Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Reduce involvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

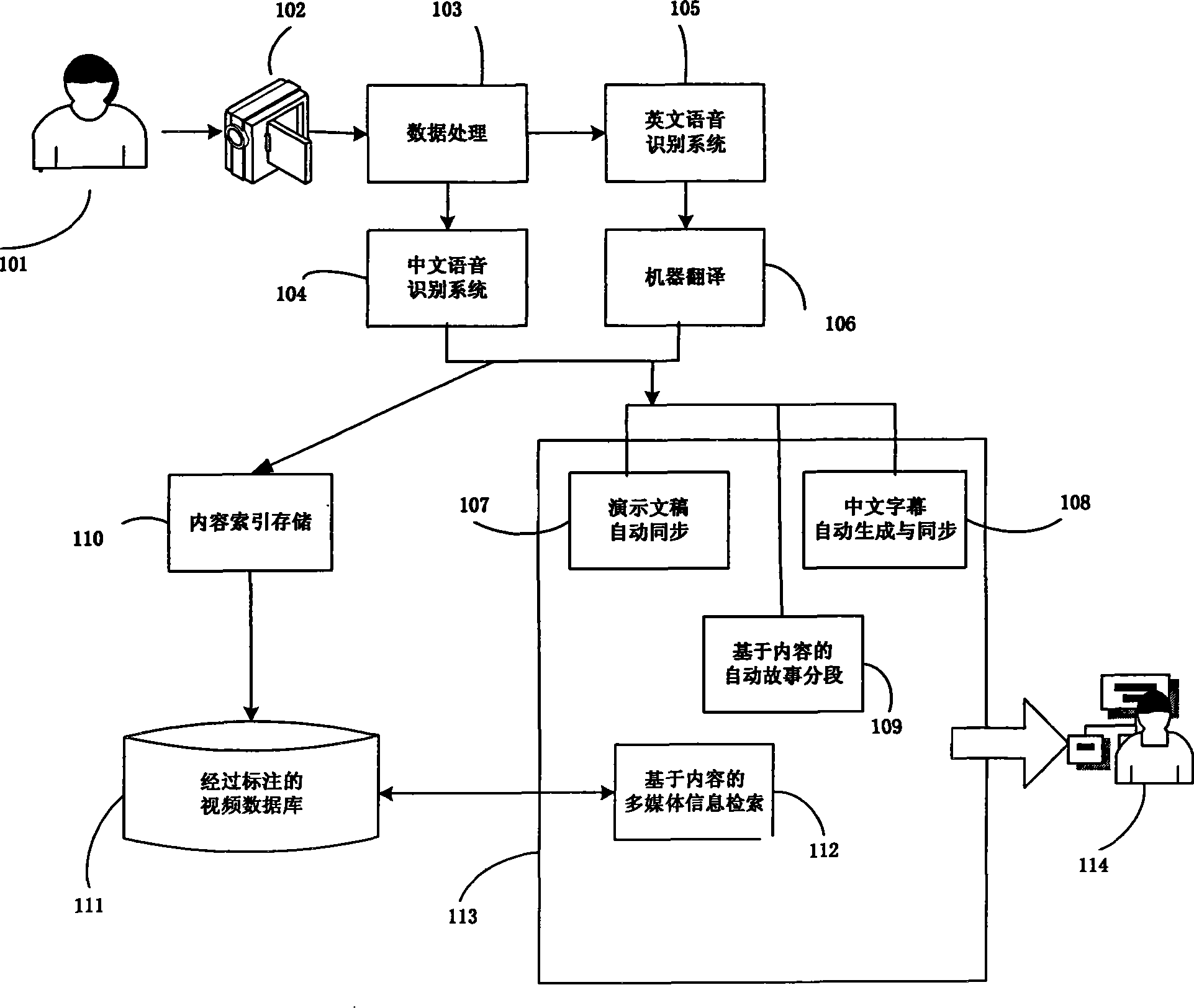

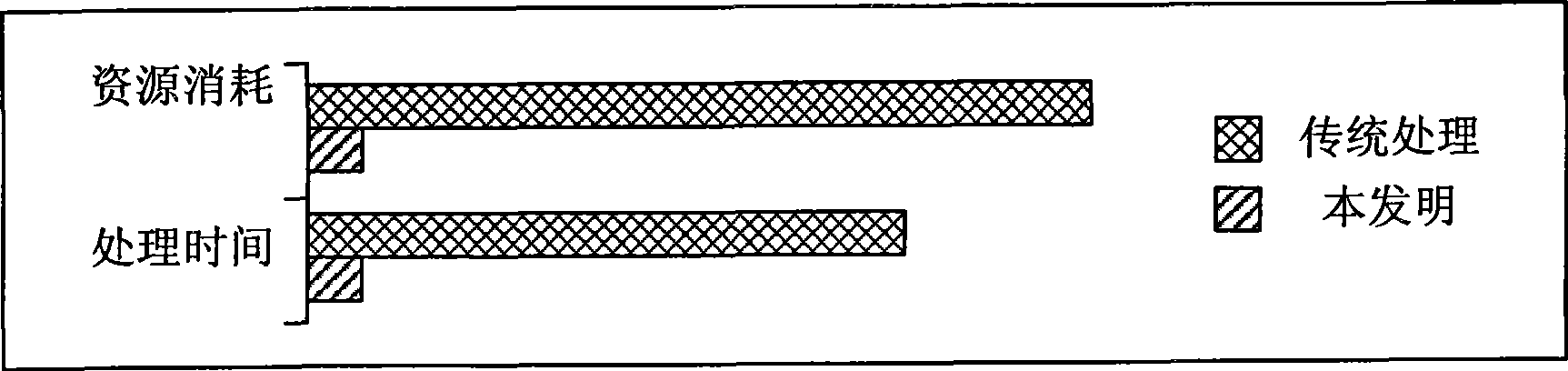

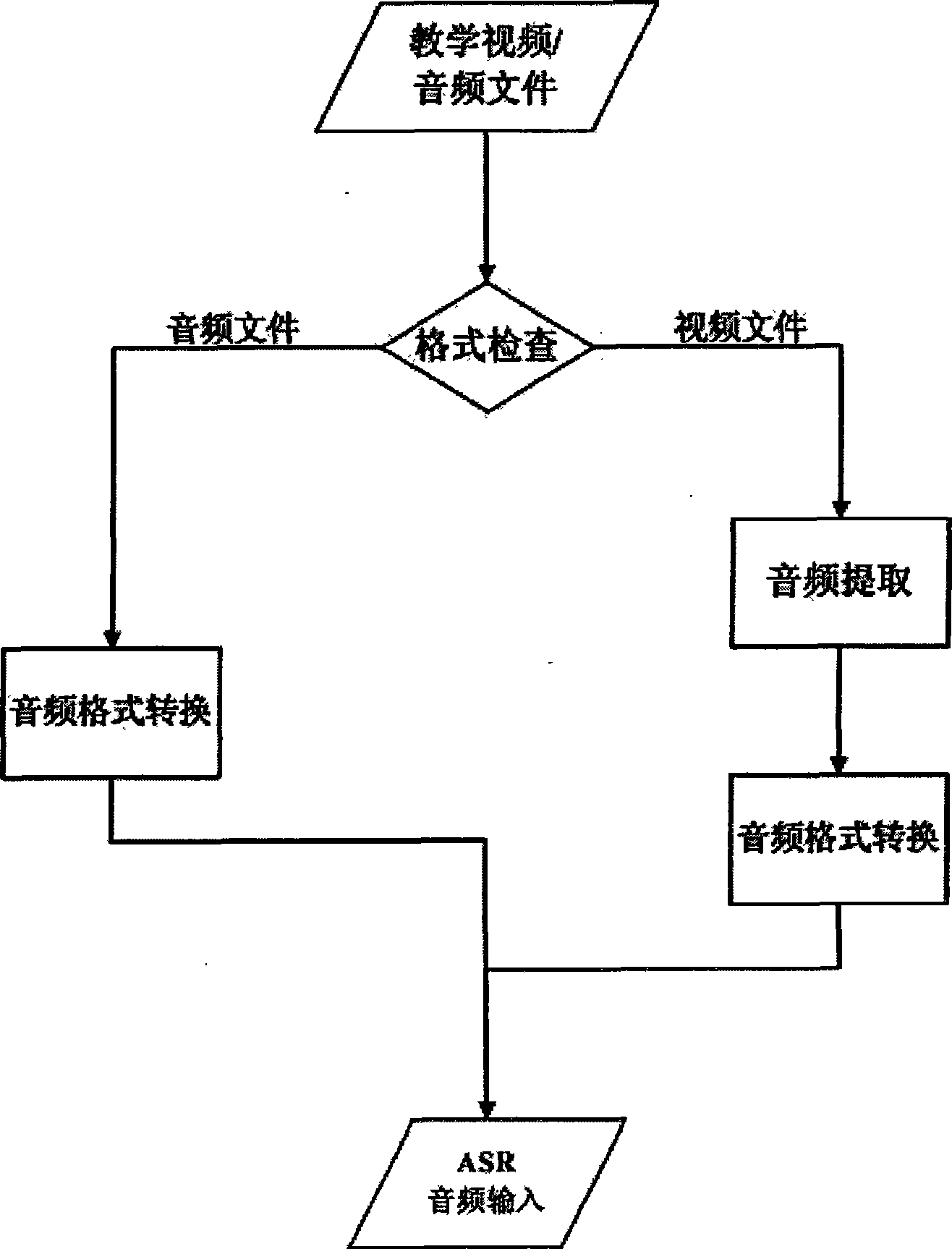

Multimedia resource processing method based on speech recognition and on-line teaching system thereof

ActiveCN101382937AProcessing speedSpeed up preparationSpeech recognitionElectrical appliancesContent retrievalSpeech identification

The invention discloses a multimedia resource processing method based on speech recognition and an online teaching system thereof. The method comprises the steps: audio and video frequencies are collected simultaneously and data are processed to process audio documents into a speech recognizable format; the audio documents are imposed with the speech recognition to generate script documents and with automatic generation and synchronization of Chinese captions with the video documents; and a content retrieval is imposed on the video documents, an automatic story segmentation based on the content is imposed on the script documents of the audio documents which are stored into the video database after being matched and labeled. The multimedia resource processing method based on the speech recognition and the online teaching system thereof are applied with the automatic processing technology of the multimedia resources, greatly increase the processing speed of such information as captions and the like by the use of high-performance computation of the computer, and reduce the participation degree of manual processing, thus accelerating the video manufacturing process and improving the work efficiency.

