Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Reduce follow-up processing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

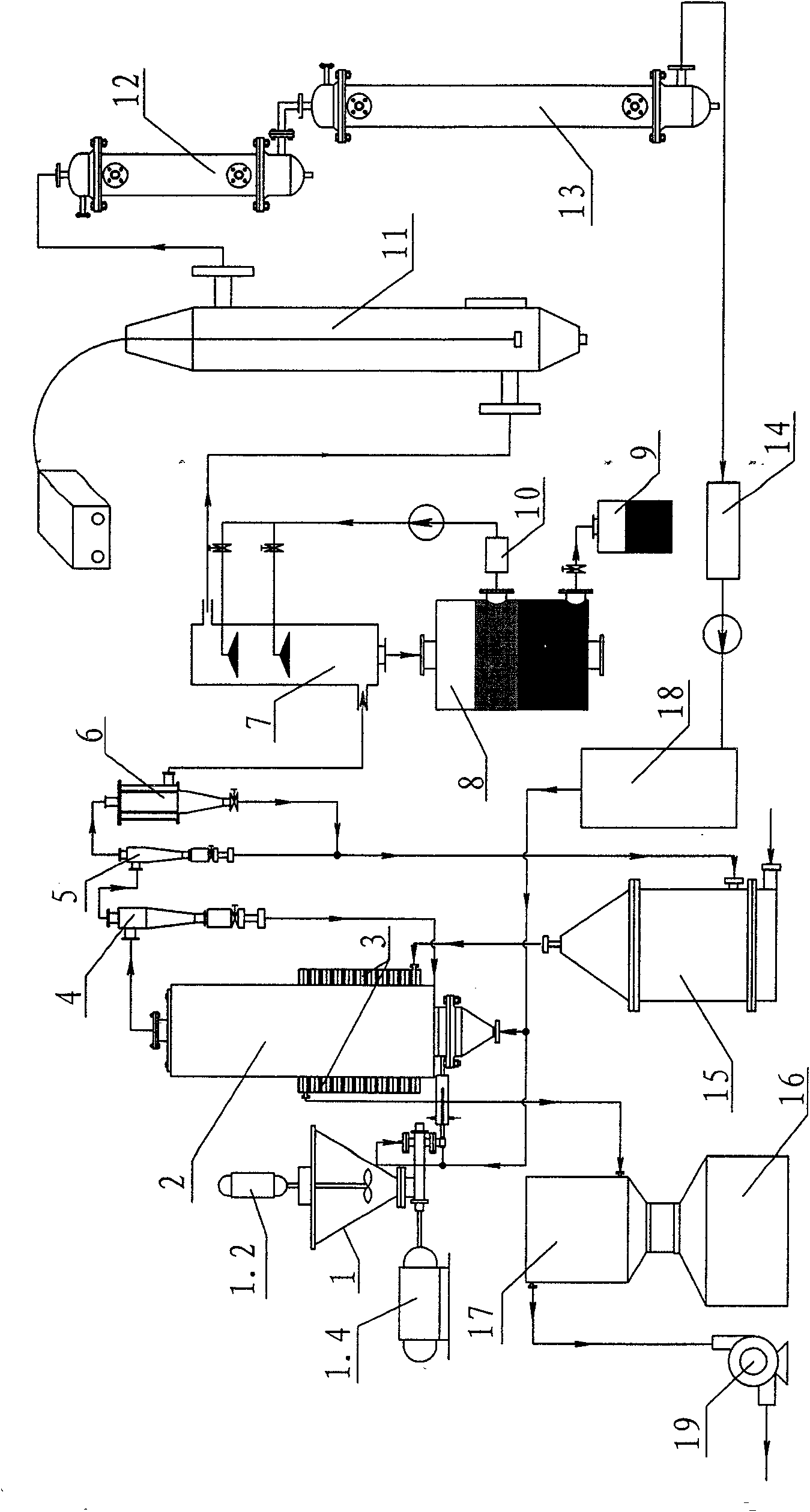

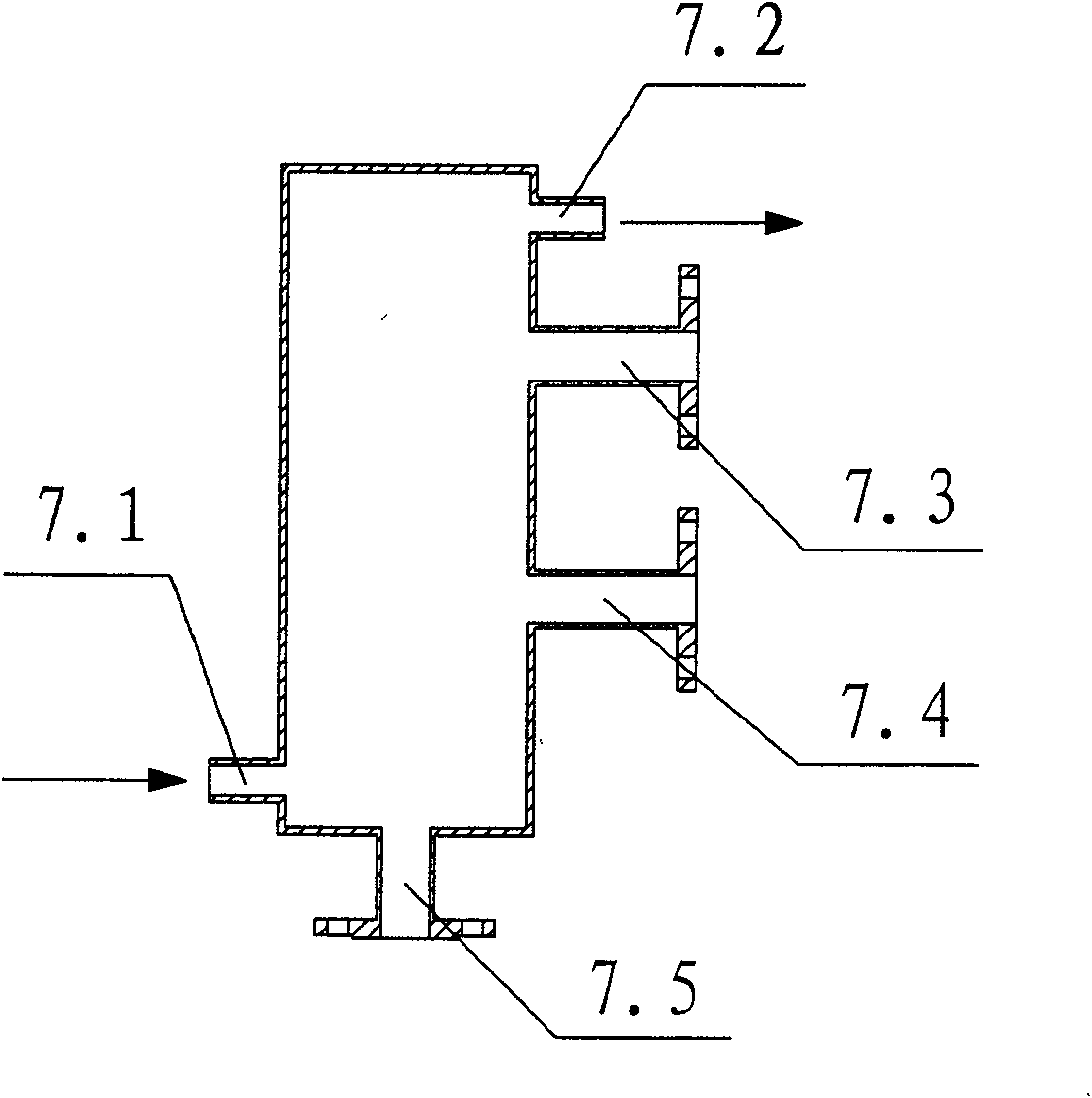

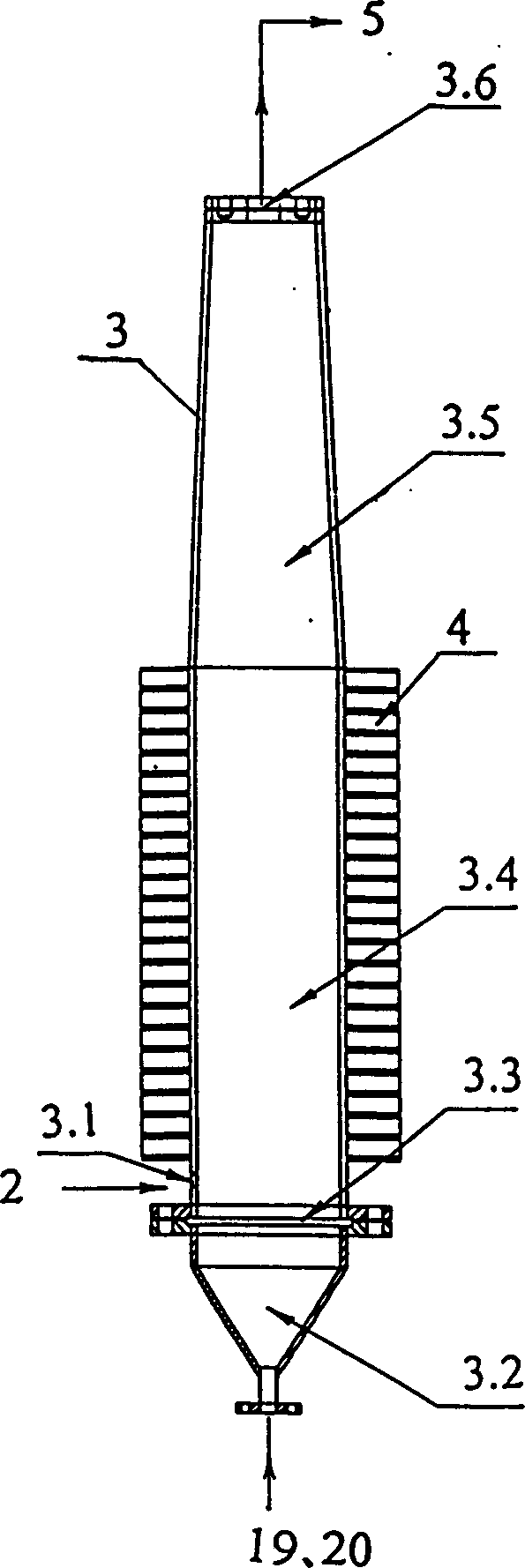

Method for preparing liquid fuels by self-heating self-circulating thermal cracking of biomass and device thereof

InactiveCN101560405ARealize self-heatingAvoid secondary reactionsLiquid hydrocarbon mixture productionCycloneElectricity

The invention relates to a method for preparing liquid fuels by self-heating self-circulating thermal cracking of biomass and a device thereof. Solid substances and carbon can be effectively reclaimed through a two-stage cyclone separator and a carbon filter, most of heavy oil components in thermal cracking volatile components are collected by adopting spray condensing, micro oil drops in the volatile components are further caught by electric catching, light oil components are complementally collected by cooling through a final dividing wall type water cooler, the volatile components are gradually cooled at an inlet of a cooling system at a temperature of 200 DEG C to collect biological oil, and finally, condensable parts in the volatile components are basically collected at an outlet at a temperature of below 30 DEG C. Through quick thermal cracking technology and stepped cooling and collecting processes, cellulose biomass wastes are converted into the liquid fuels of different levels, and simultaneously, volatile gas and coke products in the thermal cracking process are reclaimed and utilized to realize self-heating for a complete thermal cracking system and save cost.

Owner:顾赛 +1

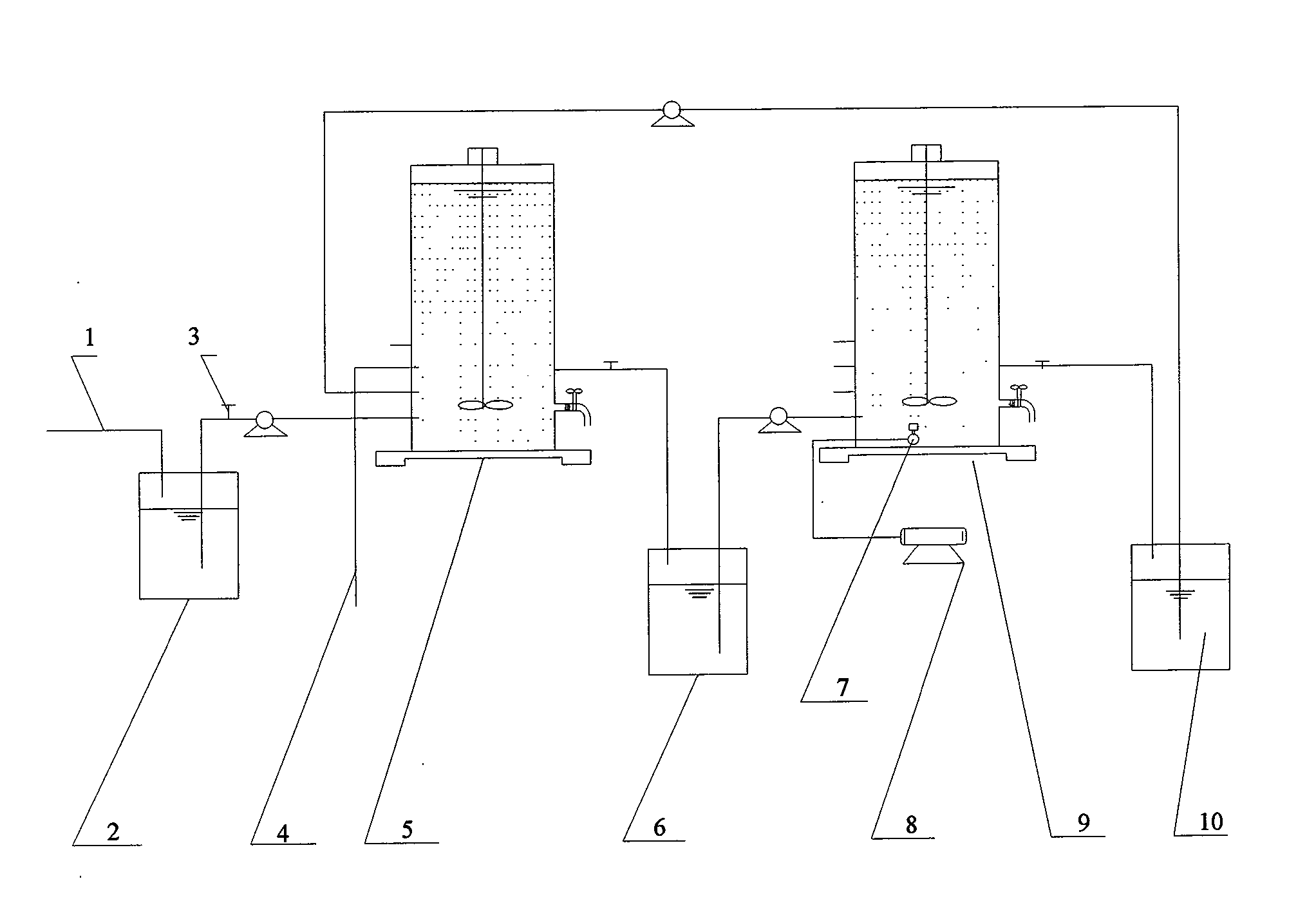

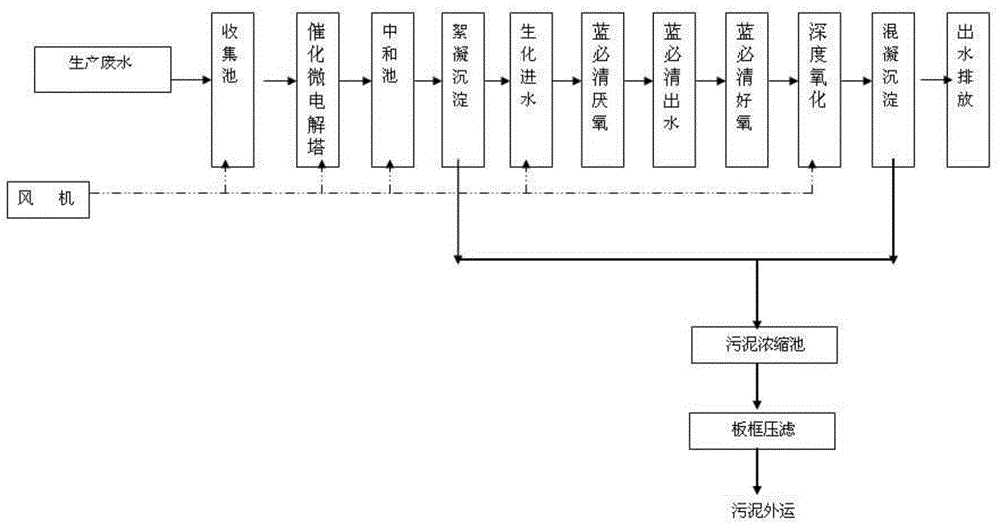

Short distance denitrifying dephosphatation double-sludge technique taking granular sludge as medium and device thereof

ActiveCN101628772ASink fastHigh activityTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesSludgeShortest distance

The invention belongs to the field of sewage treatment and provides a short distance denitrifying dephosphatation double-sludge technique taking granular sludge as medium and a device thereof. The device sequentially comprises a raw water pipe, a water inlet tank and a water inlet valve, and is characterized by further sequentially comprising an anaerobic / anoxic SBR reactor and an intermediate water tank which are connected with each other by a pipeline as well as a short distance nitration SBR reactor and a back flow water tank that are also connected with each other by the pipeline; wherein the intermediate water tank is connected with the short distance nitration SBR reactor, and the back flow water tank is connected with the anaerobic / anoxic SBR reactor; the anaerobic / anoxic SBR reactor and the short distance nitration SBR reactor are internally provided with stirring devices, and a drain pipe is arranged on the anaerobic / anoxic SBR reactor; the short distance nitration SBR reactor is internally provided with an aerating apparatus; the granular sludge which is processed by acclimatization and has the function of denitrifying dephosphatation is put into the anaerobic / anoxic SBR reactor, and the granular sludge which is processed by acclimatization and has the function of short distance nitration is put into the short distance nitration SBR reactor. The invention solves the problems of unstable effect of nitrogen and phosphorus removal of sewage, high content of effluent suspended matter and lower pass rate, so as to be used for low C / N waste water treatment.

