Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Realize industrial automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

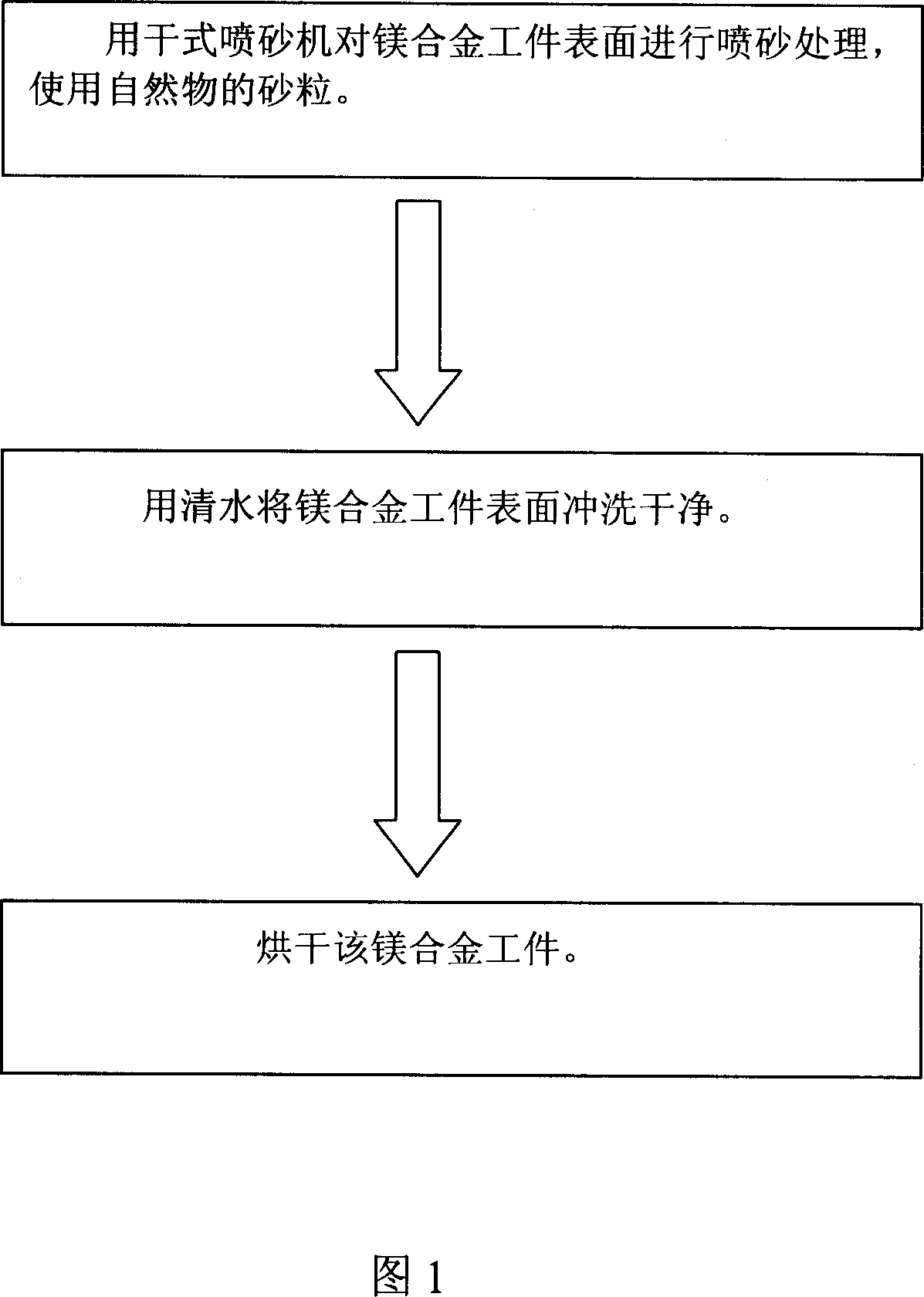

Magnesium-alloy surface pre-treatment

InactiveCN1939666AGood adhesionImprove working environmentAbrasion apparatusSand blastingSurface cleaning

A pre-treating method for the surface of Mg-alloy includes such steps as sand blasting and cleaning by flushing with clean water or high-pressure air.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