Owner:SHENZHEN INST OF ADVANCED TECH

Distributed computer network which spawns inter-node parallel processes based on resource availability

InactiveUS6925642B1Reduce expertiseReduce involvementMultiprogramming arrangementsMultiple digital computer combinationsWeb resourceDistributed computing

A parallel processing network permits processes to be spawned based on the availability of various network features. Such features may include the type of CPU's in the network, the number of CPU's per machine and other network resources. A user can select either a process group file method of process spawning or an automatic spawning method. In the automatic method, the user specifies various criteria related to how the processes are to be spawned such as the desired number of processes to be spawned, the type of CPUs to which the processes are to be spawned, the maximum number of processes to be started on any one machine and other information as desired. The spawning routine preferably runs on a root machine and accesses a process scheduler which provides the current network configuration. If CPUs and machines are available (i.e., operational) that match the user's criteria as determined by access to a process scheduler, the user desired number of processes is spawned to the CPUs and machines that match the criteria. If there are not enough CPUs and / or machines that match the user's criteria, the spawning routine decreases the number of processes from the user desired number of processes, and spawns processes to as many CPUs and machines that otherwise match the user's criteria. As such, the parallel processing network advantageously permits processes to be spawned automatically without requiring the user to have a detailed understanding of the available network features.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

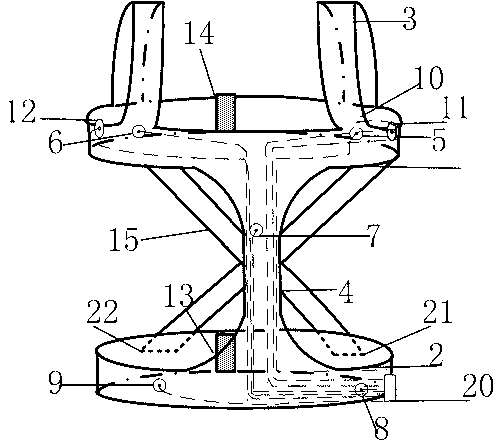

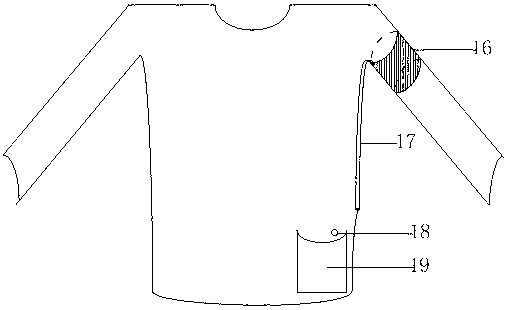

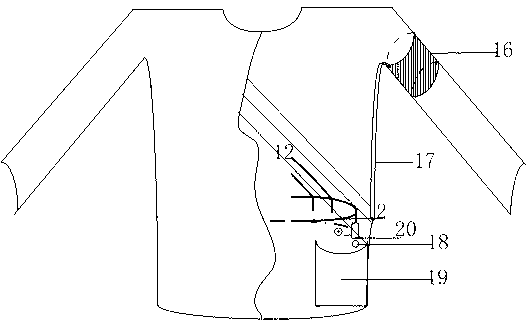

Wearable human body multiple physiological parameter acquiring device

InactiveCN103315722AAchieve separationReduce involvementDiagnostic recording/measuringSensorsHuman bodyEcg signal

The invention discloses a wearable human body multiple physiological parameter acquiring device. The wearable human body multiple physiological parameter acquiring device comprises a wearable acquiring band and acquiring clothes, wherein the wearable acquiring band comprises a chest strap, shoulder straps, a waistband and a connecting band located on the chest. The chest strap, the waistband and the connecting band comprise an outer layer and a liner respectively, the chest strap is fixedly connected with the waistband through the connecting band, and the chest strap is fixedly connected with the shoulder straps. Sandwich layers between the outer layers and the liners of the chest strap, the waistband and the connecting band are provided with corresponding electrode buttons, the outer surfaces of the liners of the chest strap, the waistband and the connecting band are correspondingly provided with electrodes for acquiring electrocardiosignals or respiratory signals, and the outer surface of the liner of the chest strap is further provided with a first temperature sensor and a second temperature sensor which are used for acquiring human body temperature signals. The acquiring clothes comprises a pocket provided with an acquiring circuit, sleeve bands for measuring blood pressure and provided with air bags are fixed at the upper-limb positions of sleeves of the acquiring clothes, and the air bags are connected with a pressure sensor in a blood pressure signal interface circuit in the acquiring circuit through air guiding tubes.

Owner:ZHEJIANG UNIV

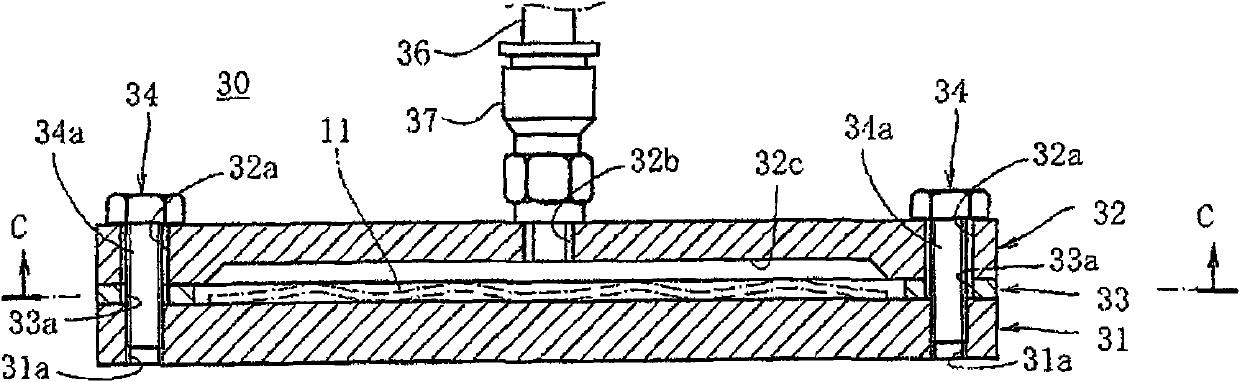

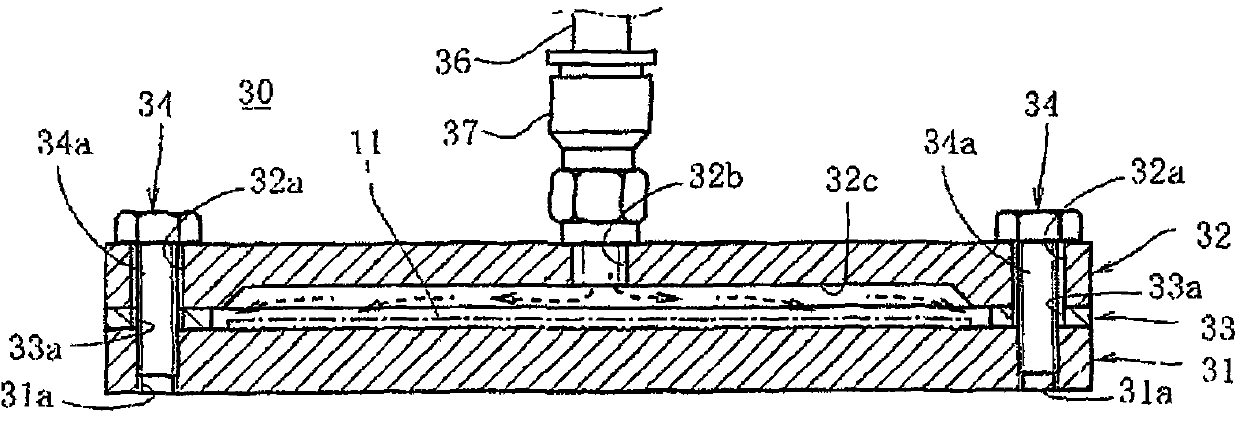

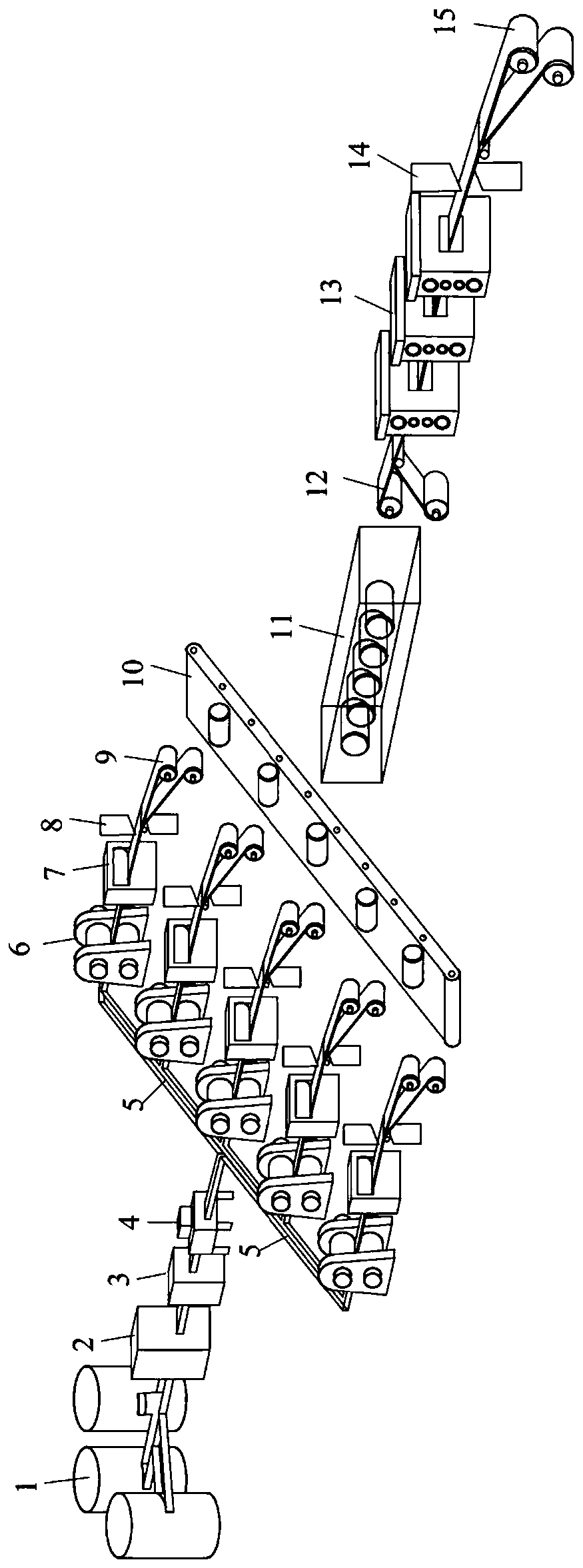

Film gauffer removing device, film tension adjusting method and film gauffer removing method