Owner:HEILONGJIANG BISHUIYUAN ENVIRONMENTAL PROTECTION ENG CO LTD

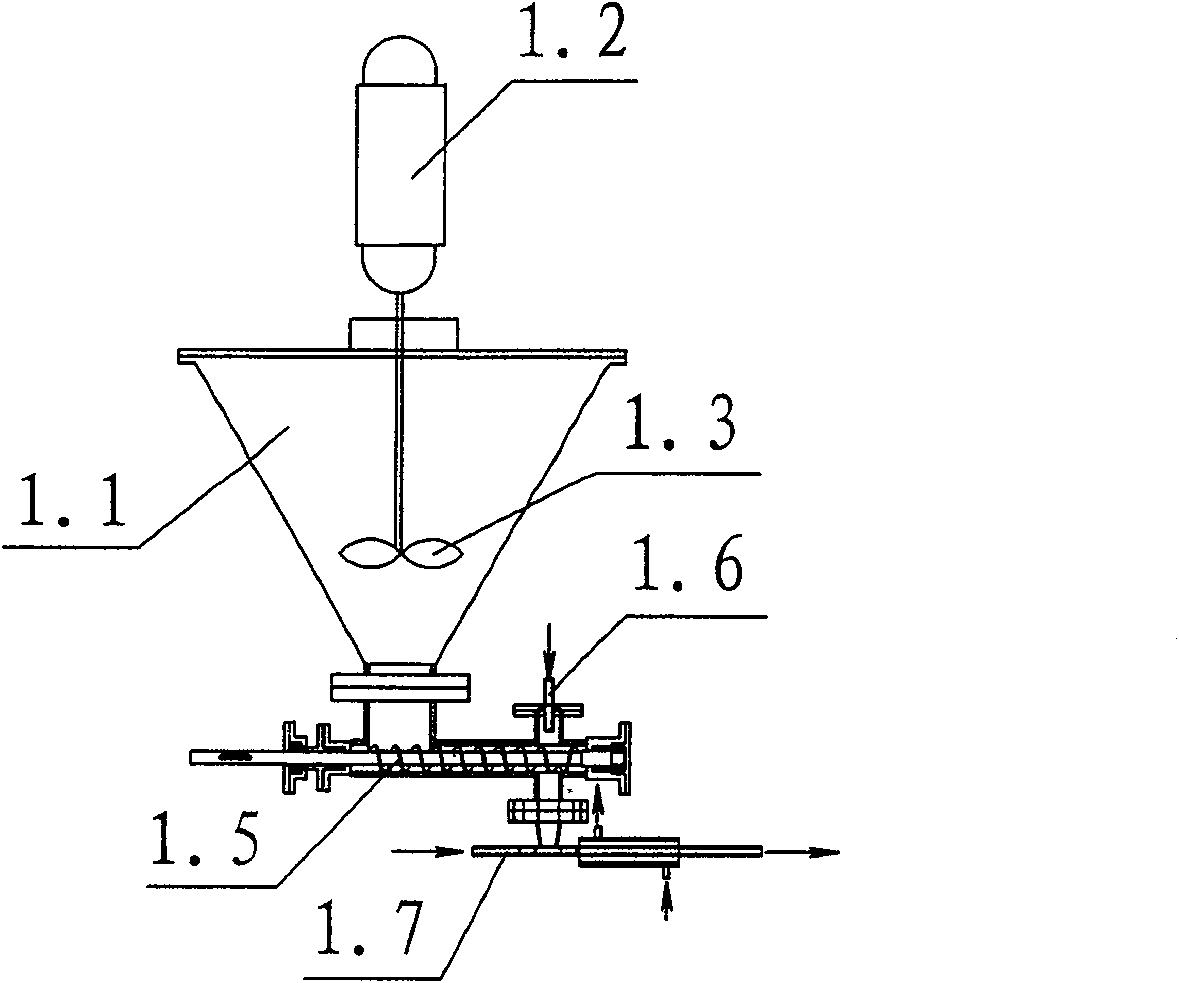

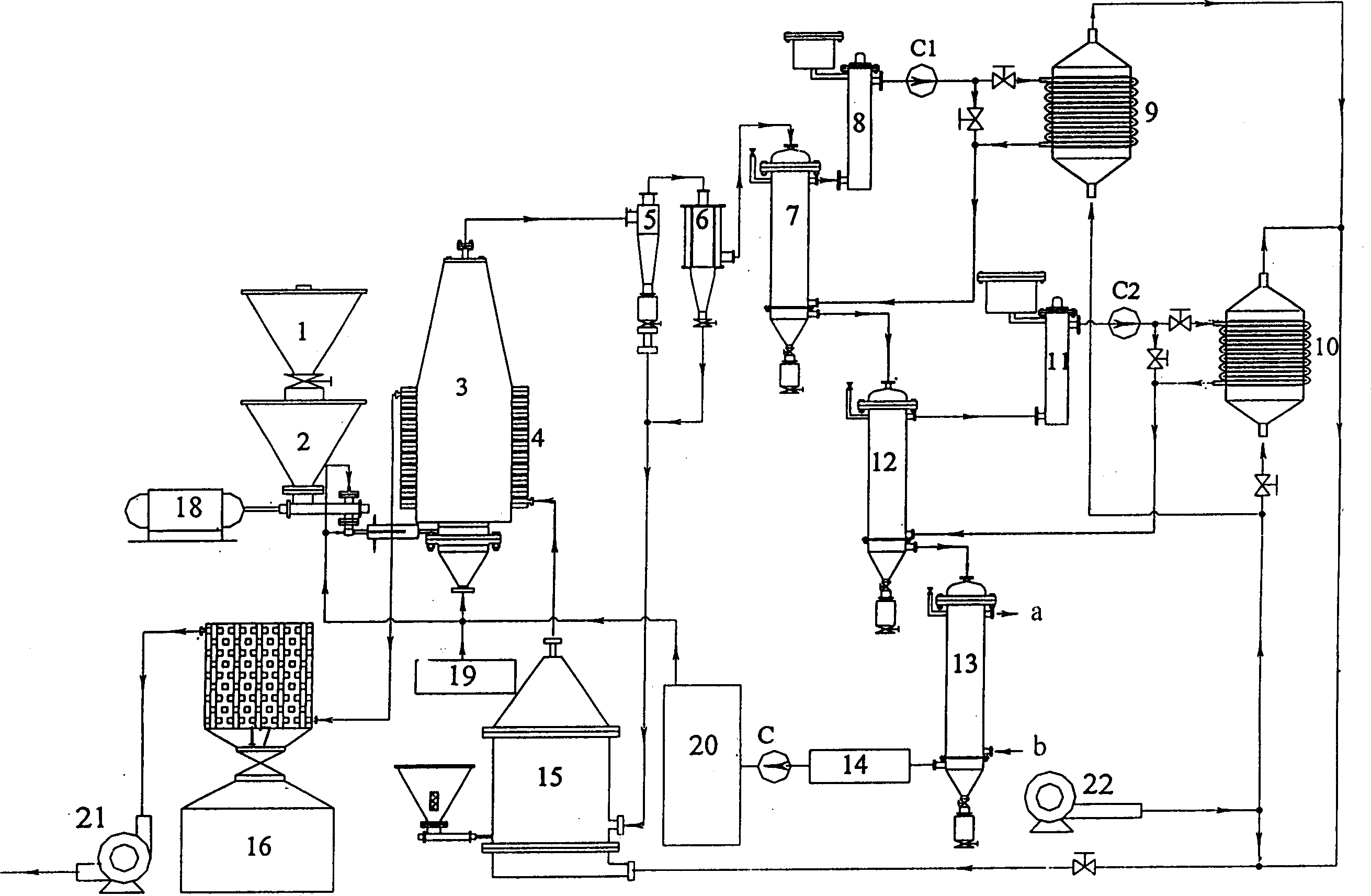

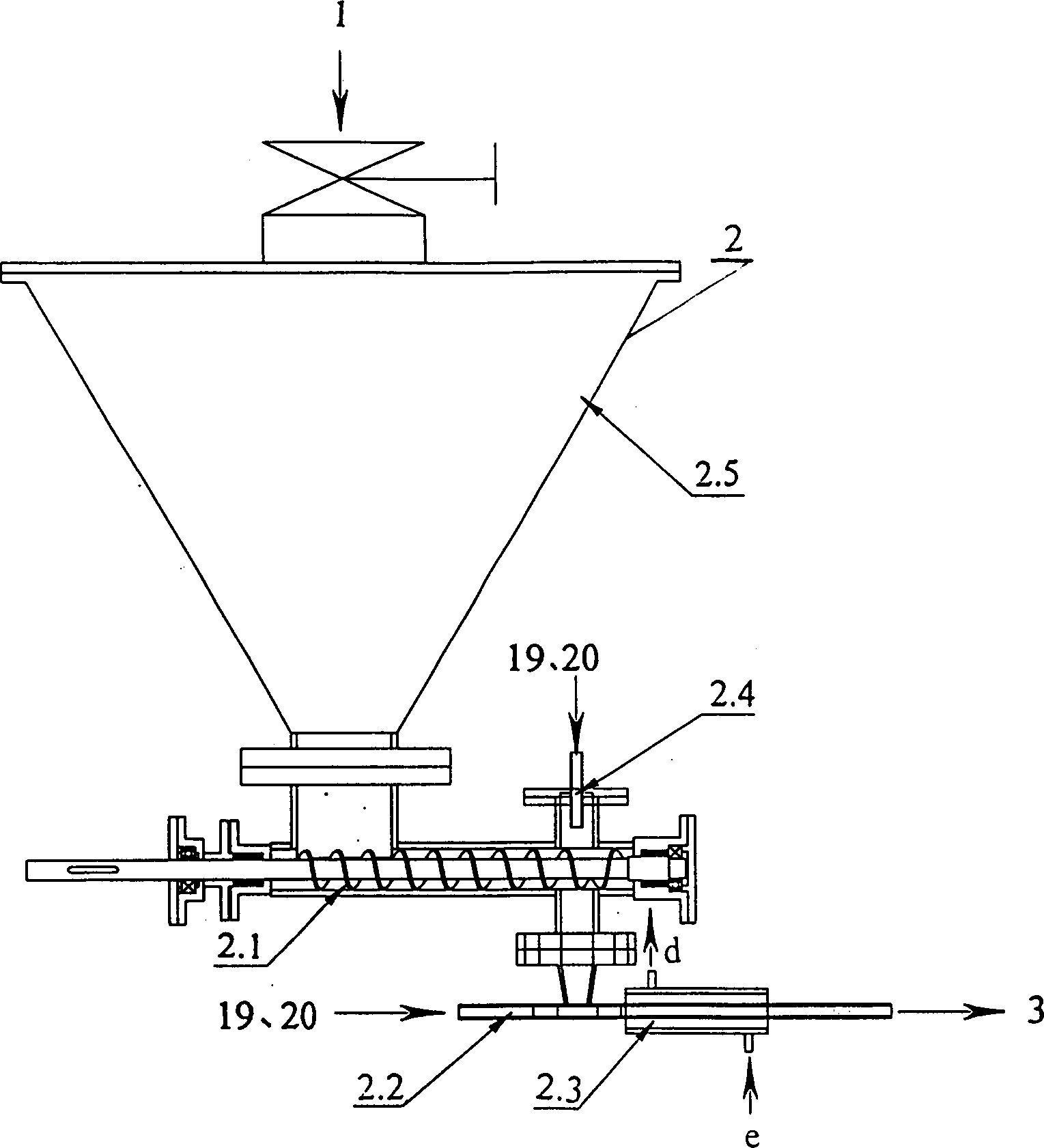

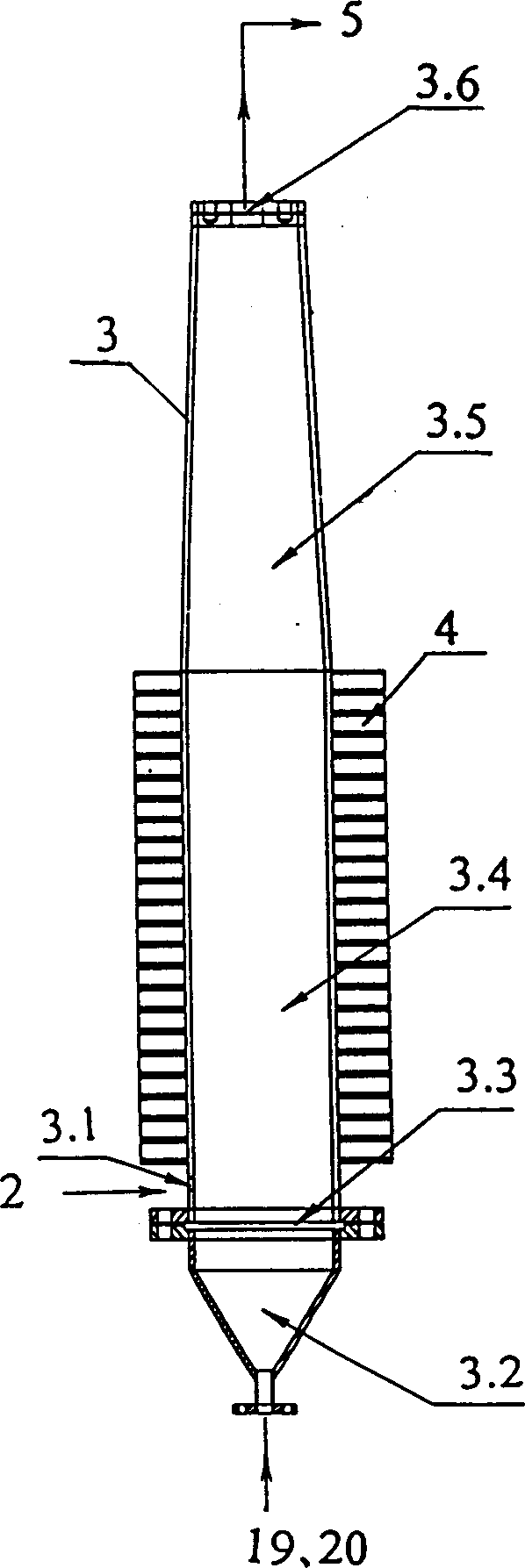

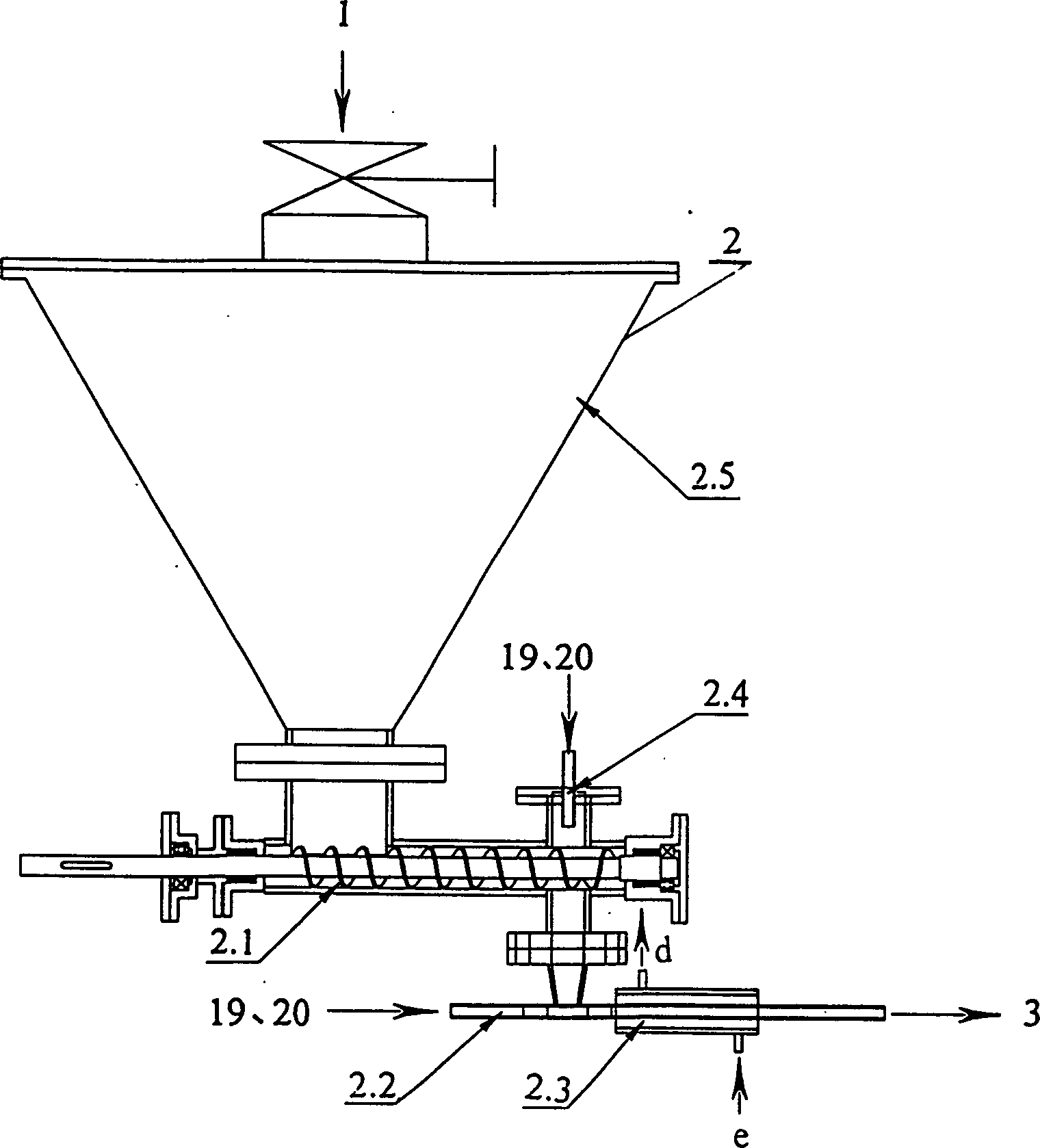

Biomass integrated thermocracking equipment for preparing liquid fuel

InactiveCN1390915ALow costGuaranteed smooth feedingLiquid hydrocarbon mixture productionBiomassProcess engineering

A integrated biomass thermocracking equipment for preparing liquid fuel is composed of cyclone separator, carbon filter, multi-stage condensing system consisting of two air coolers, two heat-transfer oil heaters and three condensers, self-heating system consisting of two air coolers, carbon burner and heat exchanger of reactor, combined feeder, and cross-section variable fluidized-bed reactor. Its advantages are flash temp-rasing of biomass, fast eduction out of volatile components and recovering solid carbon.

