Catalyst component, catalyst, preparation method and its application

A catalyst and main catalyst technology, which is applied to the supported Ziegler-Natta catalyst of Le-Natta catalyst components. In the field of catalysts, it can solve problems such as unfavorable heat transfer or control, influence, and parking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In a further embodiment, the present invention relates to a method for preparing a supported Ziegler-Natta catalyst component, which is a method for preparing a supported Ziegler-Natta catalyst component of the present invention, characterized in that , with the following steps:

[0054] (1) dissolving the magnesium compound in tetrahydrofuran in the presence of alcohol to prepare a uniform solution,

[0055] (2) adding water-containing silica gel to the solution to make it react,

[0056] (3) solid-liquid separation and drying of the obtained solid-liquid mixture to prepare a composite carrier, and then

[0057] (4) Adding titanium halide as the active component of the Ziegler-Natta catalyst to the composite carrier to prepare the supported Ziegler-Natta catalyst component.

[0058] Specifically, the preparation process of the supported Ziegler-Natta catalyst component is as follows:

[0059] Weigh a certain amount of magnesium compound, add tetrahydrofuran and alco...

Embodiment 1

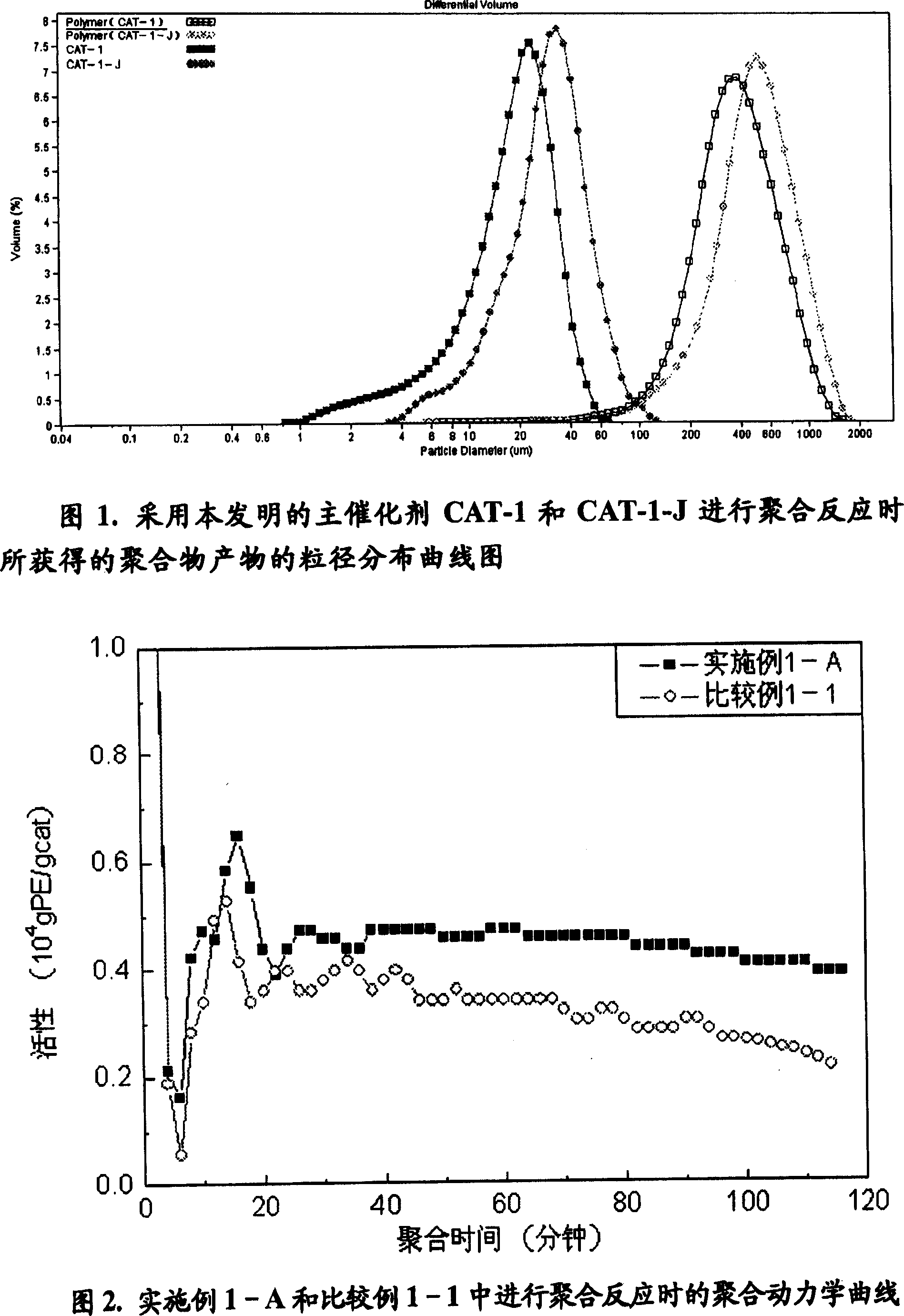

[0116] Carrier adopts silica gel, model is ES757 (Ineos company product, average particle size 25 microns, specific surface area 300m 2 / g, average pore diameter 19.5nm, pore volume 1.6ml / g), without activation, its water content is 4.09%.

[0117] Weigh 3.4g of anhydrous magnesium chloride, add 75ml of tetrahydrofuran and 8.5ml of ethanol, stir at 60°C until the anhydrous magnesium chloride is completely dissolved, add 4.0g of the silica gel, continue stirring at 60°C for 4h, cool to 32°C, add 45ml hexane (precipitation solvent), at this moment, the slurry temperature is 25°C, then filtered, washed with 45ml×2 hexane, and vacuum-dried at 80°C to obtain a powder solid.

[0118] Weigh the above powder solid, add 50ml of titanium tetrachloride hexane solution (concentration is 5% volume ratio), stir at 60°C for 5h, then filter, wash with 45ml×2 hexane, and vacuum dry at 60°C The main catalyst (i.e. supported Ziegler-Natta catalyst component) obtained as white solid particles is...

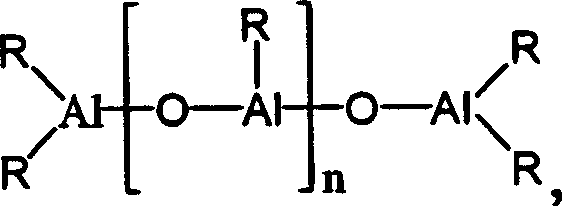

Embodiment 1-A

[0121] Take by weighing 44mgCAT-1, add the hexane solution of 3.1ml promotor triethylaluminum (abbreviated as AT, concentration 0.88mol / L), the mol ratio of the aluminum element in the procatalyst and the titanium element in the main catalyst is 98.5, The supported Ziegler-Natta catalyst of the present invention is obtained.

[0122] Add the catalyst to a 2-liter high-pressure reactor, add 1 L of hexane, start stirring at a speed of 250 rpm, and feed hydrogen to 0.11 MPa. After the temperature rises to 85°C, continuously feed ethylene to control the total volume of the reactor. The pressure is 0.8MPa, and it is vented after 2 hours of reaction. The polymer is taken out and weighed 370g after drying, and the bulk density is 0.35g / cm 3 . Oligomer content 0.14g / L. The fine powder content is 1.77%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com