InactiveCN102024563AReduce involvementAvoid misalignmentThin/thick film capacitorStacked capacitorsEngineeringInjection air

Owner:NITTOKU ENG CO LTD

Mold core for manufacturing high-temperature alloy hollow blade

The invention provides a mold core for manufacturing a high-temperature alloy hollow blade. The mold core is placed in a wax injection mold to fabricate a wax pattern and the wax pattern covered with the mold core is used for fabricating a ceramic mold case; two positioning grooves are formed at the center positions of the front and rear two surfaces of the blade tip core head of the mold core; the positioning grooves are internally tapered grooves and the center lines of the positioning grooves are coincident with each other; and a pair of convex pins matched with the blade tip is arranged corresponding to the blade tip position of the wax injection mold. The mold core for manufacturing the high-temperature alloy hollow blade provided by the invention is characterized in that in mold core design, the shape of the core head part is simplified, and exposure of the blade root core head is eliminated so as to reduce involvement with the wax injection mold and the ceramic mold case, so that core making work becomes easy and the damage of the mold core is reduced. The mold core has certain degree of rotation freedom at the blade top core head in the directional solidification process of the high-temperature alloy hollow blade in the ceramic mold case, and the blade root core head is capable of completely and freely stretching in the vertical direction; therefore, the deformation and breakage of the mold core are greatly reduced, and the yield of the hollow blade is obviously improved.

Owner:DONGFANG TURBINE CO LTD

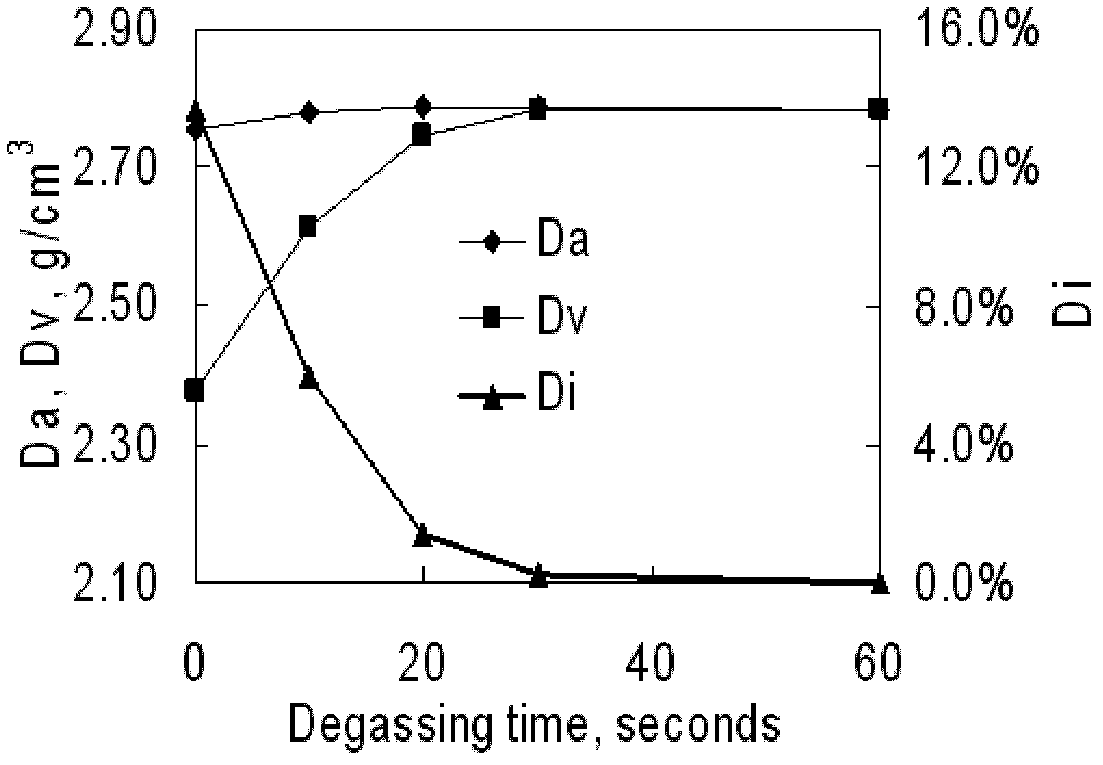

Casting method of ZL101 thin-wall aluminium alloy part

The invention discloses a casting method of a ZL101 thin-wall aluminium alloy part. The method includes steps of: 1) preparing moulding sand raw materials; 2) preparing binder slurry, wherein the binder slurry comprises 36-40% by weight of starch, 6-8% by weight of furan resin, 14-16% by weight of calcium bentonite, 3-5% by weight of bagasse cellulose powder having a size of -100 meshes, 1-2% by weight of zinc stearate and 2-3% by weight of sodium tripolyphosphate, with the balance being water; 3) preparing moulding sand; 4) manufacturing a casting and gating system; 5) smelting a ZL101 alloy, wherein 0.035% of Sr is added for modification, argon is fed after slag removal, gas removal is performed by rotation, smelting is performed when the temperature is 735-745 DEG C, and the alloy is allowed to stand for 10-12 min after smelting; 6) casting, wherein the aluminum alloy casting temperature is controlled to e 720-730 DEG C, and the casting speed is controlled in a manner that the former two fifth of the total casting amount adopts a speed of 6-8 kg / s, the middle two fifth adopts a speed of 4-5 kg / s, and the last one fifth adopts a speed of 6-8 kg / s; and 7) cooling with the mould, opening the mould, cleaning and performing thermal processing.