Owner:ZHEJIANG UNIV

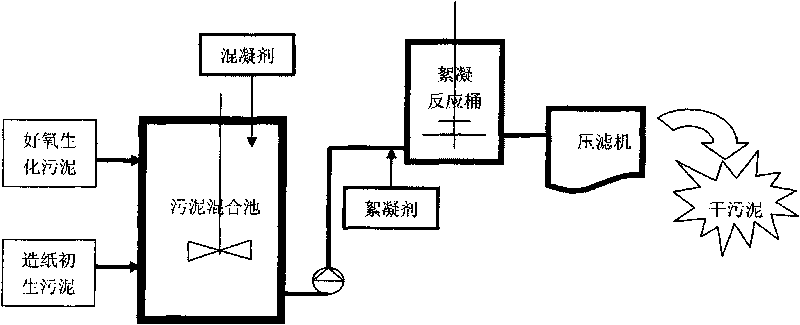

Method for dynamically controlling continuous feeding in dehydration of papermaking sludge

InactiveCN101704629ACause secondary pollutionImprove dehydration propertiesSludge treatment by de-watering/drying/thickeningFlocculationSludge

The invention discloses a method for dynamically controlling continuous feeding in the dehydration of papermaking sludge, which comprises the following process steps: 1) mixing and stirring concentrated aerobic biological sludge and the papermaking sludge to form mixed sludge; 2) adding an inorganic polymer coagulant into the uniformly-stirred mixed sludge continuously and stirring for performing a reaction; 3) conveying the reacted mixed sludge to a secondary flocculation reaction barrel by utilizing a sludge screw pump, adding the organic polymer coagulant into the mixed sludge continuously, and simultaneously, stirring to perform a flocculation reaction; and 4) performing filter-pressing and dehydration on the mixed sludge after the flocculation reaction in a filter press. The method has high dehydration efficiency, stable dehydration performance, simple process, no secondary pollution, no need of special drying equipment, economy conservation and low cost.

Owner:DONGGUAN NINE DRAGONS PAPER IND

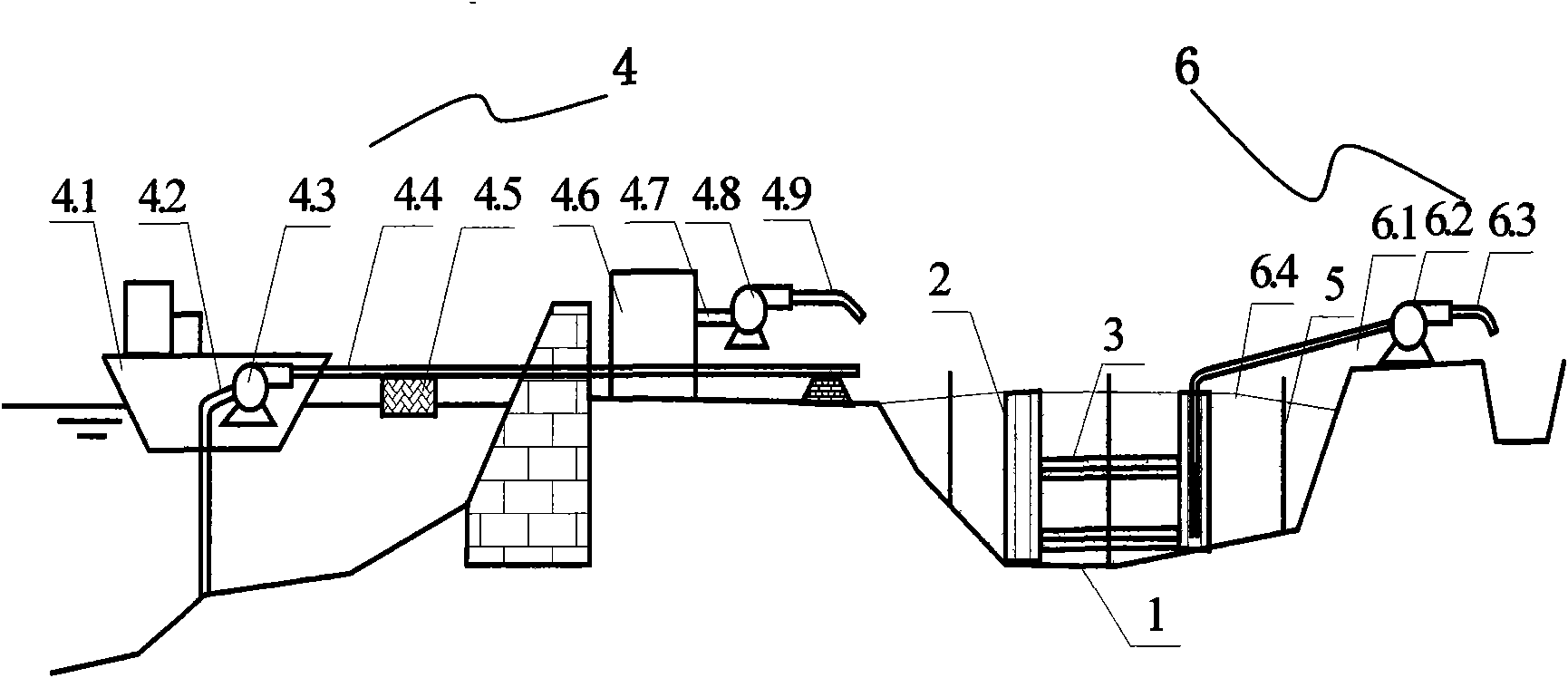

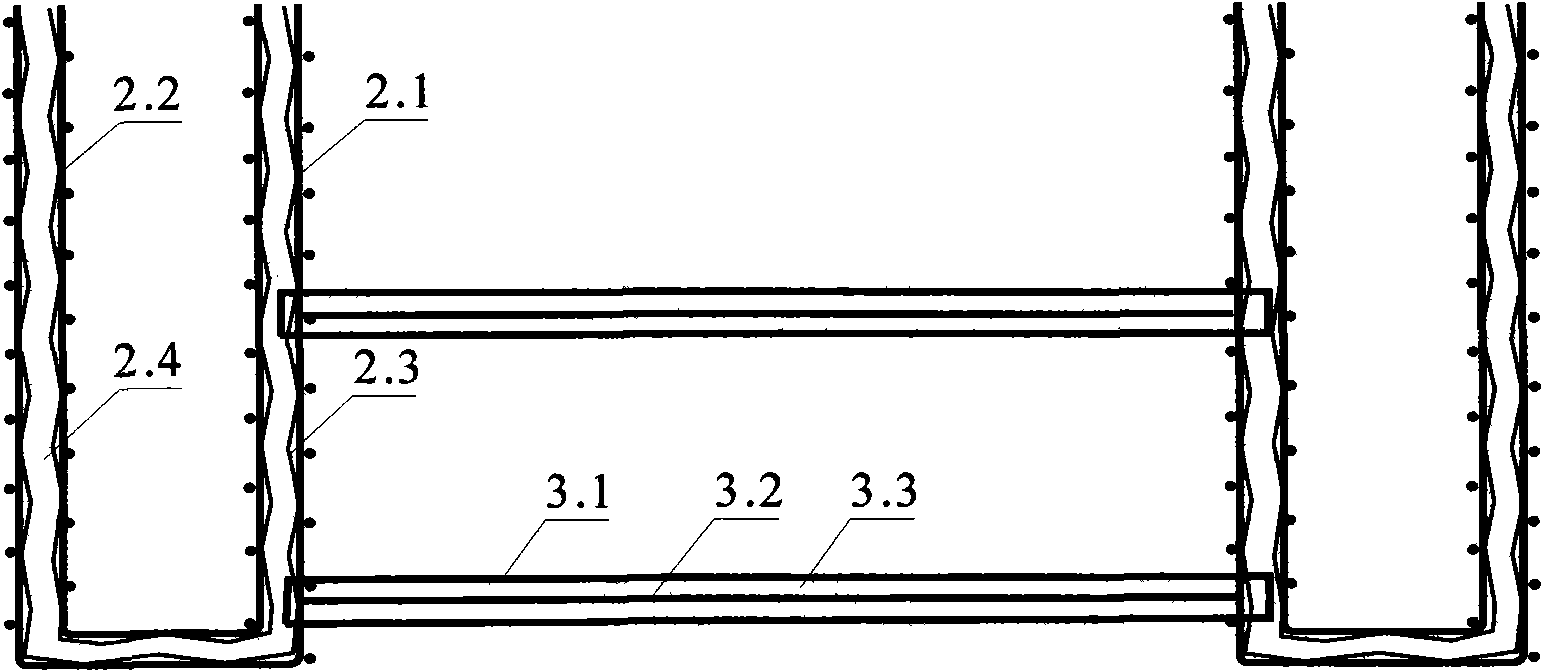

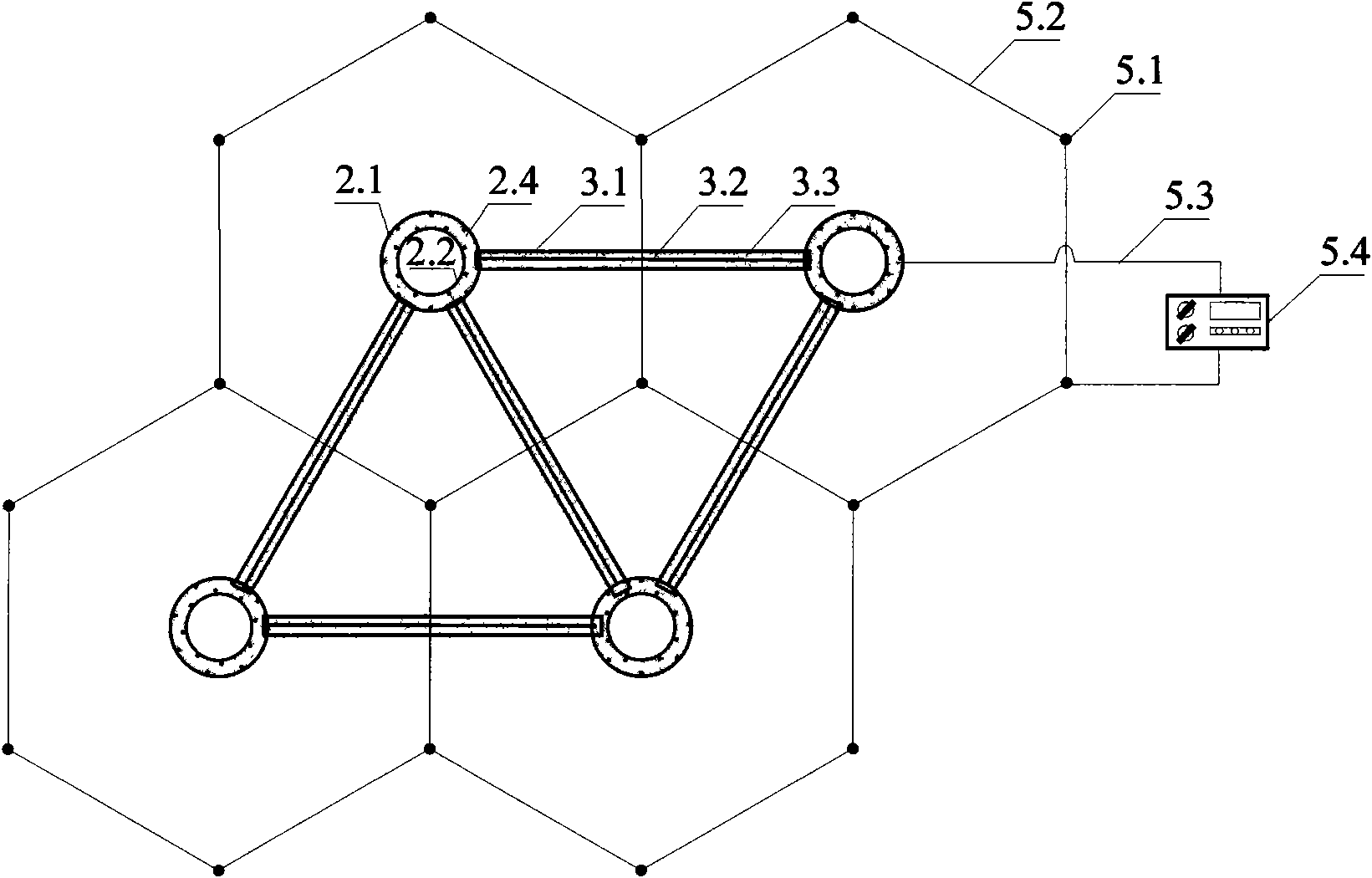

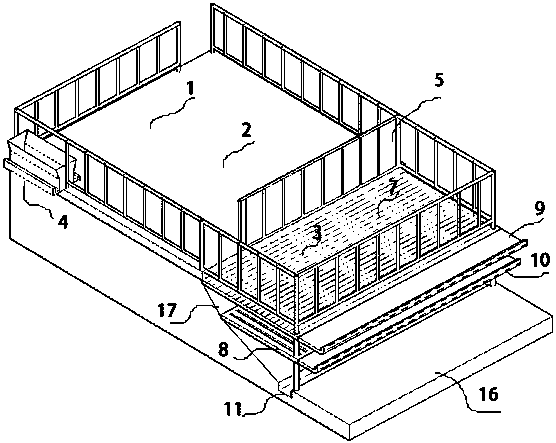

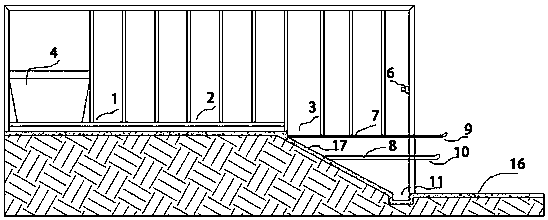

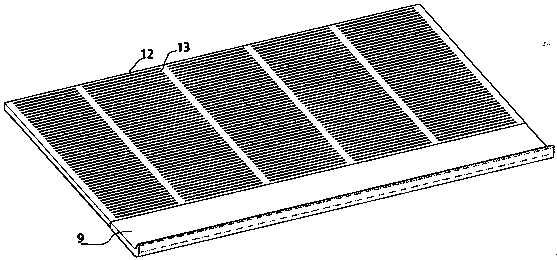

Method and device for pre-consolidating mixed hydraulically-filled soft soil foundation

InactiveCN101555689AAccelerate the rate of consolidationReduce processingSoil preservationDouble tubeCombined method

The invention discloses a method for pre-consolidating mixed hydraulically-filled soft soil foundation and a device thereof, relating to the field of pre-consolidation treatment technology of soft soil foundation. The method arranges a horizontal drainage passage in the mixed hydraulically-filled process, adopts a vacuum preloading and electroosmosis combined method for construction, carries out early intervention and consolidation of the ultra-soft soil actively during the hydraulically-filled process and the initial stage of the hydraulically-filled process, and creates a prophase condition for the subsequent foundation consolidation. The device arranges reinforcement cage sand bad collecting wells at the construction site and arranges a horizontally-communicated drainage sand bag between the reinforcement cage sand bag collecting wells; and a dual-pipe mixed hydraulically-filled equipment, the reinforcement cage sand bag collecting wells, a treatment equipment by the vacuum preloading and electroosmosis combined method and a collecting well pumping equipment are sequentially connected from left to right. The method and the device can cause the saturated soft soil to generate early consolidation and pre-settlement, leads the pre-treated foundation soil to meet the load metamorphism requirement better in the engineering usage stage and can greatly save engineering period and subsequent engineering treatment expense.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

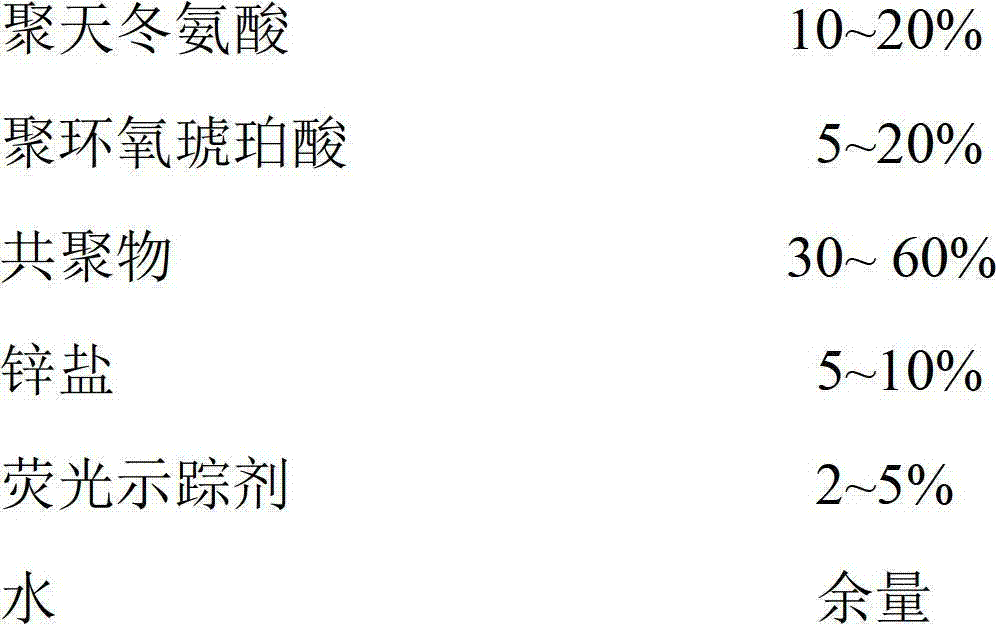

Biodegradable non-phosphorous anti-scale corrosion inhibitor and preparation method thereof

InactiveCN102774969AEasily biodegradableNo environmental problemsScale removal and water softeningPhosphorous acidBalance water

The invention discloses a biodegradable non-phosphorous anti-scale corrosion inhibitor and a preparation method thereof. The biodegradable non-phosphorous anti-scale corrosion inhibitor comprises, by mass, 10-20% of polyaspartic acid, 5-20% of polyepoxysuccinic acid, 30-60% of copolymers, 5-10% of zinc salt, 2-5% of fluorescent tracers and the balance water, wherein the molecular weight of the copolymers ranges from 2000-10000, and the copolymers are maleic anhydride / acrylic acid / acrylic acid oxylactone / 2-acrylamide-2-methylpro panesulfonic acid quaternary copolymers. The non-phosphorous anti-scale corrosion inhibitor is used for stainless steel condenser circulating cooling water systems of thermal power plants, is non-phosphorous, non-toxic, easily biodegradable, free from environmental problems and unlimited in discharge, and is capable of controlling carbon steel corrosion rate to be smaller than or equal to 0.075mm / a, controlling corrosion rate of copper, copper alloy and stainless steel to be smaller than or equal to 0.005mm / a, controlling dirt deposition rate to be smaller than or equal to 15mcm and controlling scale inhibition rate to be larger than or equal to 80%.

