Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce arcing phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anodic oxidation device and piston anodic oxidation processing process

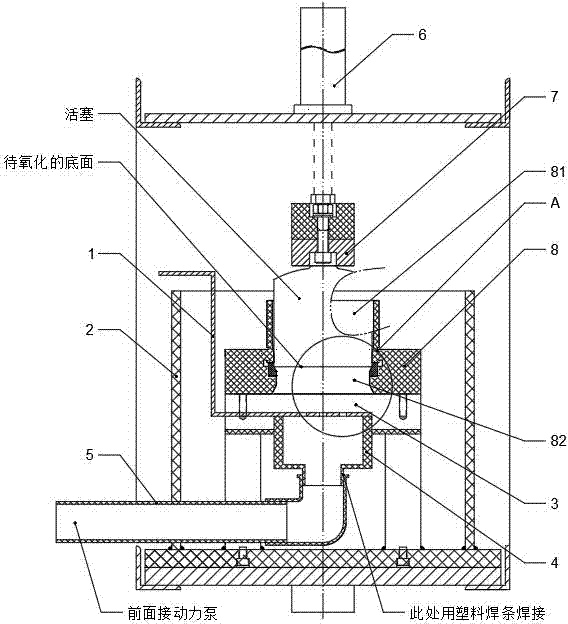

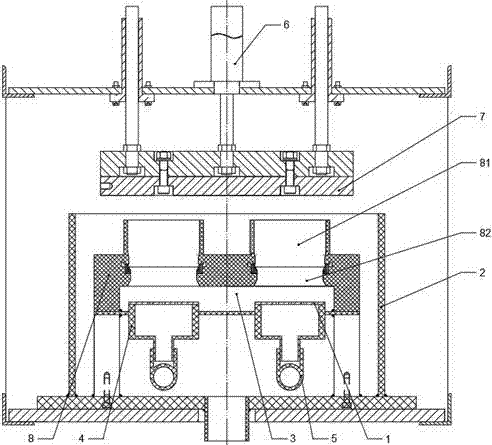

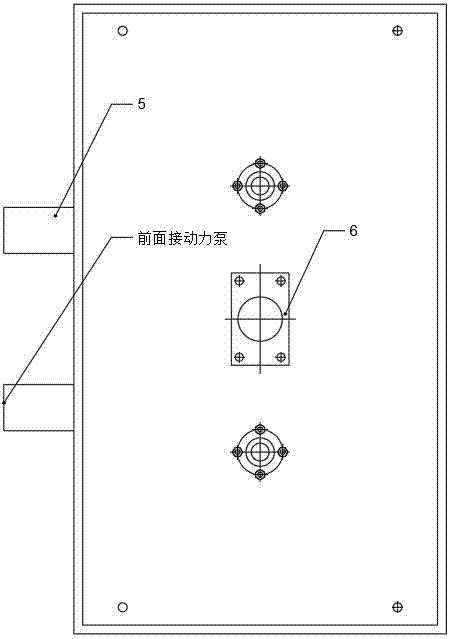

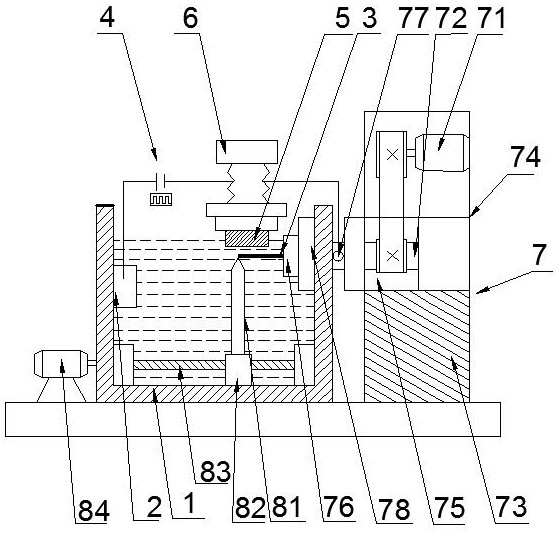

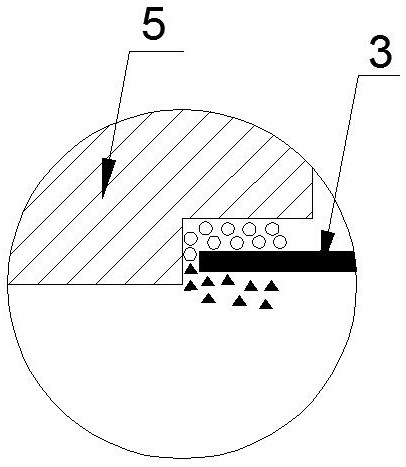

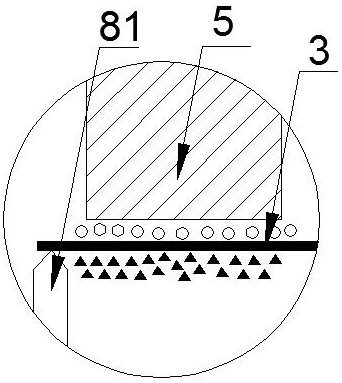

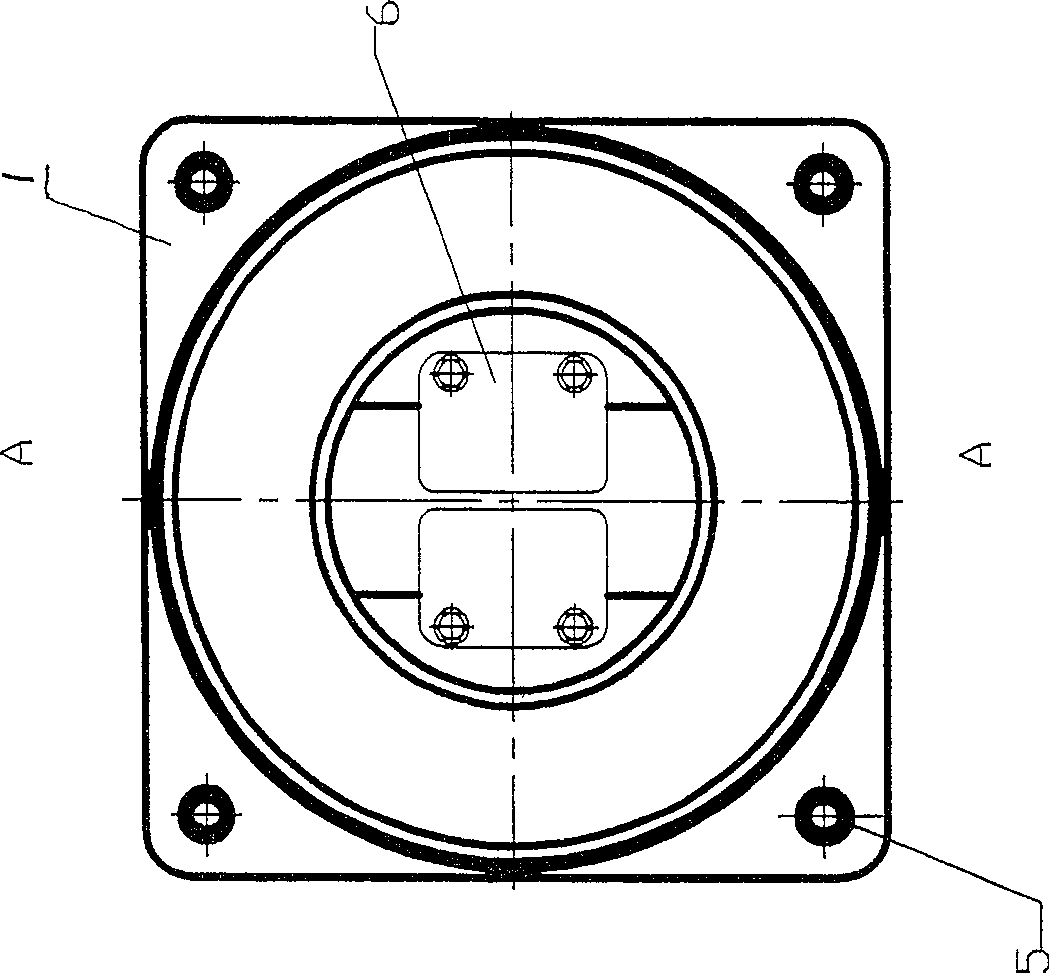

The invention belongs to the technical field of alloy surface anodic oxidation hard treatment and provides an anodic oxidation device and a piston anodic oxidation processing process. The anodic oxidation device comprises a power source, an electrolyte storage cavity, an anode component, an anode plate, an oxidation tank, a power pump and a current controller. The piston anodic oxidation processing process which adopts the anodic oxidation device includes steps: A, mounting a piston into a workpiece clamping hole to make a to-be-oxidized bottom surface downward; B, starting an air cylinder to make a conducting plate abutted against the piston; C, starting the power source and the power pump, enabling electrolyte to be sprayed out vertically through a water storage sprayer nozzle to contact with the to-be-oxidized bottom surface of the piston to form a current circuit, and adjusting current density through the current controller to finish anodic oxidation processing. The anodic oxidation device has advantages that quick heat radiation is realized to prevent overburning, and accordingly product quality can be improved.

Owner:CHONGQING XIECHENG AUTO PARTS

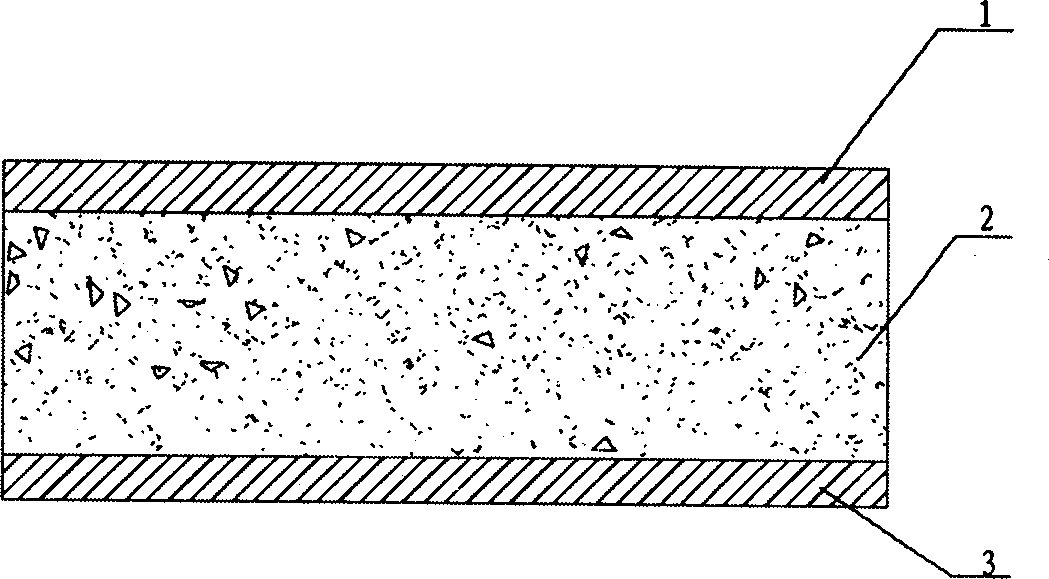

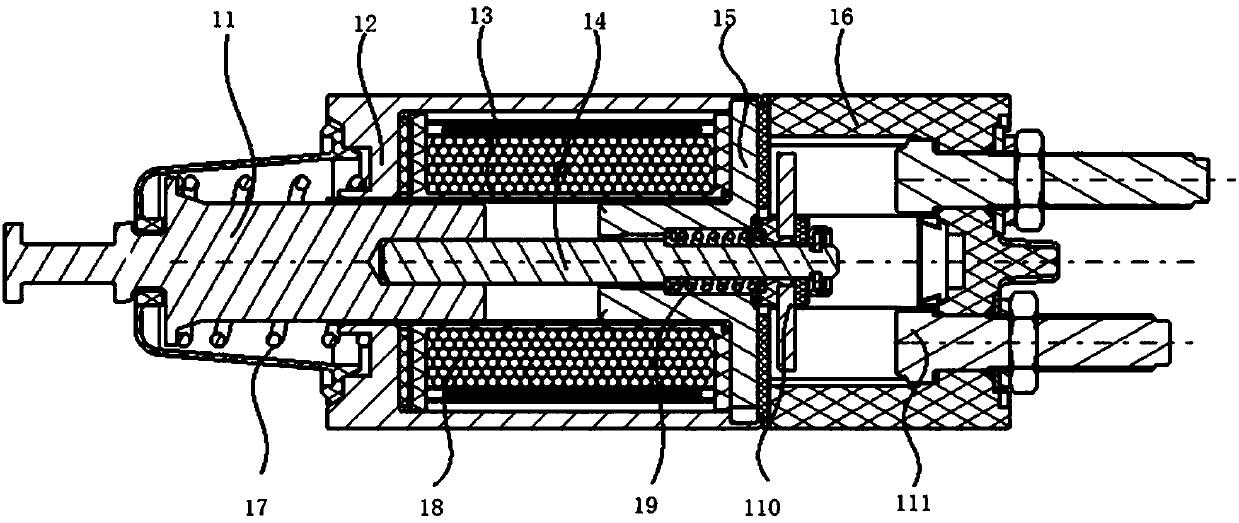

High molecular PTC thermistor without electric arc and method for producing same

InactiveCN1416142ANovel structureIncrease creepage distancePositive temperature coefficient thermistorsState of artMetal foil

The invented core material of the macromolecule PTC thermistor consists of the chip possessing the PTC characteristics and the metals foil electrodes pasted on the both sides of core material. The area of the electrode is smaller than the area of the chip. Comparing with the prior art, the etching technique and the stamping etc. techniques are adopted so as to realize the new structure of the PTC thermistor: the large chip and the small electrodes. The new structure increases the creepage distance between the electrodes, and reduces the arc discharging phenomena happened between the electrodes.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

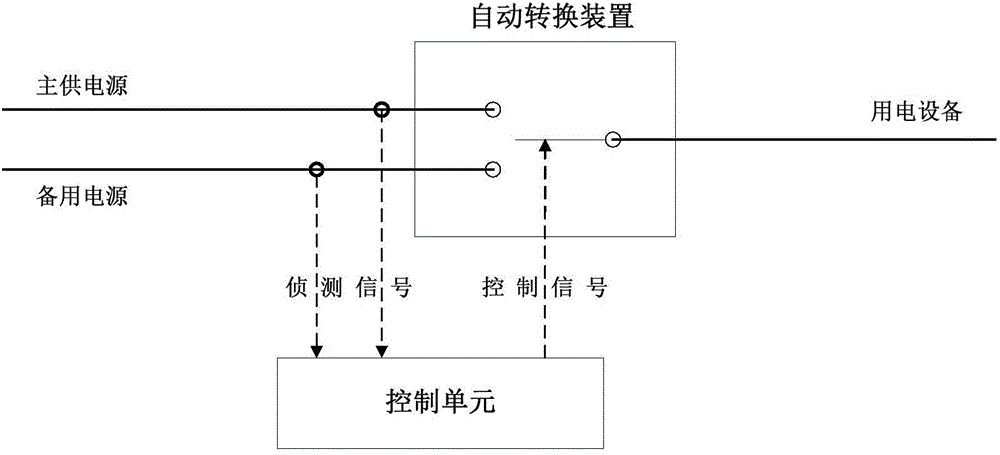

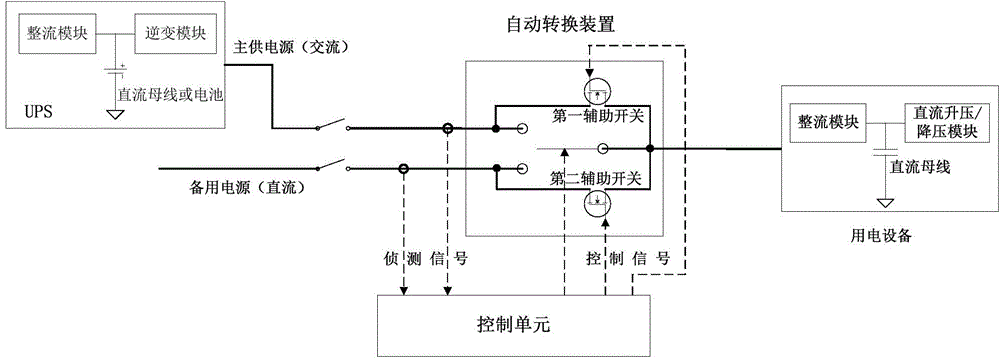

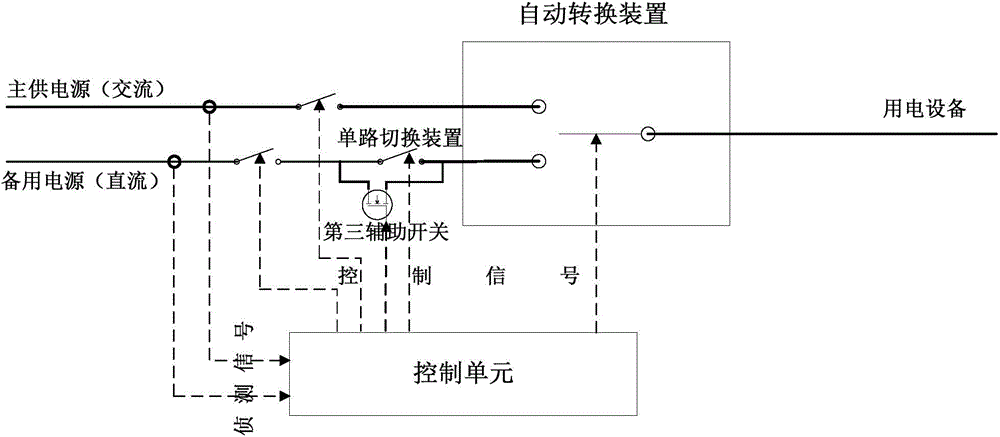

Emergency power supply circuit and power supply circuit conversion method

PendingCN104600834AReduce inverter linksReduce the rectification linkPower network operation systems integrationInformation technology support systemControl signalStandby power

The invention provides an emergency power supply circuit comprising a main power supply circuit, a standby power supply circuit and a double-circuit automatic conversion device connected to the main power supply circuit and the standby power supply circuit. The double-circuit automatic conversion device is connected to electric equipment and a control unit; the control unit is used for sampling and measuring the instantaneous voltage value and phase of the input voltage of the main power supply circuit in real time and computing the control signal transmitting time according to the action time characteristics of the double-circuit automatic conversion device so as to allow the action time point of the double-circuit automatic conversion device to be consistent with the zero time of the input voltage value of the main power supply circuit. The control unit adopts the computed voltage zero crossing time point as the switching time point, the arcing situation is eliminated thoroughly, and the safety and reliability for equipment operation is further guaranteed.