Owner:DAYE HONGTAI ALUMINUM IND CO LTD

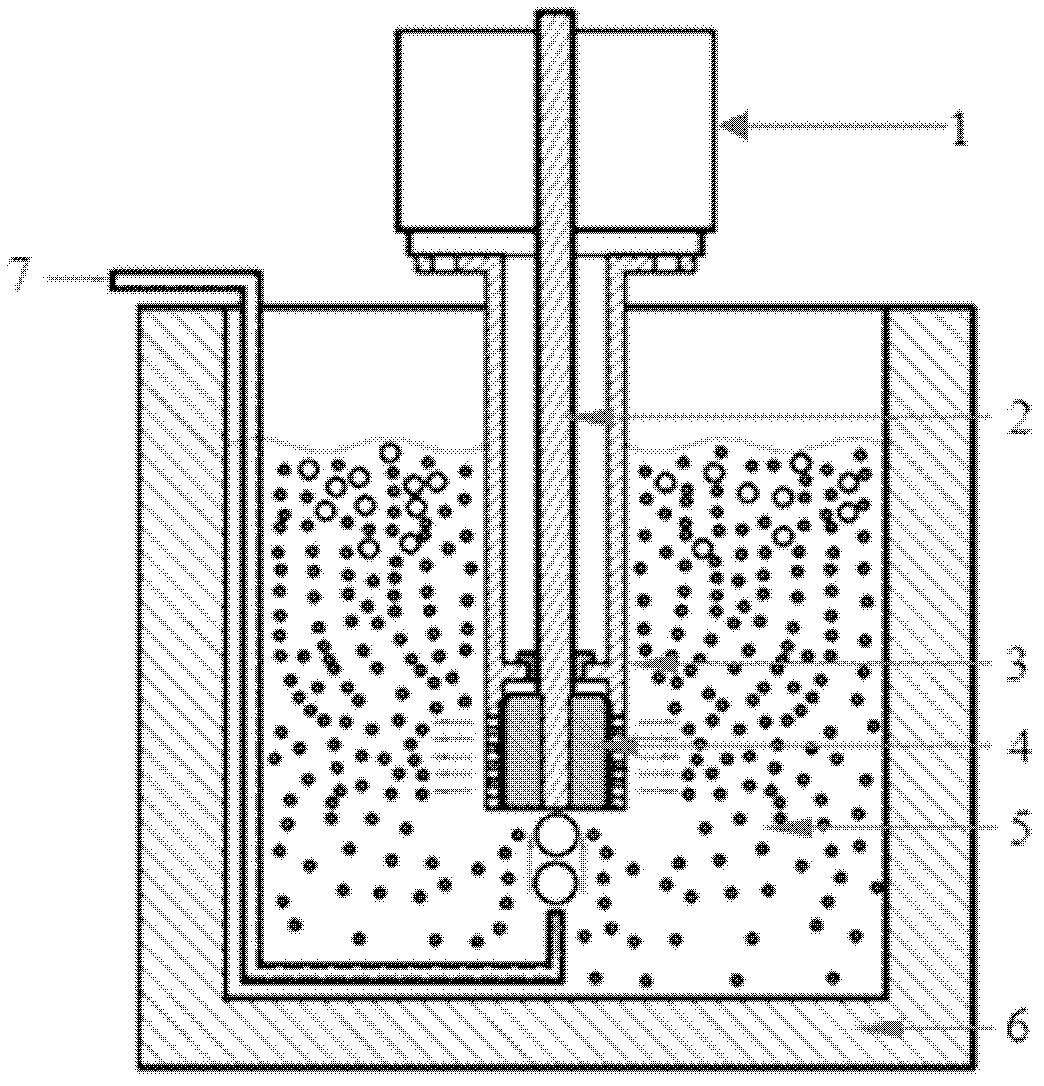

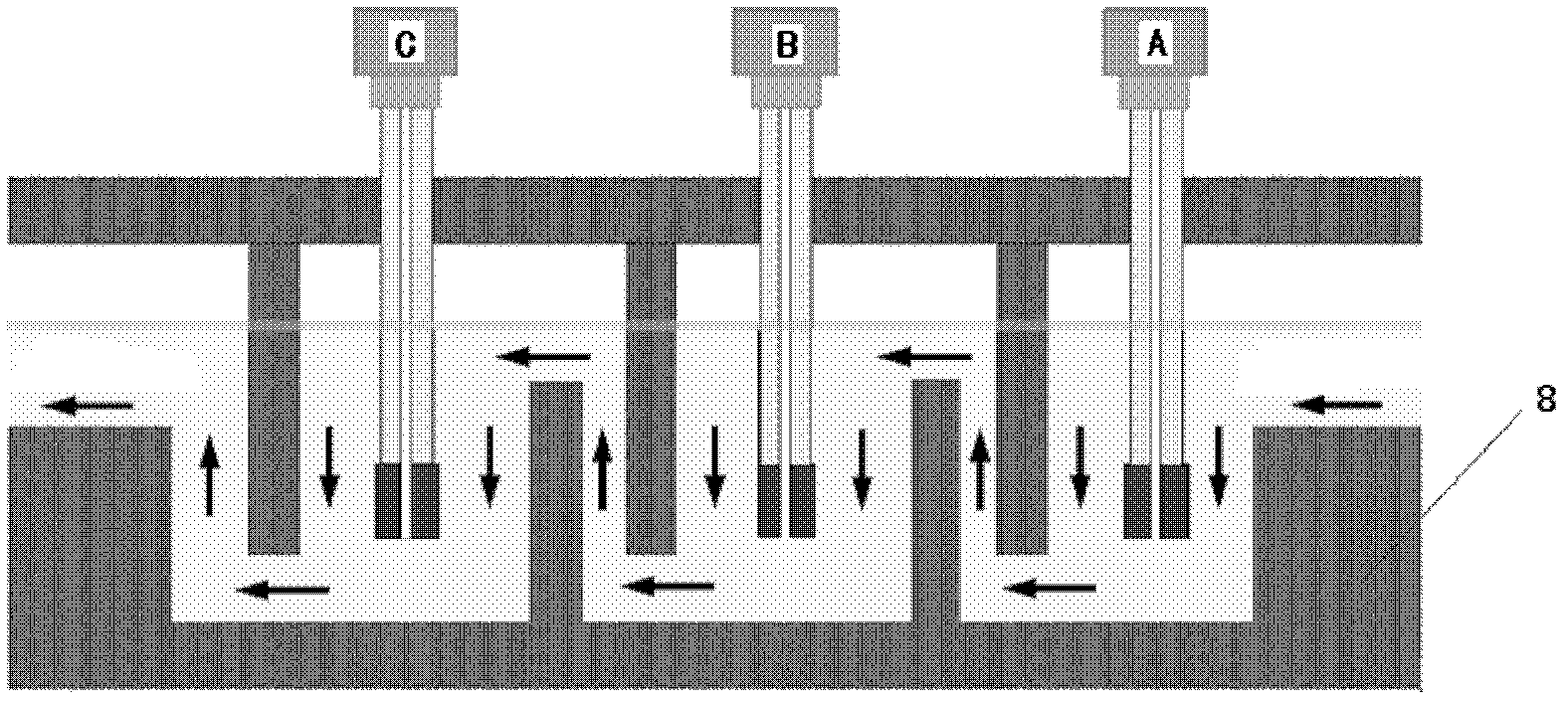

Alloy melt purifier and its method

The invention relates to an alloy melt purifier and its method, the purifier comprises a driving motor, a connection shaft, a stator and a rotor. The driving motor is directly connected with the connection shaft, the end portion of the connection shaft enables fixed connection with the rotor, the connection shaft and the rotor are arranged in the columnar stator, the stator is embedded and fixed in an insulation container, the alloy melt is filled in the insulation container, the stator is immersed in the alloy melt, an aperture is opened on the wall at the lower part of the stator, a vapor pipe is provided at one side of the insulation container, a gas outlet of the vapor pipe is in alignment with the lower part of the lower part of the rotor; The method for purifying the alloy melt by using the purifier comprises the following steps: the alloy melt and inert gas are sucked in the purifier through the high speed rotation of the rotor, high strength shearing effect formed by the stator and the rotor can be used, and the controllable forced convection can be generated under the liquid surface of the alloy melt, thereby the introduced inert gas bubbles can be smashed to fine bubbleswhich are uniformly distributed in the melt, the fine inert gas bubbles absorb impure gas in the melt and overflow the liquid surface, so that the purification of the melt with high efficiency can berealized.

Owner:NORTHEASTERN UNIV LIAONING

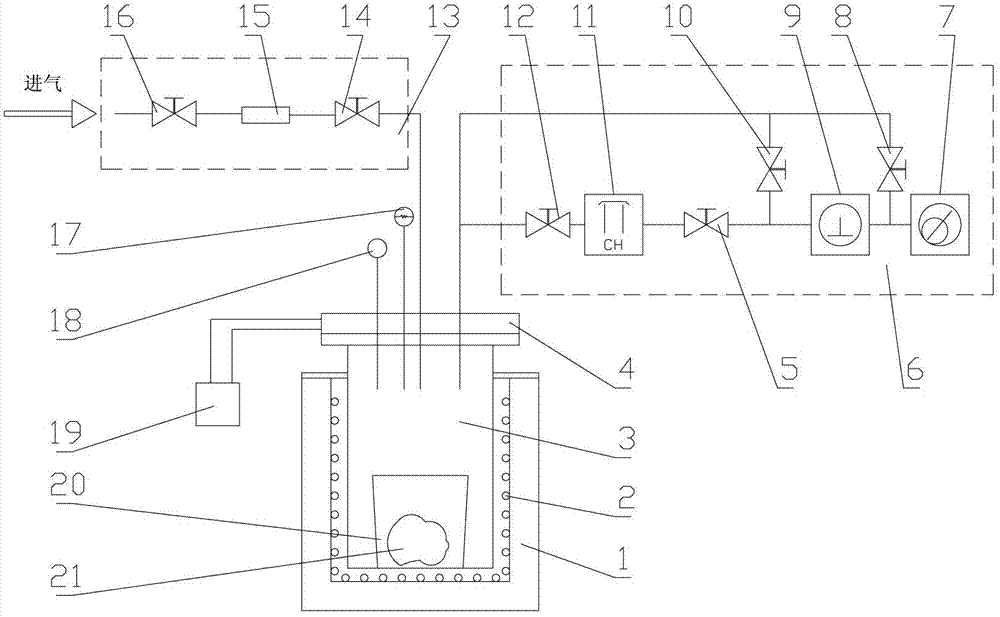

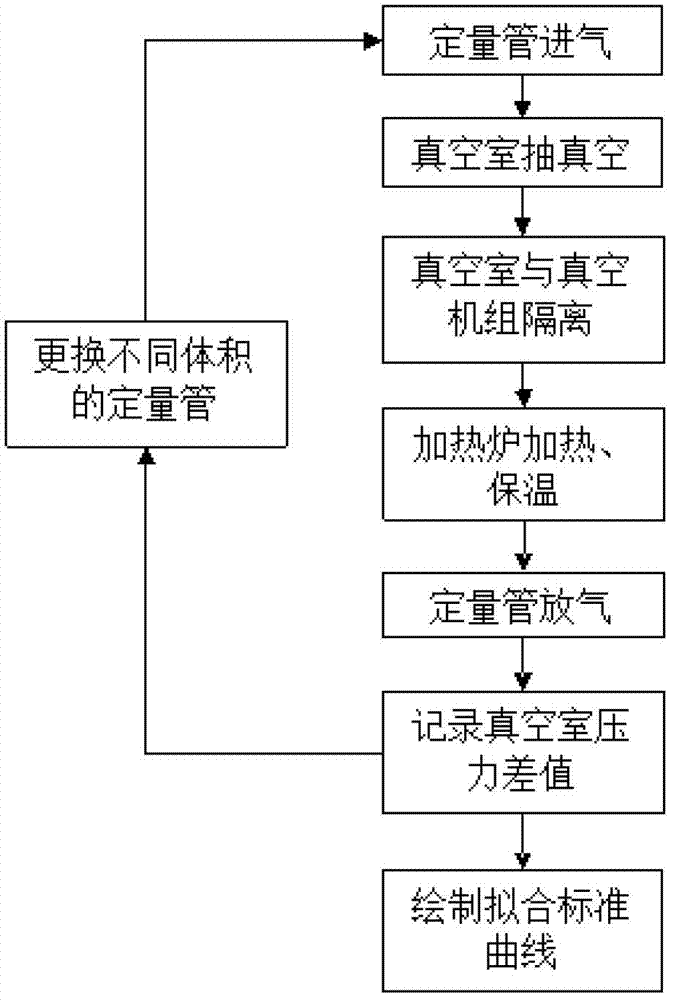

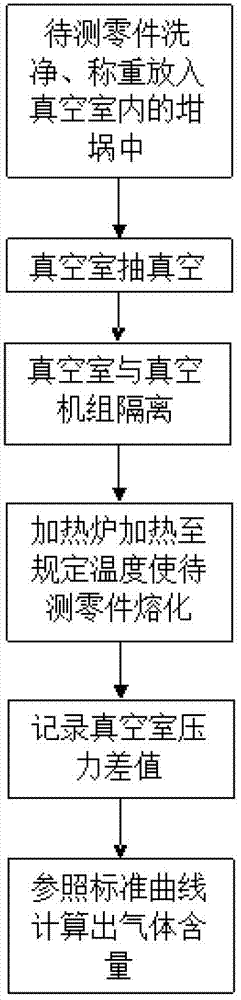

Method and device for quantitatively measuring content of gas inside aluminum alloy die casting

InactiveCN103196786AHigh measurement accuracyWorking conditions and process improvement and optimizationMaterial analysisQuantitative determinationVacuum pressure

Owner:HUAZHONG UNIV OF SCI & TECH

Process for producing magnetic sheet and magnetic sheet

ActiveCN101513153AReduce involvementReduce thickness variationMagnetic/electric field screeningMagnetic liquidsProduction rateSolvent

Owner:DEXERIALS CORP

Air distribution process and air distribution system for rotary kiln

ActiveCN102853654AReduce involvementReduce consumptionRotary drum furnacesIncreasing energy efficiencyLow oxygenEnvironmental geology

The invention provides an air distribution process and an air distribution system for a rotary kiln. The air distribution process comprises smoke purification, smoke recirculation, smoke powder feeding, smoke adjustment, oxygen enrichment preparation and enriching oxygen conveying. Smoke passing through a pre-heater or a waste heat boiler is subjected to particle and dust removal through a de-duster, and the smoke passing through a smoke recirculation fan is used for conveying coal powder for a kiln head combustor or a decomposing furnace, and is used as smoke gas at the center of the combustor to adjust flame shape and the position of a flame high-temperature area; air with high oxygen concentration is prepared by oxygen preparing equipment, and is conveyed to the kiln head combustor or is supplied into an air duct of the decomposing furnace after the air with high oxygen concentration is mixed with the air to obtain the air with relatively low oxygen concentration. According to the air distribution process provided by the invention, the oxygen enrichment air combustion supporting and the smoke recirculation can be comprehensively used on the rotary kiln, so that the involvement amount of cold air is reduced; the fuel coal consumption amount is reduced; the flame shape and the position of the high-temperature area can be adjusted; the generation of nitric oxides is reduced; the selection range of fuel is widened; and the system use ratio is improved. The air distribution process and system are simple, are convenient to use, and have good utilization effect.