Owner:ZHEJIANG ZHENENG TECHN RES INST +1

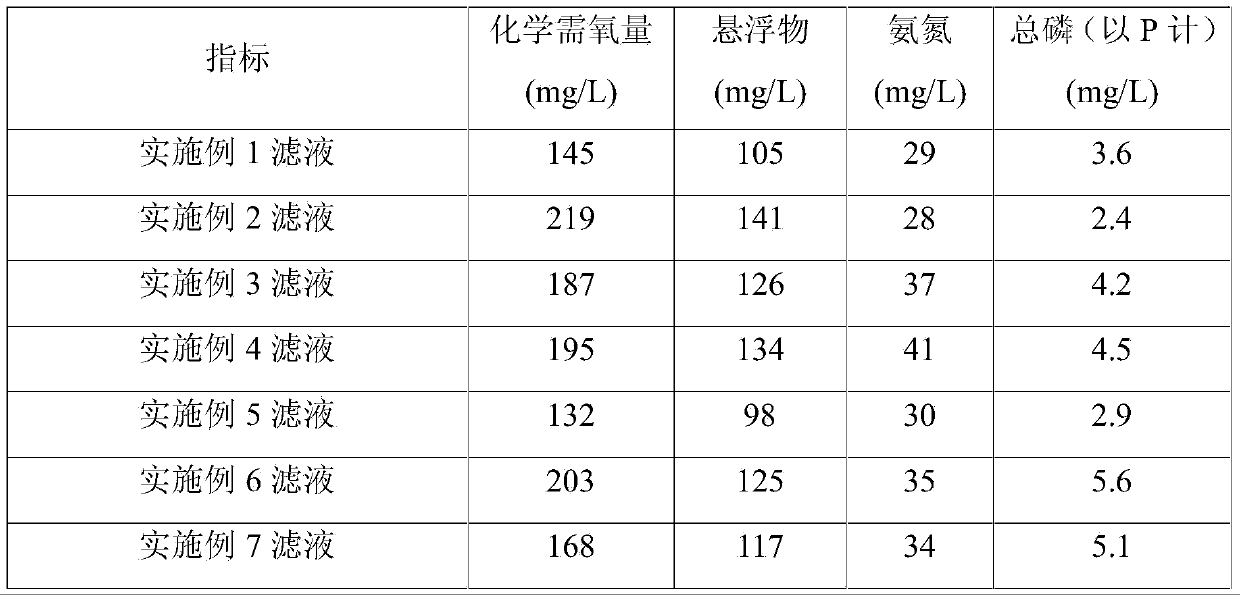

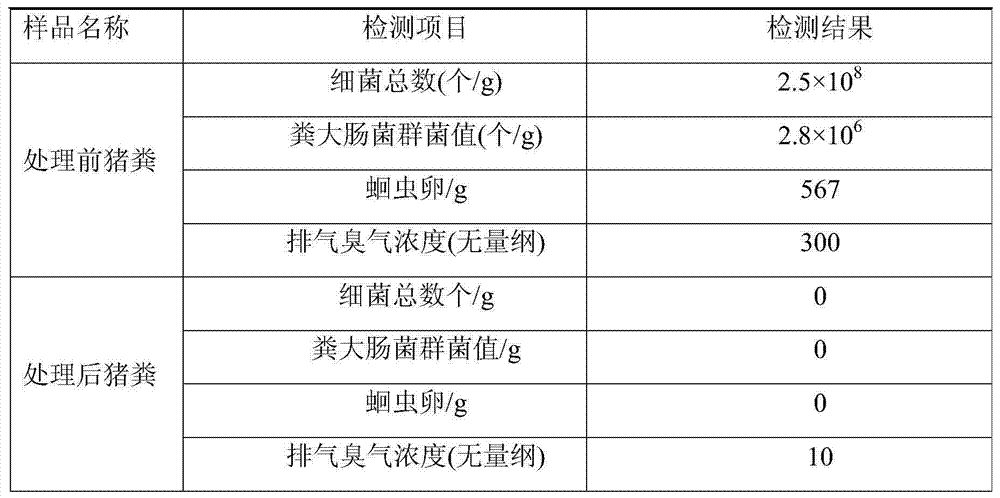

Deep dehydration recycling method for livestock and poultry feces

ActiveCN103723906AWide range of processingHigh degree of dehydrationSludge treatment by de-watering/drying/thickeningAnimal fecesFilter press

The invention relates to the field of livestock and poultry feces treatment methods, and in particular relates to a deep dehydration recycling method for livestock and poultry feces. The method specifically comprises the following steps: adjusting the pH value of the livestock and poultry feces to be 2-4, adding ferrite or ferric salt into the livestock and poultry feces with the adjusted pH value, uniformly stirring, subsequently adding hydrogen peroxide into the livestock and poultry feces, stirring for 50-180 minutes, adding a phosphorus curing agent into the treated livestock and poultry feces, adjusting the pH value to be 8.5-10.5, uniformly stirring, and performing filter pressing on the treated livestock and poultry feces by a filer press for dehydration. The method is high in speed, short in period, high in solid recycling rate, high in dehydration degree, low in energy consumption and low in cost.

Owner:HUNAN UNIV

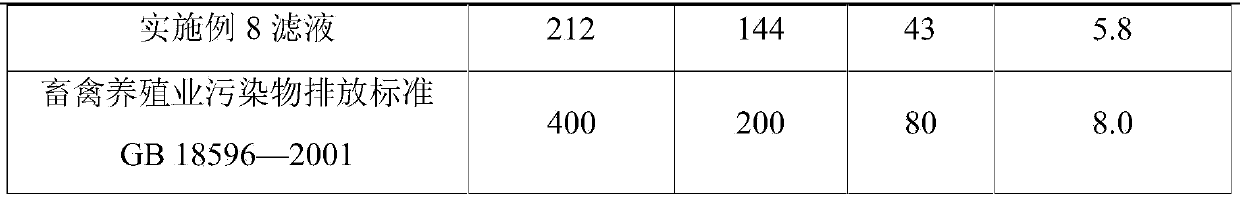

Method for efficiently fully leaching zinc from dust caused by making steel from waste galvanized plates

InactiveCN103911518AIncrease contentReduce contentProcess efficiency improvementPregnant leach solutionSlag

A method for efficiently fully leaching zinc from dust caused by making steel from waste galvanized plates comprises the following steps: (1) performing normal-temperature neutral leaching on zinc oxide dust to obtain a neutral leaching liquid and a neutral leaching slag; (2) performing high-temperature concentrated-acid leaching on zinc ferrite dust to obtain a high-temperature concentrated-acid leaching liquid and a high-temperature concentrated-acid leaching slag; (3) employing the high-temperature concentrated-acid leaching liquid as a leaching reagent to perform normal-temperature acidic leaching on the neutral leaching slag; and (4) employing the normal-temperature acidic leaching liquid as a leaching reagent to performing normal-temperature neutral leaching to obtain a neutral leaching liquid which is a finished product liquid. The method is easy to perform and easy for commissioning; and after the technology is modified, spent acid is fully utilized when the zinc source is effectively recovered, and also the iron ion content in the leaching liquid is reduced, so that the subsequent iron-removing processing cost is greatly saved.

Owner:有研资源环境技术研究院(北京)有限公司

Coagulation-oxidation combined type method for processing sewage

ActiveCN102206011ASmall footprintEasy to operate and manageMultistage water/sewage treatmentWater/sewage treatment by oxidationAutomatic controlNeutral ph

The invention relates to a coagulation-oxidation combined type method for processing sewage. According to the method, a reaction tank with an automatic control system is adopted, and a coagulation process and a Fenton oxidation process are successively carried out in the reaction tank. The method provided by the invention comprises the following steps of: carrying out the Fenton oxidation process, adjusting the pH value to a neutral pH, allowing sewage to stay, followed by separation, taking the obtained solid precipitate as a coagulant, treating the sewage in the reaction tank by the coagulation process, followed by staying and separation, allowing settled sludge to flow out through a mud collecting bucket on the lower portion of the reaction tank and enter a subsequent sludge processing system; and adding a Fenton reagent into the reaction tank to carry out the oxidation treatment, adjusting the pH value to a neutral pH, followed by staying and separation again, discharging a supernatant as the effluent, reusing the produced neutral solid precipitate as the coagulant of the next coagulation process. The method provided by the invention is suitable for the advanced treatment of sewage as well as the treatment of refractory organic sewage to reach the standard, and has advantages of simple equipment, small installation space, and convenient operation and management; in addition, the coagulation-settlement process and the Fenton oxidation reaction are finished in a reaction tank, and the whole treatment process is automatically controlled.

Owner:PETROCHINA CO LTD

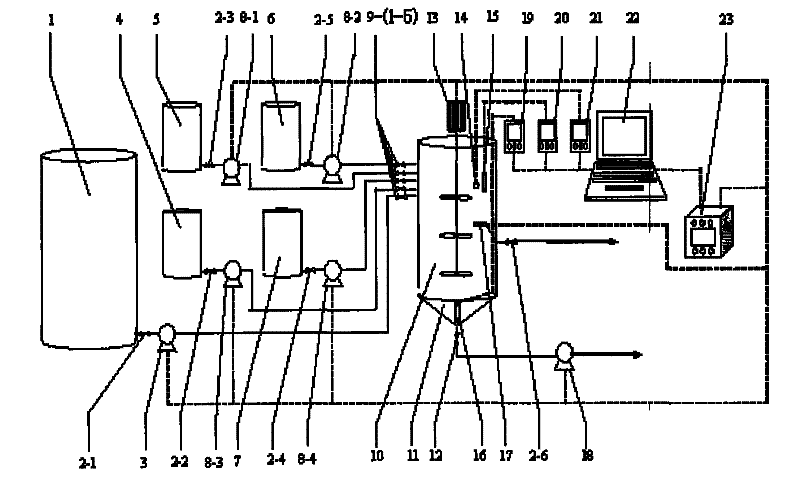

Method for treating wastewater during production of gallic acid

ActiveCN104086049ALow running costReduce lossTreatment using aerobic processesTreatment with anaerobic digestion processesGallic acid esterEmission standard

The invention discloses a method for treating wastewater during production of gallic acid so as to reach national-level emission standard. The method comprises the following steps: (1) treating wastewater during production of gallic acid through a catalytic microelectrolysis tower device and a flocculent settling technology; (2) treating flocculent-settled effluent water through (acclimated) anaerobic organism technology filled with efficient composite strain; (3) conducting aerobic microorganism technology treatment to the effluent water subjected to anaerobic treatment; and (4) conducting deep oxidization and flocculent settling to the effluent water subjected to aerobic technology and then emitting the effluent water reaching the national-level emission standard. The method solves the difficulty of wastewater treatment during the production of gallic acid, and is small in investment, low in running cost and good in treatment effect.

Owner:先微康新材料科技有限公司

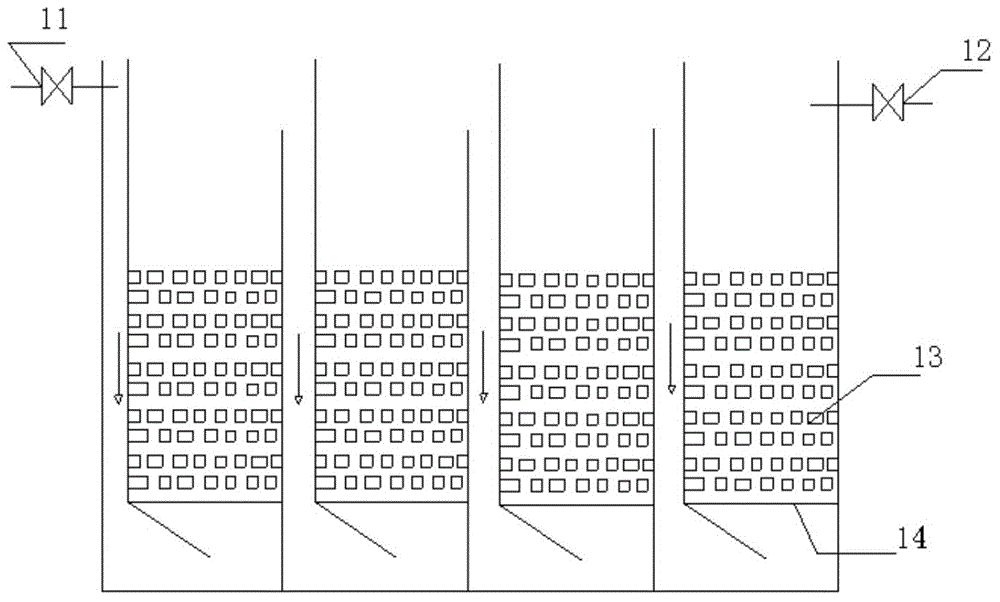

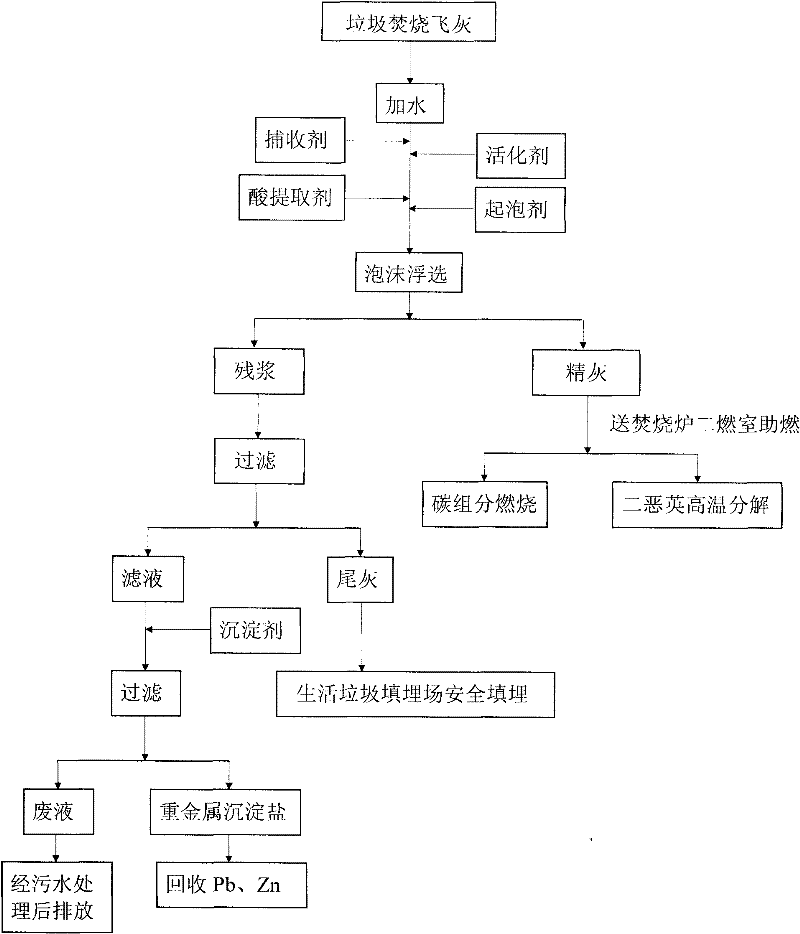

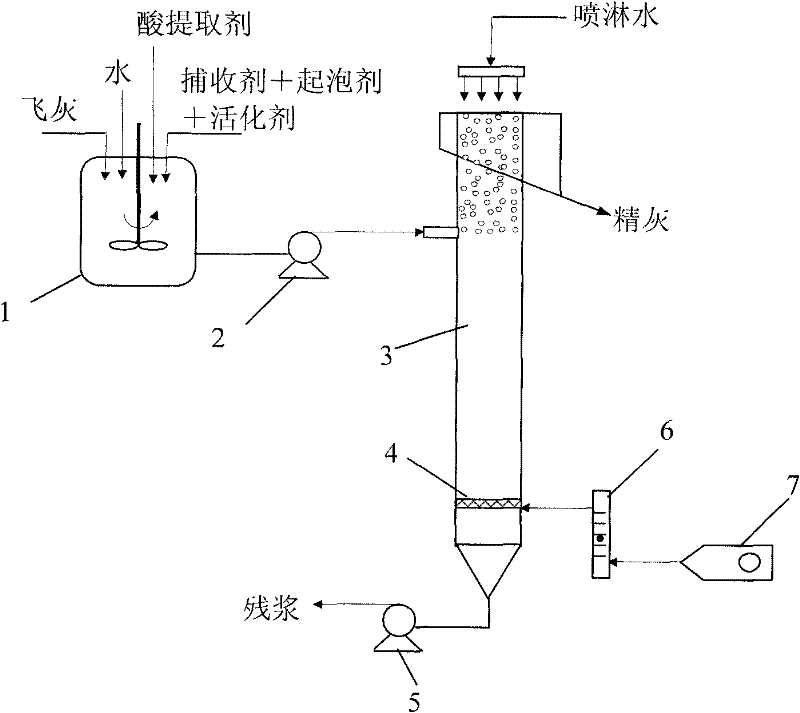

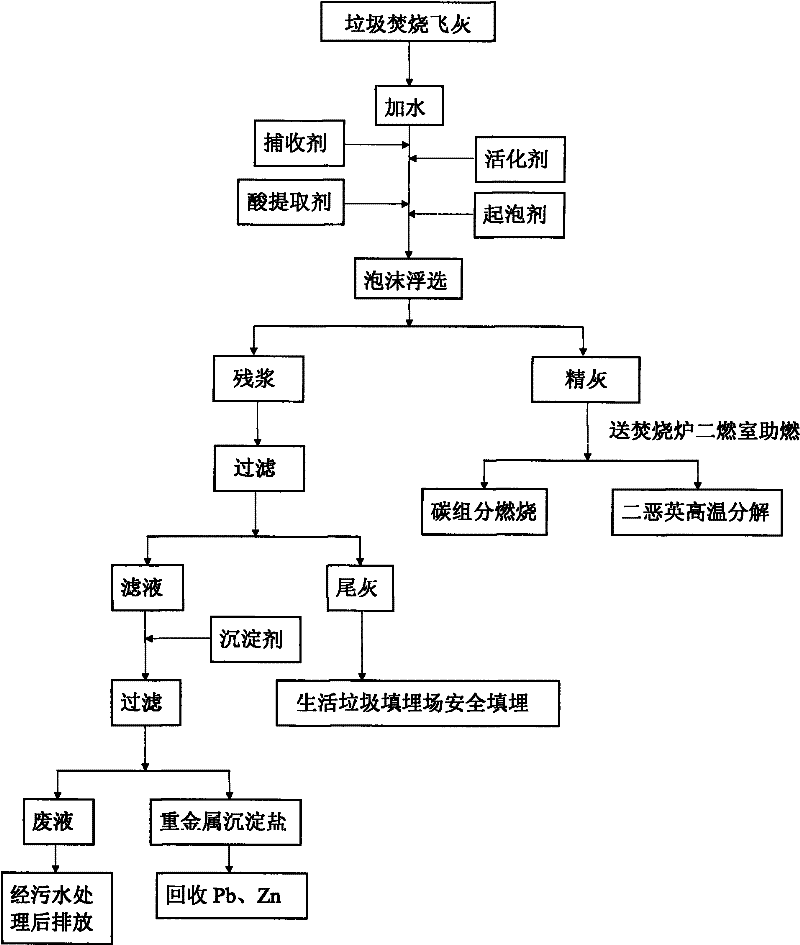

Flyash treatment method for waste incineration

InactiveCN101797575BReduce follow-up processing costsEfficient separationSolid waste disposalLiquid wasteCombustion chamber

The invention discloses a medical treatment flyash treatment method for waste incineration, comprising the following steps: (1) mixing a medical treatment flyash produced in waste incineration with water to prepare into mortar, and adding acid extractant, collecting agent and foaming agent in the mortar to blend into grout; (2) performing foam flotation treament on the grout, and separating to obtain refined flyash and residual grout; (3) feeding the fined flyash in a secondary combustion chamber of a waste incinerator for supporting combustion, wherein carbon components enriched in the refined flyash are utilized in a combusted manner and dioxin in the refined flyash is decomposed at high temperature; (4) filtering the residual grout, separating to obtain tail flyash and filtrate, feeding the tail flyash in a domestic garbage landfill site for dumping; and (5) adding heavy metal precipitator in the filtrate, filtering once again, separating to obtain heavy metal precipitator salt and waste liquor, and discharging the waste liquor after sewage treament. The invention can effectively separate and recovery carbon components in high carbon and high chlorine medical treatment waste incineration flyash, chloridion, dioxin and heavy metal atthe same time.