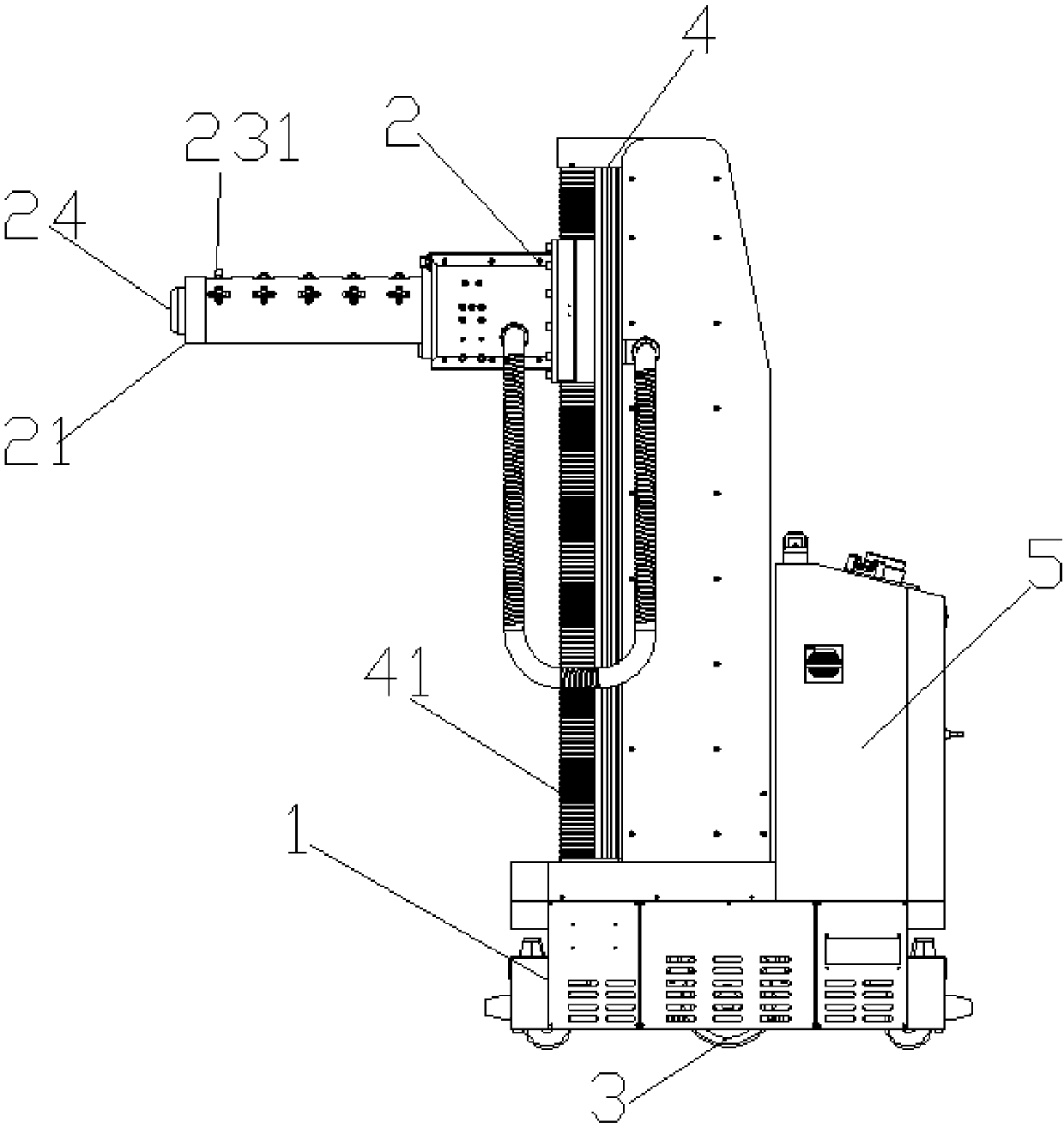

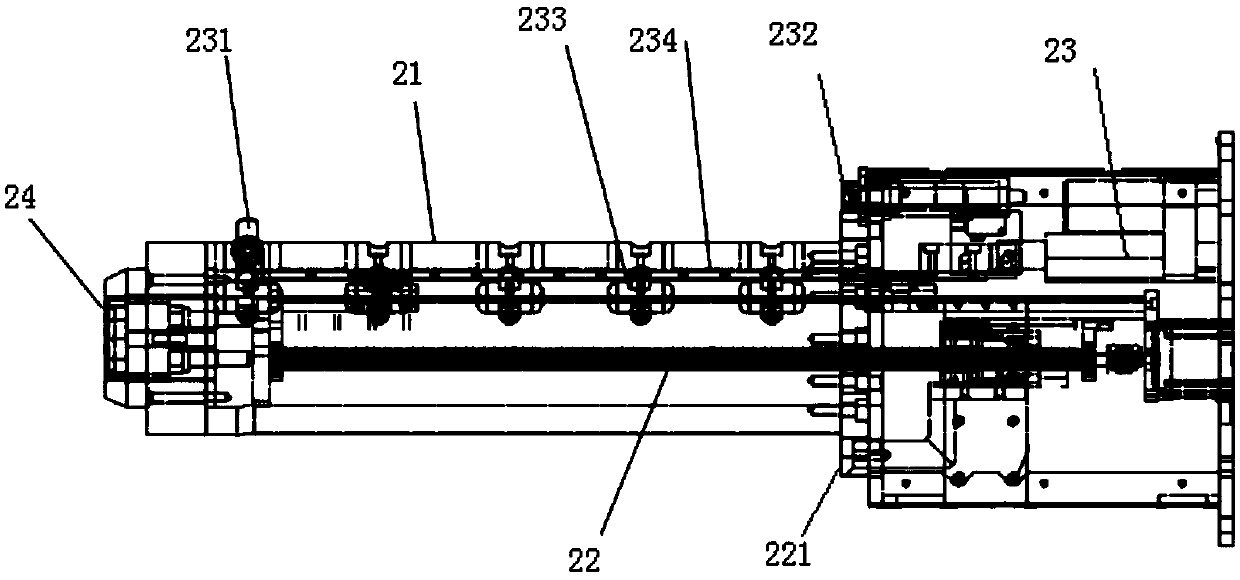

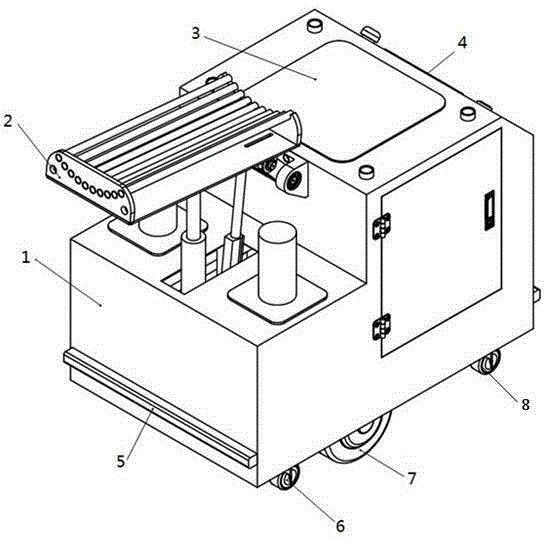

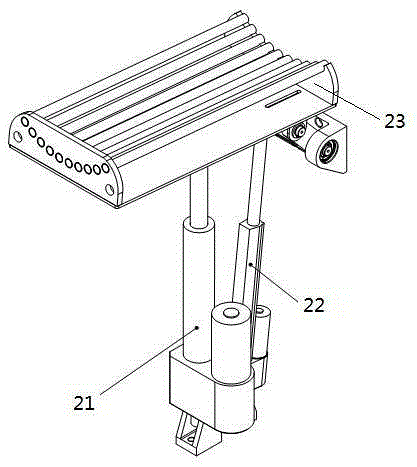

