Nozzle for spray dryer and spray dryer with nozzle

A technology of spray dryer and spray drying tower, which is applied in the direction of liquid separation into beads and granulation, which can solve the problems of microsphere bursting, production of special-shaped and fine powder, etc., and reduce the probability of particle rupture, reduce the formation of special-shaped particles, Avoid the effect of too rapid evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

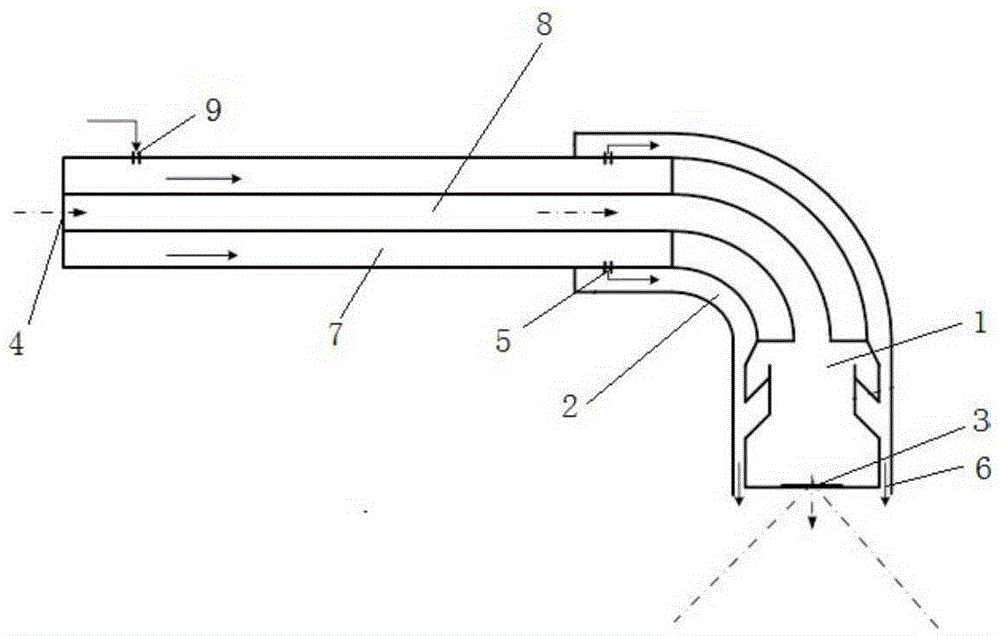

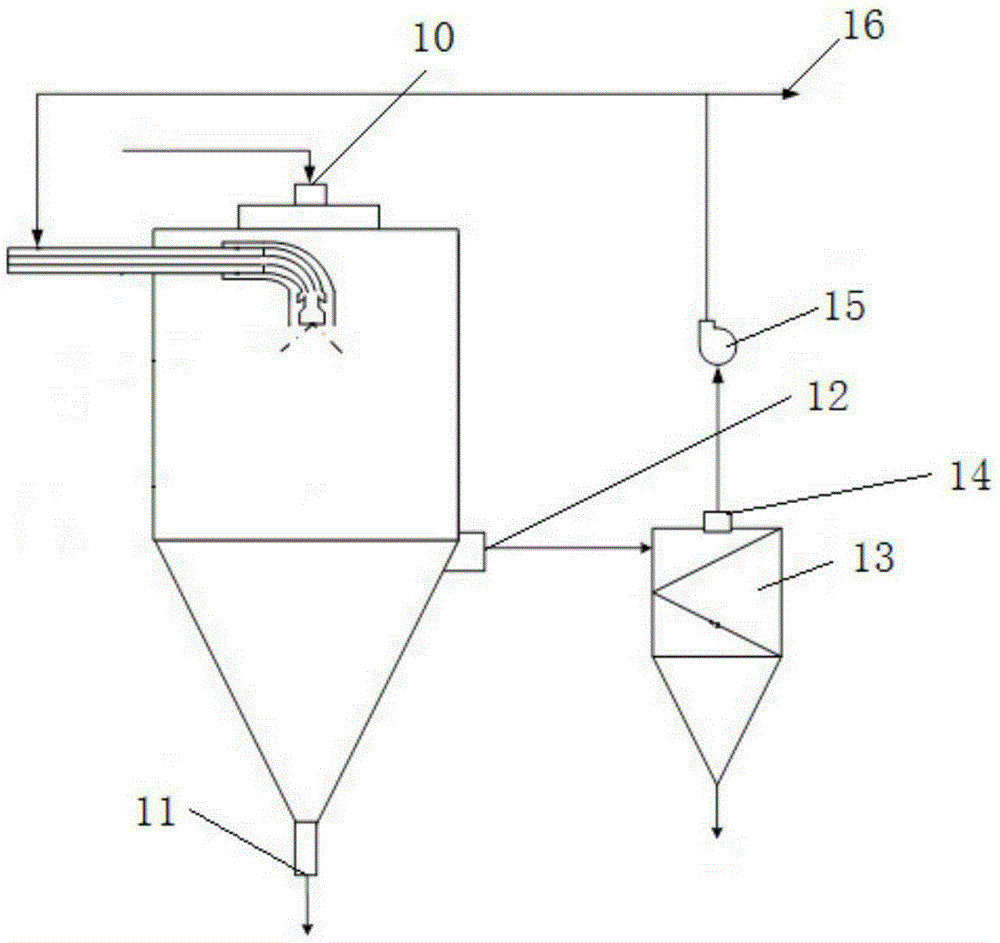

[0077] In this embodiment, the spray dryer provided by the present invention is used to dry the slurry used for preparing the catalyst. The spray dryer of the present embodiment contains such as figure 2 nozzle shown.