Owner:TIANJIN URBAN CONSTR COLLEGE

Discharging device for heat accumulating type thermal decomposition furnace to treat pyrogenic decomposition solid products of junked tire

ActiveCN103672923ADoes not destroy physical propertiesFacilitate subsequent processingIncinerator apparatusDecompositionEngineering

The invention discloses a discharging device for a heat accumulating type thermal decomposition furnace to treat pyrogenic decomposition solid products of a junked tire. The discharging device comprises a shell, a material laying plate used for containing the solid products, a chain board wheel transmission assembly, a driver and a plurality of material scraper blades. A discharge opening is formed in the shell. The material laying plate is movably arranged inside the shell. The chain board wheel transmission assembly is arranged inside the shell and placed above the material laying plate. The driver drives the chain board wheel transmission assembly to operate. The material scraper blades are respectively arranged on a transmission chain of the chain board wheel transmission assembly, the transmission chain drives the material scraper blades to move, and the material scraper blades push the solid products to the discharge opening. According to the discharging device, the traditional problems of material clamping, blocking and the like are solved, the continuous discharging purpose is achieved, the operating cost caused by abnormal maintenance and overhauling is greatly lowered, carbon black can be effectively prevented from being ground into powder, the potential risk caused by raised dust is avoided, and meanwhile the physical property of the solid products can not be damaged.

Owner:北京节净环保科技有限公司

Phosphorus-free corrosion and scale inhibitor

InactiveCN102557278AEasily biodegradableNo environmental problemsScale removal and water softeningEnvironment ProblemTreatment costs

The invention discloses a phosphorus-free corrosion and scale inhibitor. The phosphorus-free corrosion and scale inhibitor is characterized by consisting of sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), an acrylic acid-sulfonic acid terpolymer, solid alkali and water. When the phosphorus-free corrosion and scale inhibitor is used for cooling water, the phosphorus-free corrosion and scale inhibitor is nontoxic and phosphorus-free, main organic ingredients are easy to biodegrade, the environment problem is solved, the discharge is not limited by phosphorus, the subsequent treatment cost is greatly reduced, the corrosion rate of carbon steel is less than or equal to 0.1mm / a, the corrosion rate of copper, copper alloys and stainless steel is less than or equal to 0.005mm / a, and the scale inhibition rate is more than or equal to 90 percent.

Owner:天津通悦科技有限公司

Phosphate-free scale inhibitor for water treatment

InactiveCN104192870AEasy to degradeNo pollutionDouble sulfate preparationSulfate/bisulfate preparationPhosphatePollution

The invention relates to the technical field of water treatment, in particular to a phosphate-free scale inhibitor for water treatment, which is good in effect, low in cost and high in scale inhibition capacity and cannot cause secondary pollution to the water body. The phosphate-free scale inhibitor is characterized by comprising the following components: polyacrylic acid, hydrogen peroxide, rubber tannin, mirabilite, sodium citrate, zinc chloride, sodium molybdate, polyaspartic acid, acrylic acid sulfonic acid, polyepoxysuccinic acid and triethanolamine. When the phosphate-free scale inhibitor is used, the components are taken in proportion, water is added, and after a solution is prepared, the solution is added to water treatment equipment; compared with the prior art, the phosphate-free scale inhibitor is non-toxic and non-phosphorus, main organic components are easily degraded, the environmental pollution cannot be caused, and thus the subsequent treatment cost is greatly reduced.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

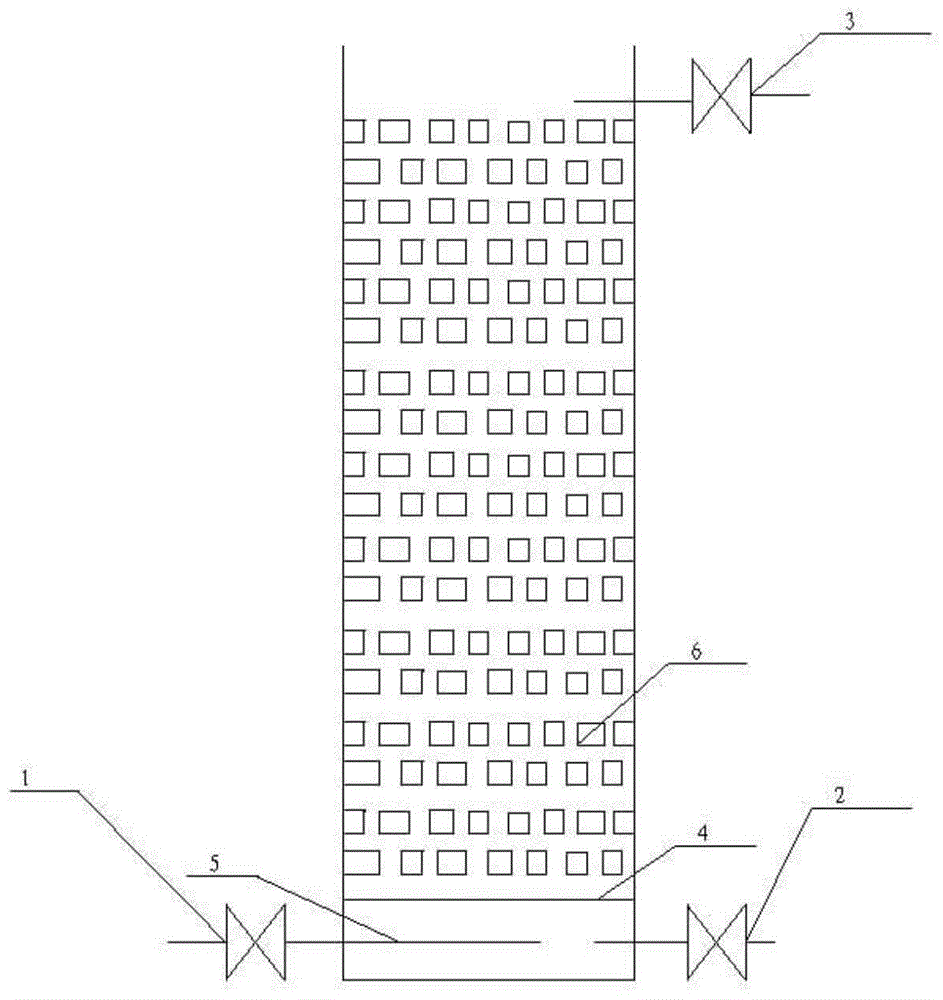

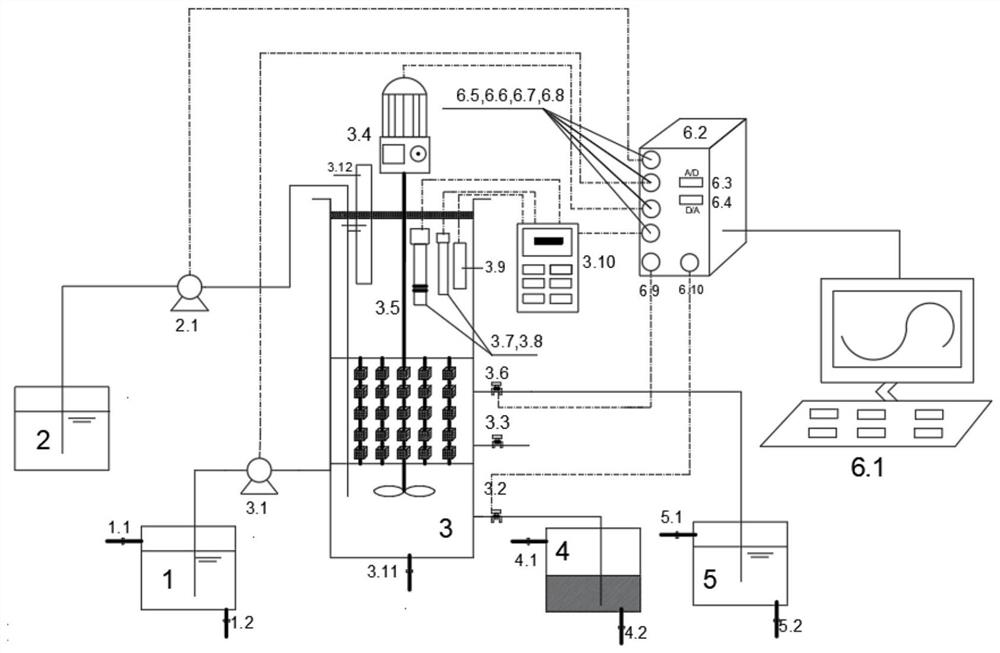

Pulping and papermaking wastewater biological treatment system

InactiveCN105481176ALow costImprove processing effectWater treatment parameter controlWater treatment compoundsWater treatment systemWater quality

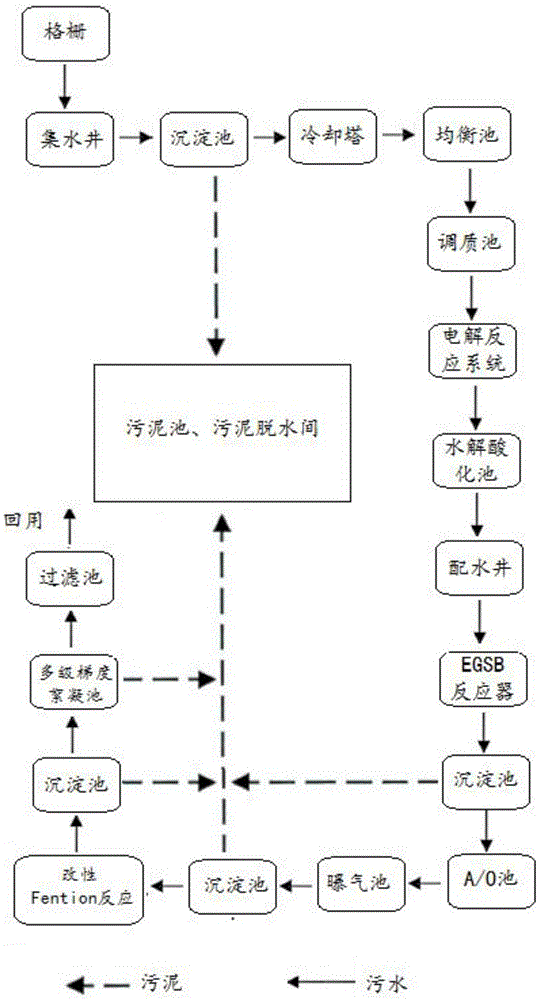

The invention discloses a pulping and papermaking wastewater biological treatment system, which is lower in running cost and capable of effectively protecting the environment. The pulping and papermaking wastewater biological treatment system comprises a grille pond, a water collecting well, a settling pond I, a cooling tower, a balancing pond, a water quality regulating pond, an electrolytic reaction system, a hydrolysis acidification pond, a water distributing well, an EGSB (Expanded Granular Sludge Bed) reactor, a settling pond II, an A / O pond, an aeration pond, a settling pond III, a modified Fention pond, a settling pond IV, a multi-gradient flocculation pond, a filtering pond, a sludge pond, a sludge dewatering room and communicating pipelines.

Owner:潘敏

Spirulina dehydration method

InactiveCN104370431BHigh degree of dehydrationReduce weightSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPhylum CyanobacteriaCyanobacteria

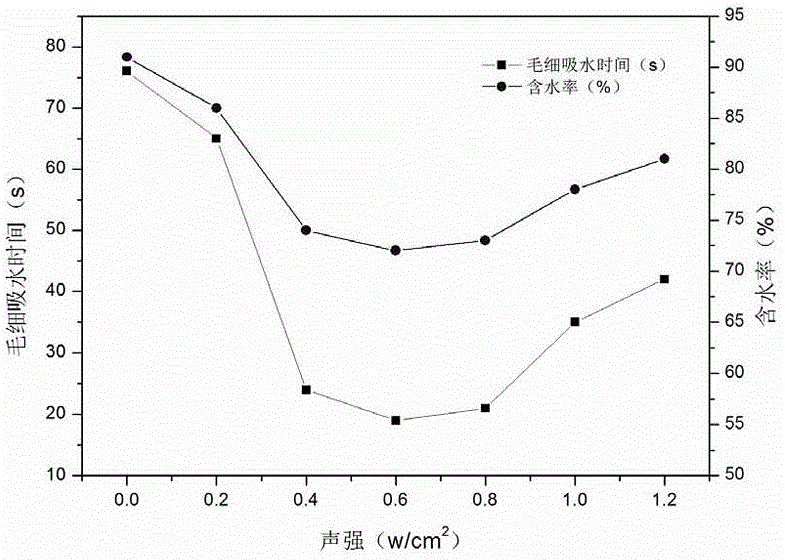

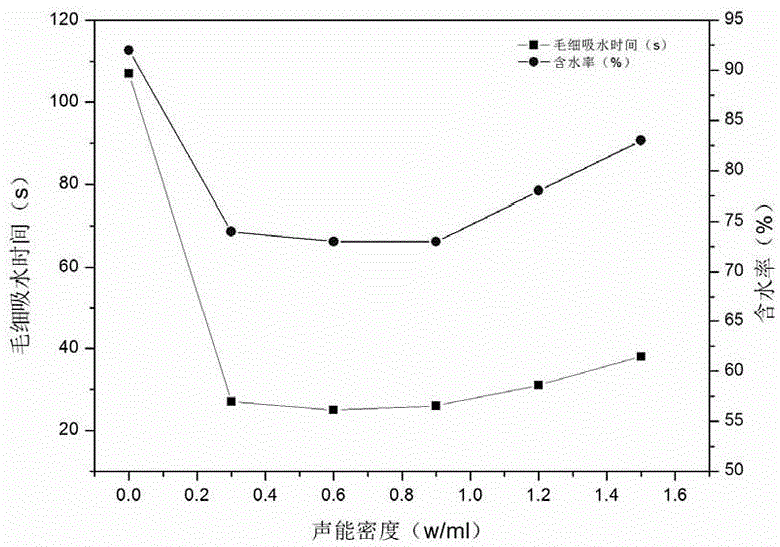

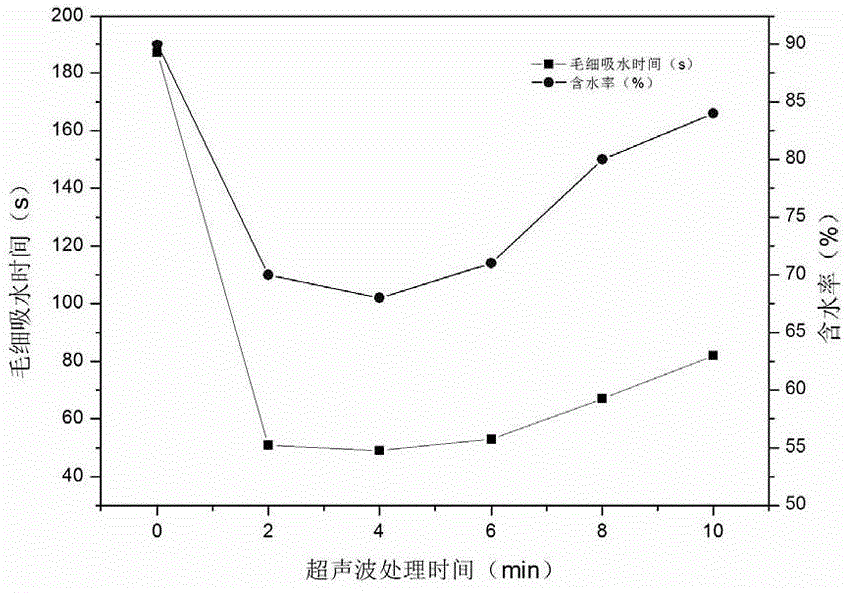

The invention discloses a blue algae dehydrating method. The method comprises the steps of performing ultrasonic processing, adding a flocculant and filter-pressing to dehydrate, wherein the specific steps are as follows: ultrasonically processing the blue algae for 2-6min; adding the flocculant in the blue algae after the ultrasonic processing, and uniformly stirring; filter-pressing the blue algae after adding the flocculant to dehydrate. Through the adoption of the method disclosed by the invention, the volume of the blue algae is greatly reduced, the heat value is not changed, and the dehydrating degree is high; the processing speed is high, the operation is simple, the large-scale production is facilitated, and the method has wide application prospect.

Owner:HUNAN UNIV

Ship flue gas purification device

InactiveCN111821804AQuick changeReduce replacement timeCombination devicesGas treatmentActivated carbonCombustion chamber

The invention discloses a ship flue gas purification device. The device comprises a first treatment chamber, a combustion chamber, a second treatment chamber and a flue gas pipe, wherein the first treatment chamber is communicated with a marine main engine through a flue gas pipe, the first treatment chamber is communicated with the second treatment chamber through a flue gas pipe, the first treatment chamber is communicated with the combustion chamber, an adsorption mechanism is arranged on the first treatment chamber, a combustion mechanism is arranged in the combustion chamber, and a purification mechanism is arranged in the second treatment chamber; the ship flue gas purification device, by means of the adsorption mechanism, not only can filter fixed particles in ship waste gas, but also can adsorb liquid components like oil mist in the ship waste gas, and through an incineration mechanism, activated carbon which is adsorbed to be saturated is sufficiently combusted, the limited space on a ship can be saved, harmful gas and oil mist adsorbed in the activated carbon can be thoroughly removed, and the subsequent treatment cost is saved.