Owner:徐州燃烧控制研究院有限公司

Method for producing high-performance aluminum alloy plate strip through sheet billet continuous roll casting

The invention relates to a method for producing a high-performance aluminum alloy plate strip through sheet billet continuous roll casting. The method comprises the following steps that firstly aluminum alloy melt is refined, and double-roller type sheet billet continuous roll casting is conducted on the melt by adopting a water-cooled casting roller with a nano-graphite coating on the surface forlubrication, so that a continuous rolled-cast sheet billet is obtained; and heat leveling, heating and homogenizing treatment, heat preservation and uncoiling for hot finish rolling are conducted. According to the method, procedures of semi-continuous casting, surface milling, homogenization heat treatment, hot rough rolling, intermediate annealing and the like of a traditional ingot casting hotrolling cogging method are omitted, the yield of the aluminum alloy plate strip is obviously improved by 20% or above, the production cycle is shortened from the original 20 days to about a 0.5 day, and the production efficiency is remarkably improved; and the production cost is reduced by 30% or above while the production process continuity is improved, and emission of pollutants of carbon / sulphide and the like are reduced by 50% or above, and large economic benefits and social benefits are generated.

Owner:NORTHEASTERN UNIV

Feeding device for cylinder-shaped sewing machine

The invention provides a feed apparatus of a cylinder sewing machine for preventing cloth getting into a rear wheel, and reducing damage of an endless belt, which is provided with a needle plate of a needle plate claw installed one a cylinder frame, a rear wheel which is configured along the upper part of the cylinder frame behind the needle plate claw and which is coupled with a front wheel in front of the needle plate claw, an endless belt which is reeled and hang on the front and the rear wheels and which is configured partly on the needle plate, and an intermittent clutch which is connected to one of the front and the rear wheels and which has rotary linkage with a spindle to make the wheel rotate intermittently; cloth on the needle plate is conveyed to cloth feed direction through the endless belt; a guide sheet with a support face is installed at two sides of the endless belt on the rear wheel; part of the support face is pushed from the endless belt of the rear wheel to the cloth feed direction.

Owner:株式会社飞马

Disposal bidirectional navel cord cutting and protecting device

InactiveCN101485584AThe operation process is simple and convenientOperational securitySurgeryNavelUmbilical cord stump

The invention relates to a disposable bidirectional umbilical cord cutting protection device. The device consists of an umbilical cord cutter, an umbilical cord protection pad and an umbilical cord protection cap, wherein the upper shell and the lower shell of the umbilical cord cutter are hinged with each other; a blade is arranged on a blade fixing bracket which is connected with the upper shell into a whole and is provided with a wedge-shaped lug boss and a transverse stop block; an A umbilical cord clamp and a B umbilical cord clamp are positioned by convex pins of the lower shell so as to be arranged on the outer sides of both cutting platforms of the lower shell; the inner surfaces of an upper arm and a lower arm of the A umbilical cord clamp and the B umbilical cord clamp are provided with two groups of racks which are meshed in a staggered way; one end of the upper arm and one end of the lower arm of the A umbilical cord clamp and the B umbilical cord clamp are connected into a whole through an elastic bow; a holder is positioned between a cutter groove and the A umbilical cord clamp, and is movably arranged inside a dovetail groove in the middle of the lower shell by means of a dovetail lug boss of the holder. During operation, a user can gradually clutch the cutter inserted into an umbilical cord; therefore, the blade enters the cutter groove to cut off the umbilical cord, and the wedge-shaped lug boss extrudes the A umbilical cord clamp out of the lower shell through the holder. The disposable bidirectional umbilical cord cutting protection device can realize one-step clamping positioning, cutting and separating the umbilical cord and protecting the umbilical cord stump.