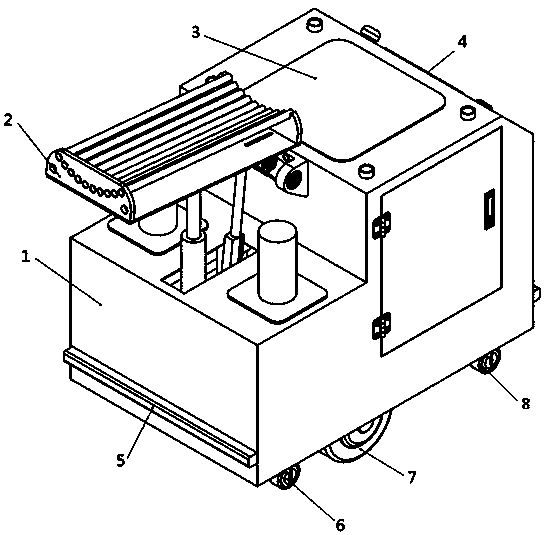

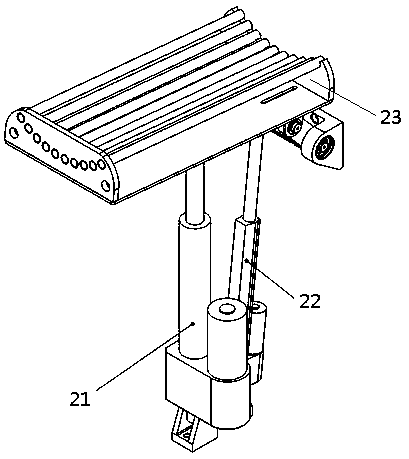

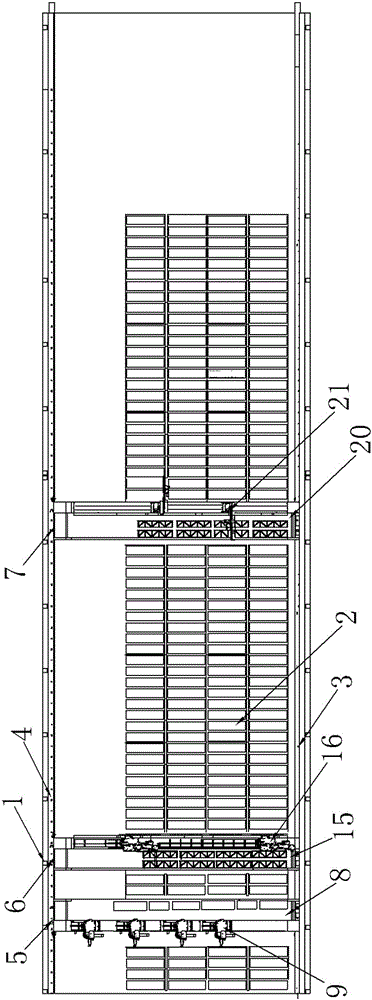

Control method for automatic feeding and discharging AGV

InactiveCN109095096AReduce labor intensityRealize industrial automationMechanical conveyorsVisual recognitionEngineering

