Method for dynamically controlling continuous feeding in dehydration of papermaking sludge

A papermaking sludge, dynamic control technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of large equipment loss, low economic cost, secondary pollution, etc., to prevent secondary pollution and reduce sludge volume , the effect of reducing follow-up processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to overcome the disadvantages of high energy consumption, low dehydration rate, large loss of equipment, and secondary pollution in the existing sludge dewatering methods, the present invention provides a continuous feed dynamic control for papermaking sludge dewatering The method has the advantages of high dehydration efficiency, simple process, no secondary pollution, no need to use special drying equipment, and low economic cost.

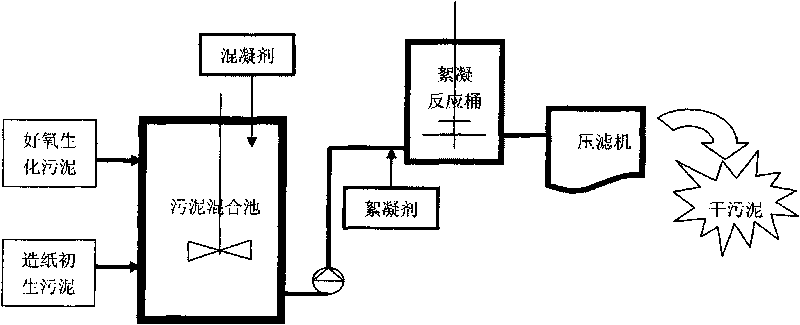

[0019] figure 1 It is the process flow chart of the continuous feed dynamic control method for sludge dewatering of the present invention. The process steps of the method are:

[0020] 1) Mix and stir the concentrated aerobic biochemical sludge with papermaking sludge to form mixed sludge;

[0021] 2) Continuously add inorganic polymer coagulant to the uniformly stirred mixed sludge, and perform stirring reaction;

[0022] 3) Use the sludge screw pump to transport the reacted mixed sludge to the secondary flocculation reaction tank, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com