Owner:深圳市昆腾电源科技有限公司

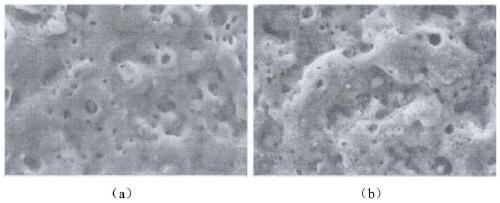

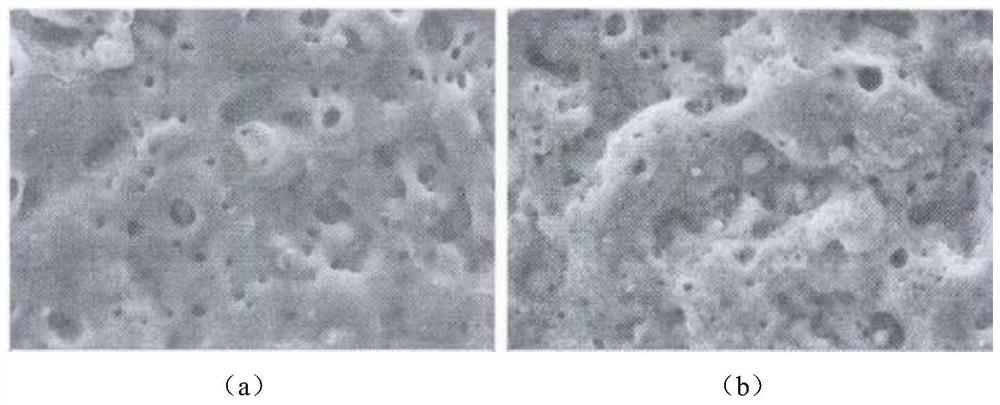

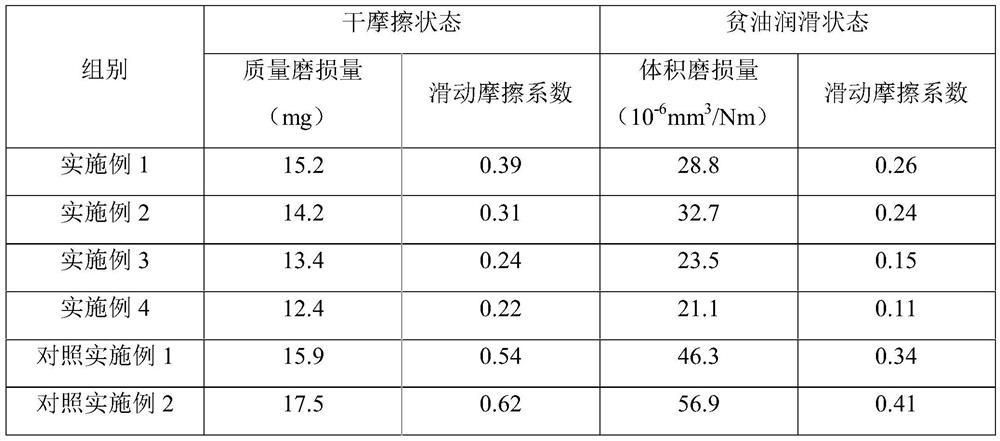

Wear resisting material and preparation method thereof

ActiveCN109868386AImprove wear resistanceImprove surface wear resistanceAnodisationOxide ceramicMicro arc oxidation

The invention discloses a wear resisting material. Aluminum nitride, aluminum oxide, molybdenum disilicide and graphite powder particles are uniformly distributed in an aluminum alloy basal body; a composite micro-arc oxidation layer is distributed on the surface of the aluminum alloy basal body; the aluminum nitride, the aluminum oxide and the molybdenum disilicide are high in hardness to prominently improve the hardness and the wear resistance of the material; and through graphite powder, the antifriction can be improved. Through the composite micro-arc oxidation layer on the surface, the alloy surface wear resistance and corrosion resistance can be effectively improved. Strengthening phases of such elements as Sn, Ru, Sr, Lu, Cu, Mn, Mg, Mo and Fe in an alloy are in dispersion strengthening to improve mechanical performances of the material. In a preparation method, through a mode of attaching mixed powder on a pure aluminum metal wire, the mixed powder is positioned in the center of mother alloy liquid during casting, so that the quick dispersion and the homogenization of micropowder particles are facilitated, and the production efficiency is improved; and micro-arc oxidation film forming parameters and conditions are optimized, so that the hardness and the smoothness degree of oxide ceramic films are improved, the film thickness is reduced, and the wear resistance of the material is effectively improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

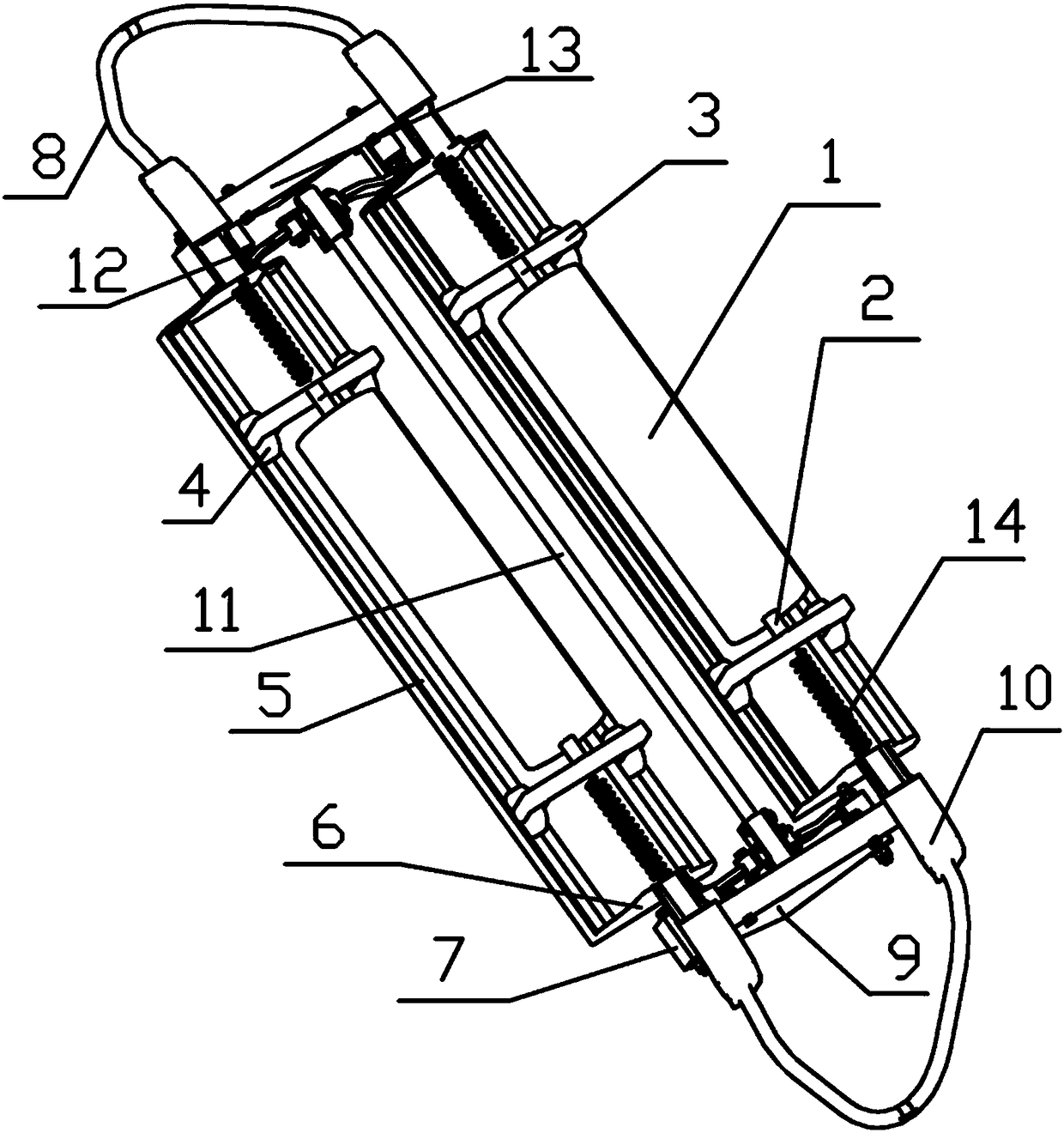

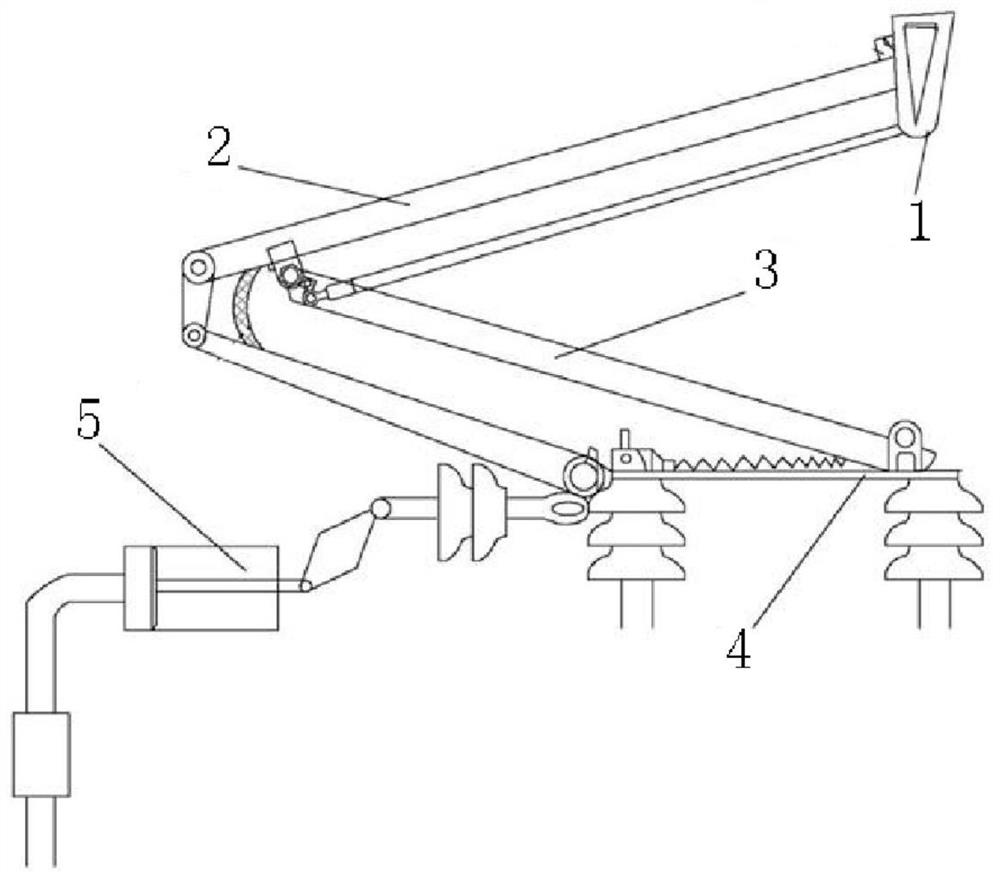

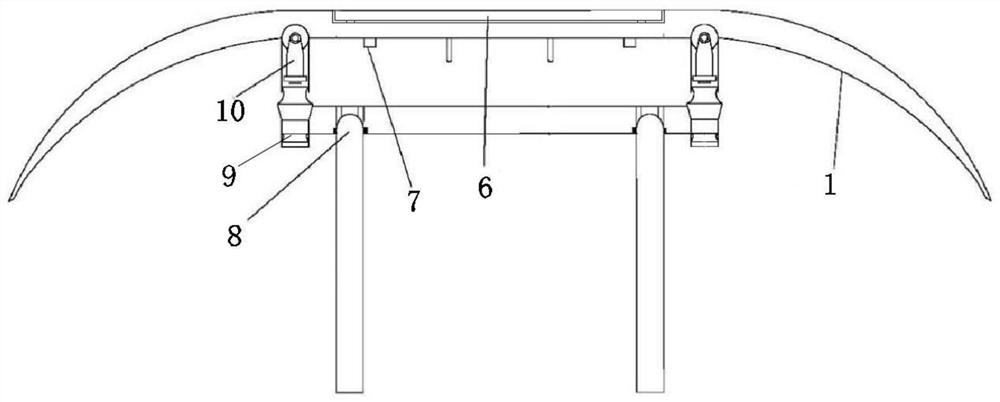

Intelligent pantograph

ActiveCN111267624AImprove automation performanceExtended service lifeRailway vehiclesPower current collectorsControl engineeringSlide plate

The invention discloses an intelligent pantograph, which relates to the technical field of railway electric locomotives. The intelligent pantograph comprises an insulating upper arm, a wing-shaped pantograph head, a controller, an acceleration sensor, a pressure sensor and a temperature sensor, the wing-shaped pantograph head is provided with a main flap, an auxiliary flap and a sliding plate, andthe wing-shaped pantograph head is connected above the insulating upper arm through an intelligent lifting support frame; a main steering engine and an auxiliary steering engine are arranged in the airfoil bow head; and the rotating part of the main steering engine is connected with the main flap, the rotating part of the auxiliary steering engine is connected with the auxiliary flap, and the intelligent lifting supporting frame, the main steering engine and the auxiliary steering engine are all in signal connection with the controller. The vertical height of the wing-shaped bow head can be adjusted through the intelligent lifting supporting frame, the included angle between the main flap and the horizontal plane can be adjusted through the main steering engine, the included angle betweenthe auxiliary flap and the horizontal plane can be adjusted through the auxiliary steering engine, the adjustment basis is pantograph state information detected by an existing sensor, and then activeadjustment of the posture of the pantograph is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

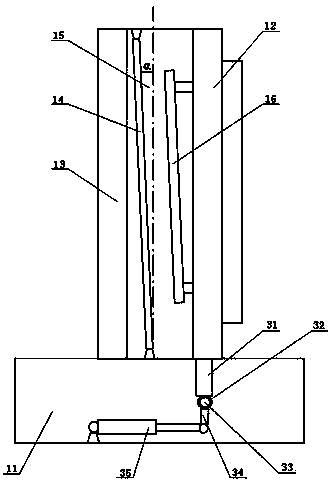

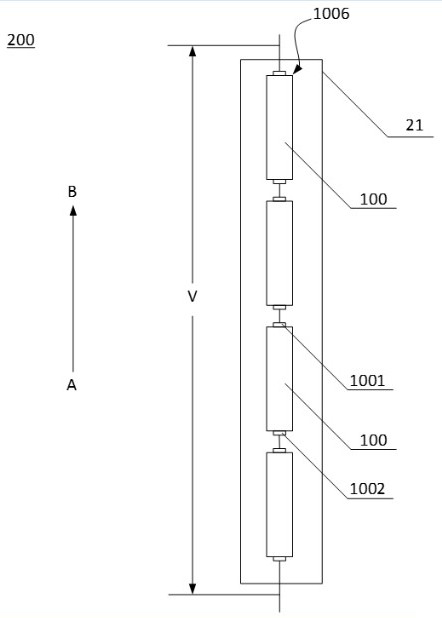

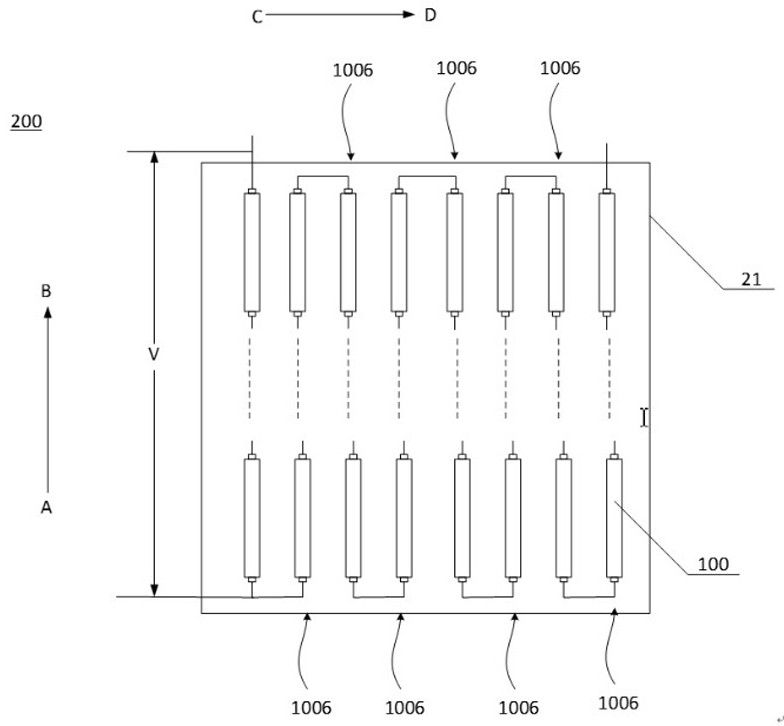

Energy-saving low-radiation glass vertical-type magnetron sputtering production device

InactiveCN103388125AUniform filmStrong adhesionVacuum evaporation coatingSputtering coatingEngineeringFilm coating

The invention discloses an energy-saving low-radiation glass vertical-type magnetron sputtering production device. The energy-saving low-radiation glass vertical-type magnetron sputtering production device comprises multiple film-coating cavity units connected in series. A process isolation cavity is arranged between each adjacent two of the multiple film-coating cavity units. An isolation valve is arranged between each one of the multiple film-coating cavity units and the process isolation cavity adjacent with the film-coated cavity unit. Each one of the multiple film-coating cavity units comprises a base, a target material frame, a backboard seat and a glass frame. The target material frame and the backboard seat are installed on the base and form a film-coating cavity. The target material frame is provided with a target material cathode. An opening / closing device is arranged between the target material frame and the base. The glass frame is arranged in the film-coating cavity, has a vertical structure and forms an angle of 0-10 degrees with a vertical plane. The opening / closing device is driven by hydraulic pressure or air pressure. The glass frame is provided with a glass conveyer. According to the energy-saving low-radiation glass vertical-type magnetron sputtering production device, in energy-saving low-radiation glass production, glass is arranged vertically so that impurities deposited on the surface of the glass are reduced, the damage produced by impurities on a film is reduced, film adhesion is improved, and arc discharge caused by deposition of impurities on the target material cathode is reduced.

