A kind of manufacturing method of germanium layer and semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting device performance, failure, etc., to reduce the number of particle defects, improve particle defects, and improve device performance and device integration. The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose and features of the present invention more obvious and understandable, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments.

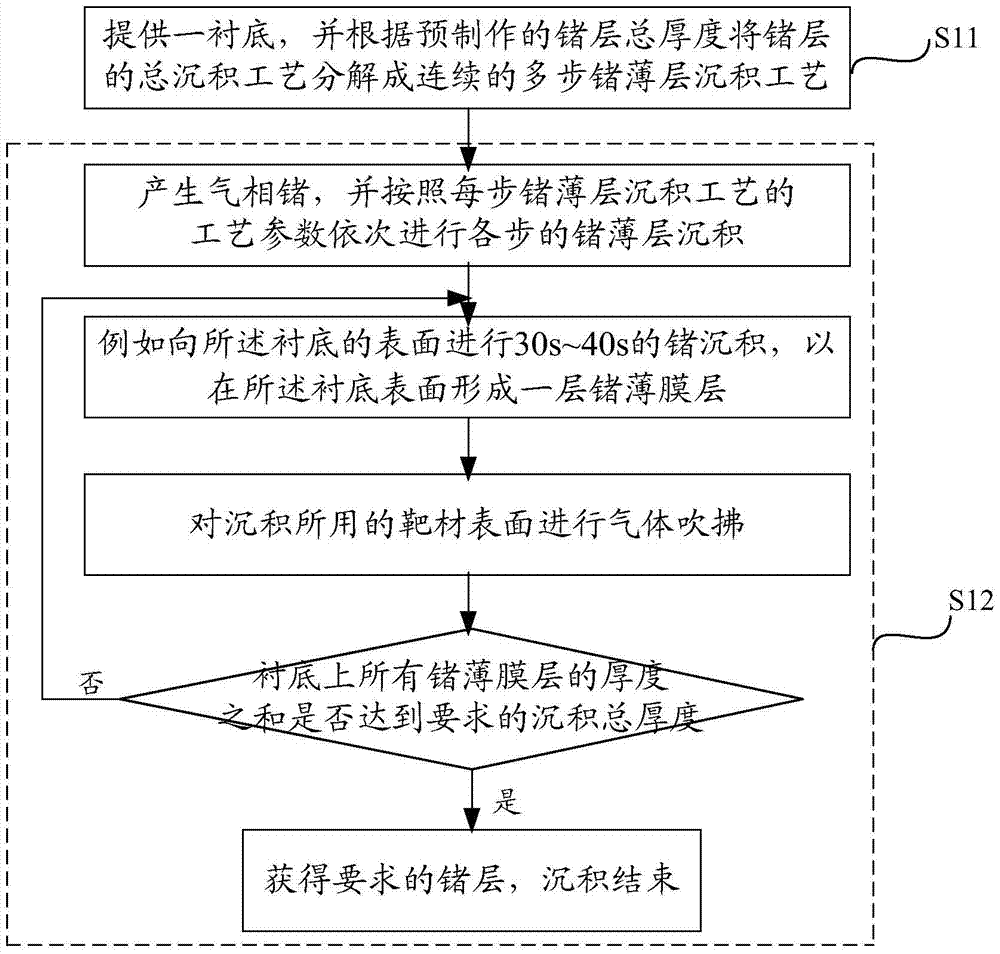

[0033] Please refer to figure 1 , the present invention proposes a kind of preparation method of germanium layer, comprises:

