Anti-icing multi-roller rigid overhead current-feed device

A rigid contact, current receiving device technology, applied in transportation and packaging, electric vehicles, power collectors, etc., can solve the problem of difficult to ensure reliable current receiving of EMUs, and achieve the effect of reducing energy consumption and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

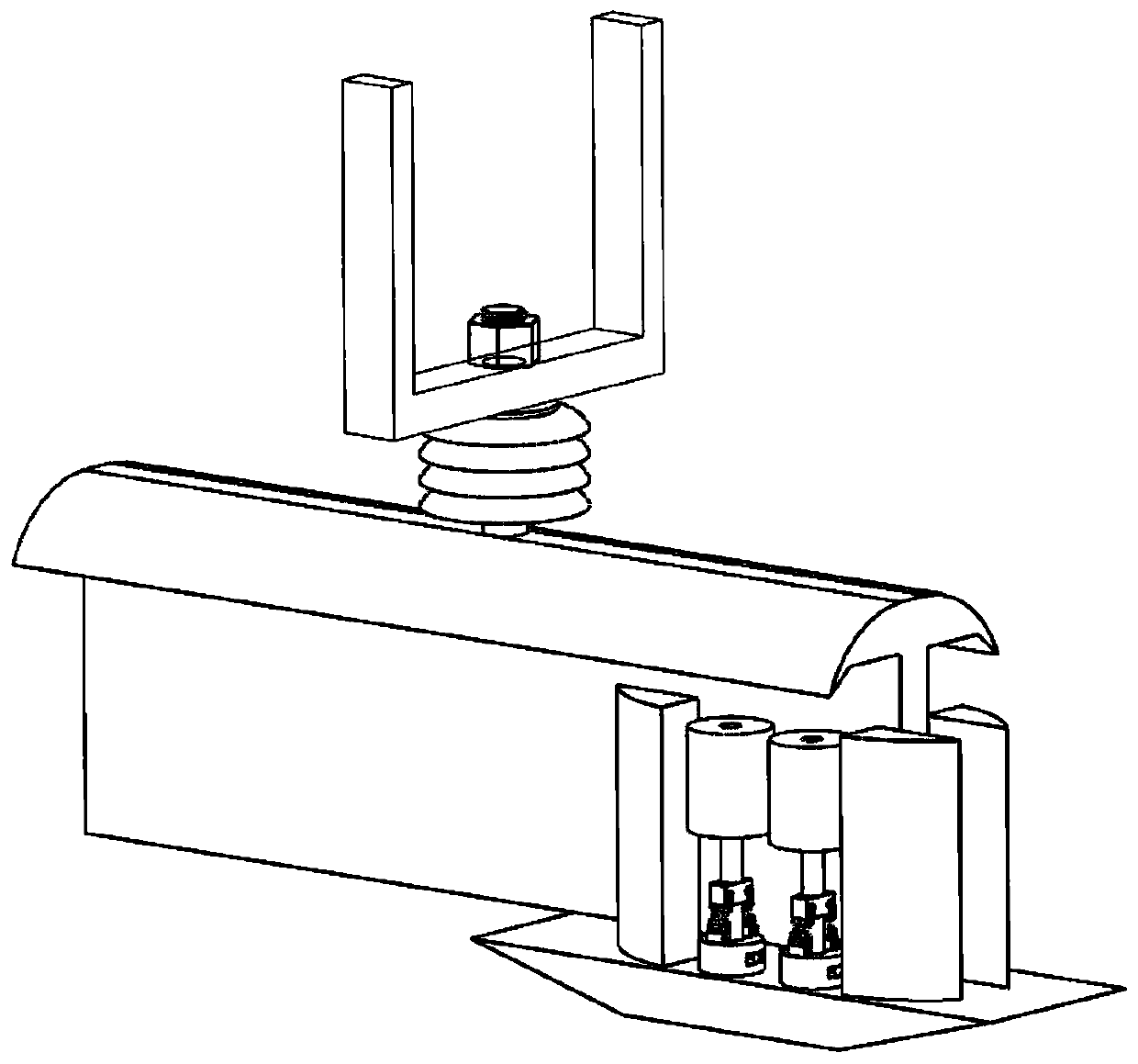

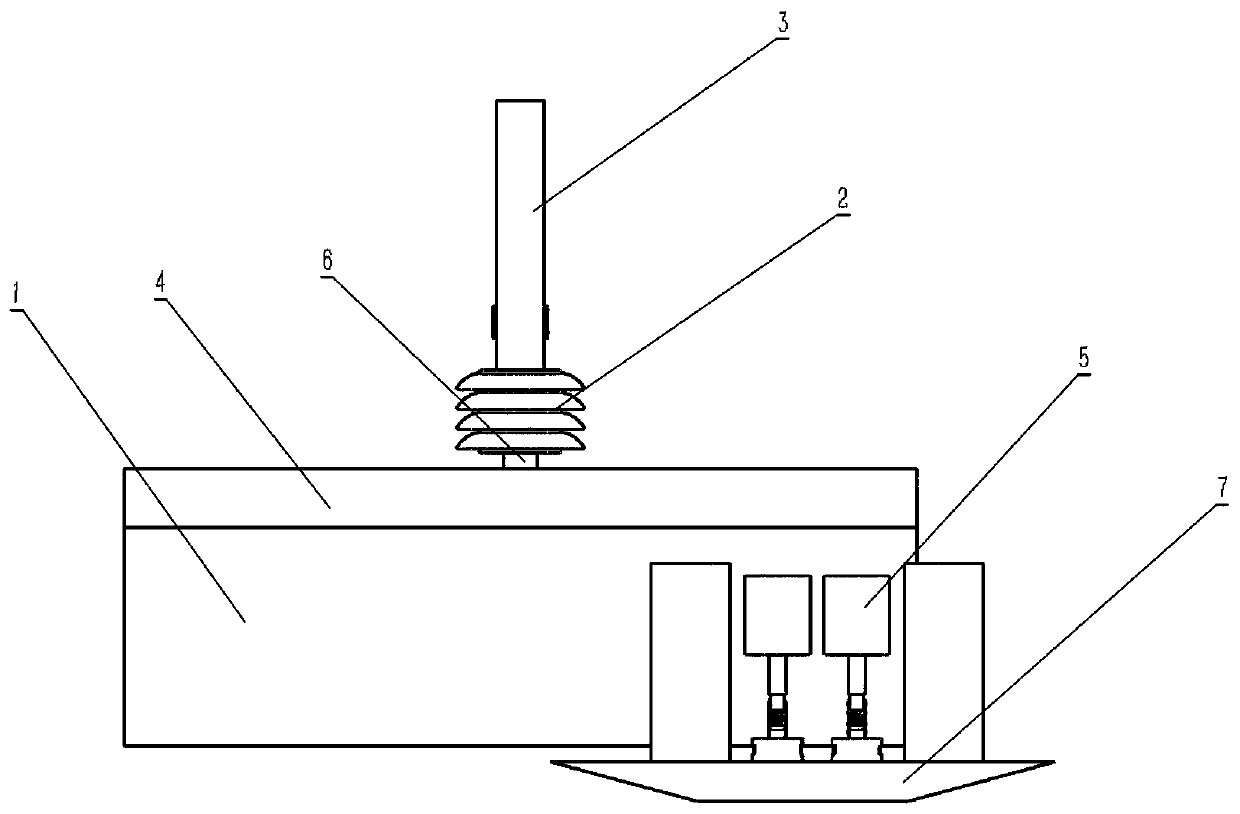

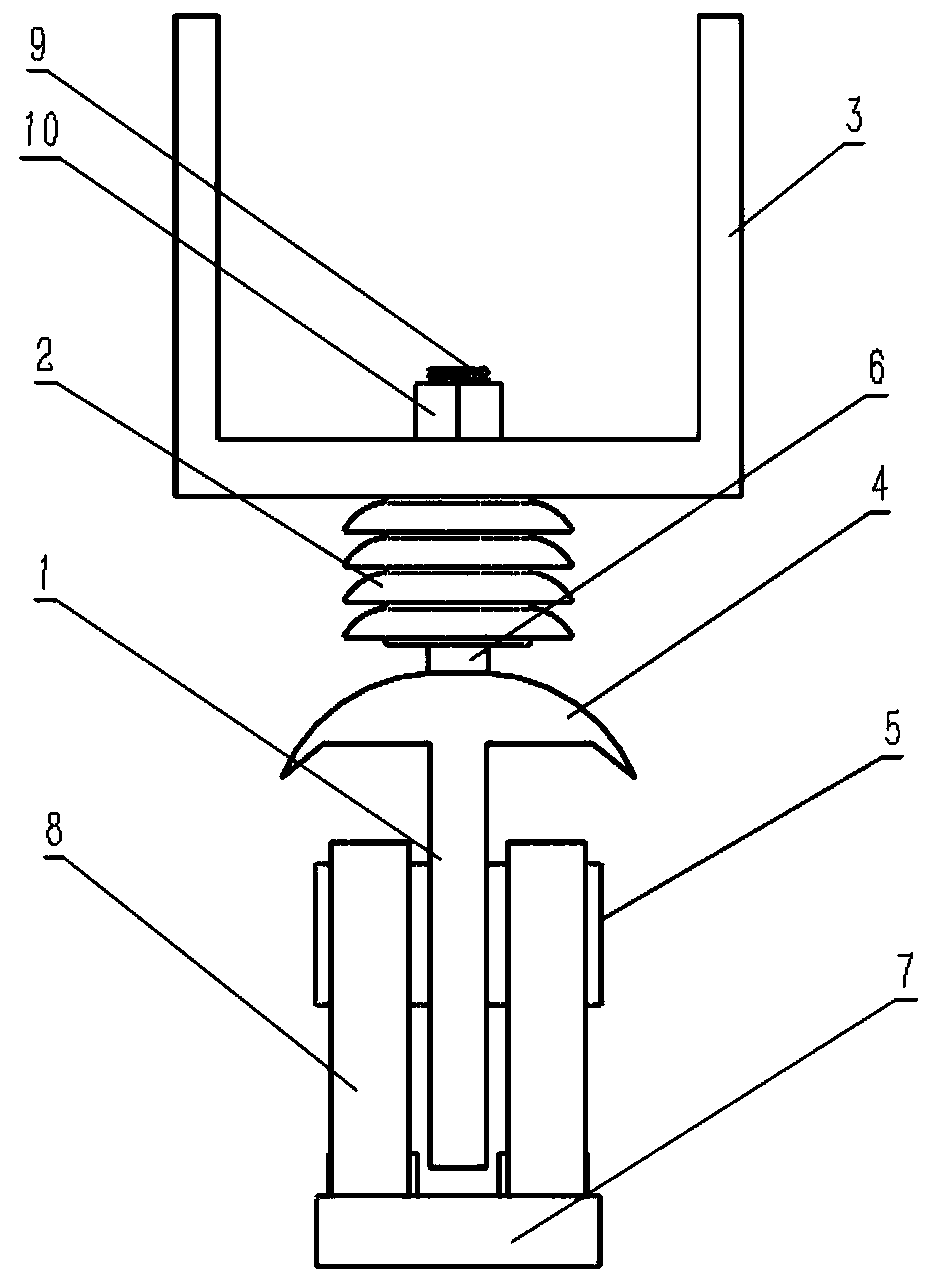

[0024] figure 1 Figure 4 It is shown that an anti-icing multi-roller rigid contact current receiving device is composed of a "T" shaped rigid catenary and a deicing and current receiving mechanism. The insulator 2 is fixed on several U-shaped overall brackets 3; the top surface of the current receiving rail 1 is arc-shaped; the deicing and current receiving mechanism is: the top surface of the lower deicing blade 7 is a horizontal plane, and the cross section is that the lower bottom is smaller than the upper one. The bottom is isosceles trapezoid, and the lower deicing blade 7 is respectively provided with front and rear side deicing blades 8 and two or more flow receiving blades between the two side deicing blades 8 on the left and right sides of the flow rail 1. The drum 5, wherein the front and rear side deicing blades 8 are symmetrical in shape, and the cross-sectional shape of the front side deicing blades is surrounded by a horizontal section from left to right, a ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com