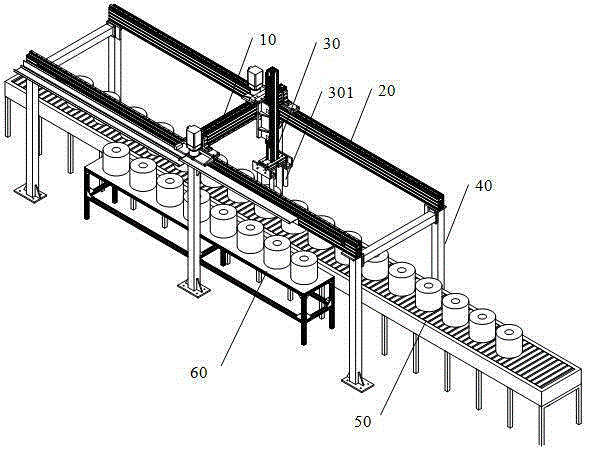

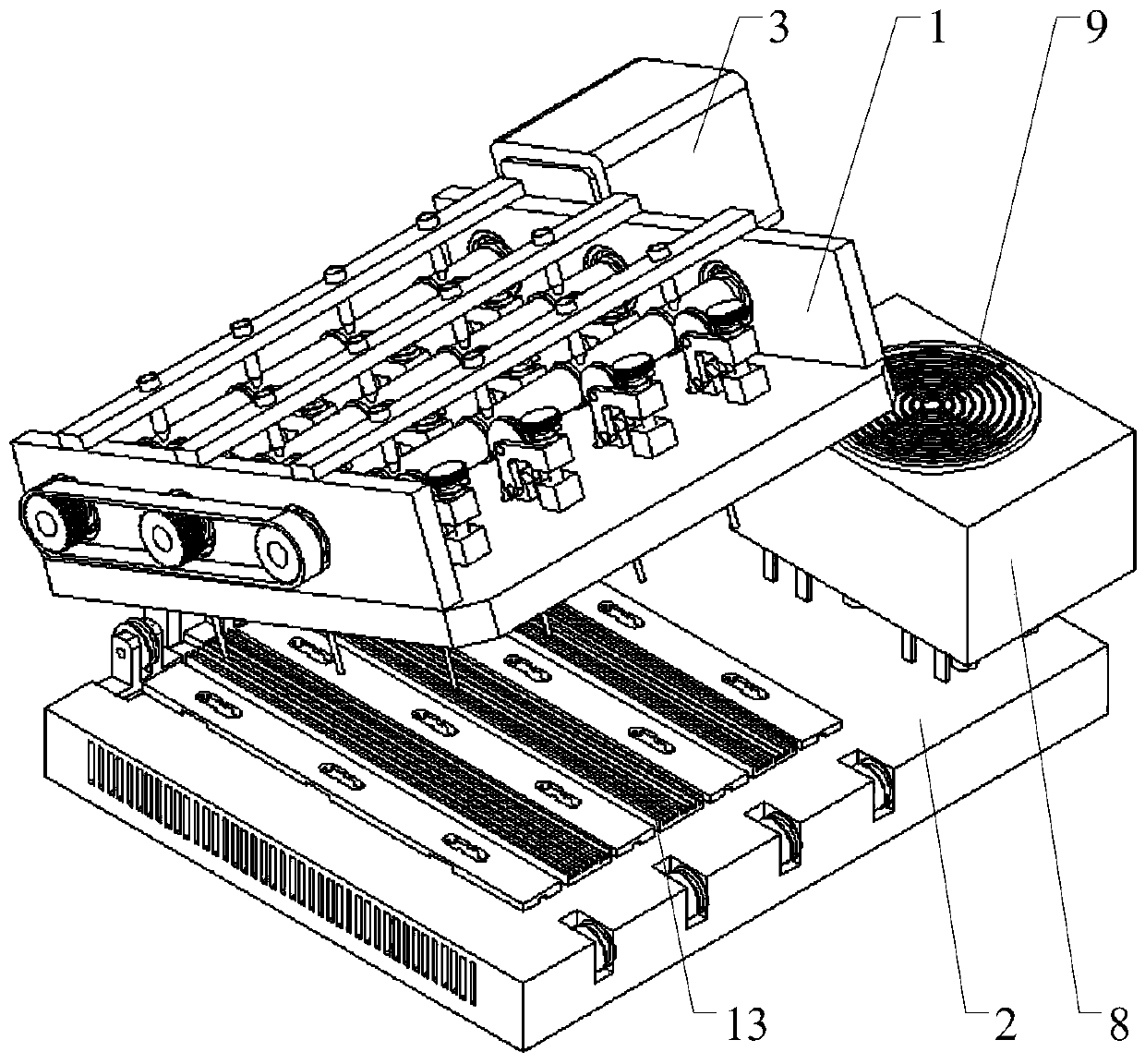