Owner:曾维著 +1

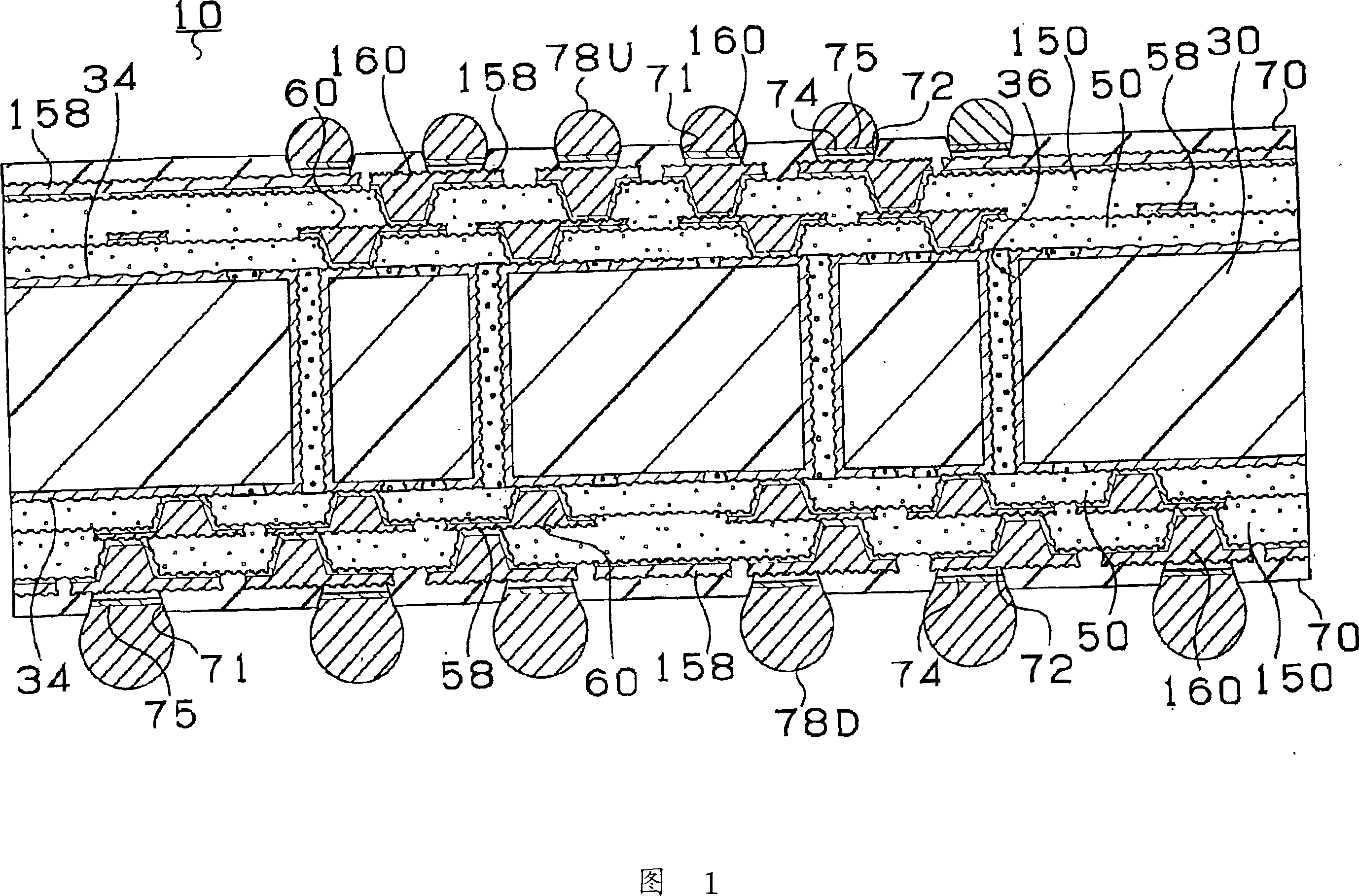

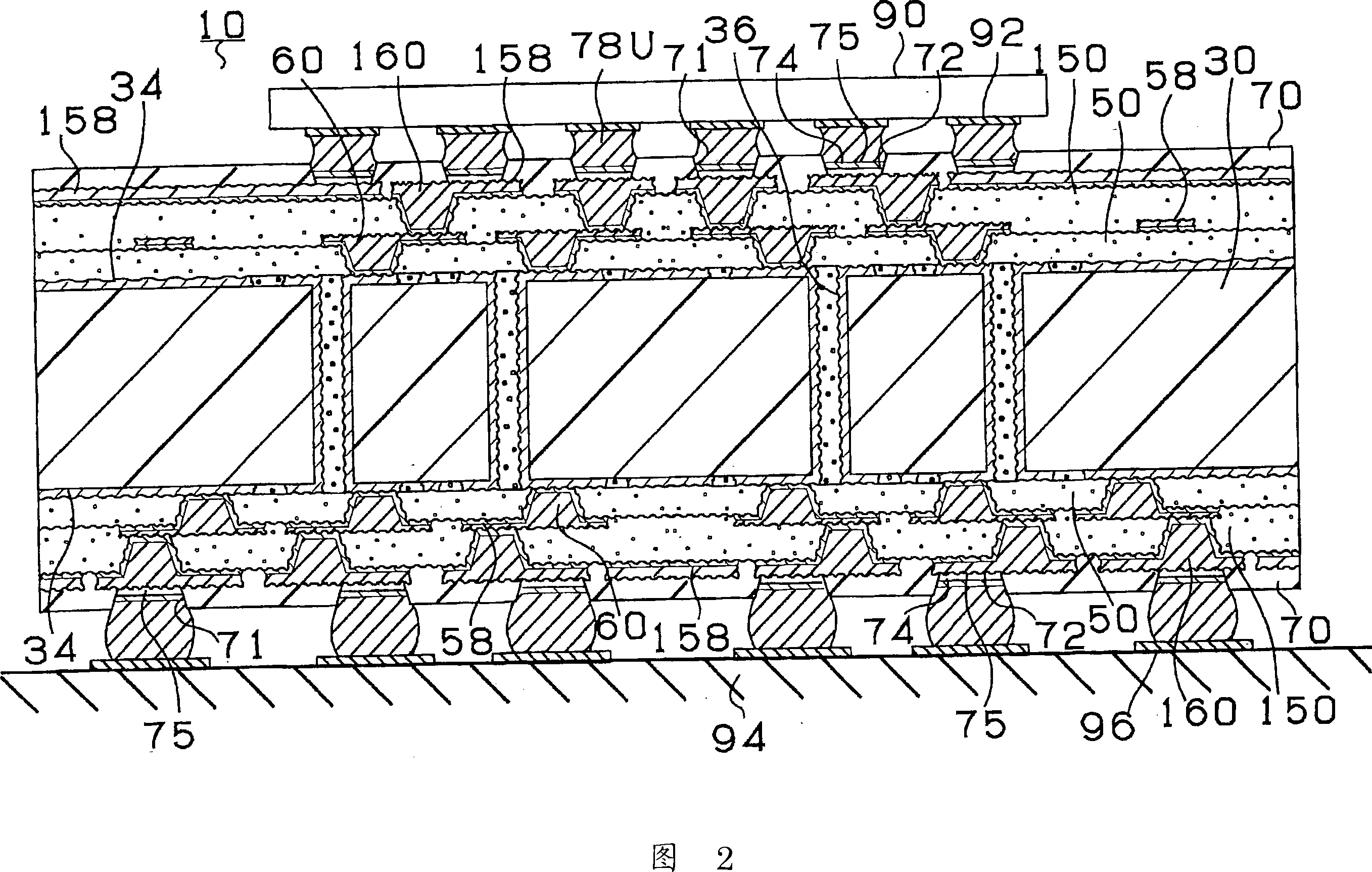

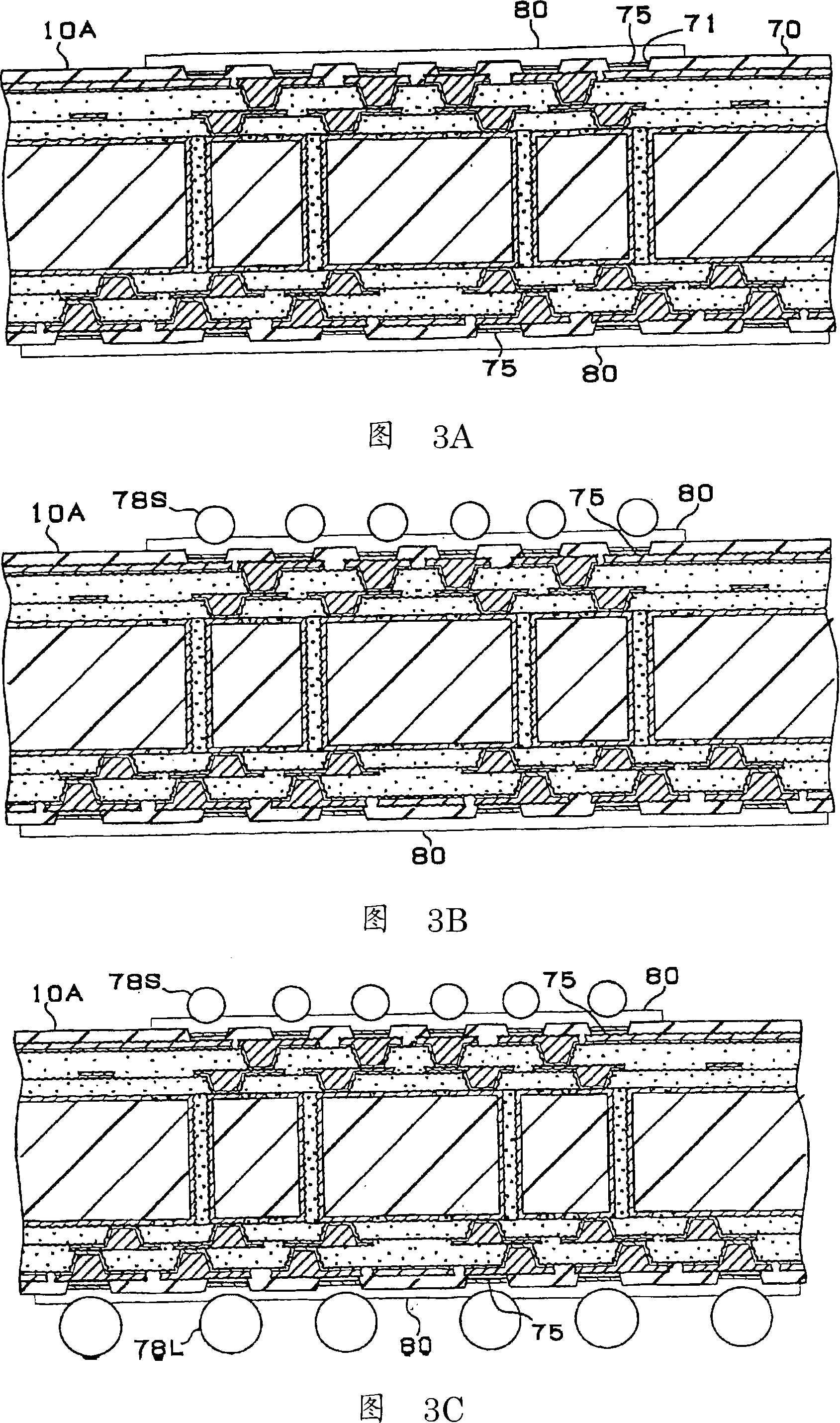

Printed wiring board

ActiveCN101171895APrevent peelingSmall insulation resistancePrinted circuit assemblingSemiconductor/solid-state device detailsResistElectrical conductor

A printed wiring board comprises a wiring substrate provided with at least one conductor circuit, a solder resist layer provided on the surface of the wiring substrate, at least one conductor pad formed from a part of the conductor circuit exposed from an opening provided in the solder resist layer, and at least one solder bump for mounting electronic parts on the conductor pad. In the printed wiring board, since the at least one conductor pad is aligned at a pitch of 200 µm or less, and a ratio (W / D) of a diameter W of the solder bump to an opening diameter D of the opening formed in the solder resist layer is within a range of 1.05 to 1.7, connection reliability and insulation reliability can be easily improved.

Owner:IBIDEN CO LTD

Die pouring system of die casting parts

The invention provides a die pouring system of die-casting parts. The die pouring system comprises a pouring gate system and a forming cavity, the pouring gate system comprises a plurality of main pouring gates, a plurality of branch pouring gates are arranged at the output ends of the main pouring gates, the cross sectional areas of the main pouring gates and / or the branch pouring gates are gradually reduced along the conveying direction of molten metal; a plurality of pouring inlets are formed in the forming cavity, the pouring inlets communicate with the output ends of the branch pouring gates in a one-to-one correspondence mode; along the conveying direction of the molten metal, a plane where the pouring inlets are located serves as the top face of the forming cavity, the molten metaldirectly falls on the bottom face of the forming cavity after entering the forming cavity from the pouring inlets; and the distance value between the setting position of the pouring inlets and the bottom face of the forming cavity comprises the maximum height value of a casting to be formed in the forming cavity. According to the die pouring system of the die-casting parts, the generation of air holes and shrinkage cavities in the inner part of the casting can be reduced, the product quality can be improved, and the production cost can be reduced under the conventional die-casting condition.

Owner:ZHANJIANG DENI VEHICLE PARTS

Casting device and casting method thereof

The invention provides a casting device and a casting method thereof. The casting device comprises a centrifugal lower mold, a centrifugal upper mold, a sand mold, a mold jacking device and a centrifugal machine, wherein an accommodating cavity is formed in the centrifugal lower mold; a guide bar is arranged at the position, on the outer side of the accommodating cavity, of the centrifugal lower mold; a cavity for accommodating the sand mold is formed in the centrifugal upper mold; a feeding pouring gate is formed in the bottom surface of the sand mold; a sprue is formed in the top surface ofthe feeding pouring gate; at least two annular casting cavities are formed in the periphery of the feeding pouring gate; each casting cavity sinks inwards from the bottom surface of the sand mold; each casting cavity is provided with a connecting channel communicating to the feeding pouring gate; the mold jacking device comprises a stripping plate arranged in the accommodating cavity, a jacking shaft connected under the stripping plate, a mold jacking plate arranged below the centrifugal lower mold and driving equipment arranged below the mold jacking plate. Two ends of the guide bar are separately fixed to the centrifugal upper mold and the mold jacking plate. The casting method comprises the following steps: stretching the mold jacking device out; retracting the mold jacking device; carrying out centrifugal casting; jacking the mold; pushing out a forming body; and removing the centrifugal pressure casting pouring gate. A casting manufactured by the casting device is uniform in tissue, and defects such as airholes are reduced.