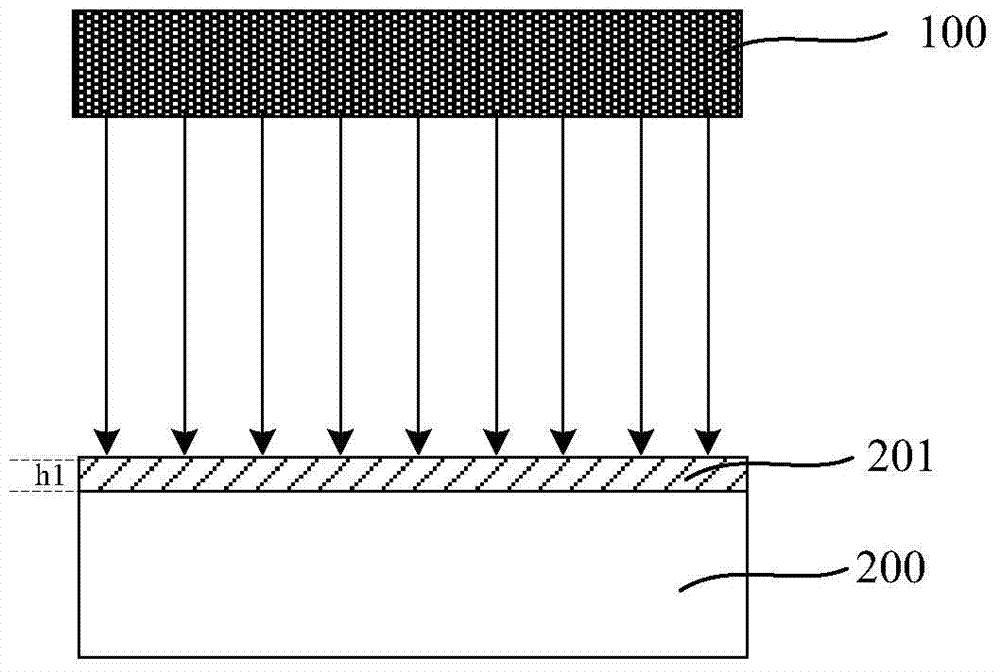

[0034] S11, providing a substrate, and decomposing the total deposition process of the germanium layer into continuous multi-step germanium thin layer deposition processes according to the total thickness of the prefabricated germanium layer;

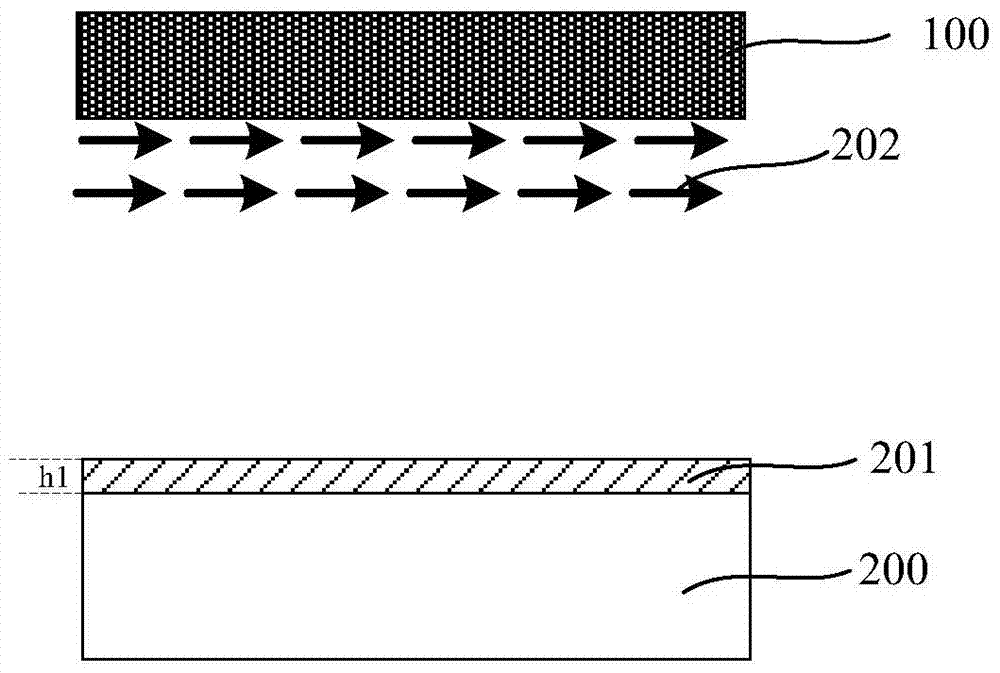

[0035] S12, according to the process parameters of each step of germanium thin layer deposition process, physical vapor deposition of each germanium thin layer in turn on the substrate, and after the last step of germanium thin layer deposition, blowing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com