Owner:YOUDU FUNCTIONAL FILM MATERIAL YANGZHOU

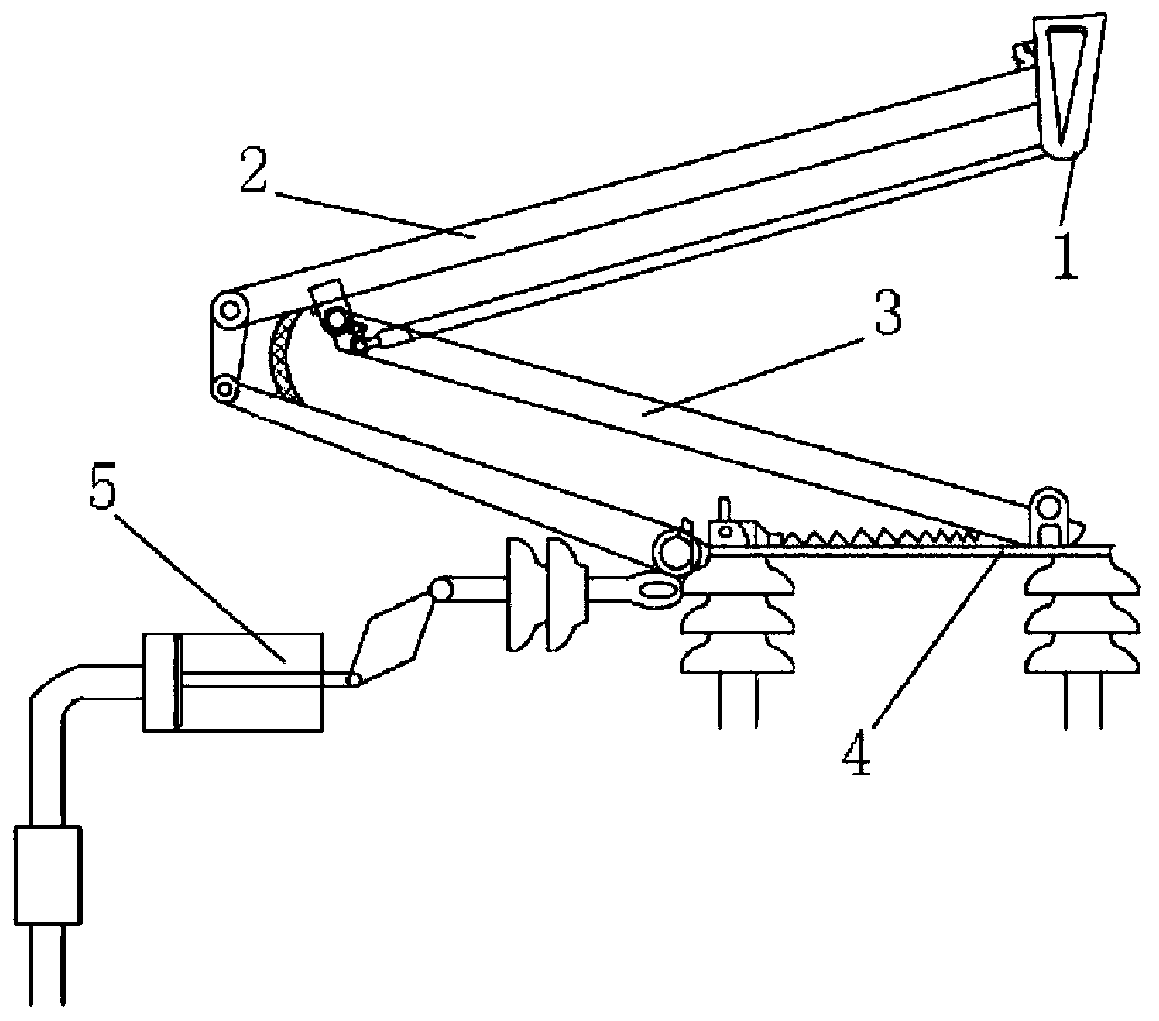

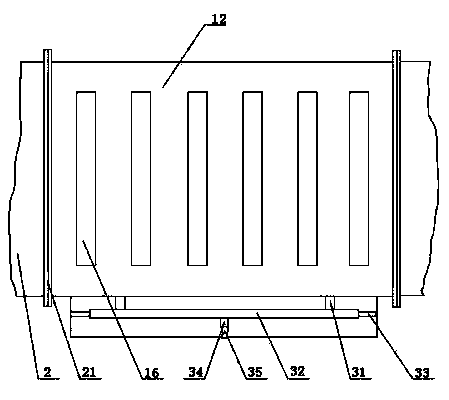

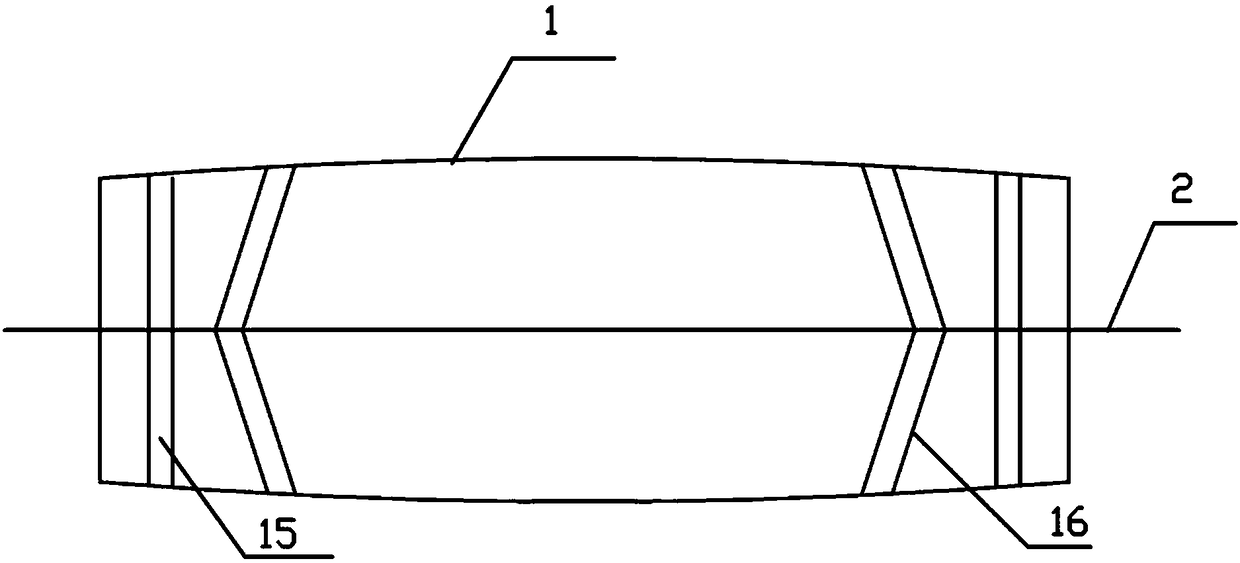

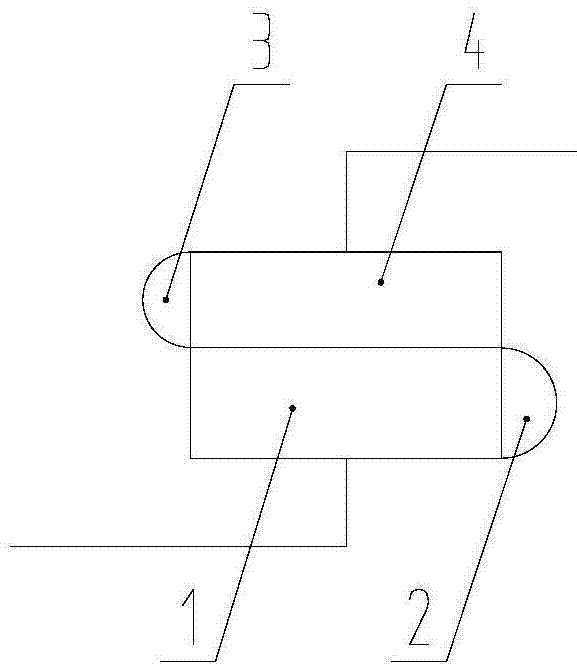

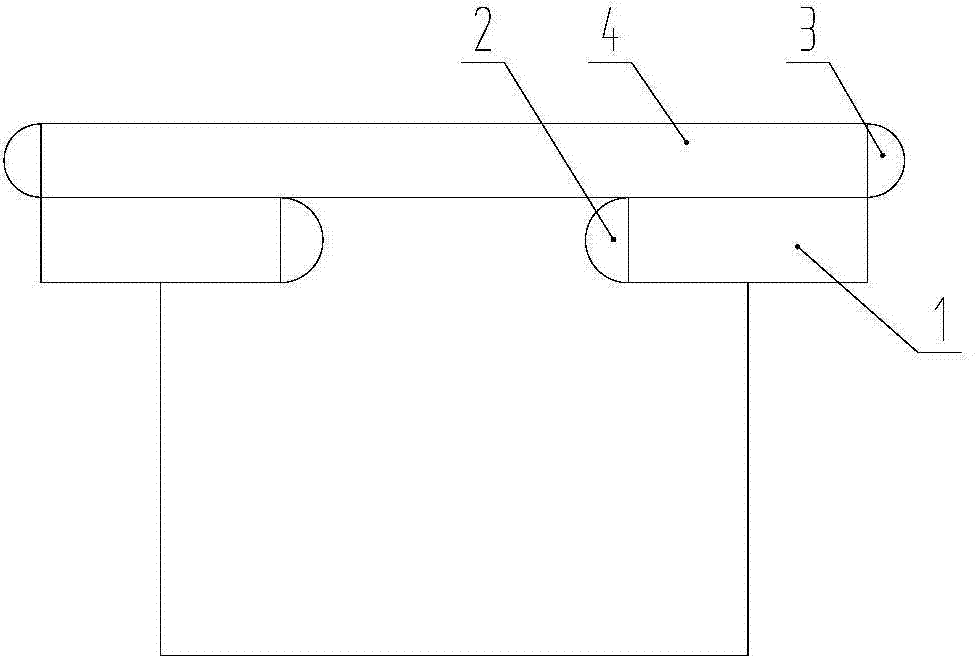

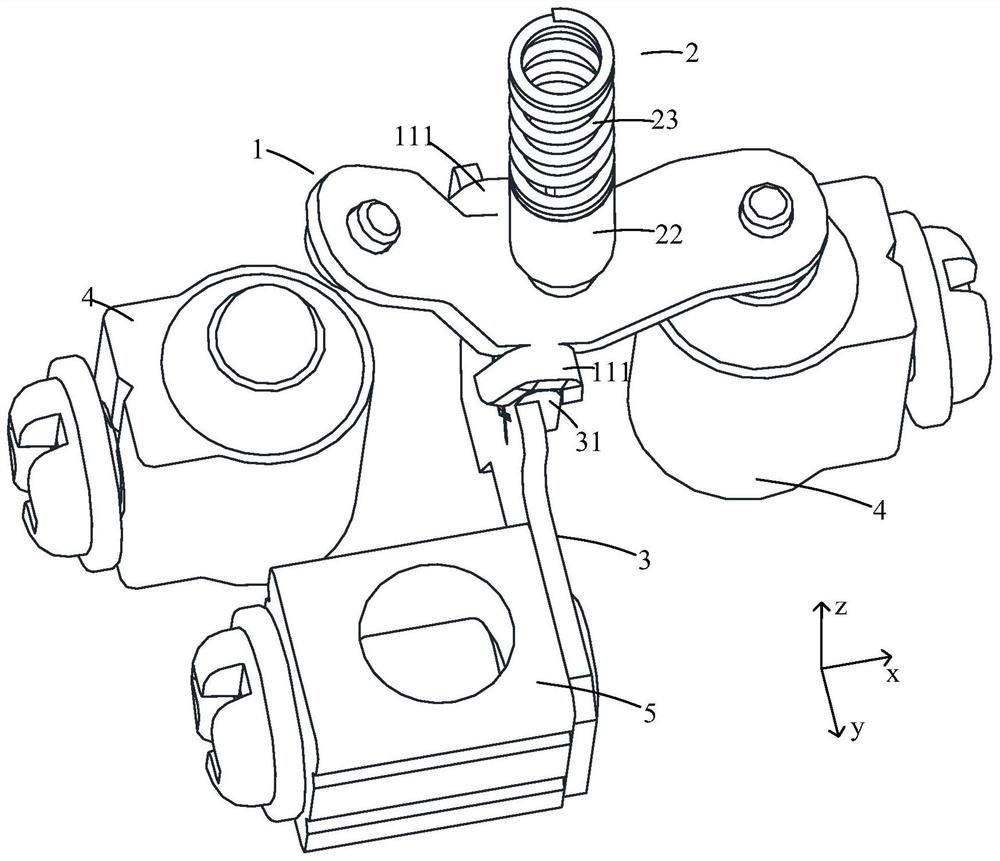

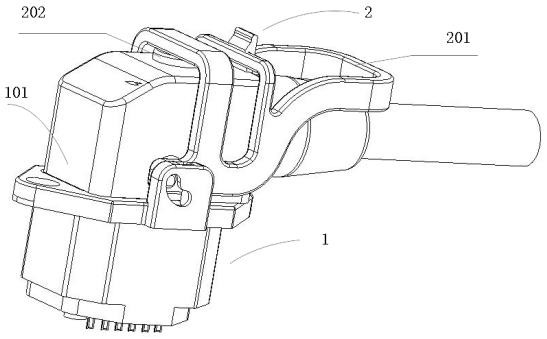

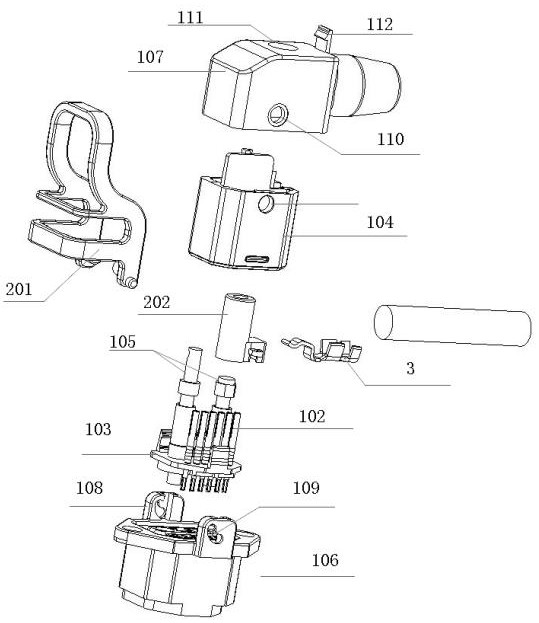

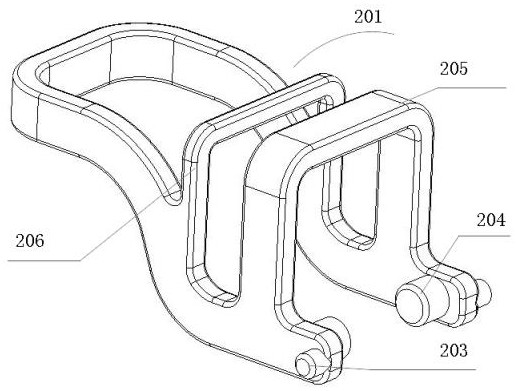

Pantograph head

InactiveCN108275003AReduce arcing phenomenonImprove flow relationshipRailway vehiclesPower current collectorsEngineeringSlide plate

The invention discloses a pantograph head. The pantograph head comprises a supporting structure, a roller structure, a connecting structure and a transverse alignment spring, wherein the roller structure can be in contact with a contact line to achieve the breakover with the contact line and can roll around the axial direction of the contact line; the connecting structure is connected with the roller structure and the supporting structure and enable the roller structure to move on the supporting structure around the radial direction of the contact line; and the transverse alignment spring is arranged on the supporting structure and can apply elastic force to the roller structure, so that the roller structure moves on the radial direction of the contact line and is aligned with the contactline again. According to the pantograph head, the sliding friction of a sliding plate and contact line of the pantograph head is avoided both laterally and longitudinally, the current receiving effectamong bow nets is significantly improved, the maintenance and the repair are simultaneously convenient, the maintenance cost is reduced, and the alignment between the contact line and the pantographhead can be better achieved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

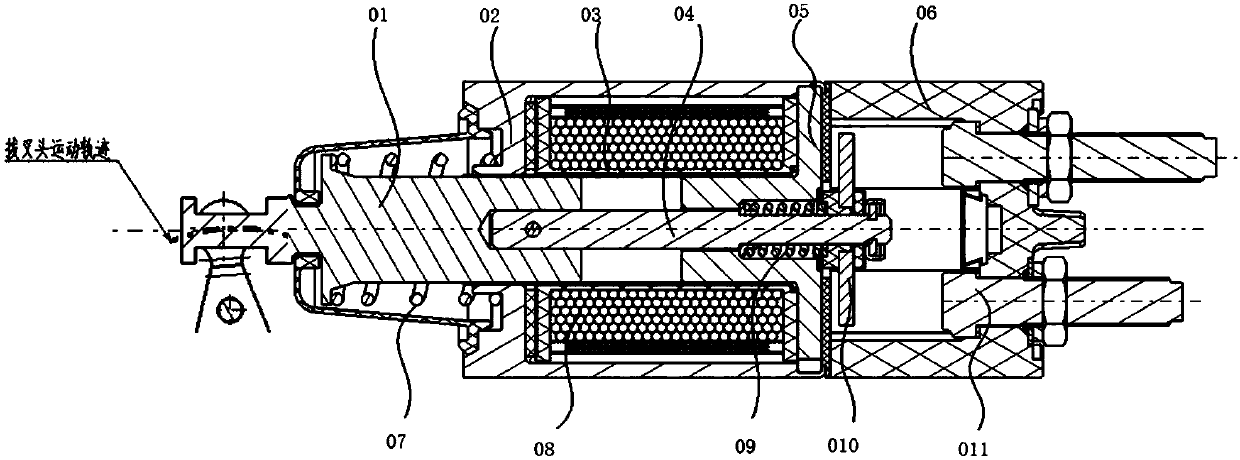

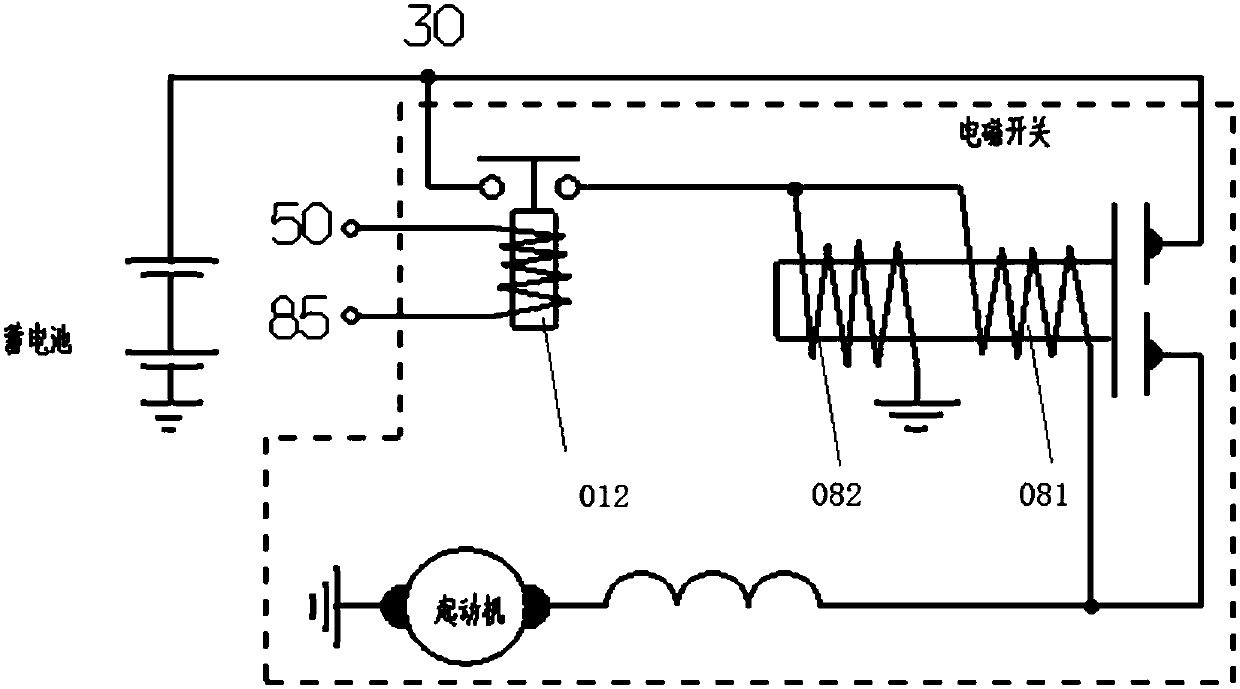

Electromagnetic switch for starter and electromagnetic switch starter

ActiveCN107068490AFit clearance is smallOrientation is accurateElectric motor startersMachines/enginesState of artIron powder

The invention discloses an electromagnetic switch for a starter, belongs to the start technology field of an engine starter and aims to solve a technical problem of contact arc caused by absorption of iron powder by a static contact existing in an electromagnetic switch for a starter in the prior art. The electromagnetic switch comprises a static core, a moving core, a coil, a contact plate, a static contact and a top rod, wherein the contact plate is fixed at one end of the top rod, the moving core is fixed at another end of the top rod, the moving core under the electromagnetic force generated by the coil moves to approach the static core, the contact plate and the static contact are made to realize contact through the top rod, and a bushing is arranged between the static core and the top rod. The electromagnetic switch is advantaged in that not only can the technical problem of contact arc caused by absorption of iron powder by the static contact existing in the electromagnetic switch for the starter in the prior art be solved, cleanliness of the contact is guaranteed, but also guiding precision of the top rod, high matching precision, low wear rate and long service life are realized.

Owner:SHANGHAI VALEO AUTOMOTIVE ELECTRICAL SYST

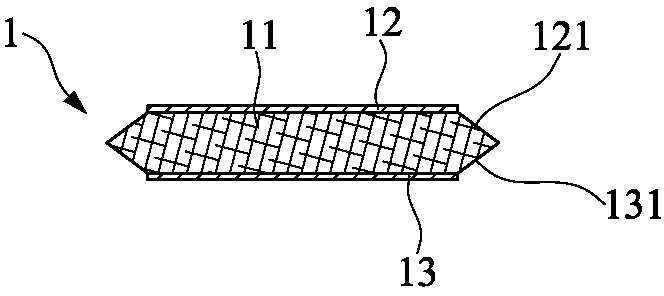

High voltage resisting level high molecular PTC (Positive Temperature Coefficient) thermistor and manufacturing method thereof

InactiveCN103021604AImprove withstand voltage characteristicsImprove performanceResistor terminals/electrodesPositive temperature coefficient thermistorsTool bitMetal foil

The invention discloses a high voltage resisting level high molecular PTC (Positive Temperature Coefficient) thermistor and a manufacturing method thereof. The thermistor consists of a high molecular core material with high PTC characteristic and metal foil electrode layers attached to both sides of the core material. A bevel or an arc-shaped face can be formed in the periphery of a sheet attached to the metal foil electrode layers by way of cutting the sheet with tools with different tool bits in shape. The creep distance between two copper foil electrodes is longer than the original linear distance, so that the withstand voltage performance of the product is improved, the arc discharge between the electrodes is effectively reduced, and probability of abnormal situations such as breakdown and combustion is effectively reduced. The bevel or the arc-shaped face is directly cut on the high voltage resisting level high molecular PTC thermistor sheet, so that the manufacturing process is simple and meanwhile, no additional manufacturing steps are increased, the cost is lowered and the performance is improved, and the thermistors can be quickly and economically produced in a large scale.

Owner:厦门莱纳电子有限公司

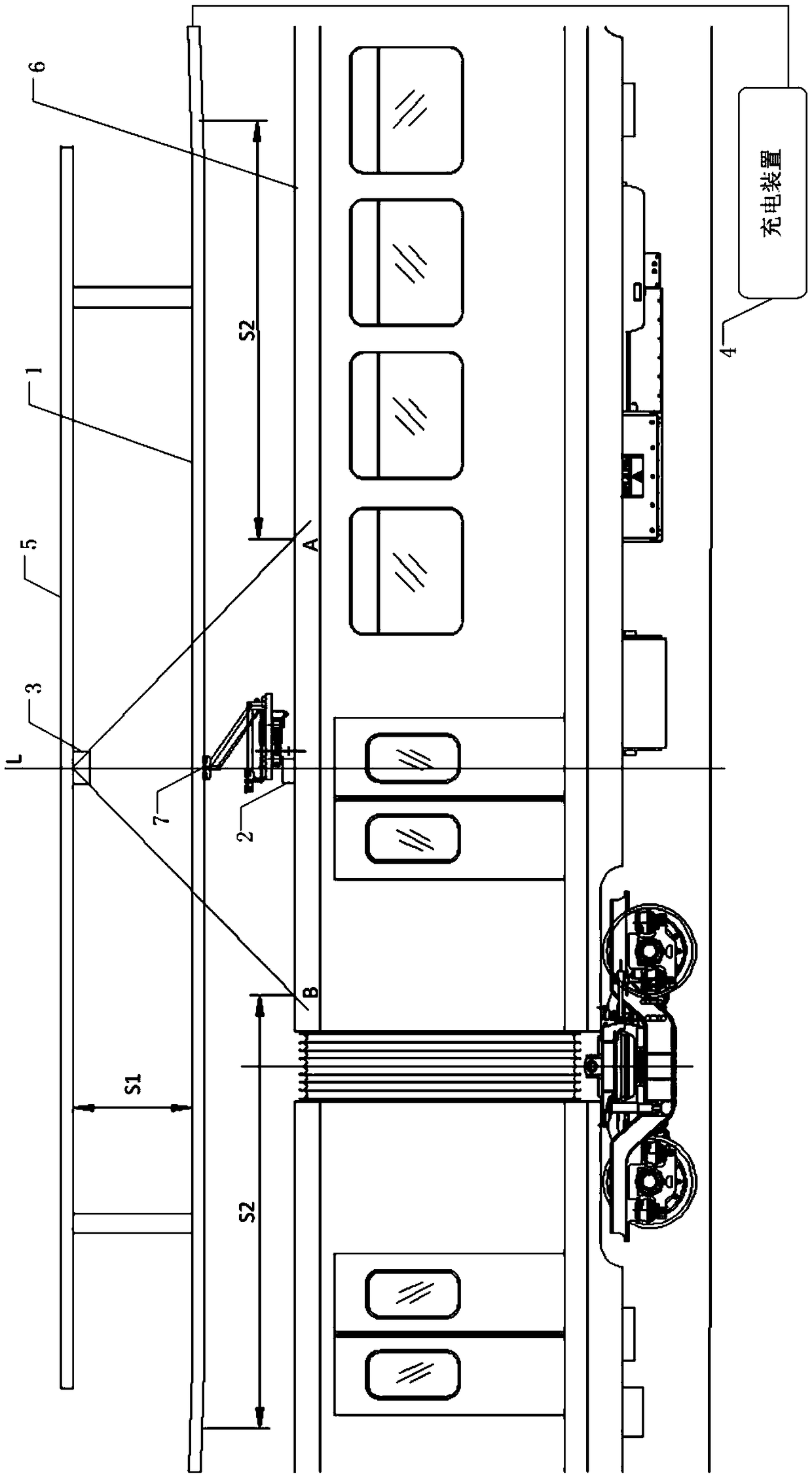

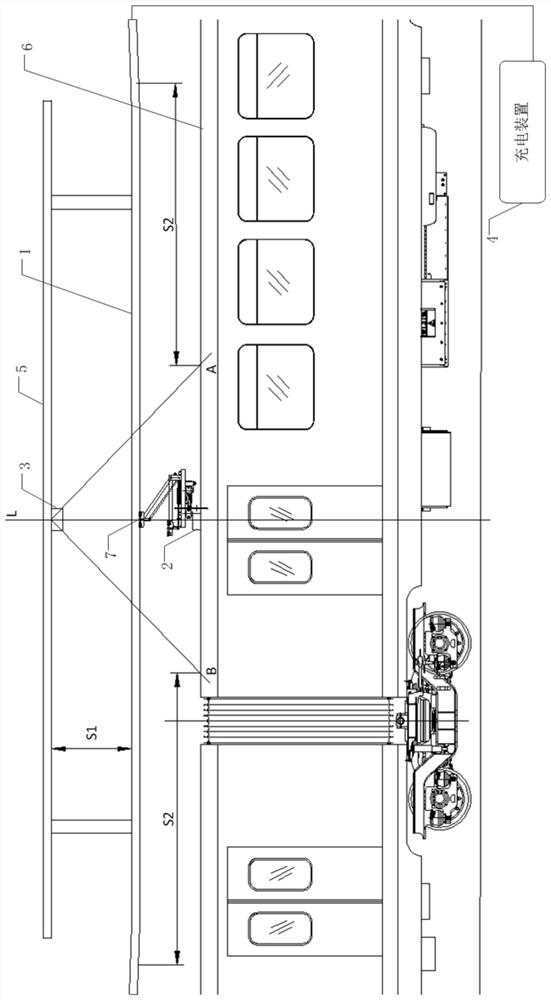

An energy storage type vehicle and an automatic charging detection system thereof

