Entrained-flow bed gasification furnace for coal hydrogenation

An entrained bed and coal hydrogenation technology, applied in the field of gasifiers, can solve the problems of heavy dust removal load, large energy consumption, and large dust volume in the processing system, reduce hydrogen consumption, reduce the amount of fine powder, and improve heat utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

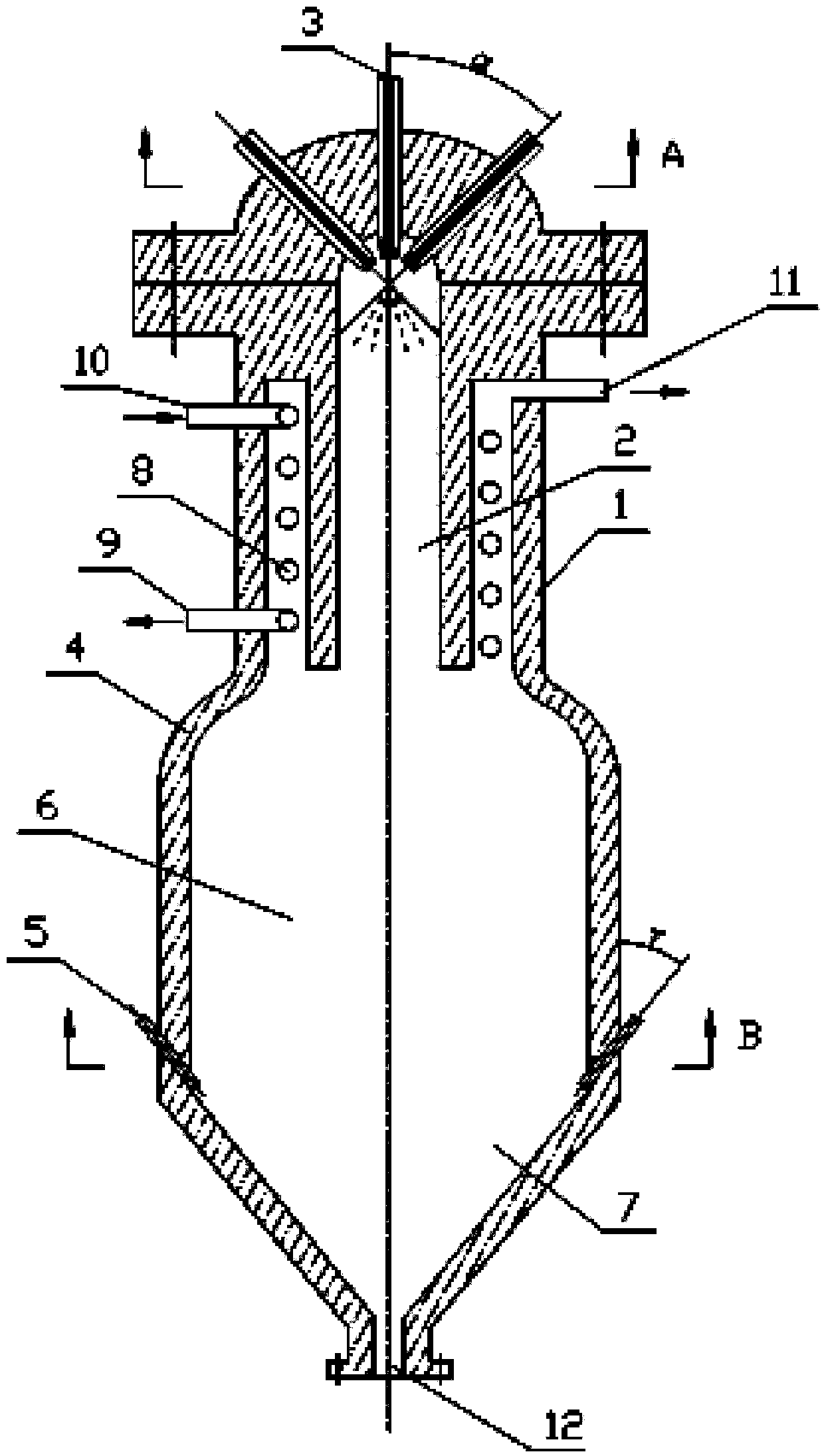

[0027] An entrained flow gasifier for coal hydrogenation, the gasifier is composed of a furnace body 1, a feed nozzle 3, a gasification chamber 2, and a semi-coke collection pool 7, and the inner wall of the furnace body 1 is coated with a refractory material 4 , the furnace body 1 is divided into upper, middle and lower parts, the upper part of the furnace body 1 is a vertical section, the middle part of the furnace body 1 is an enlarged section 6, the lower part of the furnace body 1 is a V-shaped semi-coke collection pool 7, and the furnace body 1 The upper part is the gasification chamber 2, a feed nozzle 3 is located at the center of the top of the gasification chamber 2, the outlet is vertically downward, and a preheating device for raw material gas is installed between the gasification chamber 2 and the upper part of the furnace body 1. The coil heat exchanger 8, the upper part of the coil heat exchanger 8 is provided with a low-temperature hydrogen inlet 10, the lower p...

Embodiment 2

[0030] The three feed nozzles 3 are evenly distributed at the top of the gasification chamber 2, the outlet is downward and the angle α with the center line of the furnace body 1 is 60° o Adjust the layout within the range, the lower part of the expansion section 6 of the furnace body 1 is provided with 5 high-pressure gas injection pipes 5, and the range of the angle γ between the outlet and the center line of the furnace body 1 is 45 o , the range of the angle β with the horizontal plane is 45 o . All the other are with embodiment 1.

Embodiment 3

[0032] 4 feeding nozzles 3, three of which are evenly distributed on the top of the gasification chamber 2, the outlet is downward and the angle α with the center line of the furnace body 1 is 30 o The arrangement is adjusted within the range, the other is at the center of the top of the gasification chamber 2, and the outlet is vertically downward. The lower part of the expansion section 6 of the furnace body 1 is provided with 6 high-pressure gas injection pipes 5, and the range of the angle γ between the outlet and the center line of the furnace body 1 is 60°. o , the range of the angle β with the horizontal plane is 30 o . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com