Owner:YANTAI SHUANGYUAN GENERAL PARTS

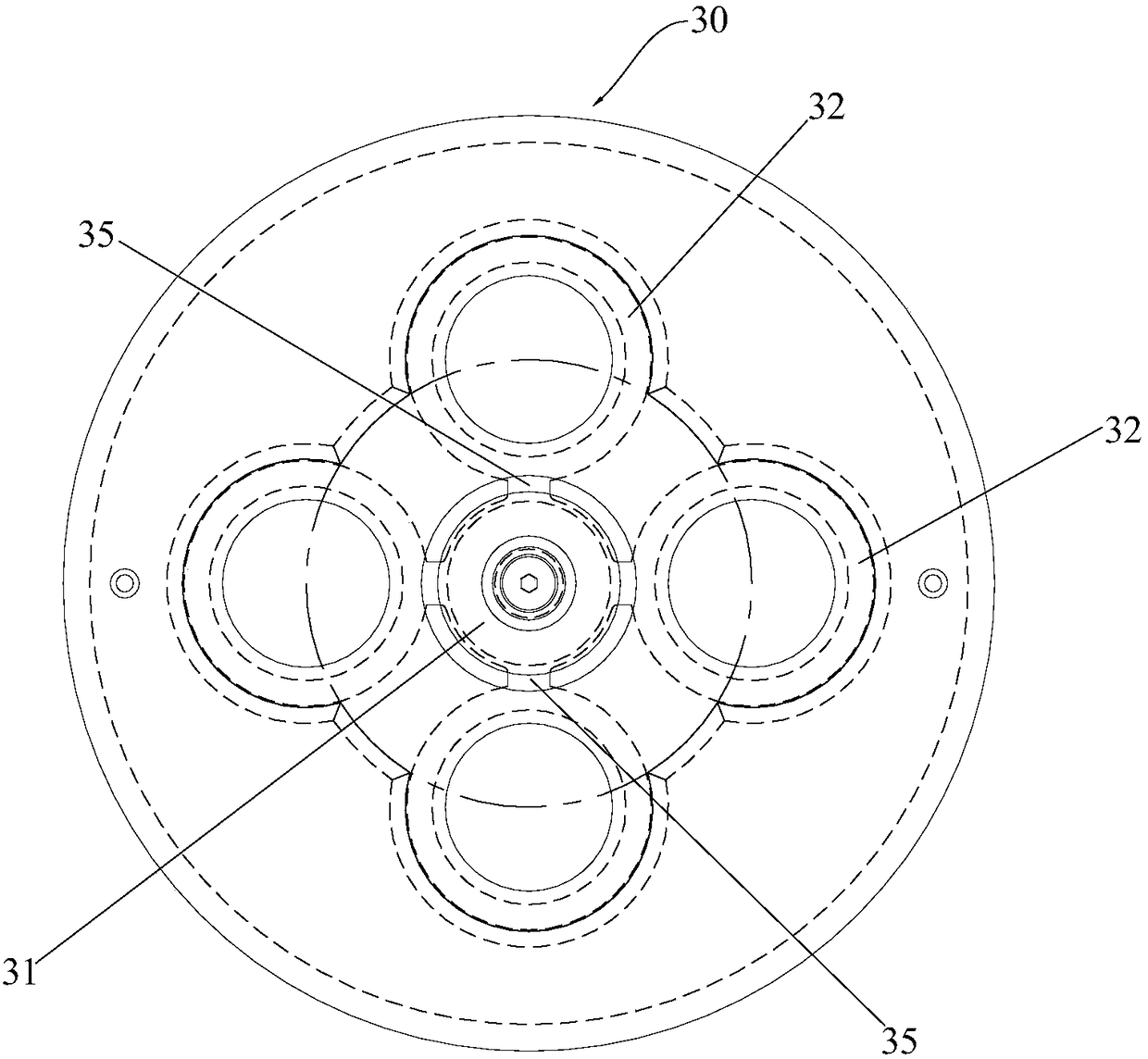

Substrate processing apparatus and method

ActiveCN1714952ASpread evenlyUniform spreadSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringAtmosphere

In the vicinity of a rim portion of a spin base 5 , a plurality of supports 7 which abut on a bottom rim portion of a substrate W and support the substrate W are formed projecting toward above from the spin base 5 . The substrate W is supported horizontally by the plurality of supports 7 , with a predetermined distance ensured from the spin base 5 which opposes the bottom surface of the substrate W. Into the space which is created between the top surface of the substrate W and an opposing surface 9 a of an atmosphere blocker plate 9 , inert gas is ejected from a plurality of gas ejection outlets 9 b which are formed in the opposing surface 9 a. The inert gas thus supplied to the top surface of the substrate W presses the substrate W against the supports 7 and the substrate W is held at the spin base 5.

Owner:DAINIPPON SCREEN MTG CO LTD

Vertical self-priming pump and vertical self-priming pump with filtration device

InactiveCN101424277AReduce constraintsEfficient deliveryPump componentsPriming pumpFiltrationEngineering

The subject of the invention is to provide a vertical self-suction pump which has low restriction in setting space and setting direction, and specifically provide a vertical self-suction pump which has easy and safe filter replacement operation, no requirement for pumping out the air in the pump or water injection before starting-up, and has low restriction in setting space and setting direction compared with the condition of adopting a horizontal pump structure, and is provided with a filtering device. The vertical self-suction pump adopts a valveless structure without a back valve. The vertical self-suction pump is characterized by comprising the following components: a pump part which is provided with a suction inlet, a suction chamber, an impeller, a self-suction chamber, a discharging opening in sequence from the upstream to the downstream of flow path, the suction inlet and the discharging opening are configured at positions above the suction chamber and the impeller, the self-suction chamber is configured at the position above the suction inlet and the discharging opening; and a driving part which is connected with the lower part of the pump body and becomes the driving source of pump body, wherein the rotation direction of impeller is an approximately horizontal direction.

Owner:WORLD CHEM CO LTD

Cylindrical grinding machine

ActiveCN111055172AImprove cooling efficiencyReduce splashRevolution surface grinding machinesGrinding/polishing safety devicesElectric machineryEngineering

The invention belongs to the technical field of grinding machine equipment, and particularly relates to a cylindrical grinding machine. The cylindrical grinding machine comprises a workbench, a firstroller and a second roller are rotationally connected to the workbench through a support, a sliding rail is arranged on the side, far away from the first roller, of the second roller, a sliding blockis slidably connected to the sliding rail, the sliding block is controlled by a displacement device to slide up and down, a grinding wheel is rotationally connected to the sliding block and rotates anticlockwise, the grinding wheel is driven by a motor which is in control connection with a power supply through a controller, a protective cover fixedly connected with the sliding block is arranged onthe periphery of the grinding wheel, a spray head for spraying cooling liquid is arranged on the side, far away from the second roller, of the first roller, and communicates with a water pump and a cooling pool through pipelines, and an arc-shaped part matching with the periphery of a workpiece is arranged at the end, close to the workpiece, of the nozzle. According to the cylindrical grinding machine, the arc-shaped part matches with the surface of the workpiece in shape, so that the arc-shaped part is tightly attached to the surface of the workpiece, the cooling liquid forms a water film uniform in thickness on the surface of the workpiece, splashing of the cooling liquid is reduced, and the workpiece cooling efficiency is improved.

Owner:TONGLING ZHAOLIN IND & TRADE CO LTD

Printed wiring board

InactiveCN101854771APrevent peelingSmall insulation resistancePrinted circuit assemblingSemiconductor/solid-state device detailsResistElectrical conductor

The invention provides a printed wiring board, wherein conductor circuits and interlayered resin insulating layers are stacked alternately on the printed wiring board, and the printed wiring board has a lamination layer for electrically connecting conductor circuits located at different layers by via holes. The printed wiring board is provided by arranging a solder resist layer to cover the interlayered resin insulating layer located at the outermost of the lamination layer nad the conductor circuit located at the outermost, forming as a conductor pad a part of the conductor circuit exposed from an opening section arranged on the solder resist layer, and by forming a solder bump on the conductor pad for mounting an electronic component. The connecting reliability and the insulating reliability are improved by permitting a rate (W / D) of a solder bump diameter (W) to the opening diameter (D) of the opening section to be 1.05-1.7, even in a narrow pitch structure where the pitch of the opening section arranged on the solder resist layer is 200[mu]m or less.

Owner:IBIDEN CO LTD

Adjustable multilayer tea caddy

The invention discloses an adjustable multilayer tea caddy which comprises a tea caddy body, a multilayer lifting device, a storage partition box and a storage drawer, wherein a first arc-shaped groove and a second arc-shaped groove are formed in the side walls of the tea caddy body; a limiting axis rod is arranged at the axis of the first arc-shaped groove; the multilayer lifting device comprisesa turbine rotating rod and a hollow vortex rod shaft pin; the turbine rotating rod is rotatably arranged in the second arc-shaped groove; the hollow vortex rod shaft pin is arrangd on the limiting axis rod in a sleeving manner; two rectangular sliding chutes are formed in the hollow vortex rod shaft pin; a plurality of triangular slots are formed in the two side walls of each of the rectangular sliding chutes; an arc-shaped groove and two rectangular sliding blocks are arranged on the storage partition box; and the rectangular sliding blocks are arranged in the rectangular sliding chutes. Theadjustable multilayer tea caddy can store tea in a layered manner; the distance between every two adjacent layers can be adjusted as needed; in addition, the usual using stability of each layer is ensured, the situation that the bottom tea is crushed caused by drag can be reduced; and moreover, quantitative storage can be realized, and different types of tea can be stored into categories as needed.

Owner:ANHUI YILIANG TANK IDUSTRY TECH CO LTD

Design method suitable for electromagnetic pump low-pressure casting mold filling technology

InactiveCN103658599AAvoid spray and splashReduces turbulence and gas entrapmentThree dimensional modelCurrent time

The invention discloses a design method suitable for the electromagnetic pump low-pressure casting mold filling technology, and belongs to the technical field of electromagnetic pump low-pressure casting. The method aims at achieving the aim that the mold filling speed can be adjusted according to the size of the cross section in the electromagnetic pump low-pressure casting mold filling process, namely the mold filling pressure can be changed in good time. According to the technical scheme, the design method includes the following steps: (1) making a casting technology three-dimensional model of a casting, (2) carrying out slice analysis on the casting in the Z direction, namely the casting direction, (3) dividing the casting into a plurality of parts in the Z direction, namely the casting direction, (4) forming a pressure-time curve P(t) of the whole casting, (5) modifying the P(t) in the step (4) into a PM(t), (6) converting the pressure-time curve PM(t) into a current-time curve I(t), (7) installing a high-temperature laser liquid level distance meter above molten aluminum, and starting the high-temperature laser liquid level distance meter, (8) testing, and recording the initial position of a liquid level, and (9) installing a casting mold, and executing the low-pressure casting mold filling technology.