ActiveCN109050323AReduce the risk of failureReduce arcing phenomenonRailway vehiclesElectric vehicle charging technologyCharge detectionEngineering

The invention discloses an energy storage type vehicle and an automatic charging detection system thereof, which comprises a conductive rail, a signal transmitter, a signal receiver and a charging device. Wherein one of a signal receiver and a signal transmitter is disposed within the station, ehe other one is mounted on the roof of the vehicle. Because the signal receiver and the signal transmitter can transmit the signal effectively within a certain range, the signal transmission state between the two devices is different with the moving of the vehicle, so that the signal entering and leaving the station of the vehicle can be detected. In accordance with that prior art, As that detection device are respectively arranged at the inbound end and the outbound end, In this system, a set of devices can be used to complete the detection, which reduces the risk of failure of a certain detection device, and then reduces the occurrence of arc phenomenon. In addition, the signals of incoming and outgoing stations are generated by this set of devices, and no matter where they are located; no signal overlap will be generated. Therefore, the difficulty of installation position is reduced.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

A kind of wear-resistant material and preparation method thereof

The invention discloses a wear-resistant material, in which aluminum nitride, aluminum oxide, molybdenum disilicide, and graphite powder particles are evenly distributed in an aluminum alloy matrix, and a composite micro-arc oxidation layer is distributed on the surface of the aluminum alloy matrix, aluminum nitride, oxide Aluminum and molybdenum disilicide have high hardness, which can significantly improve the hardness and wear resistance of the material, and graphite powder can improve friction reduction. The composite micro-arc oxidation layer on the surface can effectively improve the wear resistance and corrosion resistance of the alloy surface. Sn, Ru, Sr, Lu, Cu, Mn, Mg, Mo, Fe and other elements in the alloy strengthen phase dispersion strengthening to improve the mechanical properties of the material. In the preparation method, the mixed powder is adhered to the pure aluminum wire, so that the mixed powder is located in the center of the master alloy liquid during casting, which is conducive to the rapid diffusion and homogeneity of the micro-powder particles, improves production efficiency, and optimizes the parameters of micro-arc oxidation film formation And conditions, improve the hardness and smoothness of the oxide ceramic film, reduce the film thickness, and effectively improve the wear resistance of the material.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

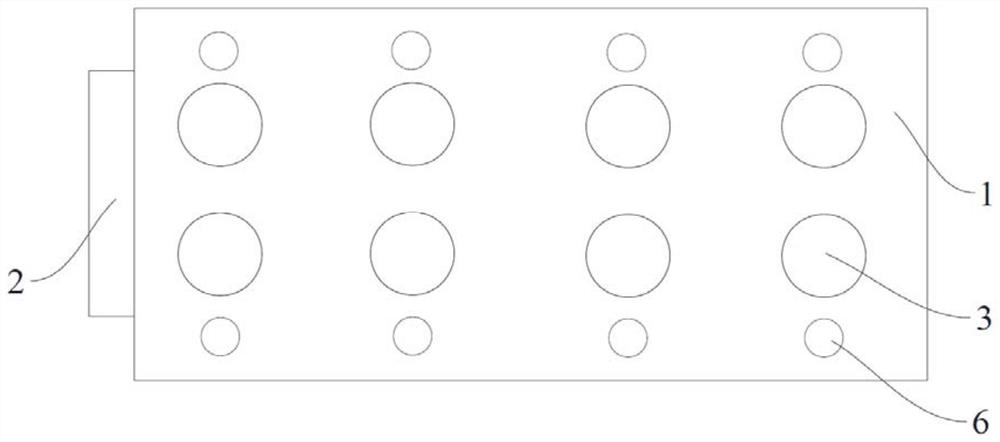

Battery pack and electric vehicle

PendingCN113328208AReduce voltagePrevent high voltage breakdownElectric devicesCurrent conducting connectionsAutomotive engineeringElectrical battery

The invention provides a battery pack and an electric vehicle. The battery pack comprises at least one battery unit, the battery unit comprises at least one battery string, the battery string comprises one or at least two single batteries, the voltage difference between the two ends of the battery string is less than or equal to 60V, and when the battery string comprises at least two single batteries, the single batteries in the battery string are sequentially arranged along the first direction, and the first direction is parallel to the direction from the tail of the vehicle to the head of the vehicle, so that through the scheme, the voltage generated by the battery pack when the battery string is short-circuited can be relatively reduced, the probability that the battery pack catches fire and explodes is reduced, meanwhile, the arcing phenomenon can be reduced, and the safety of the battery pack is improved.

