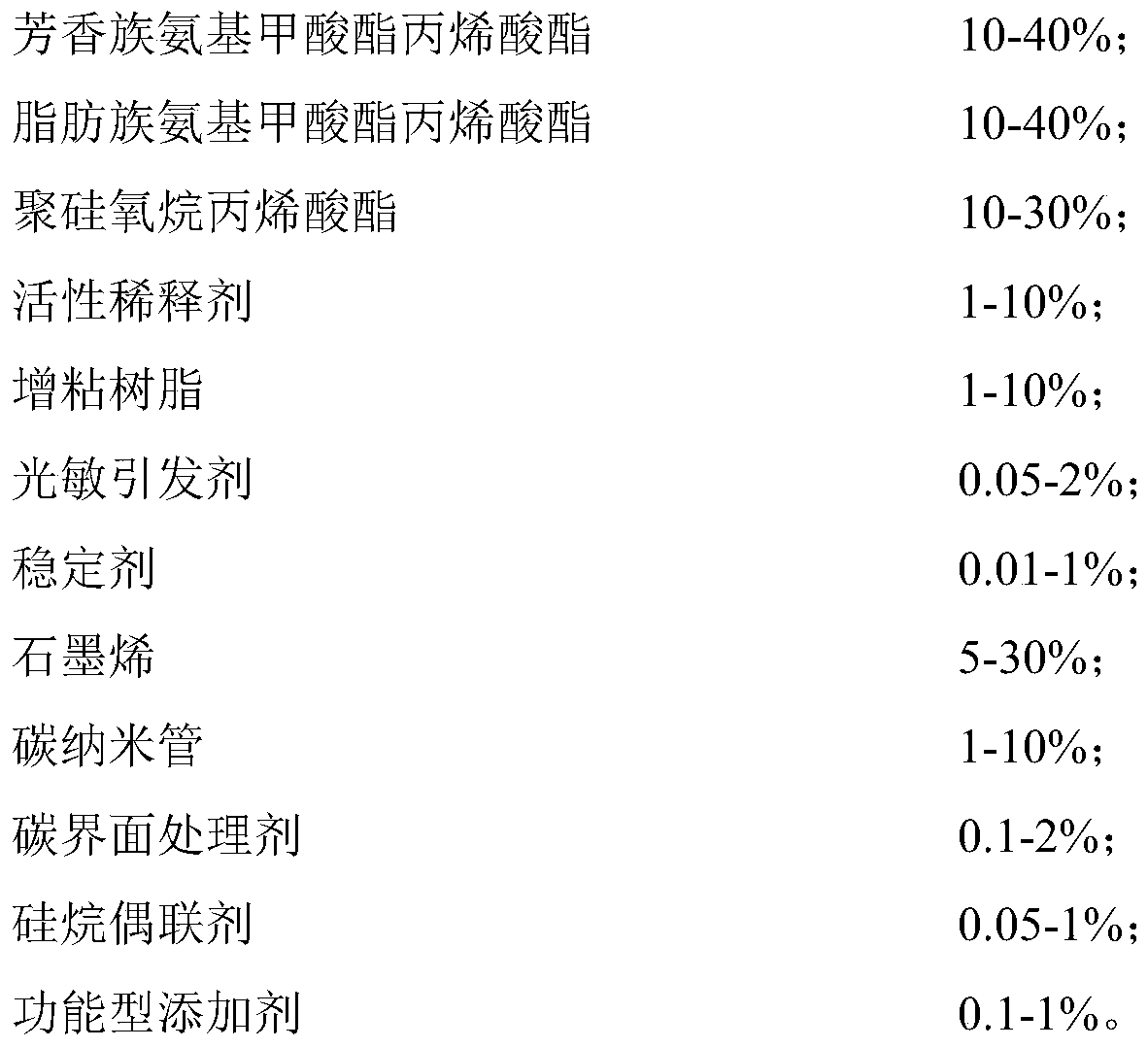

[0047] A graphene UV pressure-sensitive adhesive is characterized in that it comprises the following components and percentage by weight:

[0048]

[0049] The aromatic urethane acrylate conforms to the compound of structural formula

[0050] CH 2 CHCOOCH 2 CH 2 OOCNHR 1 NHCOOR 2 OOCNHR 1 NHCOOCH 2 CH 2 OOCCHCH 2 Formula A;

[0051] where R 1 represents tolyl; where R 2 stands for [CH 2 CH 2 O]m[CH 2 CHO(CH 3 )] n, n=5, m=2; at 25°C, the viscosity is within 500-1000mPa·s, the molecular weight is within 1000-2000, and the glass transition temperature (Tg,°C) is controlled within -30-30.

[0052] The aliphatic urethane acrylate is a compound meeting the general formula C:

[0053] CH 2 CHCOOCH 2 CH 2 OOCNHR 1 NHCOOR 2 OOCNHR 1 NHCOOCH 2 CH 2 OOCCHCH 2 Formula C;

[0054] where R 1 Represents hexamethylene; where R 2 stands for [CH 2 CH 2 O]n, n=5; a...

Embodiment 2

[0071] Embodiment 2: A kind of graphene UV pressure sensitive adhesive and preparation method

[0072] A kind of graphene UV pressure-sensitive adhesive, comprises the raw material of following mass percentage:

[0073]

[0074] A preferred embodiment is: the aromatic urethane acrylate is a mixture of compounds conforming to general formula A and general formula B in a mass ratio of 1:1:

[0075] CH 2 CHCOOCH 2 CH 2 OOCNHR 1 NHCOOR 2 OOCNHR 1 NHCOOCH 2 CH 2 OOCCHCH 2

[0076] Formula A;

[0077] CH 2 CHCOOCH 2 CH 2 OOCNHR 1 NHCOOR 2 OOCNHR 3 NHCOOCH 2 CH 2 OOCCHCH 2

[0078] Formula B;

[0079] where R 1 Represent xylylene; where R 2 stands for [CH 2 CH 2 O] n, n=10; R 3 Represents xylylene; at 25°C, the viscosity is 500-1000mPa·s.

[0080] A preferred embodiment is: the aliphatic urethane acrylate is a mixture of compounds conforming to the general formula C and the general formula D in a mass ratio of 1:1:

[0081] CH 2 CHCOOCH 2 CH 2 OOCNHR...

Embodiment 3

[0106] Embodiment 3: A kind of graphene UV pressure sensitive adhesive and preparation method

[0107] A kind of graphene UV pressure-sensitive adhesive, comprises the raw material of following mass percentage:

[0108]

[0109] A preferred embodiment is: the aromatic urethane acrylate is a compound conforming to the general formula B:

[0110] CH 2 CHCOOCH 2 CH 2 OOCNHR 1 NHCOOR 2 OOCNHR 3 NHCOOCH 2 CH 2 OOCCHCH 2

[0111] Formula B;

[0112] where R 1 represents tolyl; where R 2 stands for [CH 2 CH 2 O]m[CH 2 CHO(CH 3 )] n, n=2, m=3; R 3 Represents hexamethylene; at 25°C, the viscosity is 500-1000mPa·s.

[0113] A preferred embodiment is: the aliphatic urethane acrylate is a compound conforming to the general formula C:

[0114] CH 2 CHCOOCH 2 CH 2 OOCNHR 1 NHCOOR 2 OOCNHR 1 NHCOOCH 2 CH 2 OOCCHCH 2 Formula C;

[0115] where R 1 Represents hexamethylene; where R 2 stands for [CH 2 CH 2 CH 2 CH 2 O]n, n=5; at 25°C, the viscosity is 500-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com