Owner:CHENGXI SHIPYARD

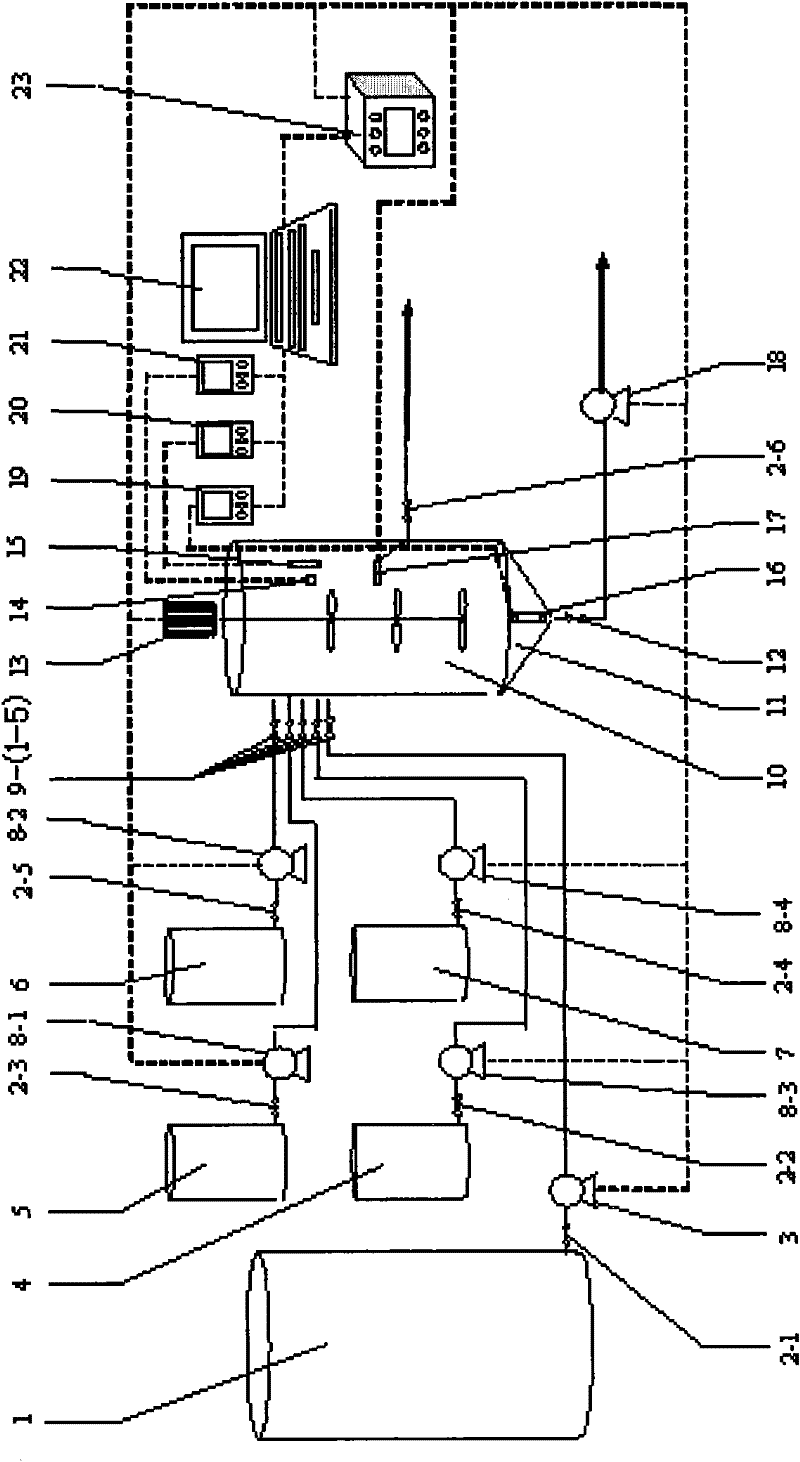

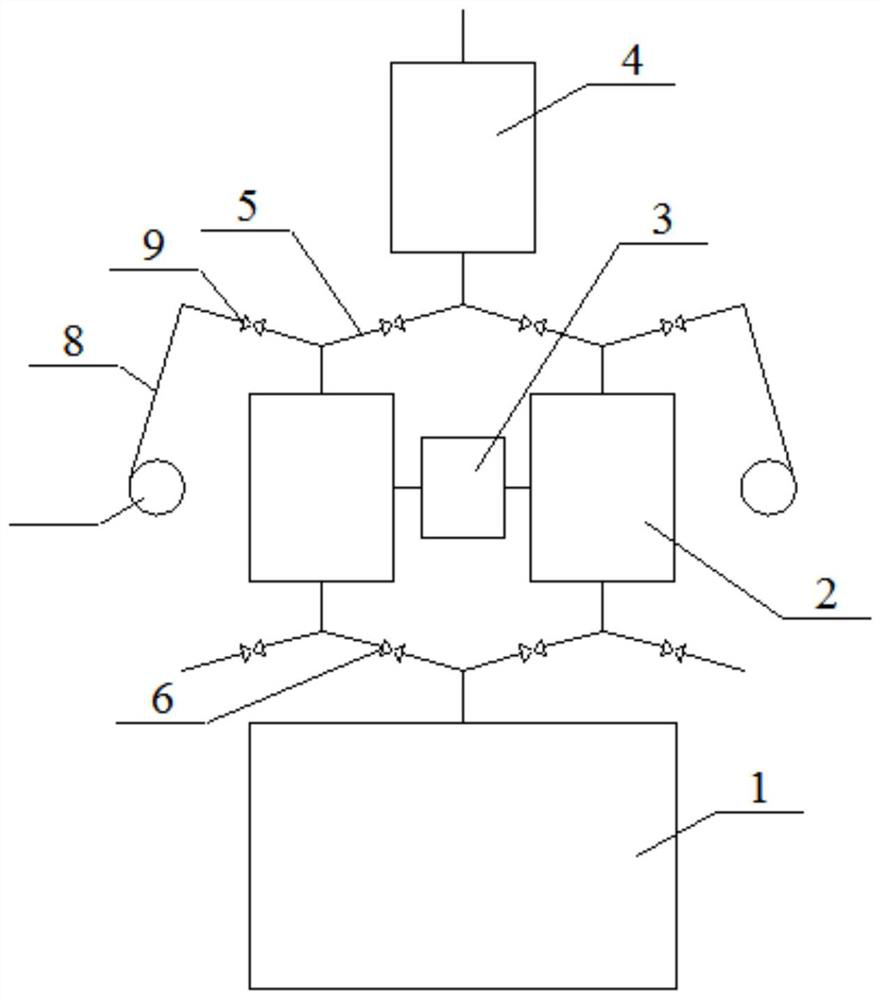

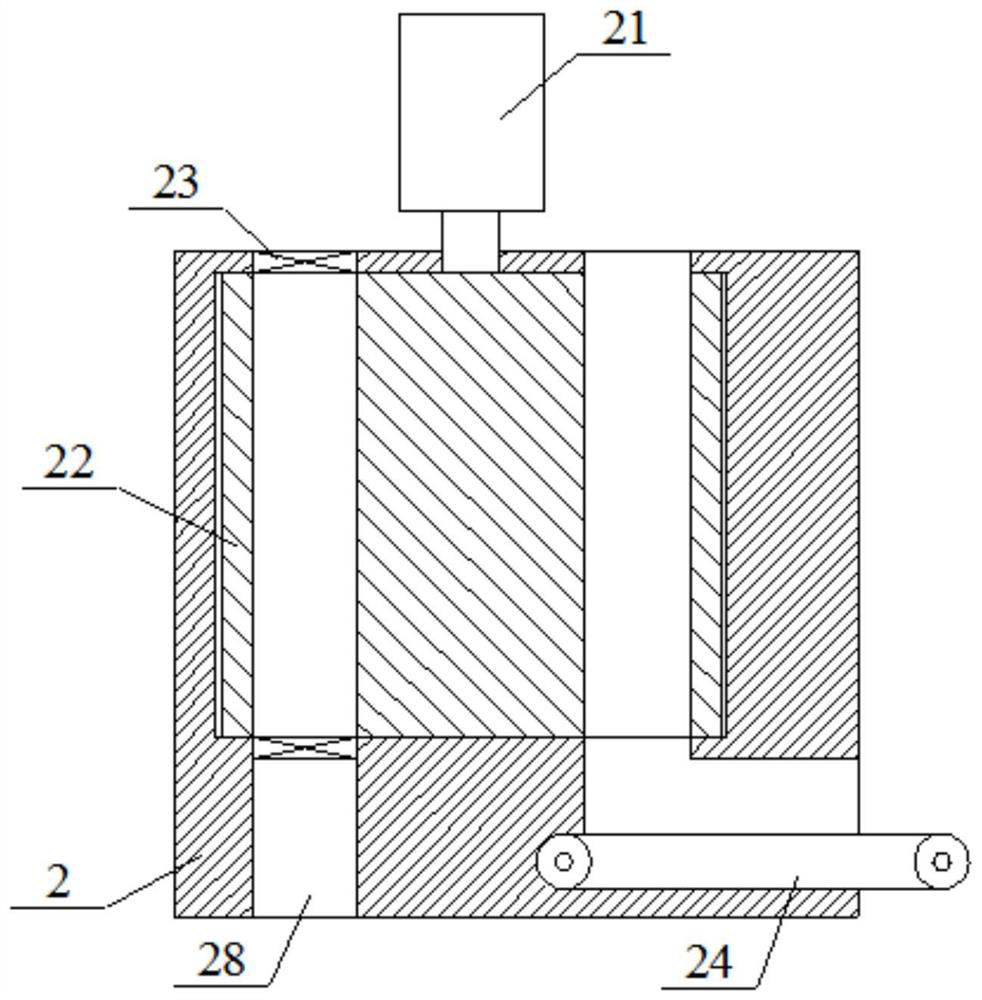

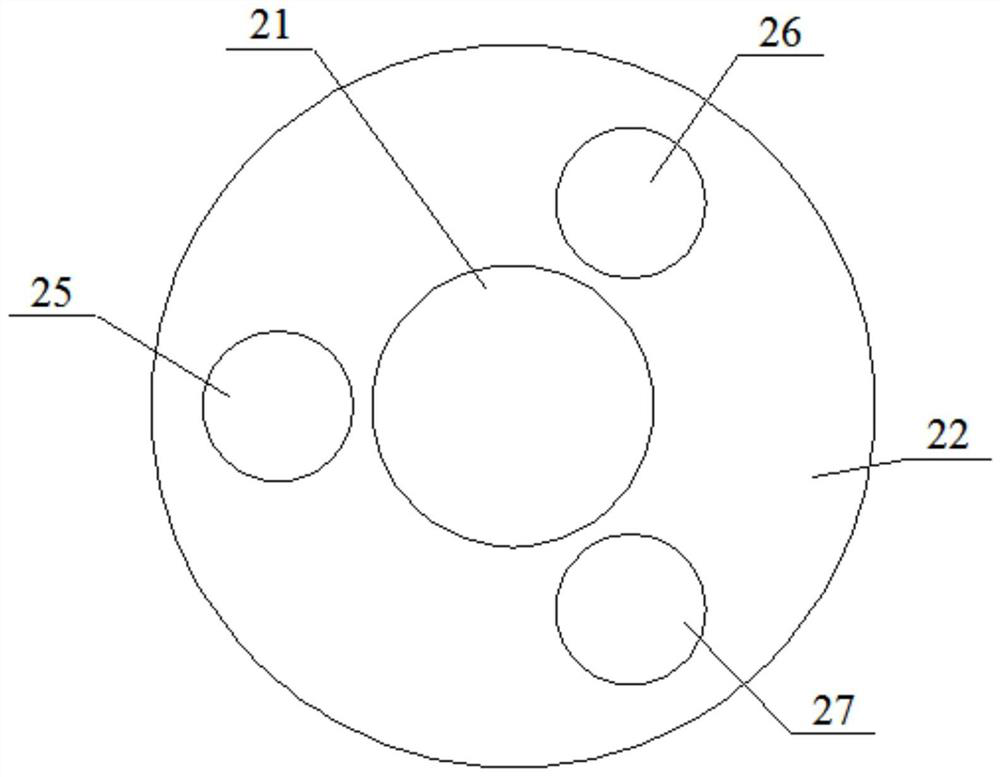

Device and method for treating high-nitrate wastewater and excess sludge

PendingCN113526659AAchieve reductionReduce volumeWater treatment parameter controlSpecific water treatment objectivesVolatile fatty acidsSludge

The invention belongs to the technical field of biological sewage treatment, and relates to a device and a method for treating high-nitrate wastewater and excess sludge. The method comprises the following steps: firstly, carrying out anaerobic fermentation on the sludge to generate volatile fatty acid (VFAs); then carrying out short-cut denitrification reaction by using the VFAs as an internal carbon source under an anoxic condition; and finally, carrying out anaerobic ammonium oxidation reaction via anaerobic ammonium oxidation bacteria which use ammonia nitrogen generated by anaerobic fermentation and nitrite nitrogen generated by short-cut denitrification as substrates so as to generate nitrogen and nitrate nitrogen. Thus, the aims of deep denitrification and sludge reduction are fulfilled, and the two problems of insufficient denitrification carbon sources and high residual sludge yield of a sewage plant at present are solved.

Owner:QINGDAO UNIV

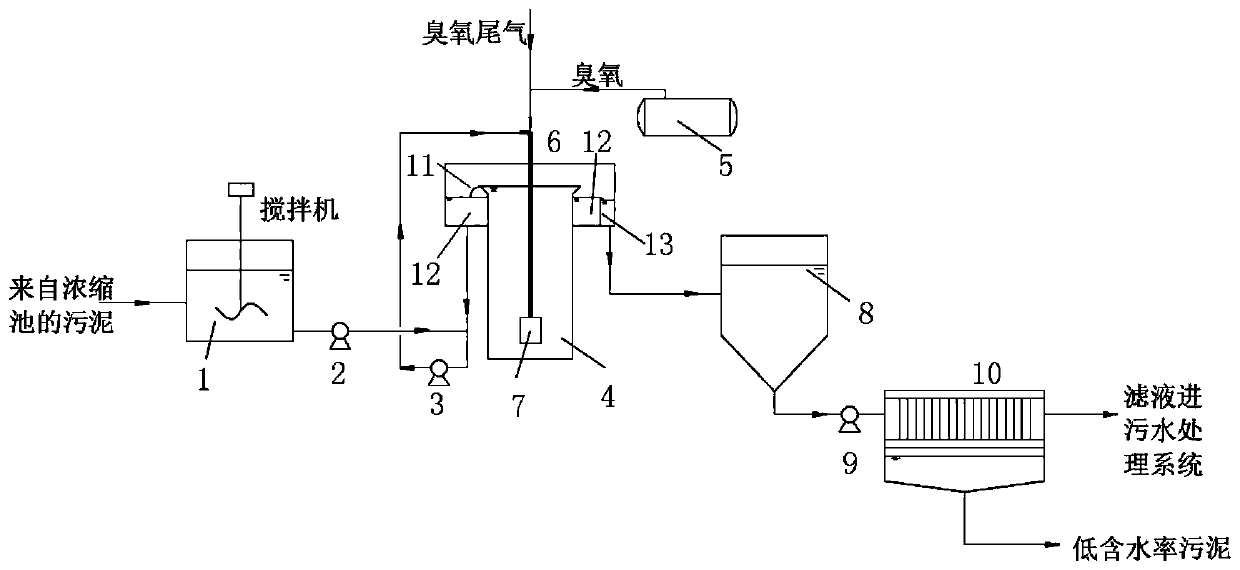

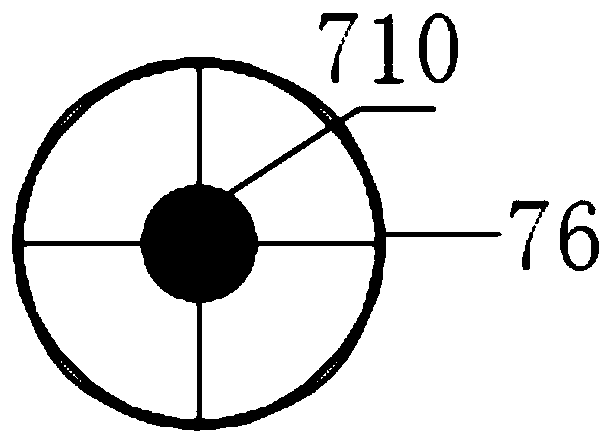

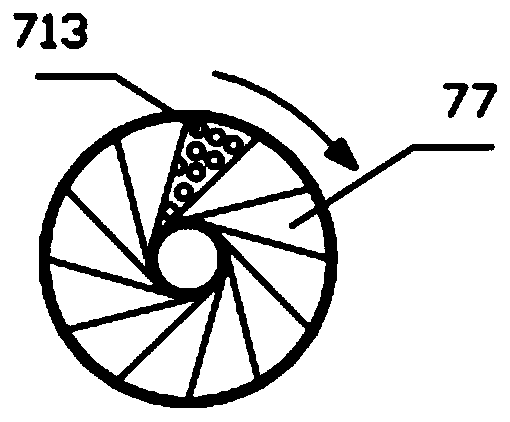

Sludge deep dehydration quantitative reduction treatment system

PendingCN110723876AIncrease contact areaIncrease profitSludge treatment by oxidationSpecific water treatment objectivesReduction treatmentSludge

The invention discloses a sludge deep dehydration quantitative reduction treatment system. The sludge deep dehydration quantitative reduction treatment system is characterized in comprising a first sludge inlet pump, a wall breaking reactor, a self-suction jet device, a releaser, an ozone generator, a sludge filter press and a circulating pump; sludge is lifted using the first sludge inlet pump toenter the self-suction jet device or the wall breaking reactor; the ozone generator or ozone tail gas is communicated into the wall breaking reactor through the self-suction jet device, the releaseris arranged at the bottom of the self-suction jet device and is arranged at the bottom of the wall breaking reactor, and sludge enters the sludge filter press after being treated by the wall breakingreactor; and the self-suction jet device, the wall breaking reactor and the circulating pump are communicated through pipelines to form a cycle. The self-suction jet device and the releaser are combined for use, so that the ozone utilization rate can be greatly improved, a good sludge treatment effect can be achieved under the condition of low ozone addition amount, and the cost is reduced.