Owner:BYD CO LTD

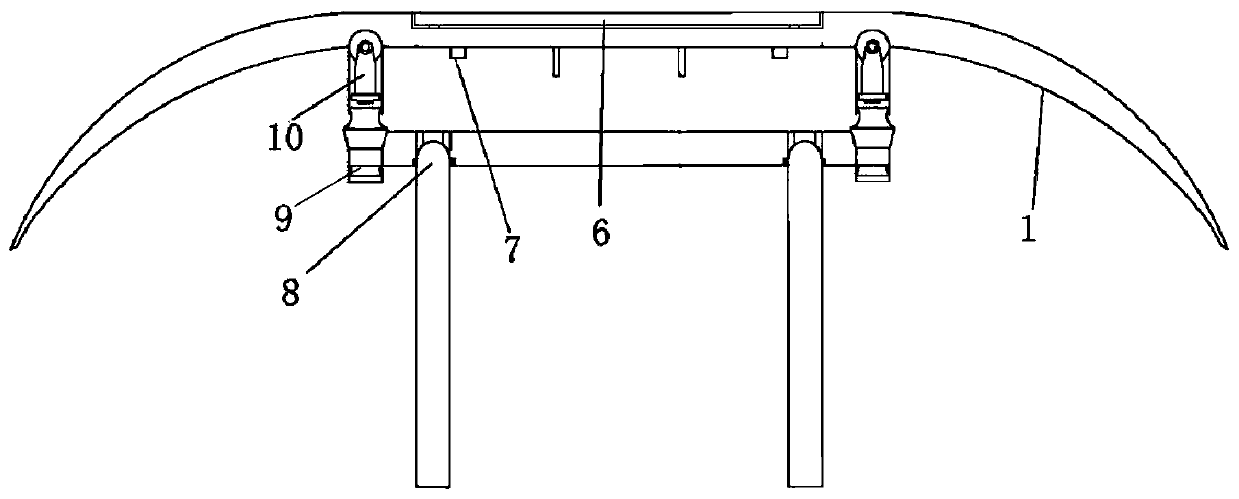

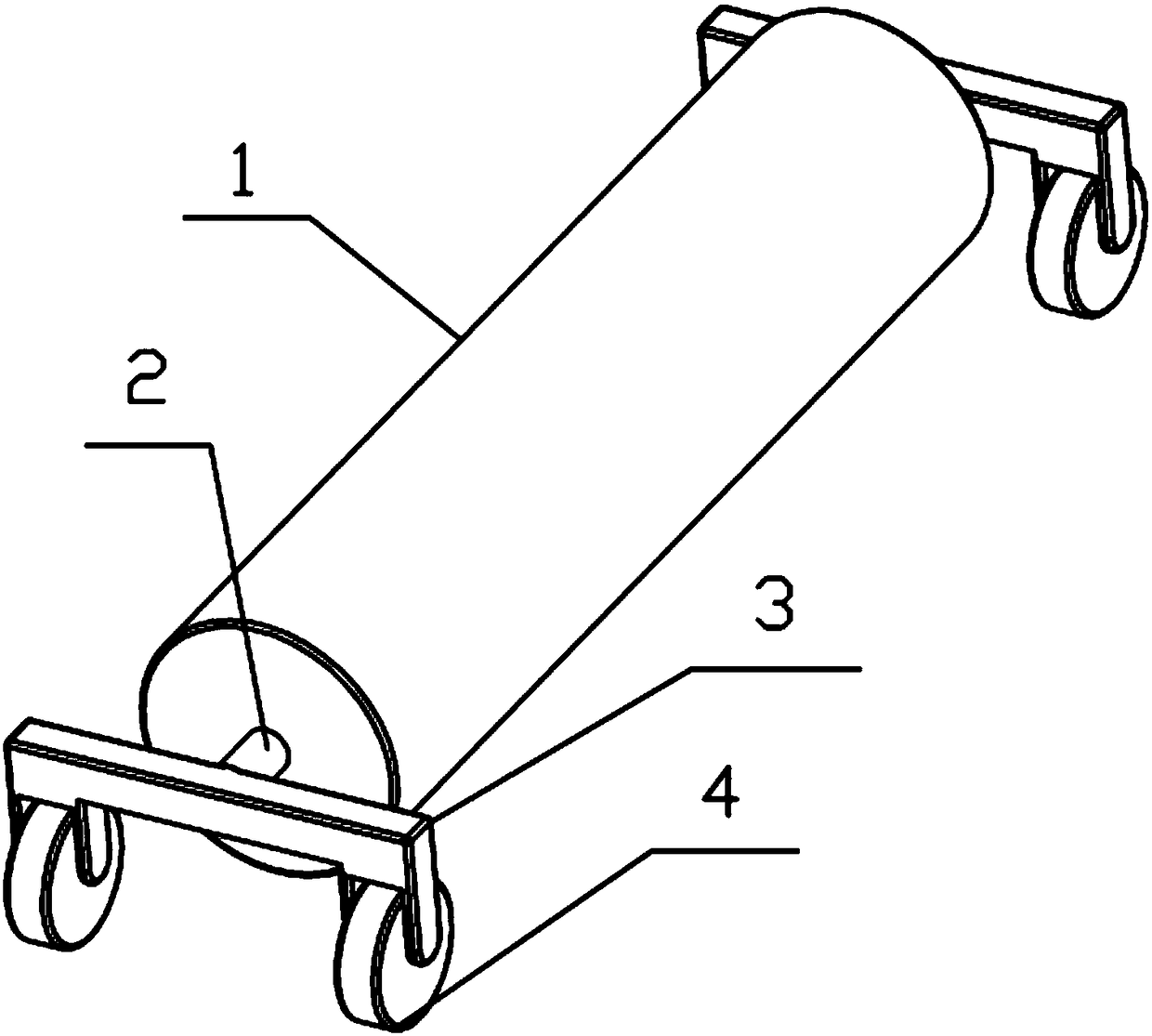

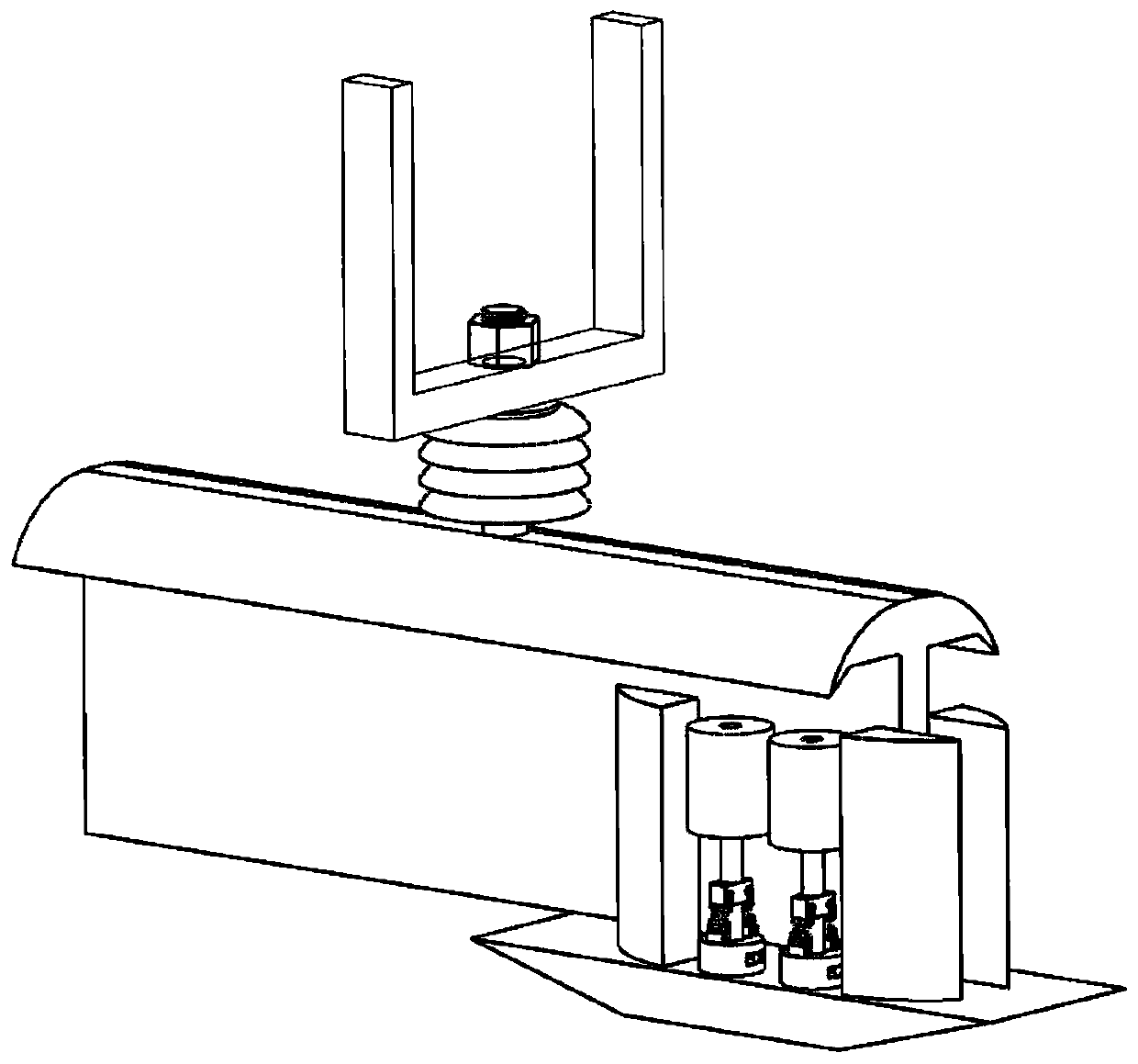

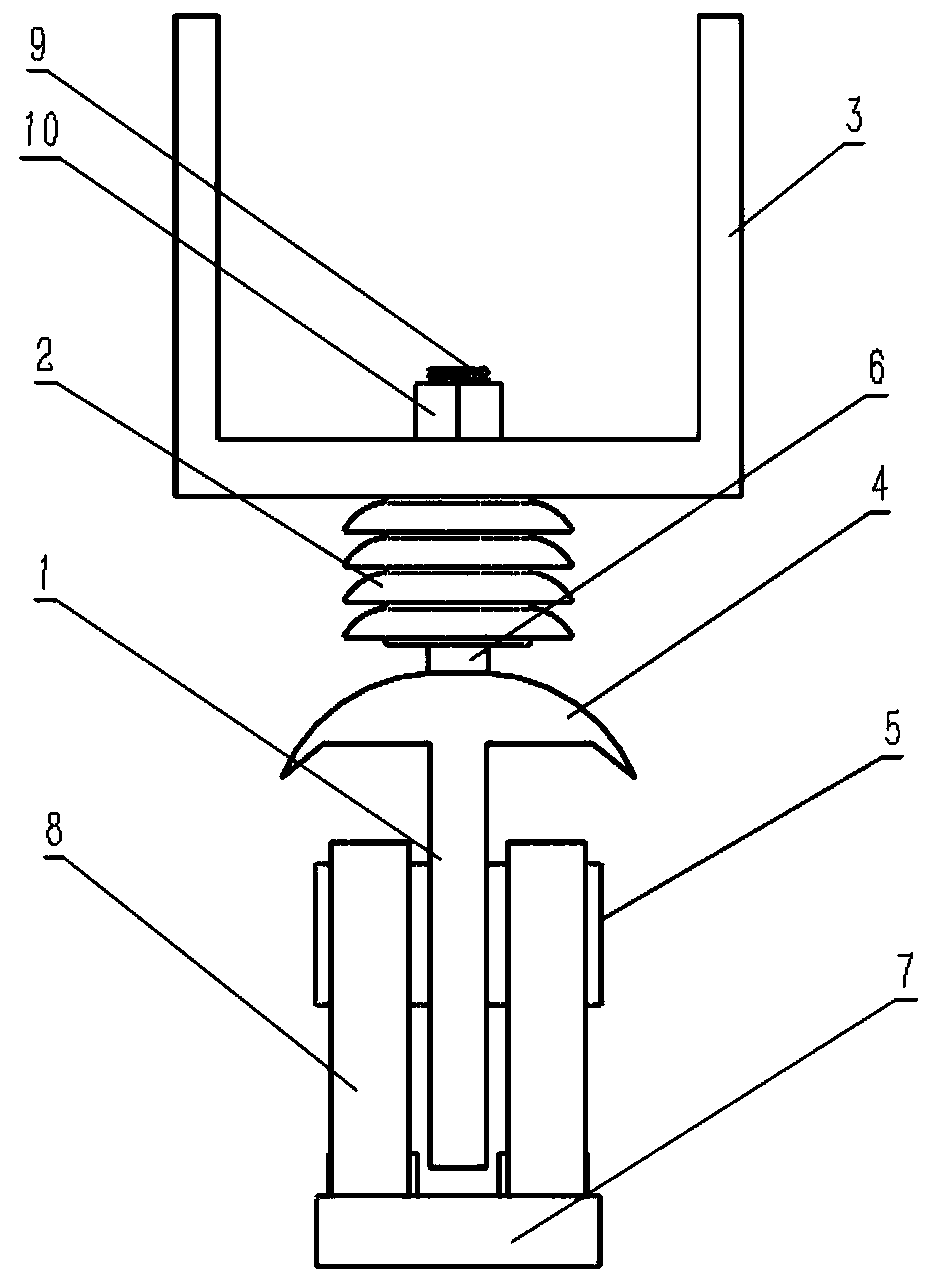

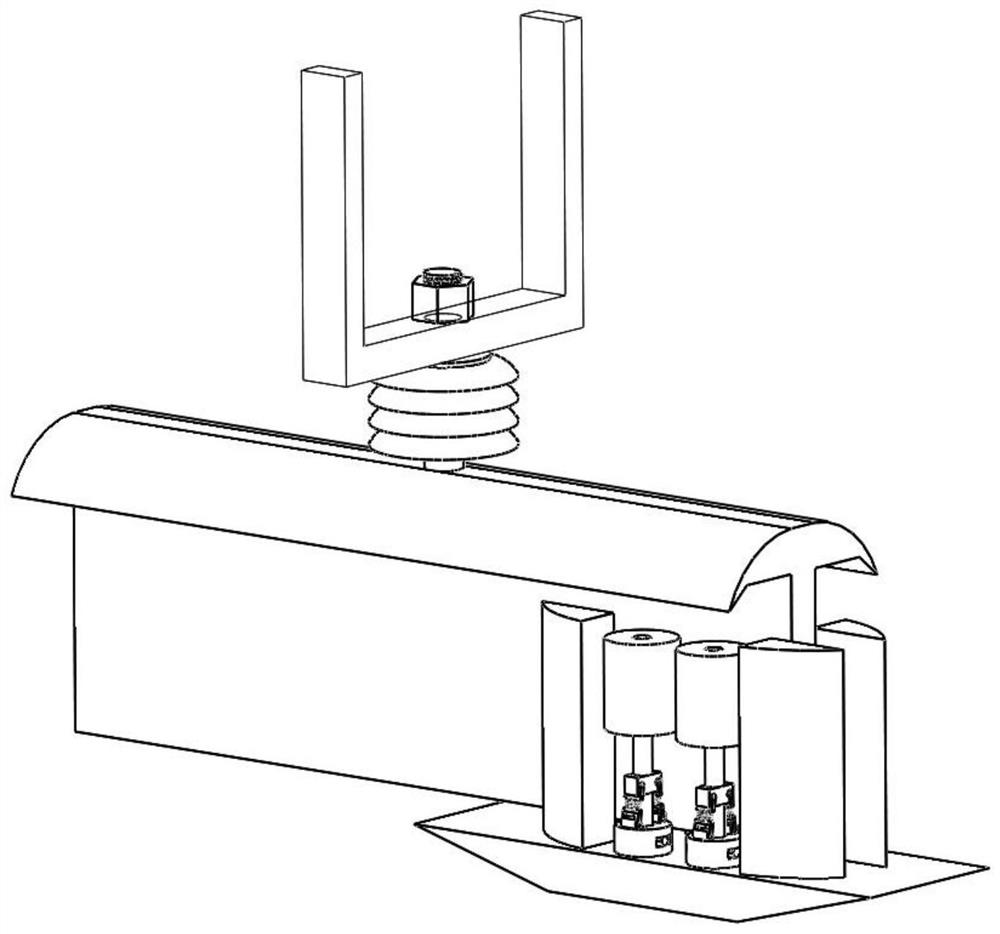

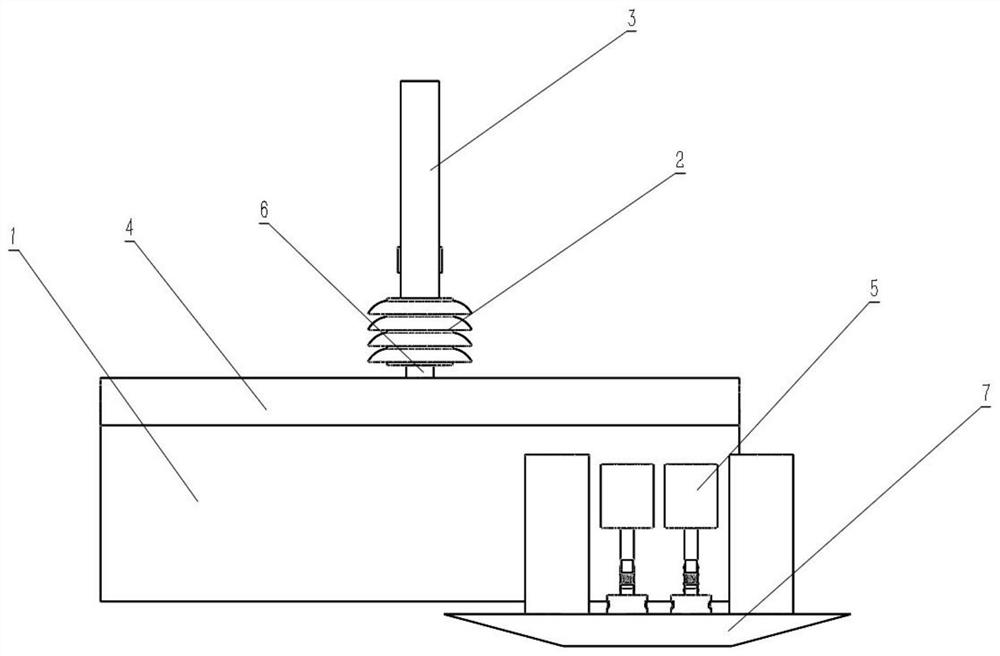

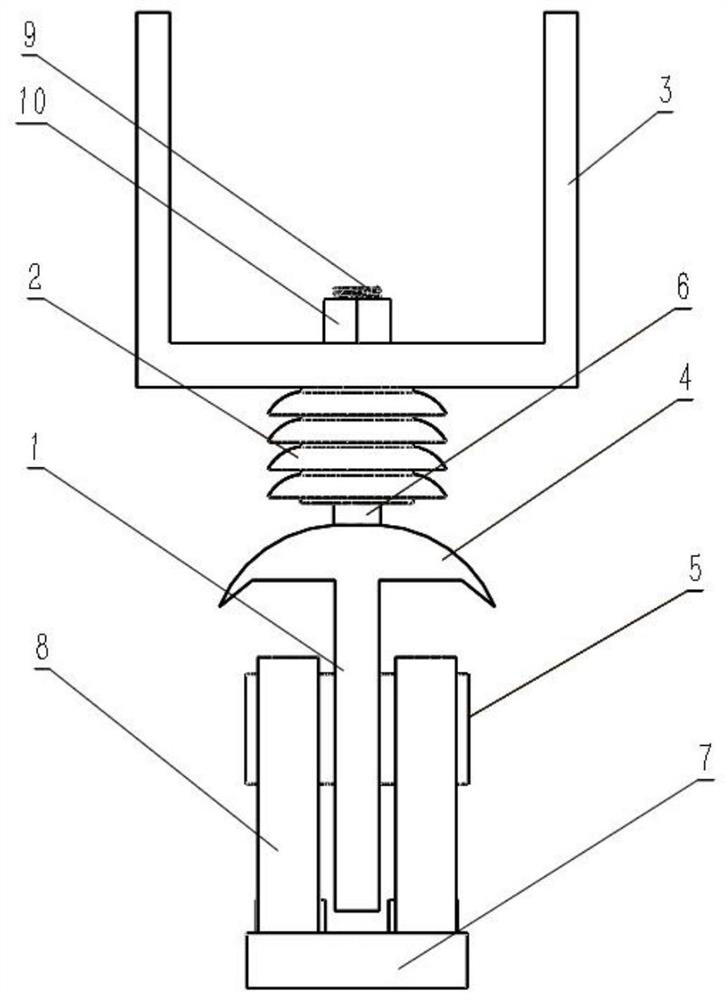

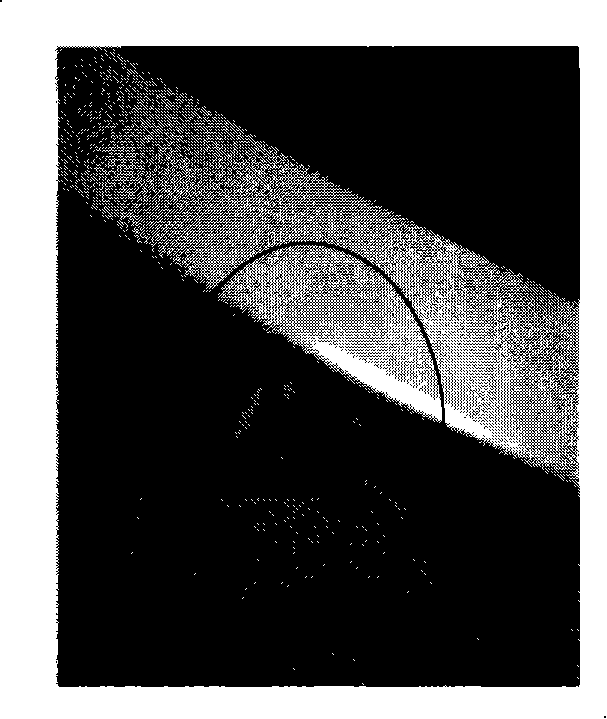

Anti-icing multi-roller rigid overhead current-feed device

ActiveCN110667392AEfficient removalThe overall benefit of deicing is not highPower current collectorsStructural engineeringOverhead line

The invention relates to an anti-icing multi-roller rigid overhead current-feed device. The device is composed of a T-shaped rigid overhead line system and a de-icing current-feed mechanism, the rigidoverhead line system is formed by correspondingly fixing a current-feed rail with T-shaped cross section on a plurality of U-shaped overall supports through insulators, the de-icing current-feed mechanism is composed of a lower de-icing blade, a front side de-icing blade, a rear side de-icing blade and two or more current-feed cylinders, wherein the left side and right side of the upper surface of the lower de-icing blade are provided with the front side de-icing blade and the rear side de-icing blade respectively which are symmetrical in shape and consistent in structure, a roller body of each current-feed roller is formed by fixing two bearings on a main shaft, the lower parts of the main shafts are movably inserted into limiting rings, limiting shafts fixed on the bottom surfaces of the main shafts form the rolling fit with the bottom surfaces of blind holes of the limiting rings, and the two sides of the main shafts of the rollers are correspondingly provided with elastic mechanisms. According to the anti-icing multi-roller rigid overhead current-feed device, ice coating on the overhead line system can be effectively eliminated in real time, and the device has the advantage ofensuring stable current feed of a pantograph.

Owner:SOUTHWEST JIAOTONG UNIV

An anti-icing multi-roller rigid contact current receiving device

ActiveCN110667392BEfficient removalThe overall benefit of deicing is not highPower current collectorsContact networkStructural engineering

An anti-icing multi-roller rigid contact current receiving device is composed of a "T"-shaped rigid contact net and a deicing current receiving mechanism. It is formed on a U-shaped integral bracket; the deicing and current-receiving mechanism is: the left and right sides of the upper surface of the lower deicing blade are respectively provided with front and rear deicing blades with the same shape and structure, and two or more current-receiving rollers, each receiving current. The drum of the drum is fixed on the main shaft through two bearings. The bottom of the main shaft is movably inserted into the limit ring, the limit shaft fixed on the bottom surface of the main shaft forms a rolling fit with the bottom surface of the blind hole of the limit ring, elastic mechanisms are respectively provided on both sides of the drum main shaft, the invention can effectively remove ice on the contact net in real time, It has the advantage of ensuring that the electrician can receive the current stably.

Owner:SOUTHWEST JIAOTONG UNIV

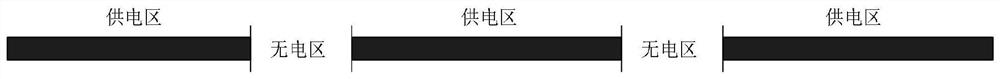

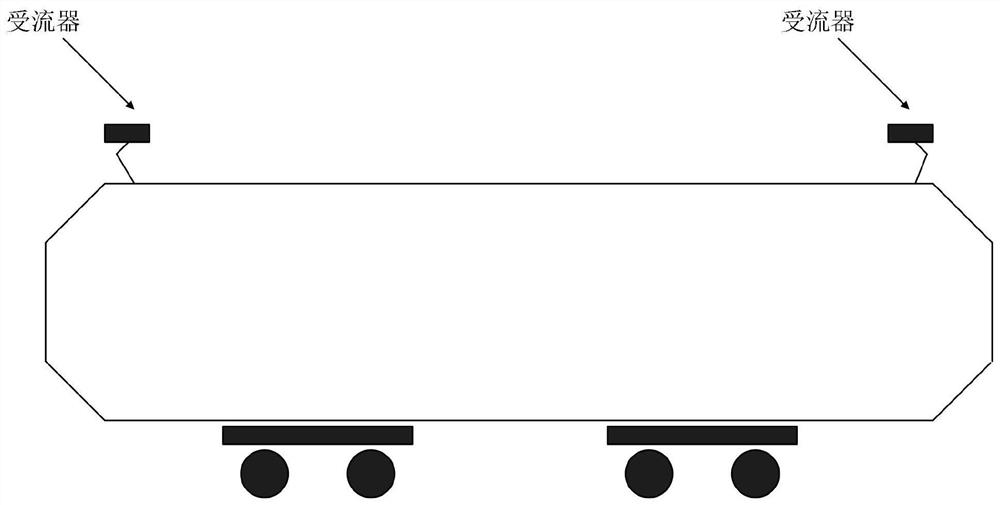

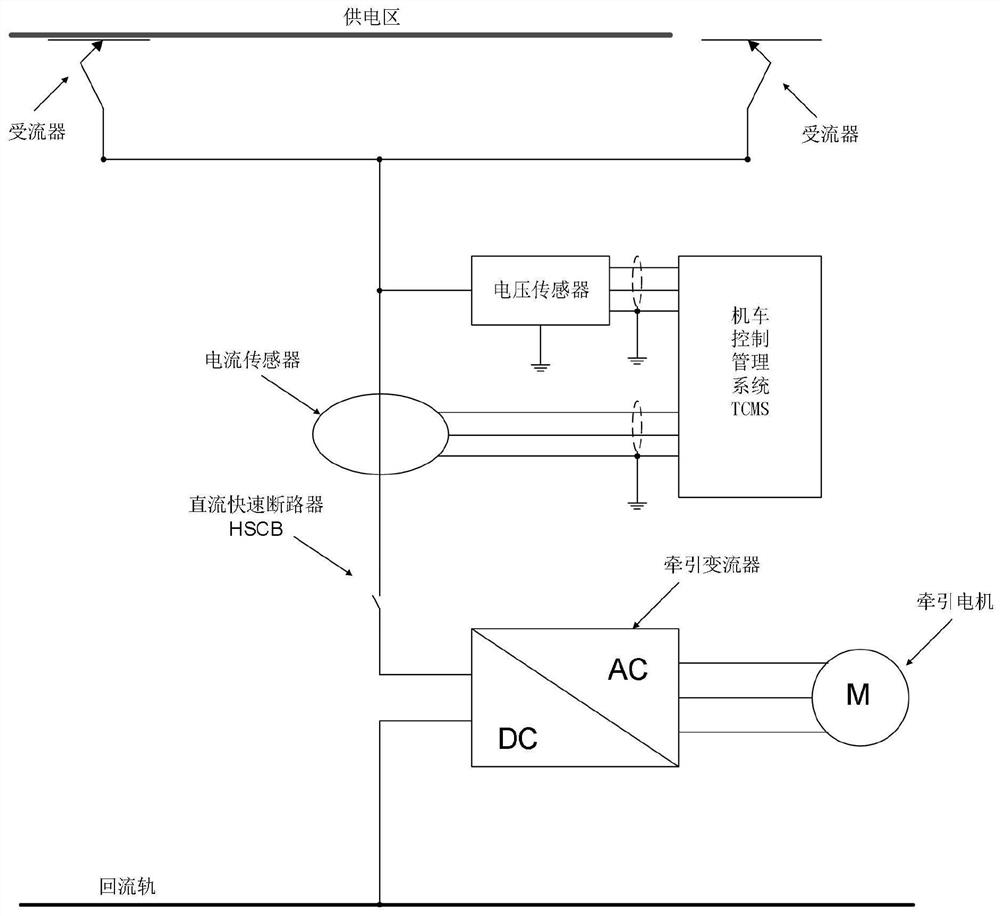

Power supply control system and power supply control method for locomotive

ActiveCN111016674BReduce arcing phenomenonReduce adverse effectsElectric devicesElectric propulsionControl systemPower grid

This application discloses a power supply control system and power supply control method for a locomotive. During the operation of the locomotive, the electric energy is obtained from the catenary through two current receivers, and according to the current value flowing through the two current receivers and the input of the intermediate circuit side voltage value to determine whether the front end of the locomotive enters the dead zone. When it is determined that the front end of the locomotive enters the dead zone, the rear receiver of the locomotive has not yet entered the dead zone, and the locomotive can still obtain power from the catenary. At this time Controlling the unloading of the converter can reduce the possibility of pantograph-catenary arcing when the rear-end current receiver of the locomotive enters the non-electric zone, and even avoid pantograph-catenary arcing, thereby reducing the impact on the locomotive equipment and the power grid. adverse effects of the device.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

A pantograph bow head

ActiveCN108177529BImprove flow relationshipEliminate uneven defectsRailway vehiclesPower current collectorsClassical mechanicsEngineering

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

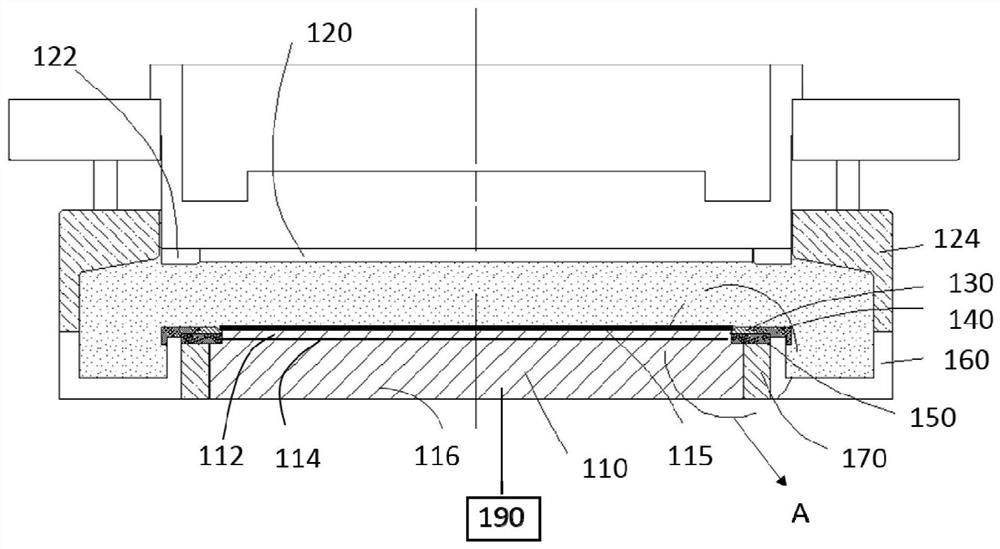

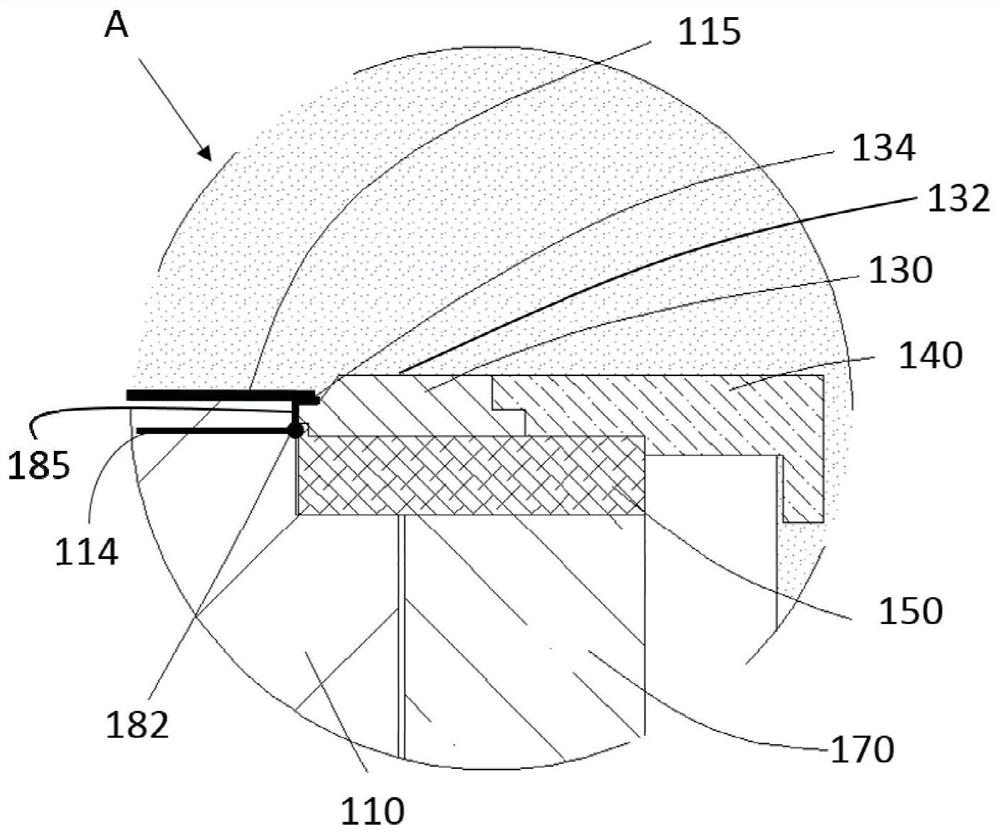

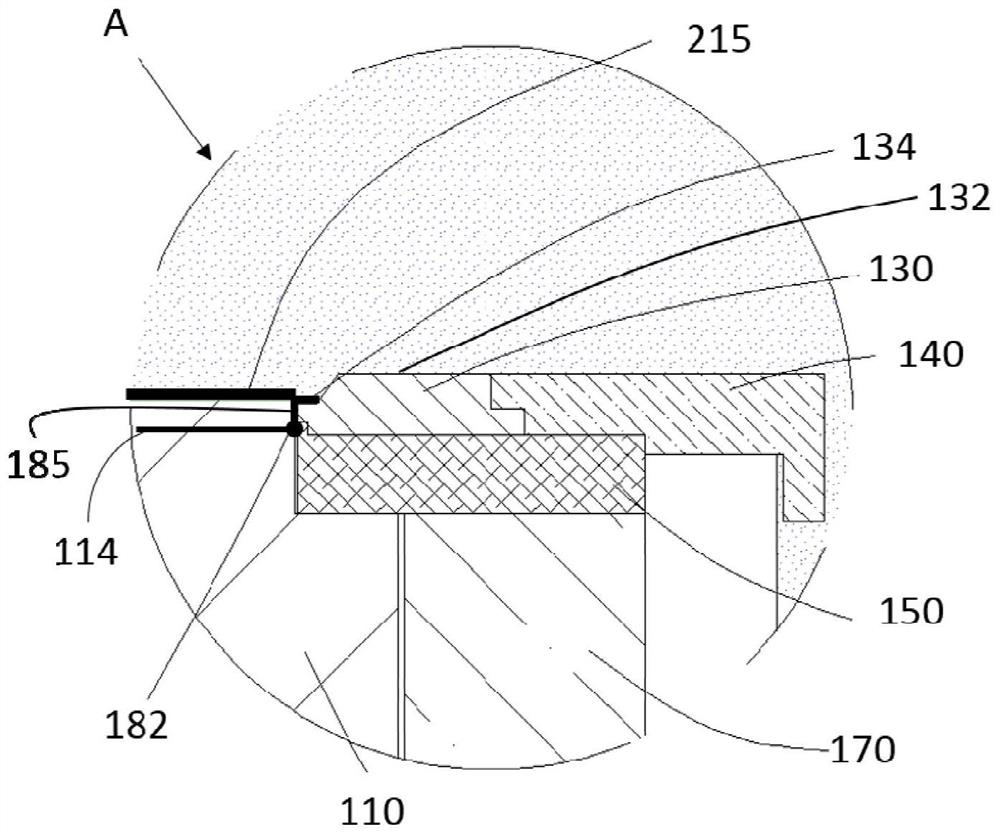

Plasma processing device and plasma processing method

PendingCN114695046AReduce damageReduce arcing phenomenonElectric discharge tubesRadio frequencyMechanical engineering

