High molecular PTC thermistor without electric arc and method for producing same

A technology of thermistor and manufacturing method, applied in the direction of resistors with positive temperature coefficient, etc., can solve problems such as thermistor failure and chip damage, reduce arc discharge, improve safety and reliability, and increase creepage effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] as table 1

[0016] high density

Carbon black dispersant

Oxidized polyethylene

Triallyliso

Cyanurate

336

400

42

17

7

7

[0017] Note: High-density polyethylene: Phillips Petroleum Company BHB5012

[0018] Carbon black: Cabot XC-72

[0019] Antioxidant: American Great Lakes Chemical Co., Ltd. ANOX70

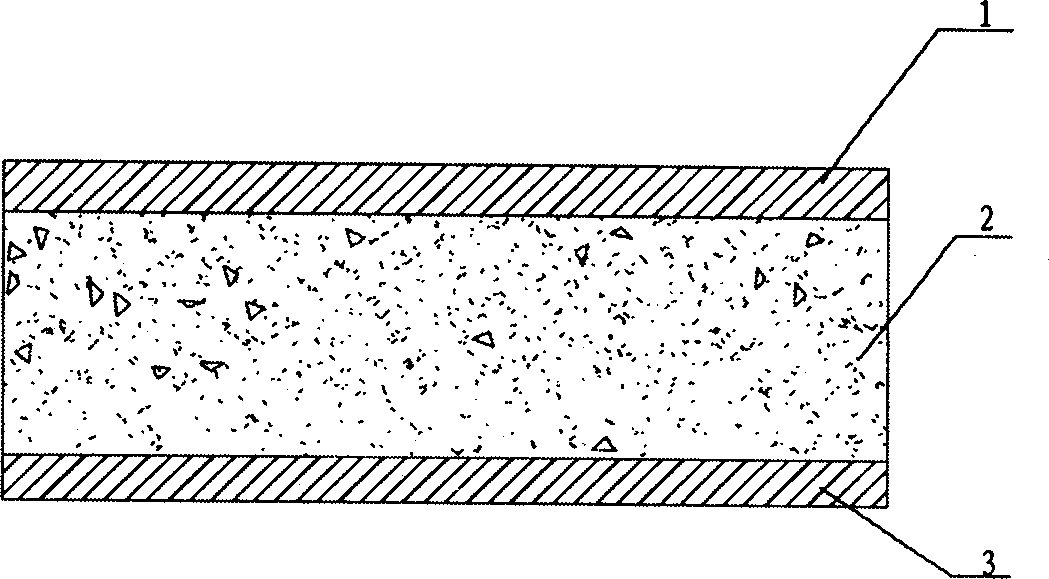

[0020] Its manufacturing method: in the first step, the components in Table 1 are mixed uniformly in an internal mixer at a temperature of 190 ° C, cooled, crushed and ground, and sandwiched between two layers of roughened copper foil. between them, put them in the compression mold, pressure 5Mpa, temperature 180℃, and press them into an area of 200cm 2 , 0.2mm thick sheet, such as figure 1 It is a schematic diagram of the composite sheet of this embodiment, wherein the nickel-plated copper foils 1 and 3 ar...

Embodiment 2

[0022] Table 2

[0023]

polyethylene

Carbon black dispersant

Oxidized polyethylene

Triallyliso

Cyanurate

340

320

30

16

7

7

[0024] Note: High-density polyethylene: Phillips Petroleum Company BHB5012

[0025] Carbon black: Cabot XC-72

[0026] Antioxidant: American Great Lakes Chemical Co., Ltd. ANOX70

[0027] In the first step, the components in Table 2 were kneaded evenly in an internal mixer at a temperature of 190°C, cooled, pulverized and ground, sandwiched between two layers of roughened copper foil, and placed in a In the compression mold, the pressure is 5Mpa, and the temperature is 180°C, and the area is 200cm 2 , Thick 2.0mm sheet. like figure 1 It is a schematic diagram of the composite sheet of this embodiment, wherein the nickel-plated copper foils 1 and 3 are laminated on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com