Owner:SHANGHAI SHIYUAN ENVIRONMENT PROTECTION TECH

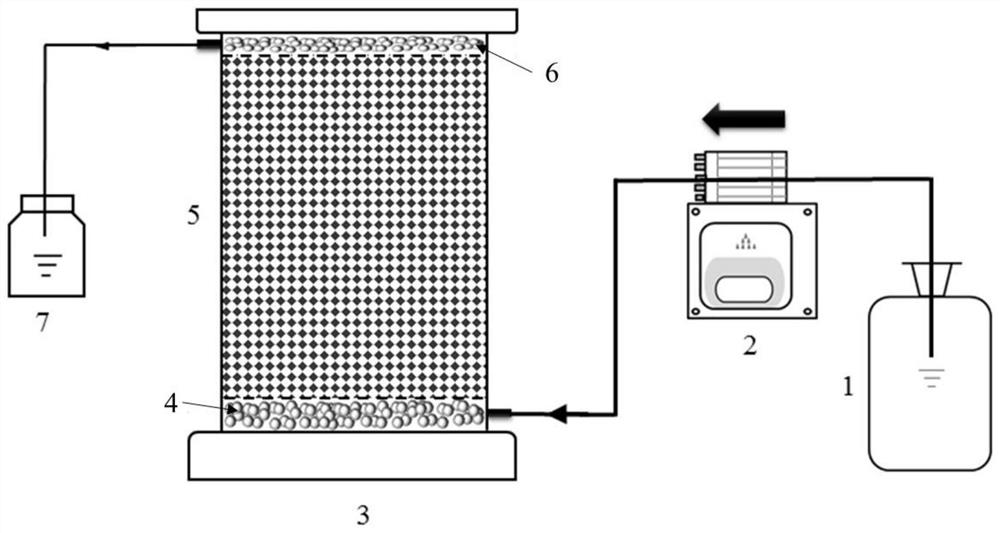

Low-carbon nitrate wastewater efficient purification device system based on mixed matrix and purification treatment method

PendingCN114195259AReduce processing difficultyReduce follow-up processing costsWater treatment compoundsWater contaminantsEnvironmental chemistryPyrite

The invention provides a low-carbon nitrate wastewater efficient purification device system based on a mixed matrix and a purification treatment method. The device system comprises a water supply unit, a purification device and an effluent collection unit which are connected in sequence, a water distribution layer, an efficient mixed matrix layer and a supporting layer are sequentially arranged in the purification device in the upward direction perpendicular to the ground; a filling medium of the efficient mixed matrix layer comprises a low-valence sulfur mixture and oyster shells. According to the sulfur-pyrite autotrophic denitrification device system disclosed by the invention, efficient denitrification can be realized; the oyster shells can replace carbonate minerals to participate in the sulfur-pyrite autotrophic denitrification process, a large number of attachment sites, trace elements and inorganic carbon sources are provided for microorganisms, and the acid-base environment of the system is kept stable. The device provided by the invention is simple and feasible in system, good in economical efficiency, free of additional addition of an organic carbon source, excellent in denitrification effect and less in by-product, and has good application potential for a water body with low organic carbon content.

Owner:TSINGHUA UNIV

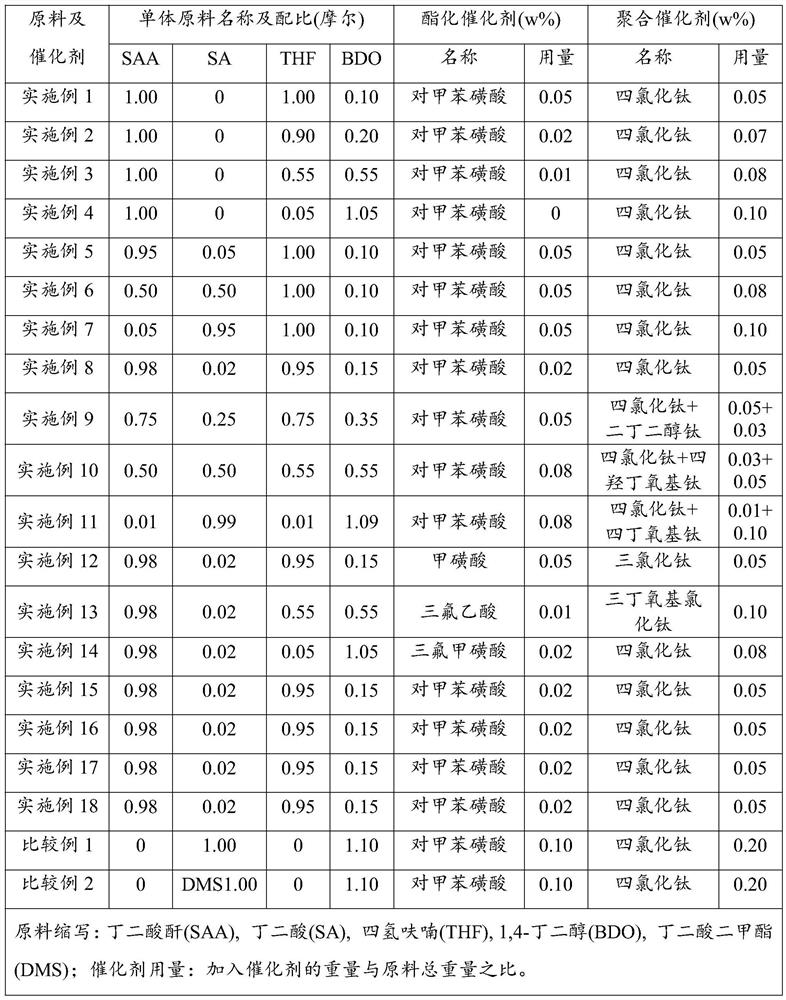

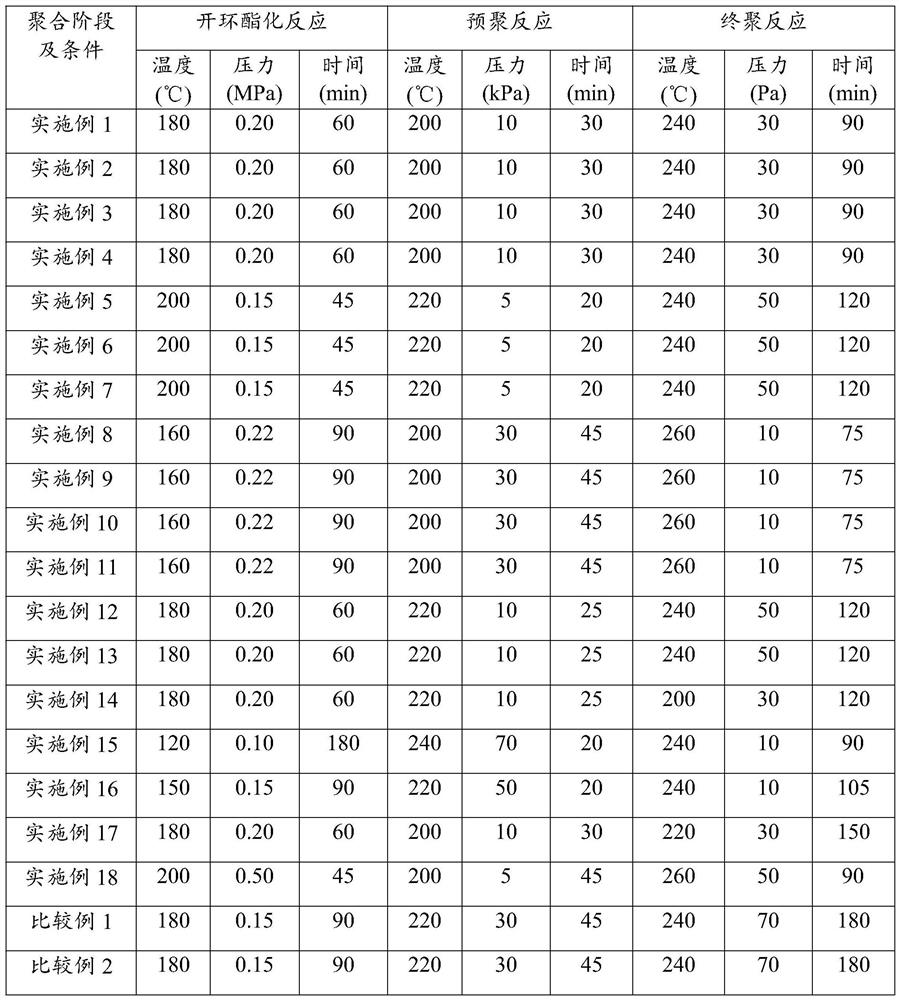

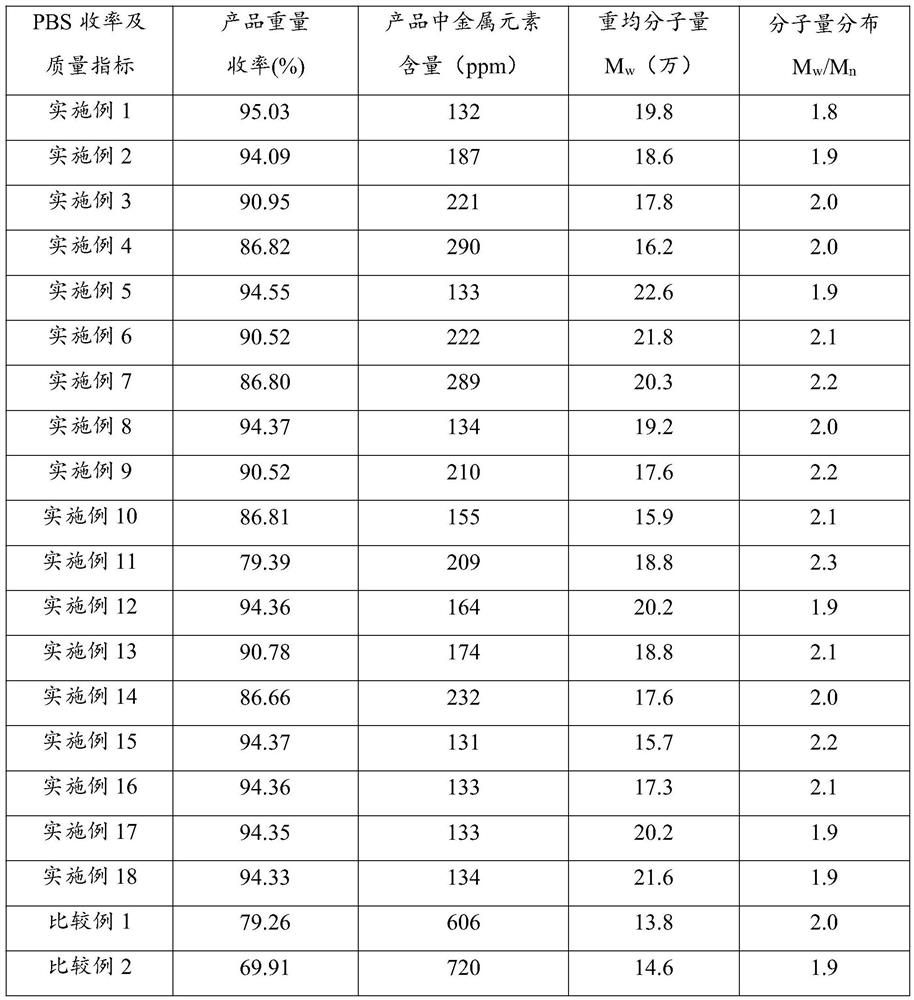

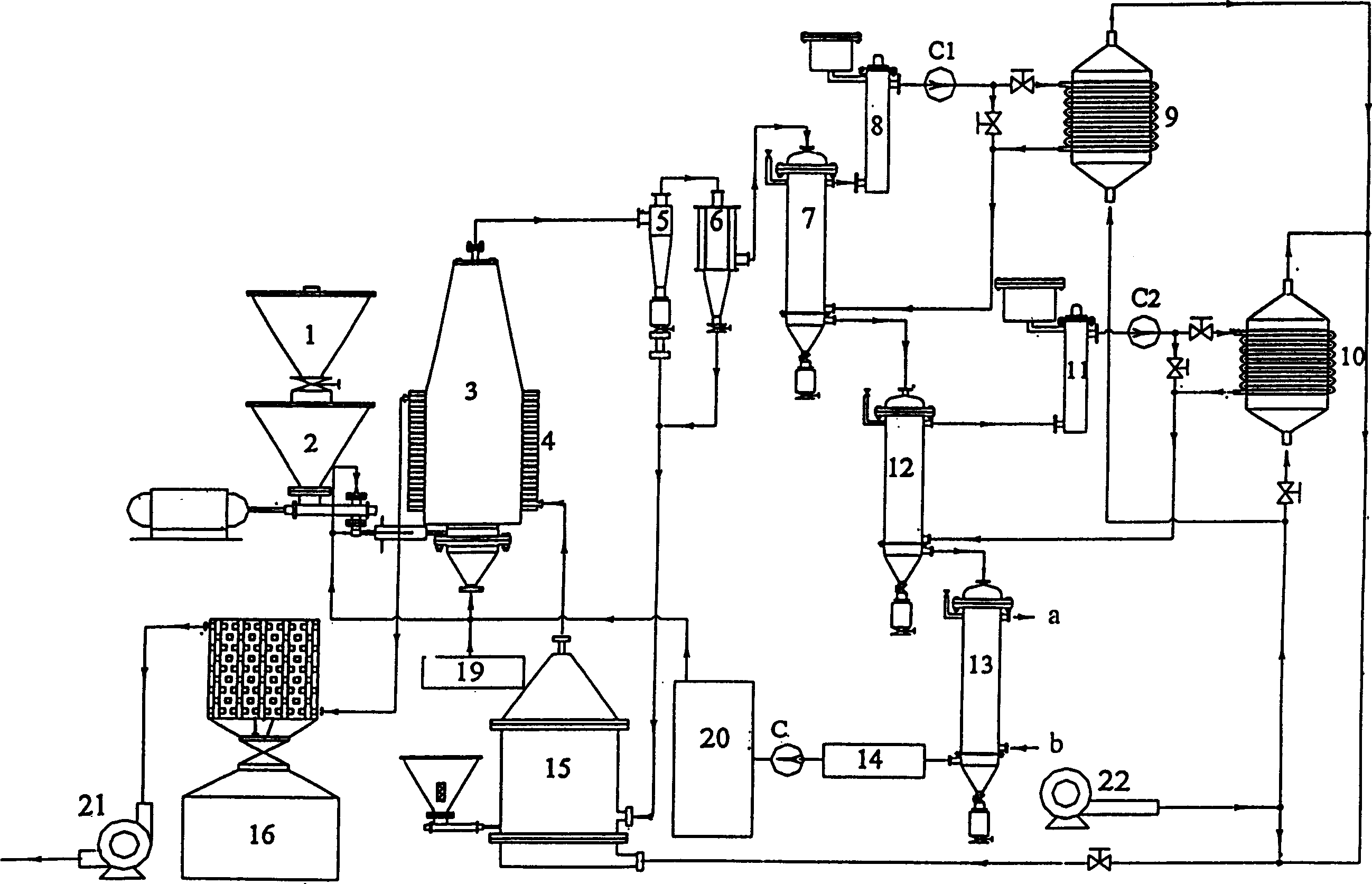

Method for synthesizing poly (1, 4-butanediol succinate) through ring-opening polymerization

The invention provides a method for synthesizing poly (1, 4-butanediol succinate) through ring-opening polymerization, the method comprises the following steps: taking two cyclic monomers, namely succinic anhydride and tetrahydrofuran, as main raw materials and 1, 4-butanediol and / or succinic acid as auxiliary monomer raw materials, under the action of a composite catalyst, preparing the poly (1, 4-butylene succinate) (PBS) through three reaction steps of ring-opening esterification, pre-polymerization and final polymerization; essentially, transmission of active groups (hydroxyl and carboxyl) is achieved through addition-ring opening, growth of chains (alkyl and ester groups) is achieved through esterification-condensation, and finally high-molecular-weight PBS is obtained through polycondensation. Compared with the prior art, the PBS product synthesized by the method has the advantages of high polymerization degree, good chromaticity, low raw material and energy consumption and high product yield so that the quality of the PBS product can be improved, the production cost can be reduced, and the process is clean and environment-friendly.

Owner:SHANGHAI NORMAL UNIVERSITY +1

Biomass integrated thermocracking equipment for graded preparing liquid fuel

InactiveCN1175085CAchieve recyclingRealize self-heatingLiquid hydrocarbon mixture productionSolid carbonHeat flow

Owner:ZHEJIANG UNIV

Industrial waste oil treatment process

InactiveCN104017618AHigh calorific valueFix stability issuesLiquid carbonaceous fuelsPower stationLiquid water

The invention discloses an industrial waste oil treatment process which comprises the following steps: dissolving ethylene glycol butyl ether and a water-coal-slurry additive in industrial waste oil, stirring at normal temperature, and forming a mixed liquid; and adding pulverized coal and water into the mixed liquid, and continuously stirring to form a water-coal-slurry product which is not layered. According to the process, the original scraped waste oil which cannot be directly discharged is changed into a valuable material, the subsequent treatment cost is saved, and the heating value of the water-coal-slurry product prepared by utilizing the industrial waste oil is correspondingly improved. Moreover, the problem that the traditional organic waste liquid water coal slurry is low in stability is solved according to a coupling agent stabilization technology provided by the invention, the problem of the system stability of the product can be fundamentally solved, the stability of the product is improved, oil-water separation is not generated due to long-term standing, the operations of loading and unloading, storage, pipeline transportation and atomization space combustion are easy, and the process can be used for oil, gas and coal combustion in power station boilers, industrial boilers and industrial furnaces.

Owner:AMER TECH CO LTD

Sterilization, deodorization and deep-dehydration method for livestock excrements

ActiveCN103708689BWide range of processingHigh degree of dehydrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFecesMicrowave

The invention relates to the field of treatment of livestock excrements, and in particular relates to a sterilization, deodorization and deep-dehydration method for livestock excrements. The method comprises the steps of acidification, namely adjusting the pH of the livestock excrements to be 3 to 6 by using acid; oxidization, namely adding an oxidizing agent into the acidified livestock excrements at the ratio that 0.5 to 1.2 moles of oxidizing agent is added into every kilogram of dry livestock excrements, and performing uniform stirring; microwave heating treatment, namely heating the oxidized livestock excrements to 95 to 120 DEG C by using microwaves, and continuing performing microwave treatment while stirring for 5 to 12 minutes at the temperature; pressure filtration dehydration, namely performing pressure filtration dehydration on the microwave-treated livestock excrements by using a pressure filter. The method is low in using cost, easy to operate and high in treatment speed, and the treated livestock excrements are high in solid recovery rate, low in heat value reduction and high in dehydration degree.