The invention discloses a plasma processing device and method, and the device comprises a reaction chamber, and the reaction chamber comprises a gas inlet device which is used for conveying clean gas to the reaction chamber; the radio frequency power supply is used for dissociating the clean gas into clean plasma; a cleaning wafer having a first diameter; and the electrostatic chuck is used for bearing the cleaning wafer and has a second diameter, and the difference value between the first diameter and the second diameter is smaller than or equal to + / -0.5 mm. In the cleaning step, the cleaning wafer with the size close to that of the electrostatic chuck 110 is adopted to cover the surface of the electrostatic chuck, the damage degree of cleaning plasma to the upper surface of the electrostatic chuck can be effectively reduced, meanwhile, the cleaning wafer cannot shield the second upper surface 134 of the focusing ring and a gap between the focusing ring and the electrostatic chuck, and the cleaning efficiency is improved. Sediments on the second upper surface of the focusing ring and in the gap can be effectively removed by the cleaning plasma.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

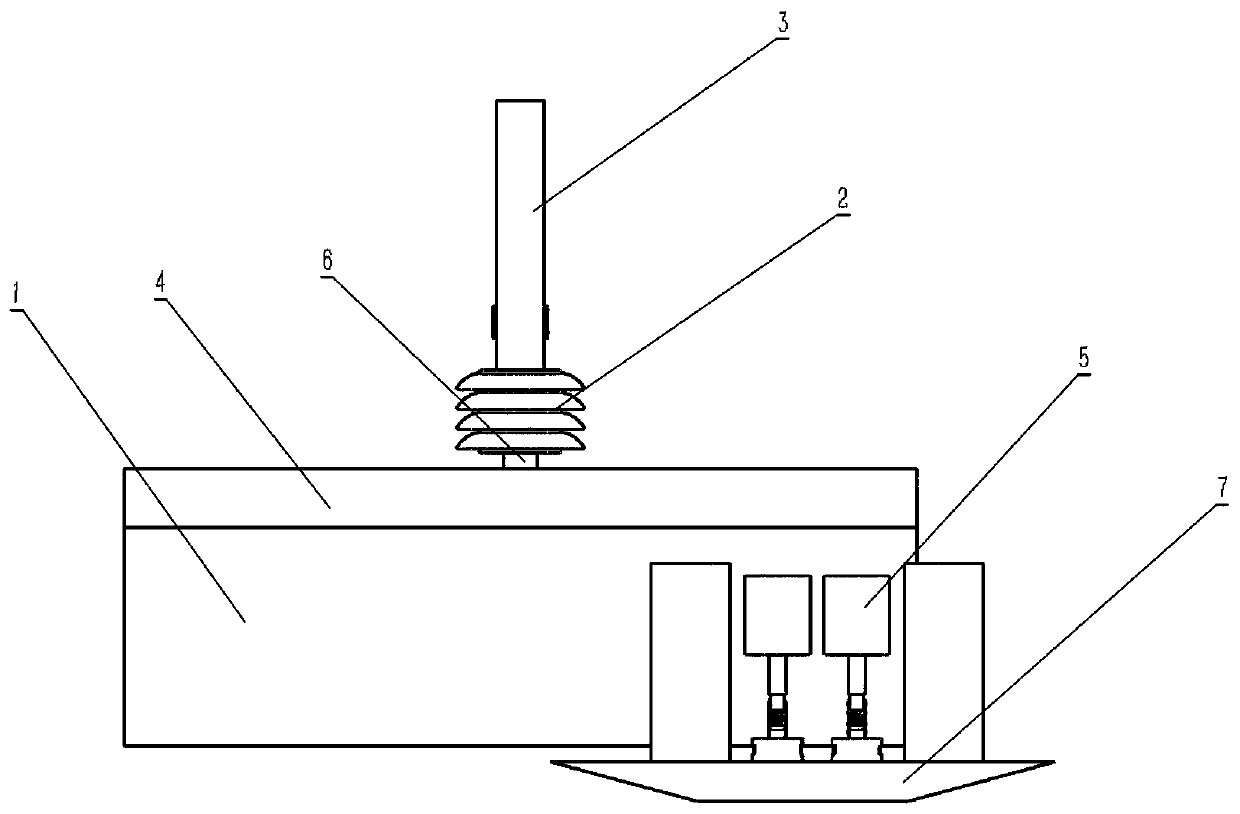

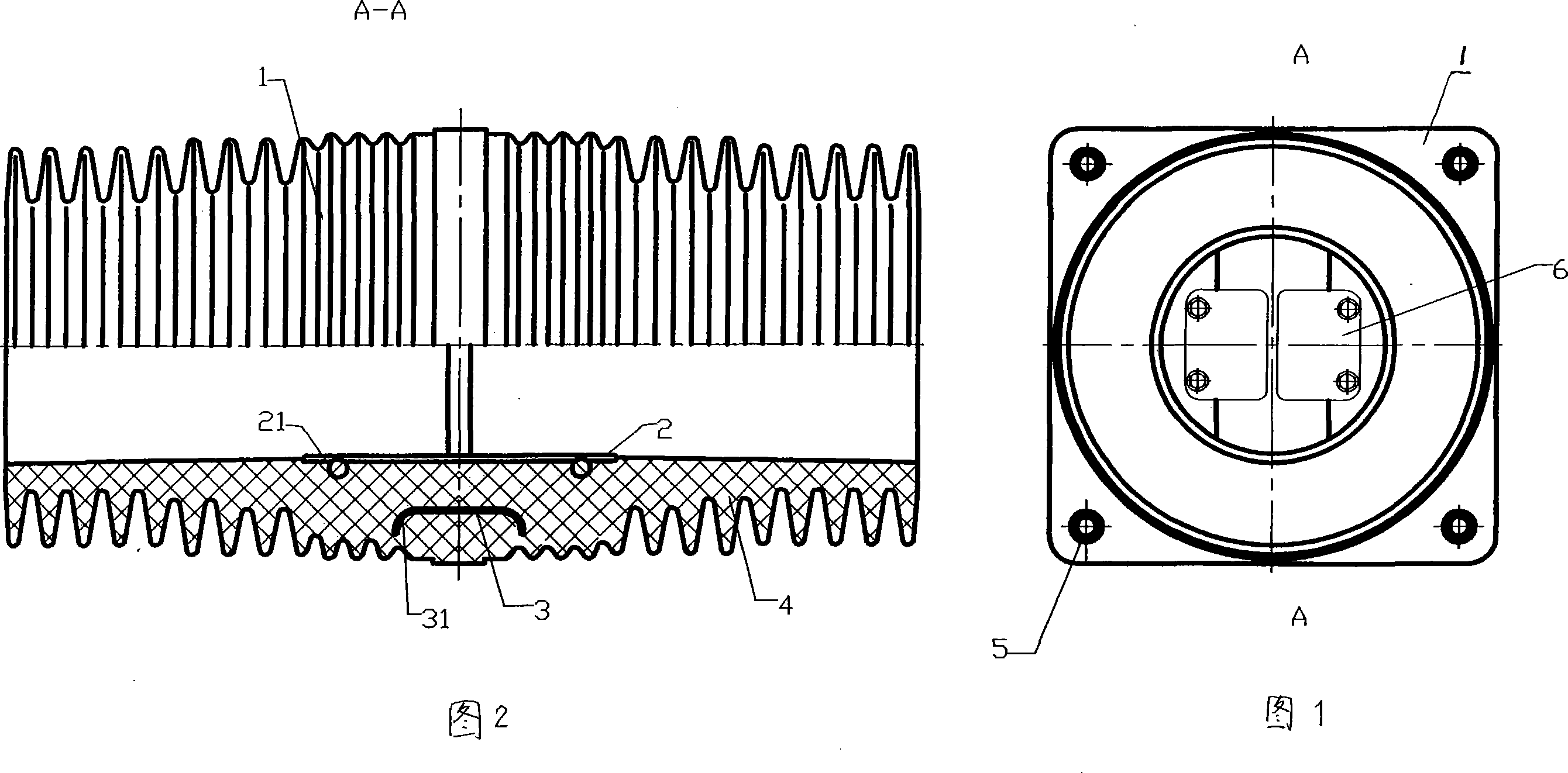

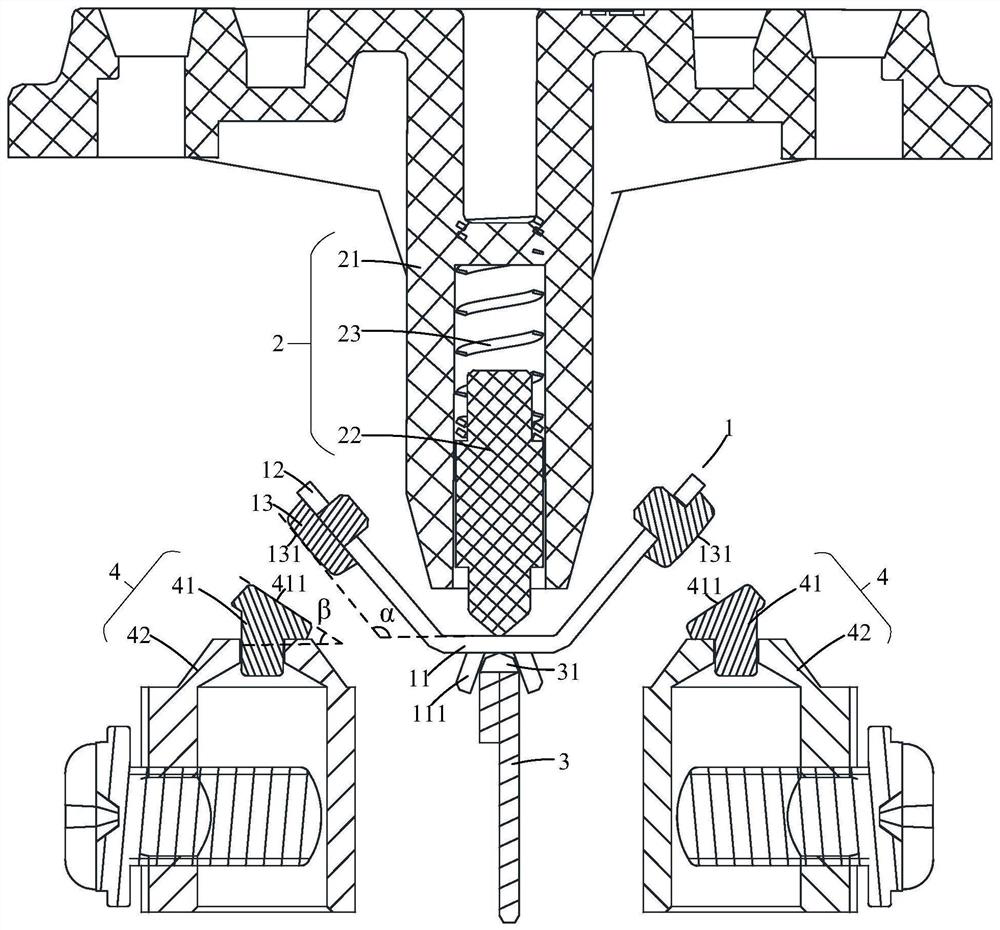

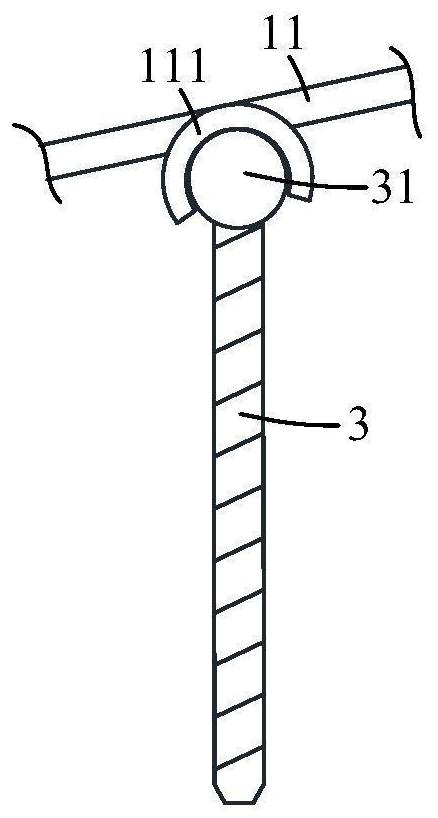

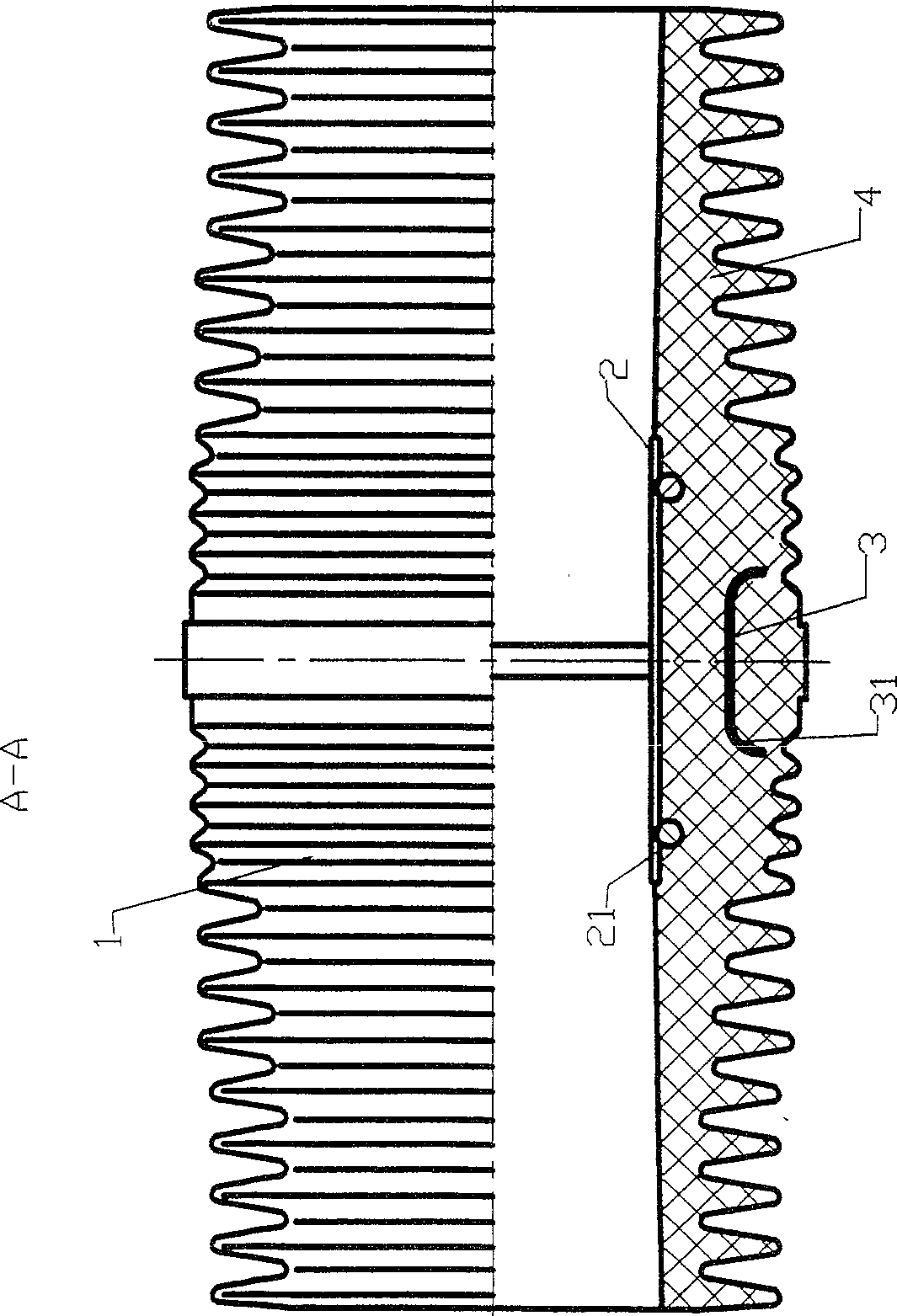

Electrical bushing

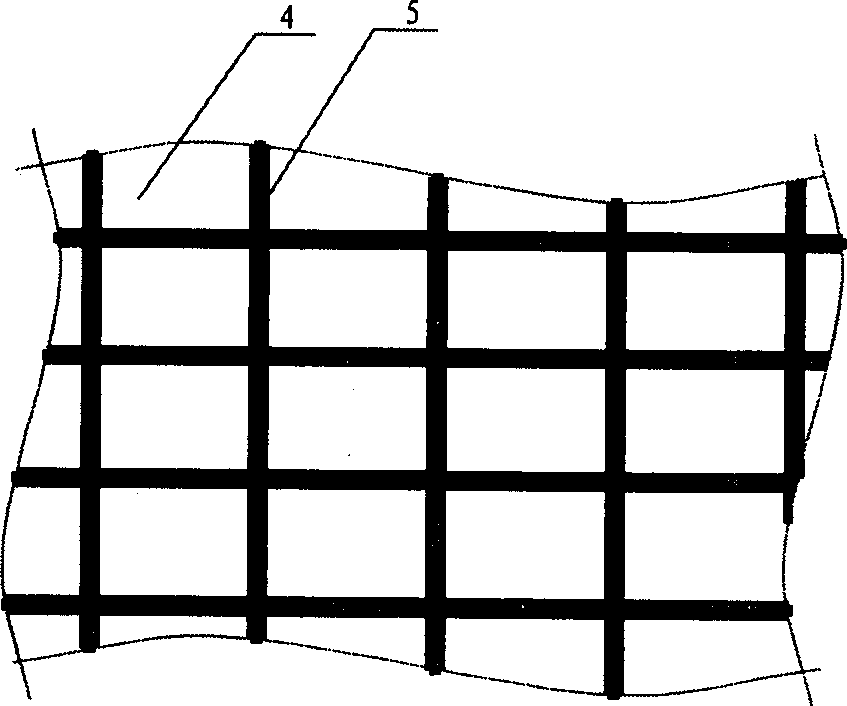

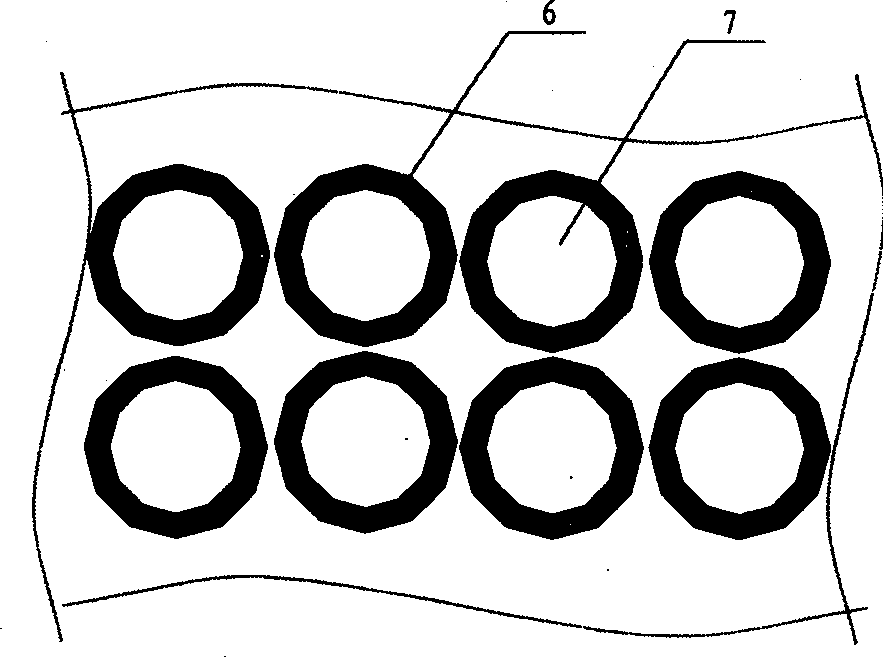

InactiveCN101169198AEliminate dischargeUniform electric fieldPipe supportsRigid pipesEpoxySemiconductor materials

A power casing comprises a body (1) made of a thick layer (4) with epoxy resin mixed material. The internal wall of the body is provided with a bus voltage-equalizing ring (2), and two ends are respectively provided with a copper spiral ring (21); the bus voltage-equalizing ring and the copper spiral rings are cast in the thick layer of epoxy resin mixed material of the casing; a shielding ring (3) is arranged between the voltage-equalizing ring and the grounding; two ends of the shielding ring are respectively provided with an arc (3) the internal and the external surfaces of which are encased with semiconductor material layers; the voltage-equalizing ring is provided with a spring leap (6) which contacts with the bus. The invention has the advantage that the voltage-equalizing ring and an earth shielding ring are additionally arranged in epoxy resin of a bus casing with a nominal voltage of 35kV to eliminate partial discharge and equalize the electric field; secondly, the end parts of the voltage-equalizing ring are additionally provided with the copper spiral rings to equalize the electric field to achieve better and closer combination with the epoxy resin thick layer and eliminate the air space. The invention has rational structure and can considerably reduce the partial discharge quantity and the phenomenon of casing discharge arc in operation and improve the operational safety and reliability; in addition, the invention has a long service life.