Owner:ZHONGBEI UNIV

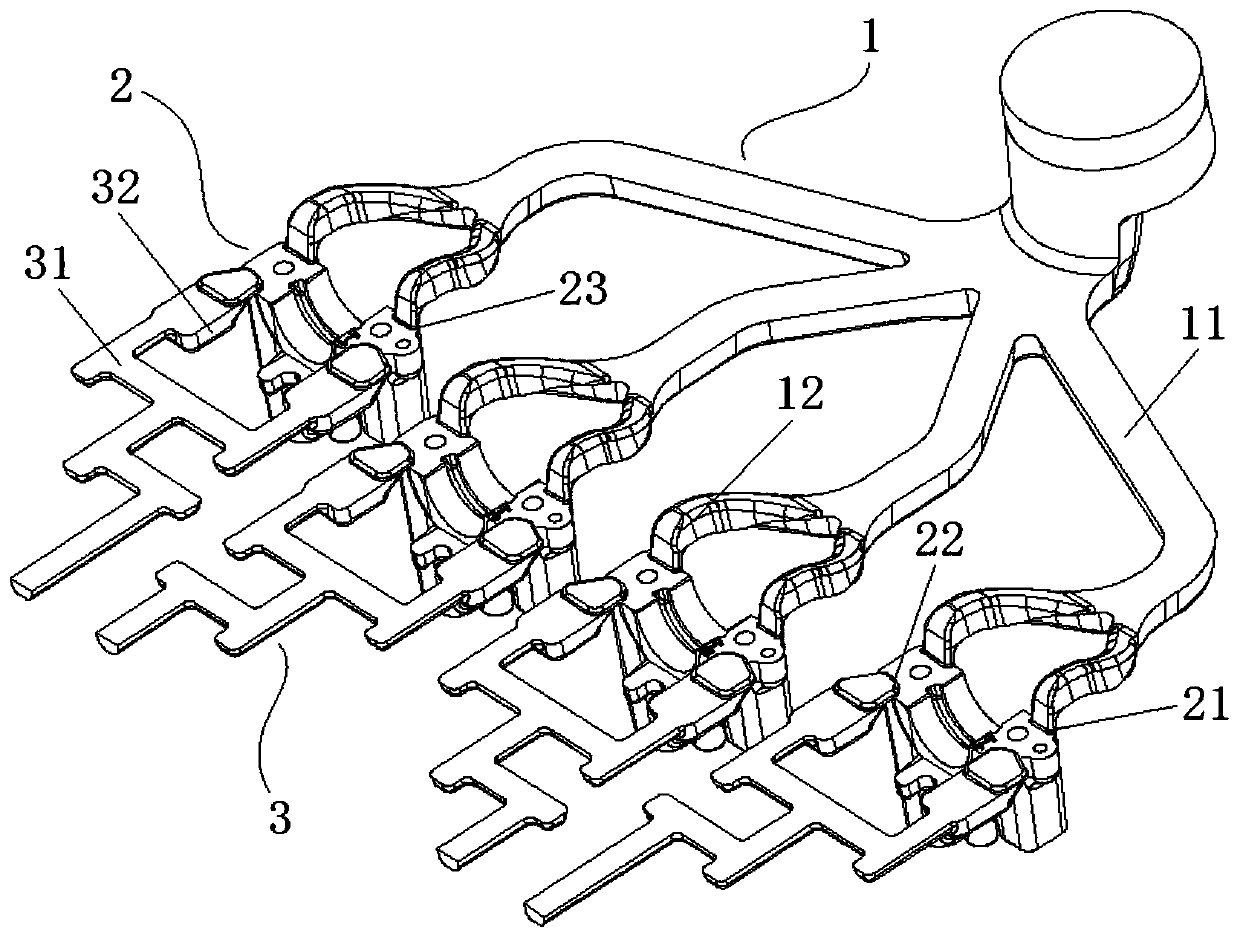

Method for producing fire-fighting sprinkler head frame through semi-solid forming of brasses

The invention discloses a method for producing a fire-fighting sprinkler head frame through the semi-solid forming of brasses. The method comprises the following steps: (1) selecting a brass raw material; (2) adding the raw material into a smelting furnace to heat, so that liquid slurry is obtained; (3) carrying out heat-retaining storage on the obtained liquid slurry, and controlling part of the slurry to convey; (4) after the slurry is conveyed to a casting preparation chamber, carrying out semi-solid temperature control on the slurry and controlling the one-time casting amount of the slurry; (5) carrying out stress relieving treatment, and carrying out casting forming on semi-solid brasses in a mold for producing fire-fighting sprinkler head frames; (6) cooling a formed part; and (7) carrying out finish machining on the formed part so as to obtain a finished product. Compared with traditional methods, no secondary heating for melting is required to be performed in the method, therefore, the method is energy-saving and environment-friendly; and according to the invention, parts are formed more rapidly, continuous casting is performed at higher speed, lower energy consumption is produced, the service life of the mold is long, the gas entrapment can be reduced in the process of production, castings have less cavities, and the strength is higher, therefore, the method is of great significance to the production of fire-fighting sprinkler head frames.

Owner:JINGGANGSHAN YUJIE FIRE SCI & TECH

Node deployment method and device for OpenStack

ActiveCN109039784ARealize automatic configuration and installationImprove deployment efficiencyData switching networksNode deploymentNetwork service

The invention relates to a node deployment method for an OpenStack, comprising the following steps: obtaining type information of a node currently installed by the OpenStack; Acquiring network information of the node according to the type information; Generating a first type configuration file corresponding to the node according to the type information and the network information; According to thefirst type configuration file and the installation function of the node, installing the network service installation package corresponding to the node, and generating and starting the corresponding network plug-in. After obtaining the type information of the currently installed node, obtaining the network information of the node correspondingly. Thus automatically completing the generation of configuration files, the installation of network services where the node is located, and ultimately generating and starting the corresponding network plug-in, the automatic configuration of the node installation can be achieved. The node deployment process has the advantages of low user involvement and easy operation, which effectively improves the deployment efficiency of each node.

Owner:COMBA TELECOM SYST CHINA LTD

Substrate processing apparatus and method

ActiveCN100508159CPrevent reattachmentReduce involvementSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringMechanical engineering

A substrate processing apparatus and a substrate processing method capable of effectively preventing re-adhesion of the processing liquid to the surface of the substrate in the substrate processing apparatus for performing predetermined processing on the substrate while supplying the processing liquid to the substrate while rotating the substrate. In the vicinity of the peripheral portion of the rotary base (5), a plurality of supporting portions (7) are protruded upward from the rotary base (5) and support the substrate (W) while contacting the peripheral portion of the lower surface of the substrate (W). The substrate (W) is horizontally supported in a state separated by a predetermined distance from a rotating base (5) facing the lower surface of the substrate (W) by a plurality of support parts (7). Inert gas is ejected from a plurality of gas ejection ports (9b) provided on the facing surface (9a) of the environment blocking plate (9) into a space formed between the upper surface of the substrate (W) and the facing surface (9a). Thereby, the substrate is pressed against the support portion (7) by the inert gas supplied to the upper surface side of the substrate and held by the rotary base (5).

Owner:DAINIPPON SCREEN MTG CO LTD

Application switching method and system of intelligent terminal

InactiveCN105677190AReduce involvementEasy to operateInput/output processes for data processingProcessor registerMultiple applications

The invention relates to an application switching method and system of an intelligent terminal. The method includes the steps that when a return key of the intelligent terminal is continuously triggered, the continuous triggering time is detected; a background application corresponding to the continuous triggering time is searched for in an application list according to the continuous triggering time, wherein the application list records multiple applications which are opened recently and switched to a background to operate; an address of the background application is read from a register of the intelligent terminal, and the intelligent terminal is switched into the background application to operate according to the address. According to the technical scheme, the use habits of a user are fully considered, the user can achieve the switching function on the return key, operation is simplified, keys related in the switching process are reduced, mistakes are avoided, the background application is selected through the continuous triggering time, multiple-tapping operation is not needed, and operation efficiency is high.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Product and method for carrying out magnesium or magnesium-calcium treatment on molten steel

The invention discloses a product and a method for carrying out magnesium or magnesium-calcium treatment on molten steel, and belongs to the technical field of metallurgy. The product for carrying out the magnesium or magnesium-calcium treatment on the molten steel is composed of a sealed shell and an alloying material packaged in the shell, the alloying material comprises magnesium oxide, a composite reducing agent and a stable diluent, wherein the composite reducing agent is used for reducing magnesium in the magnesium oxide, and the stable diluent is used to provide a substance that forms a miscible alloy melt with magnesium. According to the technical method of the invention, the product is inserted into the deep position of molten steel, a reduction reaction of magnesium oxide is excited through the energy of the molten steel, magnesium metal is stabilized, diluted and dispersed by forming the magnesium alloy miscible melt through gradual reduction, rapid evaporation of magnesium in the magnesium modification treatment process of inclusions in steel can be effectively inhibited, the gasification and oxidation loss of magnesium is reduced, the yield of the magnesium element in the steel is improved and stabilized, and the purity of the molten steel after magnesium treatment is guaranteed.

Owner:MAANSHAN XINGDA METALLURGICAL NEW MATERIAL +1

Preparation method and device of semi-solid slurry

The invention relates to a preparation method and device of semi-solid slurry and belongs to the technical field of semi-solid formation. The preparation method comprises the steps that molten metal melt is poured into a crucible container and cooled in the crucible container to the temperature between the liquid phase line temperature and the solid phase line temperature; inert gas shielding or vacuum shielding is performed on the melt in the cooling process of the metal melt, the metal melt in the crucible is subjected to weak disturbance treatment under the outfield effect, the liquid surface of the melt in the crucible is kept to be static or the melt keeps a weak laminar motion in the horizontal direction during disturbance treatment, surface layer oxide or gas is prevented from beinginvolved in, the outfield effect is stopped when the melt is cooled to be within the semi-solid temperature interval, and the semi-solid slurry in the crucible is poured into a pressure forming apparatus. The invention further discloses the preparation device adopted in the method. The semi-solid slurry prepared by the method and the device has the advantages of being high in purity, good in quality and consistency, easy to industrially produce and control, and the like.

Owner:有研科技集团有限公司 +1

Method and apparatus for continuous casting of metals

Provided is a metal continuous casting method in which continuous casting is performed while applying a static magnetic field in the thickness direction of the continuous casting, by intermittently applying the above static magnetic field, it is possible to obtain substantially no auxiliary Continuous casting slab with flux entrainment and surface segregation.

Owner:JFE STEEL CORP

Degradable antibacterial magnesium alloy and preparation method thereof

ActiveCN110373588AEnhance biological antibacterial effectImprove antibacterial propertiesTissue regenerationProsthesisOsteoblastDie casting

The invention provides a degradable antibacterial magnesium alloy and a preparation method of the degradable antibacterial magnesium alloy, and relates to the field of metal biomedical materials. Thedegradable antibacterial magnesium alloy comprises main active elements of Ag, Cu, Zn and Sr, and by means of composition optimization design of the magnesium alloy, the components comprise, by mass,1.35-1.65% of Ag, 0.9-1.1% of Cu, 3.6-4.4% of Zn, 0.9-1.1% of Sr, 0.36-0.44% of Ca and the balance Mg and other inevitable impurities. After the magnesium alloy material implant finishes the action, the magnesium alloy material implant can be completely degraded to avoid secondary operation removal, the medical cost and the pain of patients are reduced, the antibacterial property of the implant isimproved, and the magnesium alloy material implant has the functions of promoting osteoblast formation and inhibiting osteoclast bone absorption; the degradable antibacterial magnesium alloy adopts asemi-solid rheological die casting process, the microstructure of the product is uniformly distributed, the internal structure is compact, the defects of pores, segregation and the like are few, andthe requirements for high quality and high precision of implant products can be met.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com