[0078] The catalyst slurry (the total content of kaolin and pseudo-boehmite is 30% by weight) is introduced into the nozzle from the material inlet by a high-pressure pump. The tower body of the spray dryer is sprayed to form a mist cone, wherein the cone angle of the mist cone is 110 degrees, and the tower body is filled with high-temperature hot air from the drying air distributor. At the same time, the protection wind is introduced from the protection wind inlet (1), and the protection wind is sprayed into the tower body through the protection wind casing, the protection wind distribution port (4), the protection wind guide pipe and the protection wind injection port to surround the tower body. The mist cone is such that the outer surface of the mist cone...

Embodiment 2

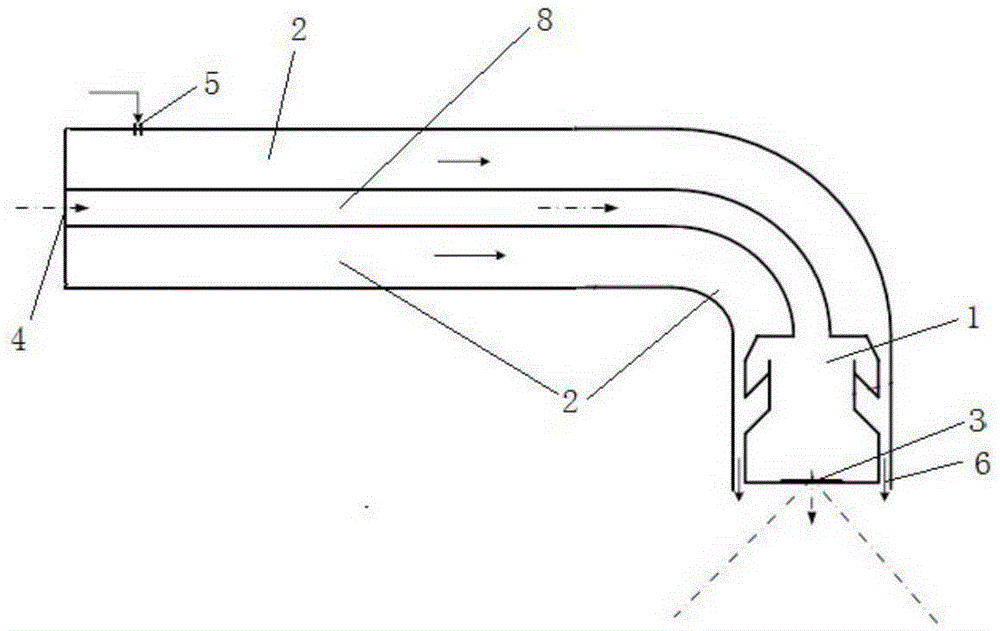

[0081] In this embodiment, the spray dryer provided by the present invention is used to dry the slurry used for preparing the catalyst. The spray dryer of the present embodiment contains such as figure 1 nozzle shown.

[0082] The catalyst slurry (the total content of kaolin and pseudo-boehmite is 30% by weight) is introduced into the nozzle from the material inlet by a high-pressure pump. The tower body of the spray dryer is sprayed to form a mist cone, wherein the cone angle of the mist cone is 120 degrees, and the tower body is filled with high-temperature hot air from the drying air distributor. At the same time, the protection wind is introduced from the protection wind distribution port (1), and the protection wind is sprayed into the tower body through the protection wind guide pipe and the protection wind injection port to surround the fog cone, so that the outer surface of the fog cone It is relatively isolated from the high-temperature hot air in the tower, wherein...

Embodiment 3

[0085] In this embodiment, the spray dryer provided by the present invention is used to dry the slurry used for preparing the catalyst. The spray dryer of the present embodiment contains such as figure 2 nozzle shown.

[0086] The catalyst slurry (the total content of kaolin and pseudo-boehmite is 30% by weight) is introduced into the nozzle from the material inlet by a high-pressure pump. The tower body of the spray dryer is sprayed to form a mist cone, wherein the cone angle of the mist cone is 100 degrees, and the tower body is filled with high-temperature hot air from the drying air distributor. At the same time, the protection wind is introduced from the protection wind inlet (2), and the protection wind is sprayed into the tower body through the protection wind sleeve, the protection wind distribution port (3), the protection wind guide pipe and the protection wind injection port to surround the tower body. The fog cone is such that the outer surface of the fog cone i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com