Owner:宁波三爱互感器有限公司 +1

Electric arc erosion resisting switch

InactiveCN104766728AExtended service lifeProtect the surfaceMake-before-break contact arrangementAlloyEngineering

The invention relates to the field of switches, in particular to an electric arc rotation resisting switch. The electric arc erosion resisting switch comprises a first contact portion and a second contact portion. The first contact portion and the second contact portion are in sliding contact with each other. One end of the first contact portion is provided with a first alloy contact. One end of the second contact portion is provided with a second alloy contact. When the first contact portion is not in contact with the second contact portion, the first alloy contact is opposite to the second alloy contact. When the first contact portion is in contact with the second contact portion, the first alloy contact and the second alloy contact are arranged with the back towards each other. According to the electric arc rotation resisting switch, the two contact portions of the switch are provided with the alloy contacts respectively, after the two contact portions are in contact with each other and then separated, because the resistance of the alloy contacts is large, the discharging effect of the contact portions is lowered, and the probability of an arc discharging phenomenon is reduced; because the alloy contacts are resistant to erosion, the erosion, caused by an electric arc, of the contacts is reduced, the surfaces of the two contact portions of the on-load switch are protected, the stability of contact is guaranteed, and the service life of the switch is prolonged.

Owner:北京博瑞莱智能科技集团有限公司 +1

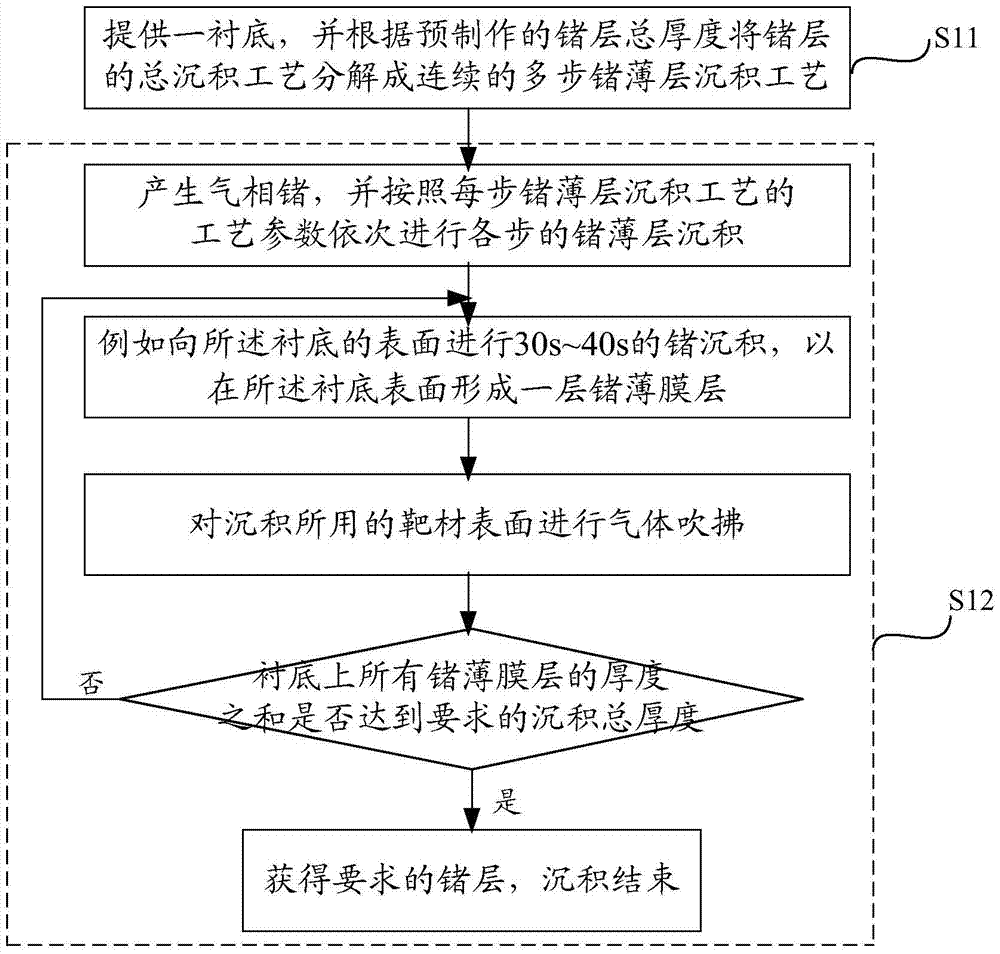

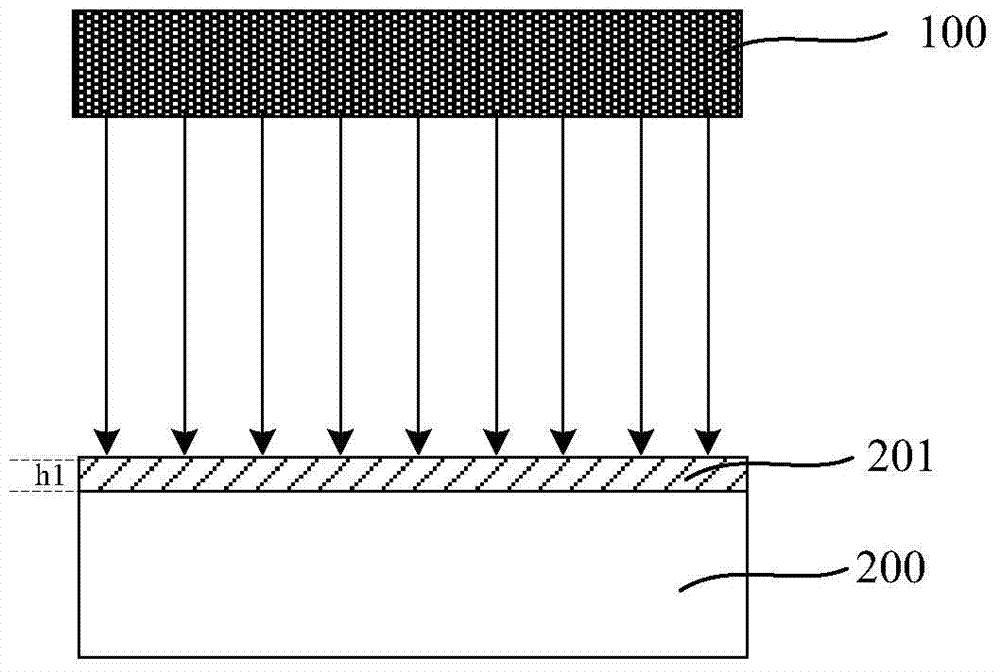

A kind of manufacturing method of germanium layer and semiconductor device

ActiveCN104867822BReduce the number of sputtered particlesReduce the number of defectsSemiconductor/solid-state device manufacturingParticulatesHigh pressure

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

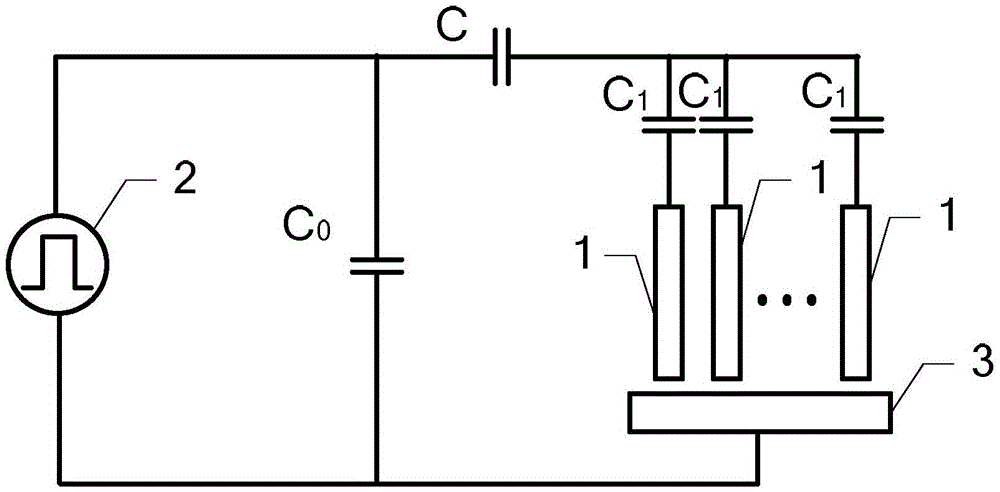

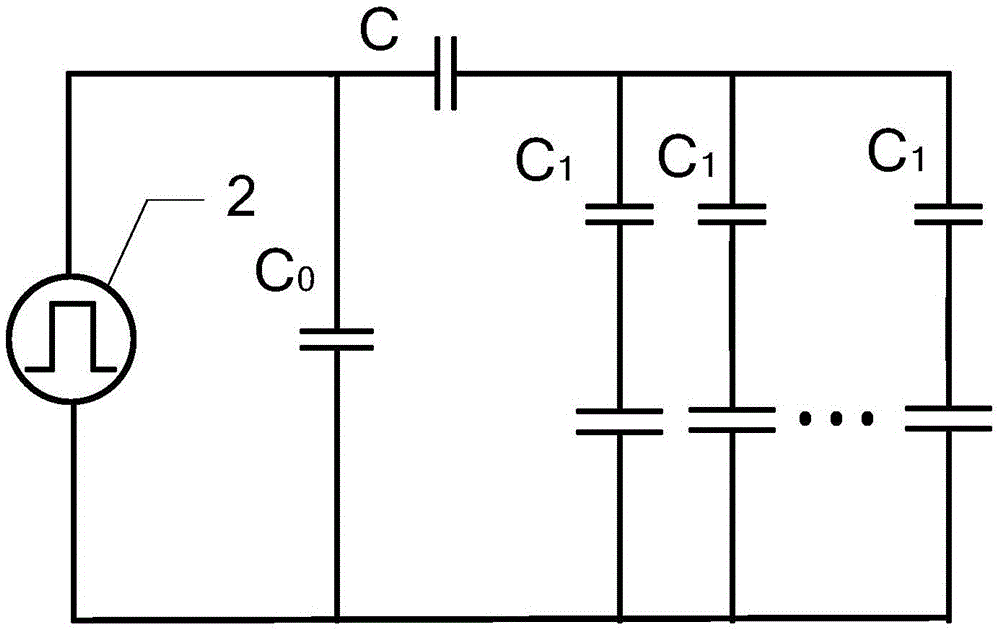

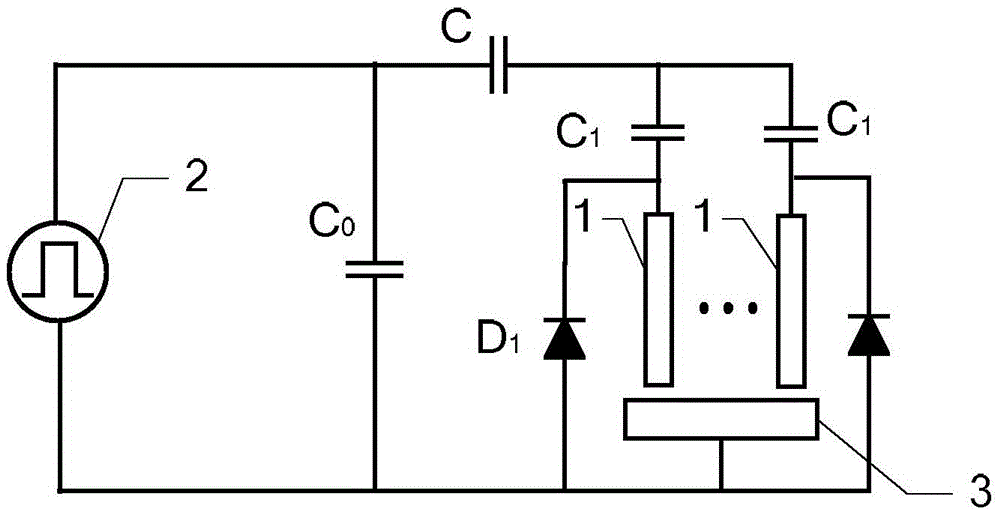

A novel electrical discharge machining circuit and machining method capable of realizing multi-point electrical discharge high-speed electrical discharge machining

The invention relates to a novel electric spark machining circuit and method capable of achieving multi-point-discharge high-speed electric spark machining, and belongs to the field of electric spark machining. The novel electric spark machining circuit and method solve the problems that according to a traditional single-electrode electric spark machining circuit and method, workpiece machining is low in efficiency and speed. The novel electric spark machining circuit comprises N electrodes, a pulse power source, N isolation capacitors C1, a compensation capacitor C0 and a power supply capacitor C. One end of each electrode is connected with one end of the corresponding isolation capacitor C1, and meanwhile the other end of each isolation capacitor C1 is connected with one end of the power supply capacitor C. The other end of the power supply capacitor C is connected with one end of the compensation capacitor C0 and the positive electrode of the pulse power source. The negative electrode of the pulse power source is connected with the other end of the compensation capacitor C0 at the same time to serve as the electric signal input end of a workpiece to be machined. The N electrodes are mutually insulated and are arranged opposite to the workpiece to be machined. The vertical distance between the electrodes and the workpiece to be machined is d. The novel electric spark machining circuit and method are used in the field of electric spark machining.

Owner:HARBIN INST OF TECH

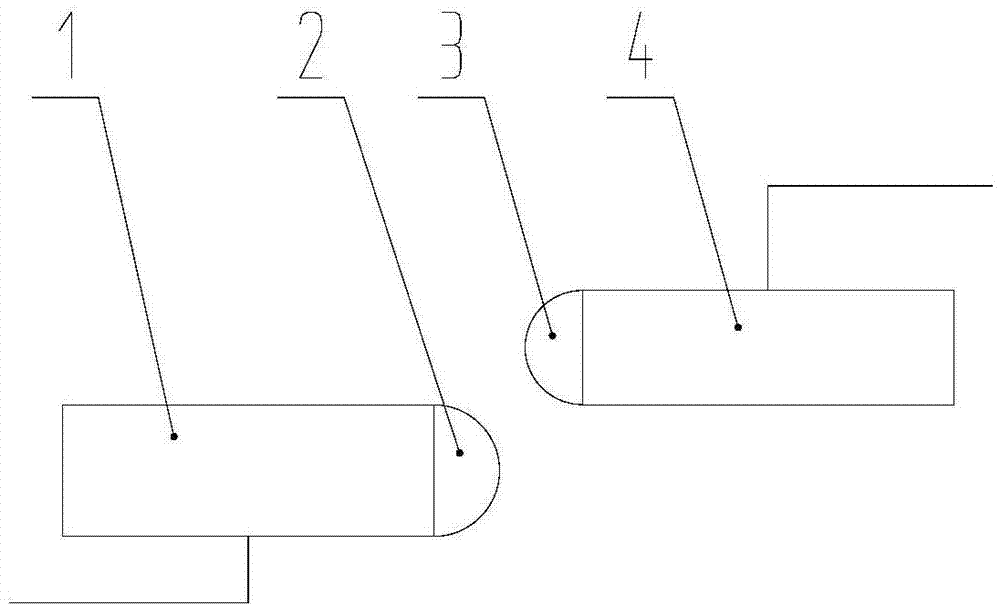

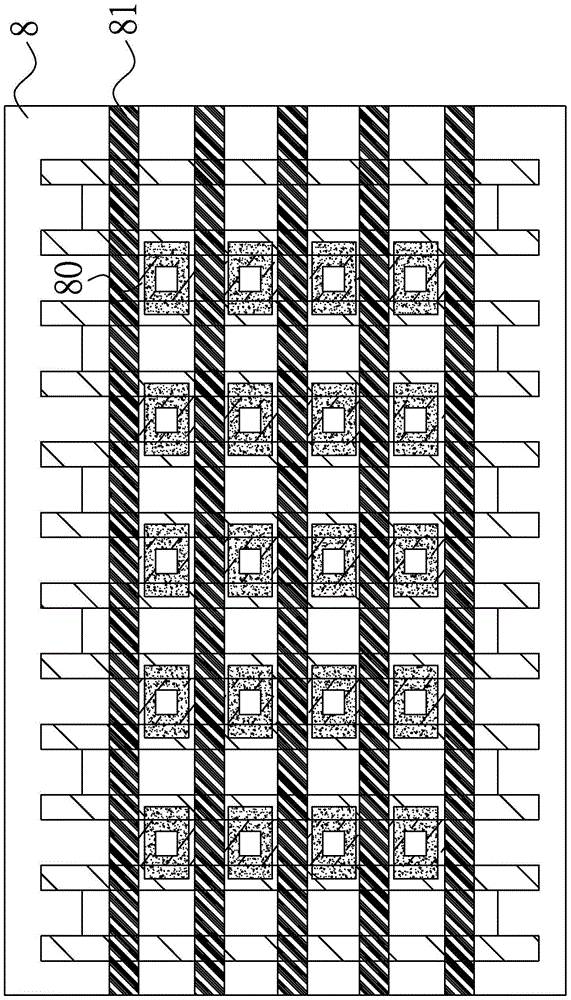

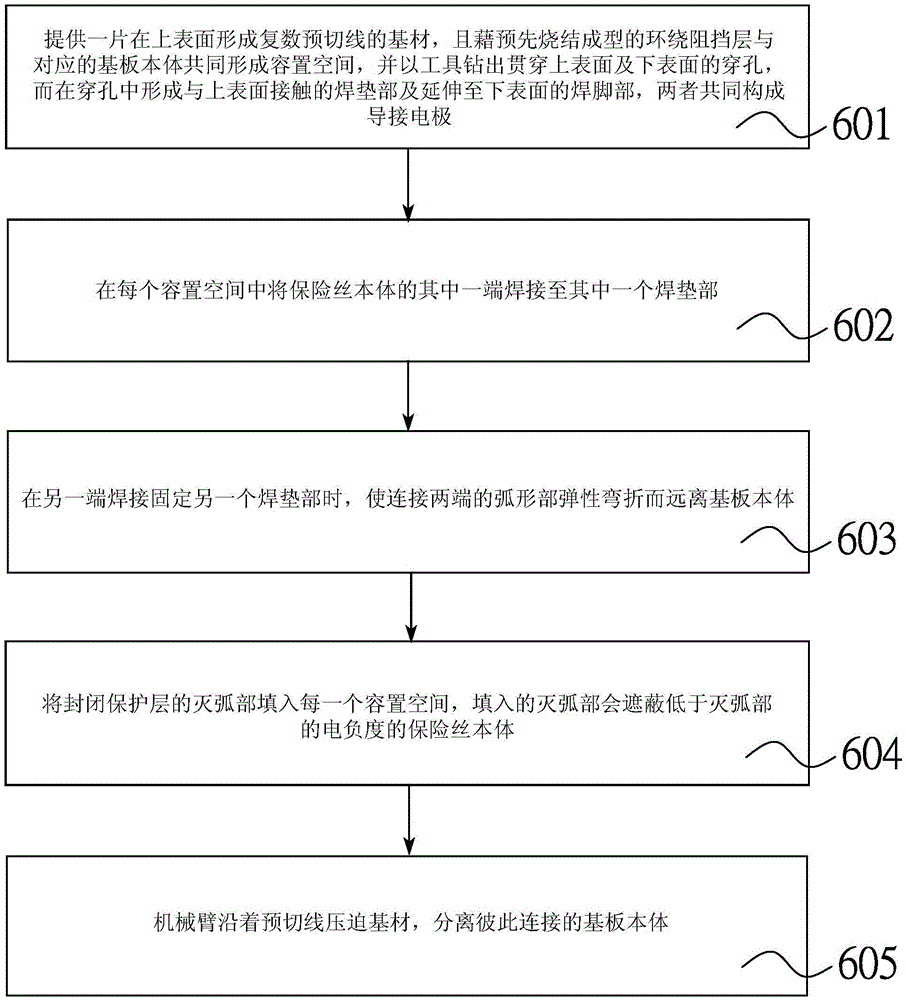

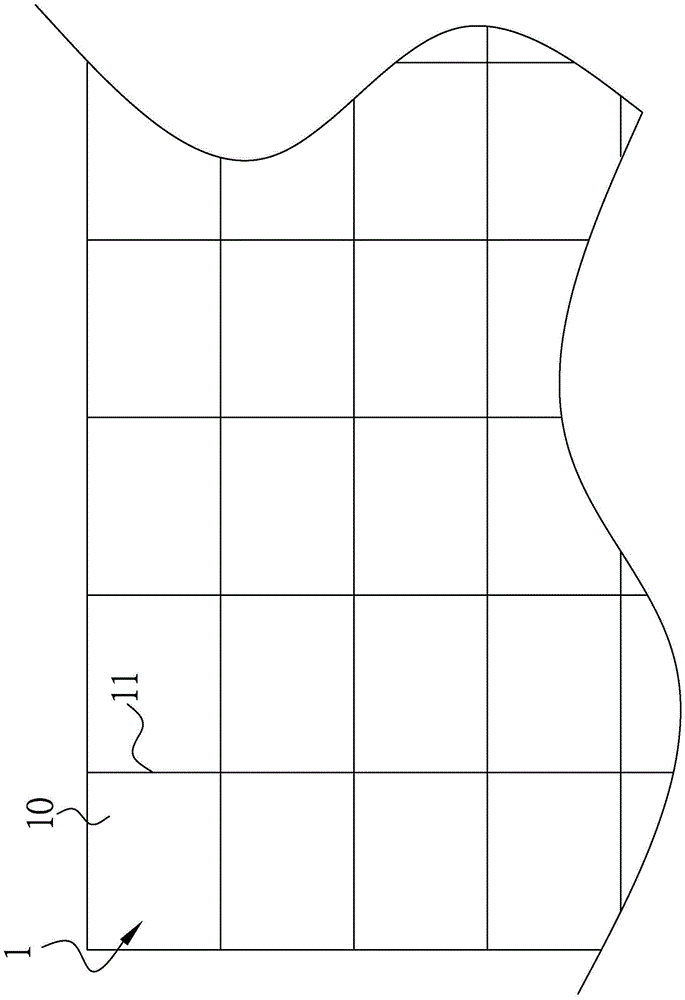

Wafer fuse element having precut line substrate and manufacturing method thereof

ActiveCN106816428AGuaranteed reliabilityImprove fluencySemiconductor/solid-state device detailsSolid-state devicesSurface mountingProtection layer