Owner:HUNAN UNIV

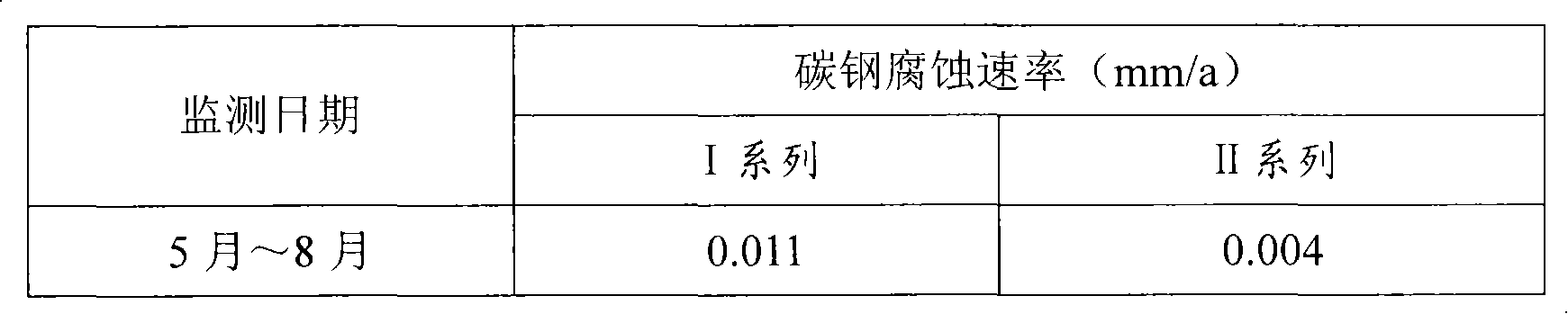

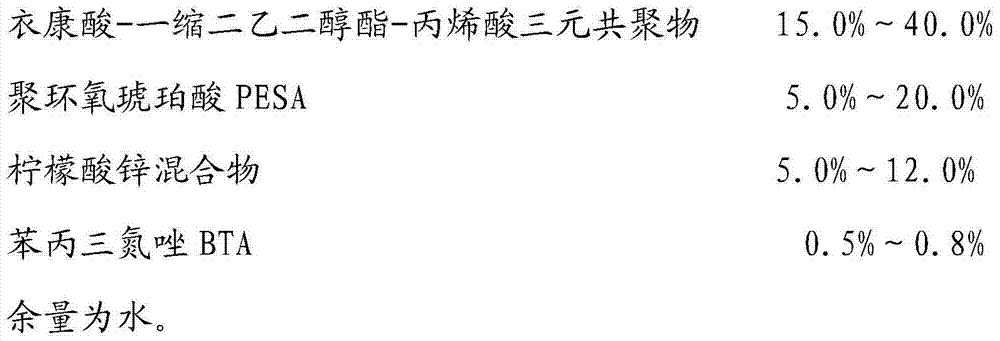

Non-phosphorus corrosion and scale inhibitor for industrial cooling water system as well as preparation method and application thereof

ActiveCN103936177AIncrease content limitRaise the upper limit of scale inhibition limitScale removal and water softeningEutrophicationWater quality

The invention discloses a non-phosphorus corrosion and scale inhibitor for an industrial cooling water system as well as a preparation method and application thereof. The non-phosphorus corrosion and scale inhibitor is composed of an itaconic acid-diethylene glycol ether-acrylic acid terpolymer, Polyepoxysuccinic Acid (PESA), zinc citrate, Benzotriazole (BTA) and water, wherein the weight percentage of the itaconic acid-diethylene glycol ether-acrylic acid terpolyme in the non-phosphorus corrosion and scale inhibitor is 15.0%-40.0%, the weight percentage of the PESA in the non-phosphorus corrosion and scale inhibitor is 5.0%-20.0%, the weight percentage of the zinc citrate in the non-phosphorus corrosion and scale inhibitor is 5.0%-12.0%, and the weight percentage of the BTA in the non-phosphorus corrosion and scale inhibitor is 0.5%-0.8%, and the balance of water. Wastewater discharged after the use of the non-phosphorus corrosion and scale inhibitor does not cause phosphorus-induced eutrophication pollution to water, and is environment-friendly; the dosage of the non-phosphorus corrosion and scale inhibitor for treating water per ton is 3-10mg / L; the non-phosphorus corrosion and scale inhibitor is stable in performance and widely applied to different water qualities.

Owner:天津沃川水处理工程技术有限公司

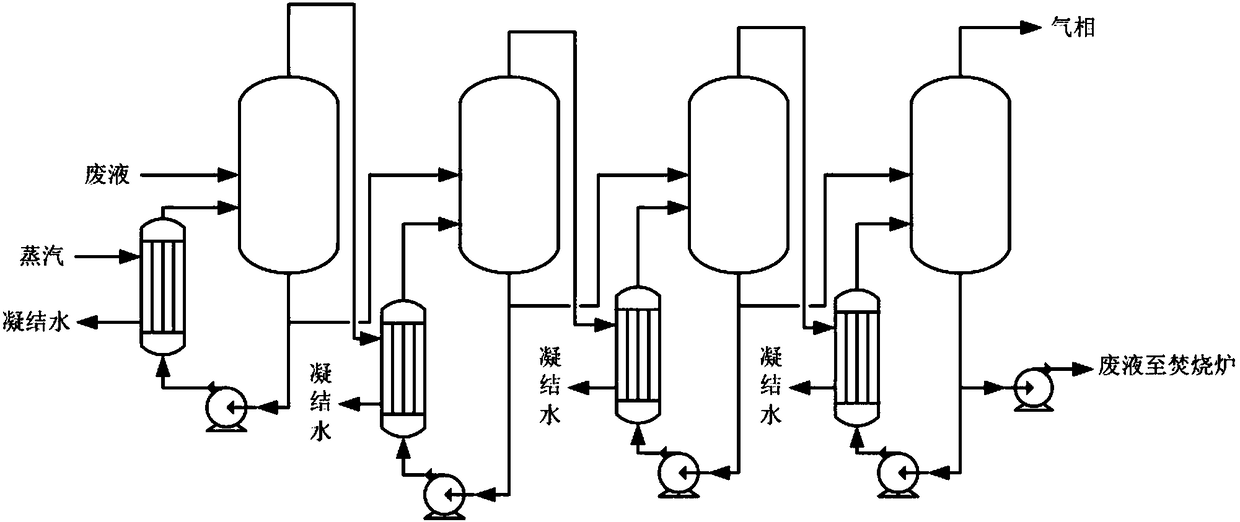

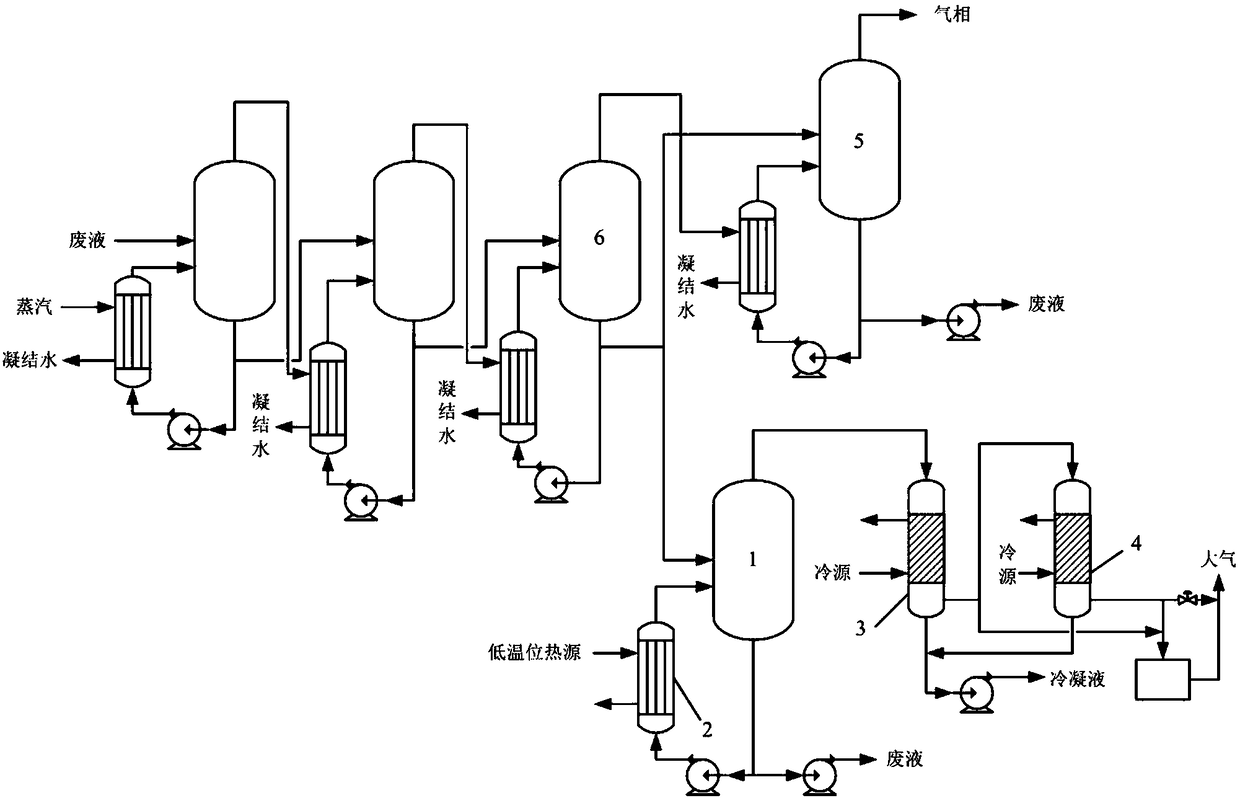

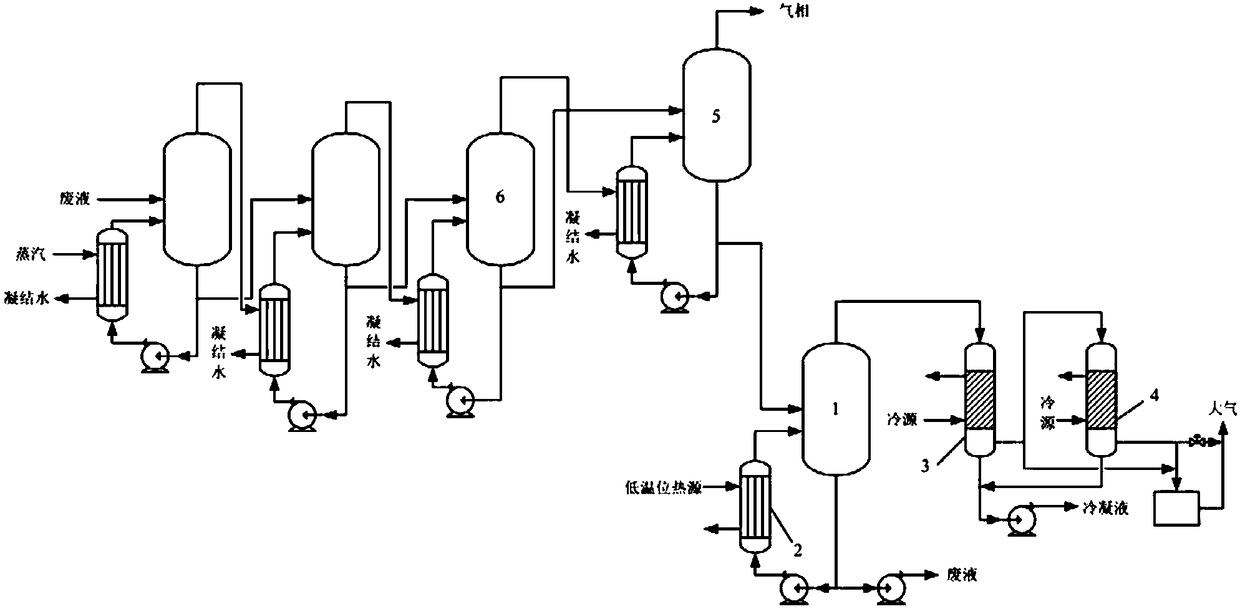

Heat recovery system of multi-effect evaporation system and processing method thereof

PendingCN108325227AReduce dosageReduce follow-up processing costsEvaporation with vapour compressionMultiple-effect evaporationLiquid wasteMultiple-effect evaporator

The invention provides a heat recovery system of a multi-effect evaporation system and a processing method thereof. The heat recovery system of the multi-effect evaporation system comprises an evaporating device connected in parallel or / and in serial with an end effect evaporating device of the multi-effect evaporation system; the bottom of the evaporating device is provided with a heat supply device, and the heat source of the heat supply device is a low-temperature heat source at 90-130 DEG C. The heat recovery system of the multi-effect evaporation system makes full use of end-effect low-temperature hot trap of the multi-effect evaporation system to recover low-temperature heat of other technical devices, thereby reducing consumption of fresh steam of an initial-effect evaporator as well as the costs of aftertreatment of concentrated liquid waste.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD +1

A pigsty pen with a urine-separating toilet

The invention relates to a pigsty provided with a faeces-urine-separated toilet. The pigsty comprises a feeding region, a lying region and an excretion region. The feeding region is located on the front portion of the pigsty, the excretion region is located on the rear portion of the pigsty, the lying region is located between the feeding region and the excretion region, and the lying region is separated from the excretion region through a PVC curtain. A concrete inclined surface is arranged from the joint of the excretion region and the lying region to the position below the excretion region. An upper layer of slatted floor and a lower layer of slatted floor are laid on the excretion region, the first layer is a cast iron slatted floor, and the lower layer is a concrete slatted floor. The bottom of the concrete inclined surface is provided with a faeces and urine ditch, and a faeces removing channel is adjacent to the faeces and urine ditch. Most of the faeces directly excreted by pigs on the cast iron slatted floor falls on the concrete slatted floor after being trampled by the pigs, separation of dry nightsoil can be achieved to the maximum degree through the mode of combination of the double-layer slatted floors, the environmental hygiene of the pigsty is improved, and the organic load and cost of subsequent faeces processing are lowered.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

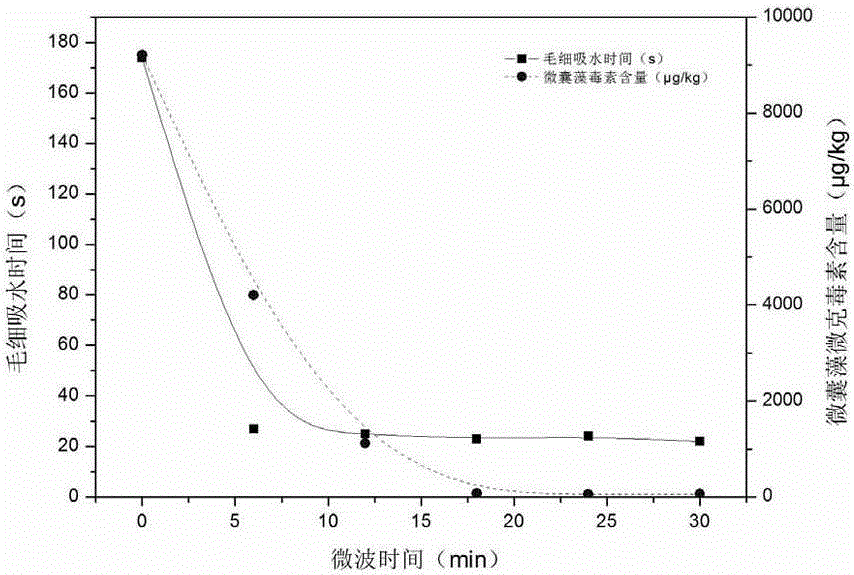

A method for simultaneously detoxifying and dehydrating cyanobacteria

InactiveCN104399315BEfficient dehydrationReduce capillary water absorption timeFiltration separationEnergy based chemical/physical/physico-chemical processesMicrobiologyCyanobacteria

The invention discloses a method for simultaneously detoxifying and dehydrating blue-green algae, which specifically comprises the following steps: adjusting the pH of blue-green algae to be acidic; adding an oxidant to the acidic blue-green algae, and then performing microwave radiation treatment; Carry out pressure filtration and dehydration to complete the treatment of cyanobacteria. The invention can carry out detoxification and rapid dehydration treatment on large quantities of salvaged cyanobacteria, with simple equipment, low use cost, convenient operation and maintenance, high degree of dehydration, greatly reduced volume of cyanobacteria, thorough detoxification, no secondary pollution, and broad application potential. Application prospects.

Owner:HUNAN UNIV

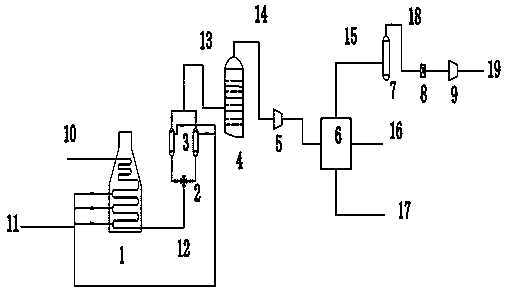

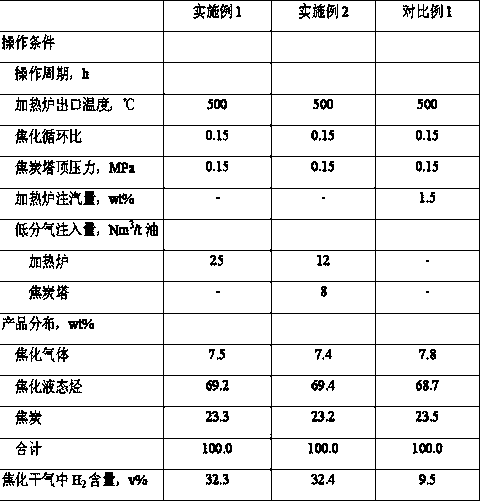

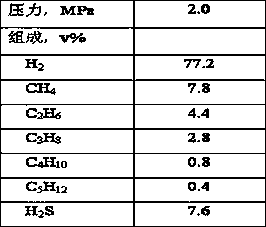

Hydrogen-consuming apparatus low gas optimization utilization method and hydrogen-consuming apparatus low gas optimization utilization system

ActiveCN109929587ALess investmentReduce energy consumptionDispersed particle filtrationTreatment with hydrotreatment processesWaxHydrogen

The invention provides a hydrogen-consuming apparatus low gas optimization utilization method and a hydrogen-consuming apparatus low gas optimization utilization system. According to the method, hydrogen-consuming apparatus low gas is conveyed to the coking heating furnace in a delayed coking device; the heated coking raw material and the low gas enter a coke tower, and are subjected to a reaction; the high-temperature oil gas obtained by the reaction is separated to obtain coking rich gas, and the coking rich gas enters an absorption stabilization system, and is separated to obtain coking drygas, coking gasoline, coking diesel oil and coking wax oil; and the obtained coking dry gas is desulfurized and filtered so as to be used as a hydrogen producing raw material. The invention further provides a hydrogen-consuming apparatus low gas optimization utilization system. With the method and the system of the present invention, the hydrogen-consuming apparatus low gas is subjected to optimization utilization by using the existing coking device, the novel efficient utilization method is provided for the hydrogen-consuming apparatus low gas, and the advantages of low investment and low energy consumption are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com