Horizontal electrolytic electric spark machining device and method

A machining device and electric spark technology, applied in the field of horizontal electrolytic EDM devices, can solve the problems of slow efficiency and limited machining range, and achieve the effects of expanding the machining range, stabilizing the state of electric discharge machining, and improving machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

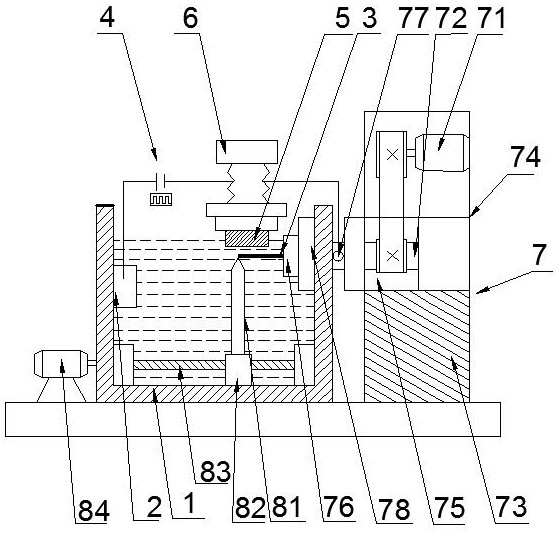

[0031] In order to expand the processing range, solve the problem of high-efficiency processing of "line" and "surface" in the EDM process, and realize the processing of thicker non-conductive materials, a horizontal EDM device is disclosed in this embodiment.

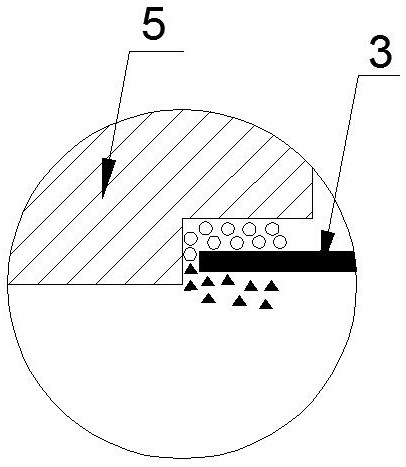

[0032] The device includes an electrolysis box 1, an auxiliary electrode 2, a tool electrode 3, a power supply 4, a workpiece 5, a feed adjustment system 6, and an electrode horizontal rotation system 7; connected, the tool electrode 3 is connected to the negative pole of the power supply 4, the tool electrode 3 and the workpiece 5 are immersed in the electrolyte at the same time, the tool electrode 3 is horizontally placed under the workpiece 5, and the workpiece 5 is connected to the feed adjustment system through the workpiece chuck The feed is controlled by the feed adjustment system, and the feed movement in the machining process is realized through the feed of the workpiece. The tool electrode 3 is connected with ...

Embodiment 2

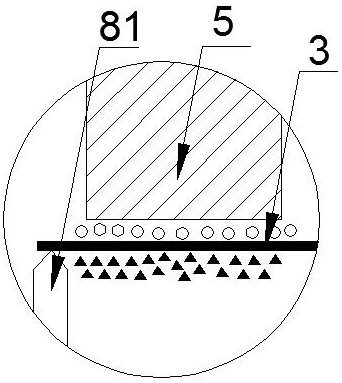

[0043] The only difference between this embodiment and the first embodiment is that a set of electrode supporting device 8 is arranged at the bottom of the electrolytic box, and the other structures are the same as those in the first embodiment.

[0044] When the length of the tool electrode 3 is short (<30 mm), the state of the electrode is relatively stable during the machining process, and there will be no obvious shaking at the end, but when the length of the tool electrode 3 is long (≥30 mm), the electrolytic machining process There will be a certain vibration in the process, which may have a certain impact on the stability of the processing process and the processing effect. In order to solve this problem, an electrode support device 8 is installed at the bottom of the electrolytic box 1, and the electrode support device 8 includes a support rod 81 , the movable block 82 and the screw mandrel 83, the screw mandrel 83 is placed horizontally at the bottom of the electrolyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com