The invention provides a wafer fuse element having a precut line substrate for surface mounting to a circuit board. The wafer fuse element comprises a substrate body having an upper surface, a lower surface and two end rims connected the upper surface with the lower surface, the substrate body is provided with precut lines corresponding to the two end rims on one of the upper surface and the lower surface; a pair of separate conductive electrodes, the conductive electrodes comprise welding pad portions arranged on the supper surface and welding pin portions extending from the welding pad portions to the lower surface; a surrounding blocking layer which is arranged on the supper surface and is used for sealing and surrounding the welding pad portions, the surrounding blocking layer and the substrate body commonly form an accommodation space, the precut lines are not covered by the surrounding blocking layer and are exposed outside; a fuse body which is arranged in the accommodation space, two ends of the fuse body are respectively welded with the welding pad portions; and a sealing protection layer used for sealing and blocking the accommodation space.

Owner:CHEERING SUN APPLIED MATERIALS

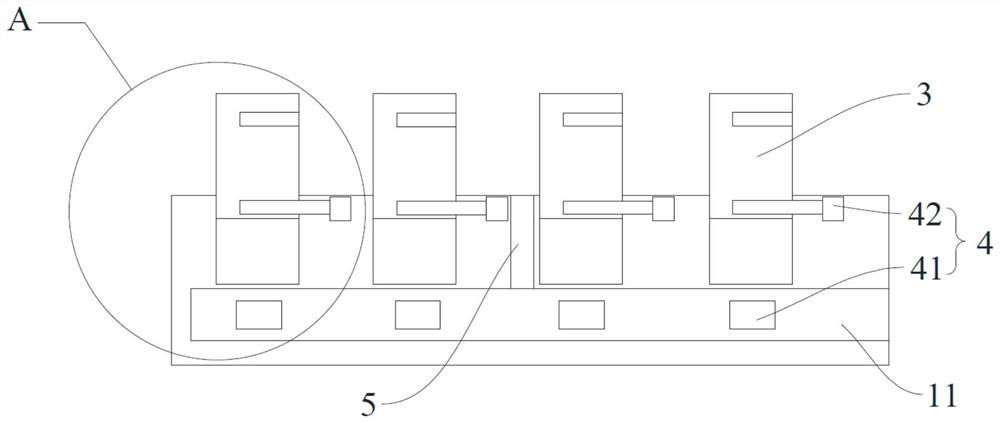

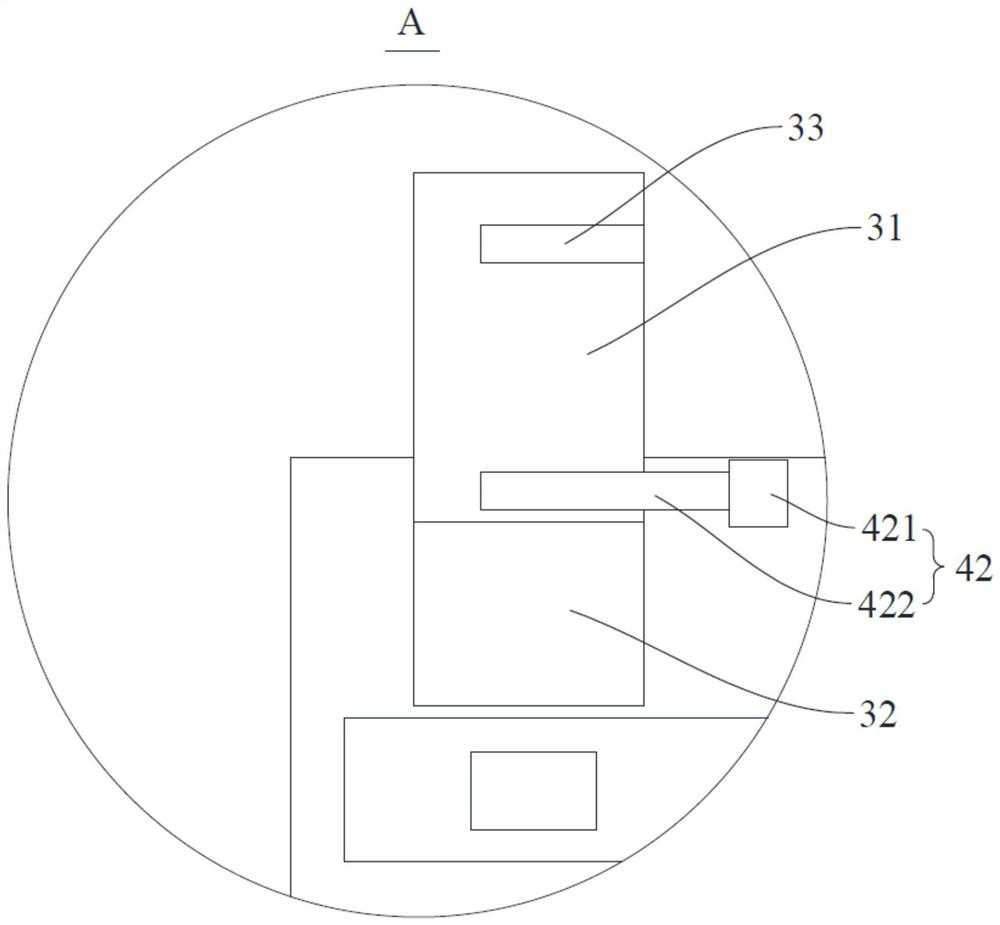

A smart pantograph

ActiveCN111267624BImprove automation performanceExtended service lifeRailway vehiclesPower current collectorsEngineeringMachine

The invention discloses an intelligent pantograph, which relates to the technical field of railway electric locomotives. It includes an insulating upper arm, an airfoil bow head, a controller, an acceleration sensor, a pressure sensor and a temperature sensor. The airfoil bow head is provided with a main flap, Auxiliary flaps and skateboards, the airfoil bow head is connected to the top of the insulating upper arm through the intelligent lifting support frame; the main steering gear and the auxiliary steering gear are arranged inside the airfoil bow head; the rotating part of the main steering gear is connected with the main flap, and the auxiliary rudder The rotating part of the machine is connected with the auxiliary flap, and the intelligent lifting support frame, the main steering gear and the auxiliary steering gear are all connected with the controller signal. The invention can adjust the up and down height of the airfoil bow through the intelligent lifting support frame, the angle between the main flap and the horizontal plane can be adjusted through the main steering gear, and the angle between the auxiliary flap and the horizontal plane can be adjusted through the auxiliary steering gear , and the adjustment is based on the state information of the pantograph detected by the existing sensor, so that the active adjustment of the attitude of the pantograph is realized.

Owner:SOUTHWEST JIAOTONG UNIV

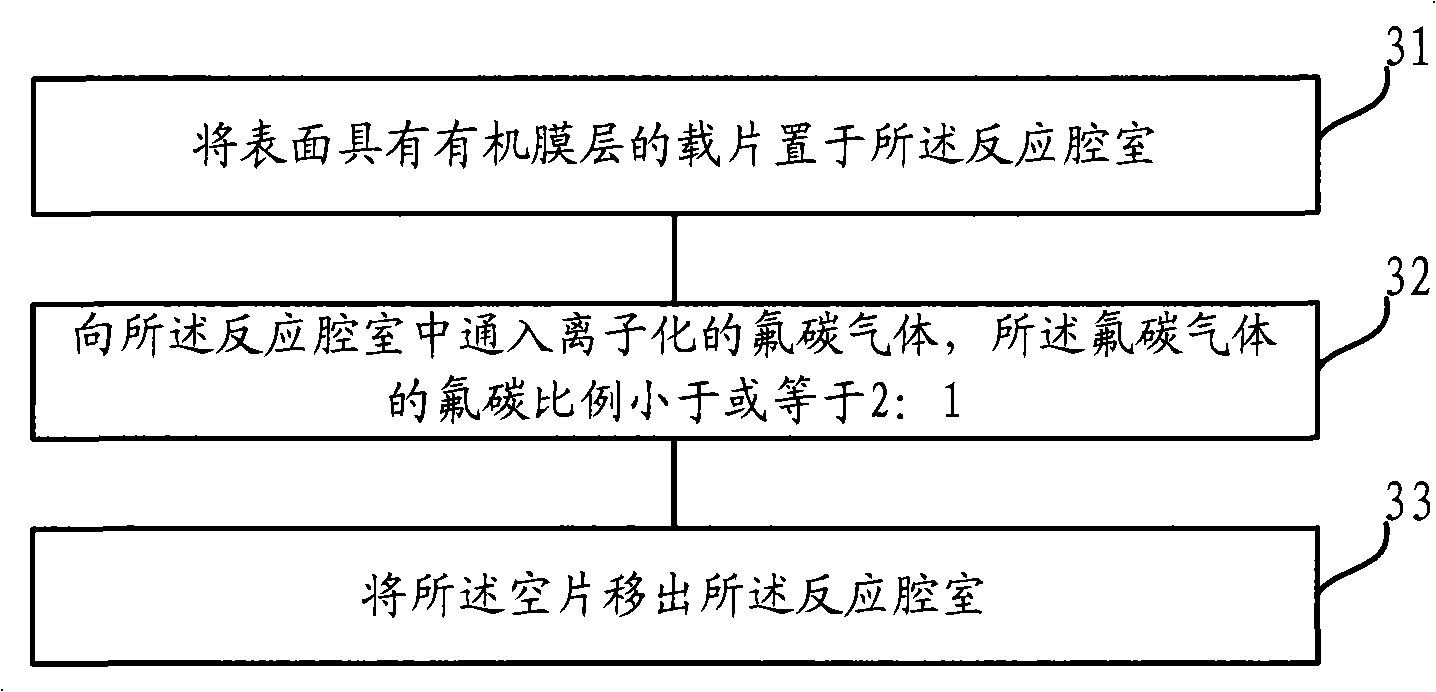

Plasma reaction chamber pretreatment method

InactiveCN101643895BReduce sheddingReduce arcing phenomenonElectric discharge tubesSemiconductor/solid-state device manufacturingPretreatment methodFluorocarbon

The invention discloses a plasma reaction chamber pretreatment method. Before executing a processing operation for a substrate introduced into a reaction chamber by using the reaction chamber, the method also comprises the following steps: placing a slide glass of which the surface is provided with an organic membrane layer into the reaction chamber; introducing ionized fluorocarbon gas into the reaction chamber, wherein the ratio of fluorine to carbon in the fluorocarbon gas is less than or equal to 2 to 1; and shifting the slide glass out of the reaction chamber. The method can reduce the generation of arc discharge phenomenon.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Rocker switch

PendingCN112635225AExtended service lifeReduce the number of bouncesTumbler/rocker switch detailsEngineeringStructural engineering

The invention relates to a rocker switch, and belongs to the technical field of switches. The rocker switch comprises a rocker, a transition piece, a support piece and two outgoing line terminals; the rocker, the transition piece and the support piece are located between the two outgoing line terminals, the transition piece is pressed on the upper surface of the bottom of the rocker, and the supporting piece is supported on the lower surface of the bottom of the rocker. The rocker comprises a supporting plate and two movable contact plates, the two movable contact plates are connected to the two ends of the rocker, each movable contact plate is provided with a movable contact, each outgoing line terminal is provided with a static contact, and each static contact is located on the circular motion trail of the movable contact on the same side; a first included angle is formed between the plane where the movable contact face of each movable contact is located and the plane where the supporting plate is located, a second included angle is formed between the plane where the static contact face of each static contact is located and the horizontal plane, the first included angle and the second included angle are both larger than 0 degree and smaller than 180 degrees, and the sum of the first included angle, the second included angle and the rotating angle of the rocker is 180 degrees. By adopting the rocker switch, the service life of the rocker switch can be prolonged.

Owner:NINGBO BULL ELECTRIC CO LTD

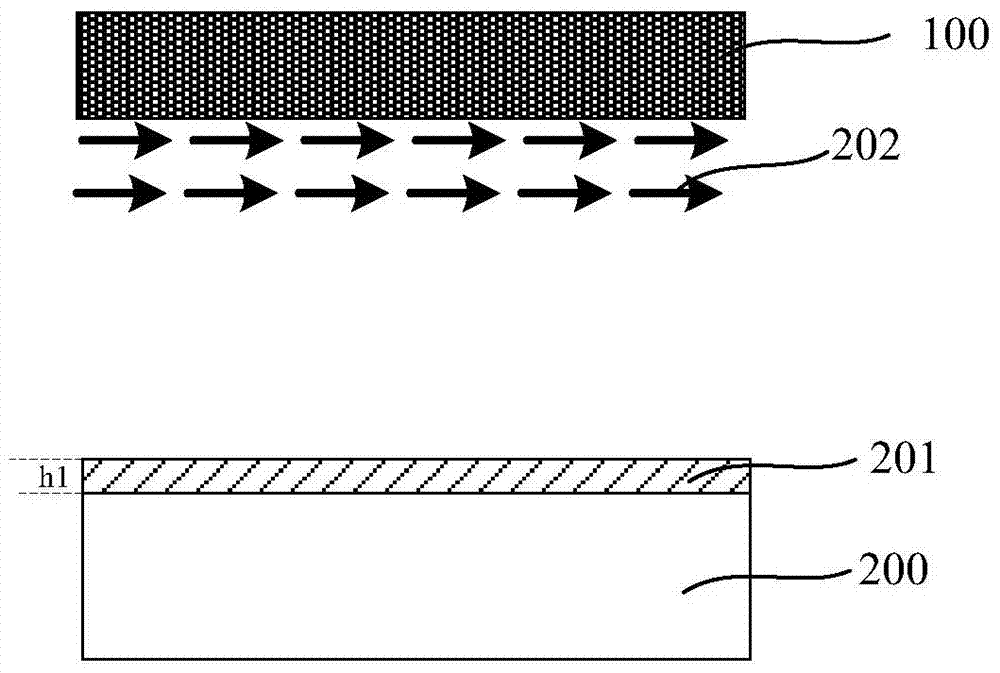

Horizontal electrolytic electric spark machining device and method

During machining, a tool electrode and a workpiece are immersed in electrolyte at the same time, the tool electrode is horizontally arranged below the workpiece, feeding of the workpiece is controlled by a feeding adjusting system, and rotation of the tool electrode is controlled by an electrode horizontal rotating system. According to the device, the relative position between the tool electrode and the workpiece in the traditional machining process is changed, and the workpiece is machined through the feeding movement of the workpiece. The layout form that a workpiece is inverted and a tool electrode is horizontally placed is adopted, linear or plane type machining is formed, the defect of single longitudinal point type machining of a conventional electrolysis electric spark machining device is overcome, the machining quality of a groove is greatly improved, corrosion removal products can be rapidly discharged out of electrodes under the action of gravity, the electrolyte flowing capacity in the machining process is enhanced, and the machining efficiency is improved. A stable gas film can be formed, so that the processing efficiency is improved.

Owner:JIANGSU UNIV OF TECH

Electrical bushing

InactiveCN100532902CEliminate dischargeUniform electric fieldPipe supportsRigid pipesEpoxySemiconductor materials

An electric bushing, which comprises a body (1) made of a thick layer (4) of epoxy resin mixture, the inner wall of the body is provided with a busbar pressure equalizing ring (2) and copper spirals are respectively provided at both ends rings (21), which are poured in the thick layer of epoxy resin mixture of the sleeve, a shielding ring (3) is arranged between the equalizing ring and the ground, and arcs ( 31) and its inner and outer surfaces are surrounded by a layer of semiconductor material; the pressure equalizing ring is provided with a spring piece (6) in contact with the bus bar. A voltage equalizing ring and a ground screen shielding ring to eliminate air gap discharge and make the electric field uniform; secondly, a copper spiral ring is added at the end of the voltage equalizing ring to even out the electric field, and to achieve better tightness with the epoxy resin Combined to eliminate the air gap, its structure is reasonable, which can greatly reduce the partial discharge during operation and the phenomenon of bushing discharge arcing, improve the operation safety and reliability, and have a good service life.

Owner:宁波三爱互感器有限公司 +1

Anti-electric shock power taking mechanism and electric energy meter

ActiveCN111693744AReduce the safety risk of mistakenly touching the meter body and getting an electric shockReduce the risk of taking electricityVehicular energy storageTime integral measurementControl theoryElectricity meter

The invention discloses an anti-electric shock power taking mechanism, which is used for being connected with a zero line assembly and / or a live line assembly in an electricity meter body and comprises a shell and a plurality of power taking wiring terminals, wherein the shell is provided with a matching groove, and a closing piece is arranged in the matching groove in a sliding mode and used forclosing or opening the matching groove; the power taking wiring terminals are movably arranged on the shell in a penetrating mode, each power taking wiring terminal is provided with a power taking position and a power failure position, and when the power taking wiring terminal is located at the power failure position, the power taking wiring terminal is located above the closing piece, is disconnected from the zero line assembly or the live line assembly and can be connected with a wire; when the power taking wiring terminal is located at the power taking position, the power taking wiring terminal is arranged in the matching groove in a penetrating mode, and the power taking wiring terminal is electrically connected with the zero line assembly or the live line assembly.

Owner:GUANGDONG POWER GRID CO LTD +1

Electric vehicle charging plug and socket assembly

PendingCN112736581AImprove securityInhibit sheddingCoupling contact membersCouplings bases/casesEngineeringElectric cars

An electric vehicle charging plug and socket assembly disclosed by the invention comprises a plug assembly and a locking assembly. The plug assembly comprises a shell, a PIN group, a fixing block for fixing the PIN group, a connector and a conductive wire, the locking assembly comprises a locking switch and a pressing switch, and the locking switch is rotatably installed on the shell of the plug assembly. The pressing switch is connected with a conductive wire and a conductive sheet in the plug assembly, the conductive sheet is connected with an external cable, the pressing switch can connect the conductive sheet with the conductive wire only when the locking switch is placed at a specified position, and in addition, the inner cavity of the pressing switch is provided with the isolation chamber for isolating the conductive wire from the contact of the conductive sheet so that electric arcs are prevented from being generated. Good safety performance is realized.

Owner:深圳市鑫海林电子科技有限公司

An energy storage vehicle and its automatic charging detection system

ActiveCN109050323BReduce the risk of failureReduce arcing phenomenonCharging stationsRailway vehiclesCharge detectionTransmitter

The invention discloses an energy storage type vehicle and its automatic charging detection system, which comprises a conductive rail, a signal transmitter, a signal receiver and a charging device. Wherein, one of the signal receiver and the signal transmitter is arranged in the platform, and the other is installed on the roof. Since the signal receiver and the signal transmitter can only realize the effective transmission of the signal within a certain range, therefore, As the vehicle moves, the signal transmission status between the two devices is different, and thus the vehicle's entry and exit signals can be detected. Compared with the existing technology, which adopts the detection devices at the inbound end and the outbound end, this system can complete the detection with a set of devices, which reduces the risk of a certain detection device failure, thereby reducing the risk of arcing. In addition, the inbound and outbound signals are all generated by this set of devices, no matter where the two are set, there will be no overlapping of signals, thus reducing the difficulty of the installation location.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com