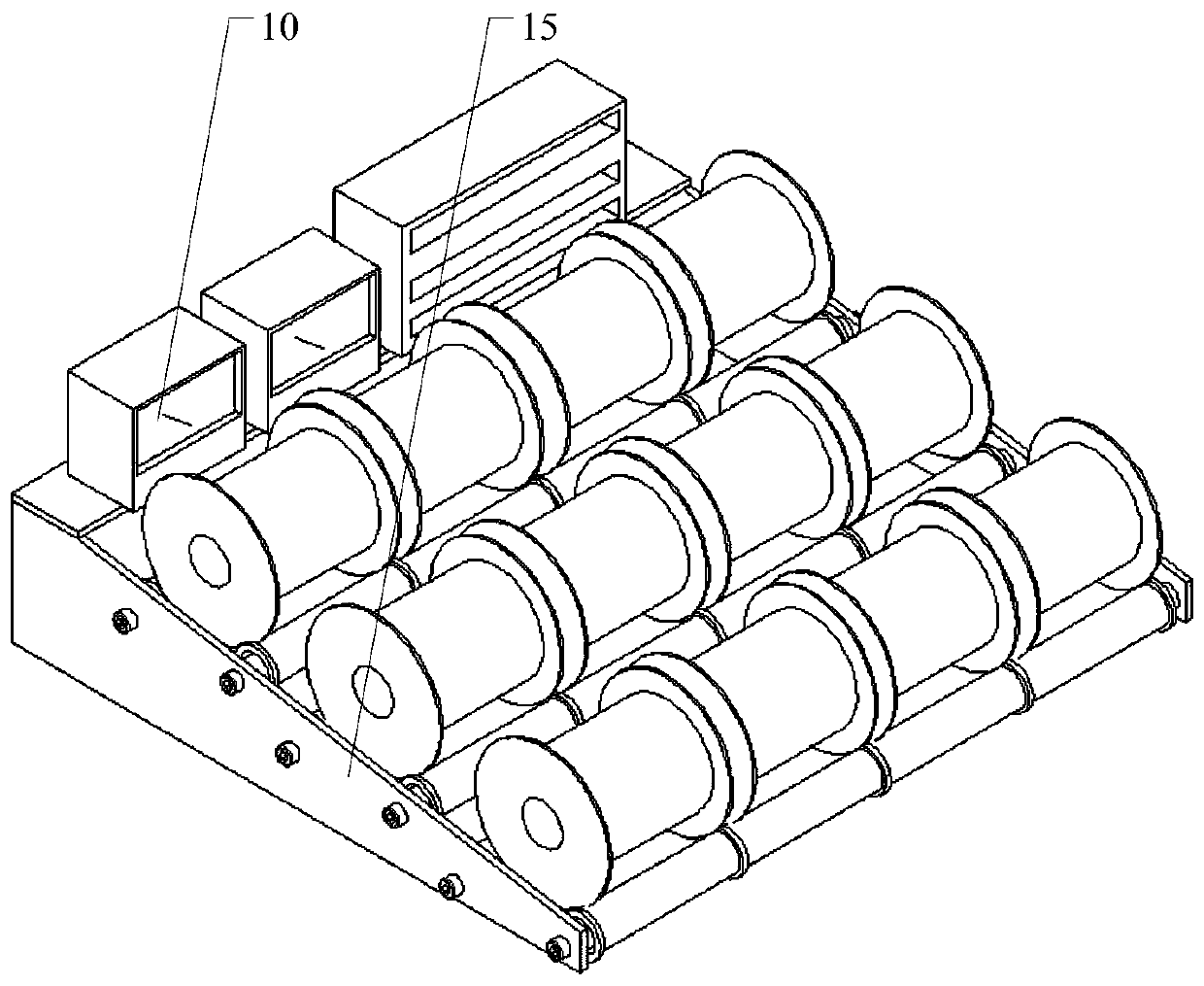

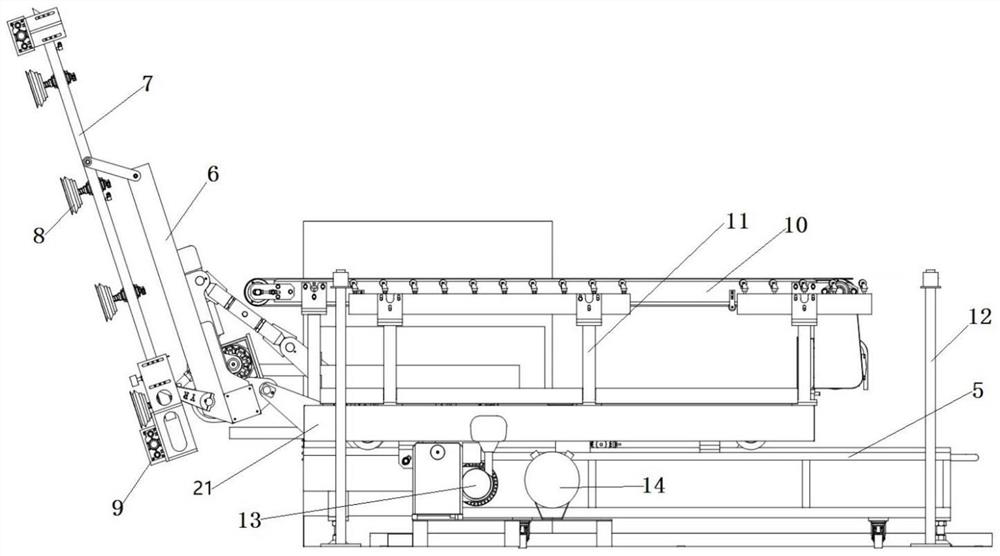

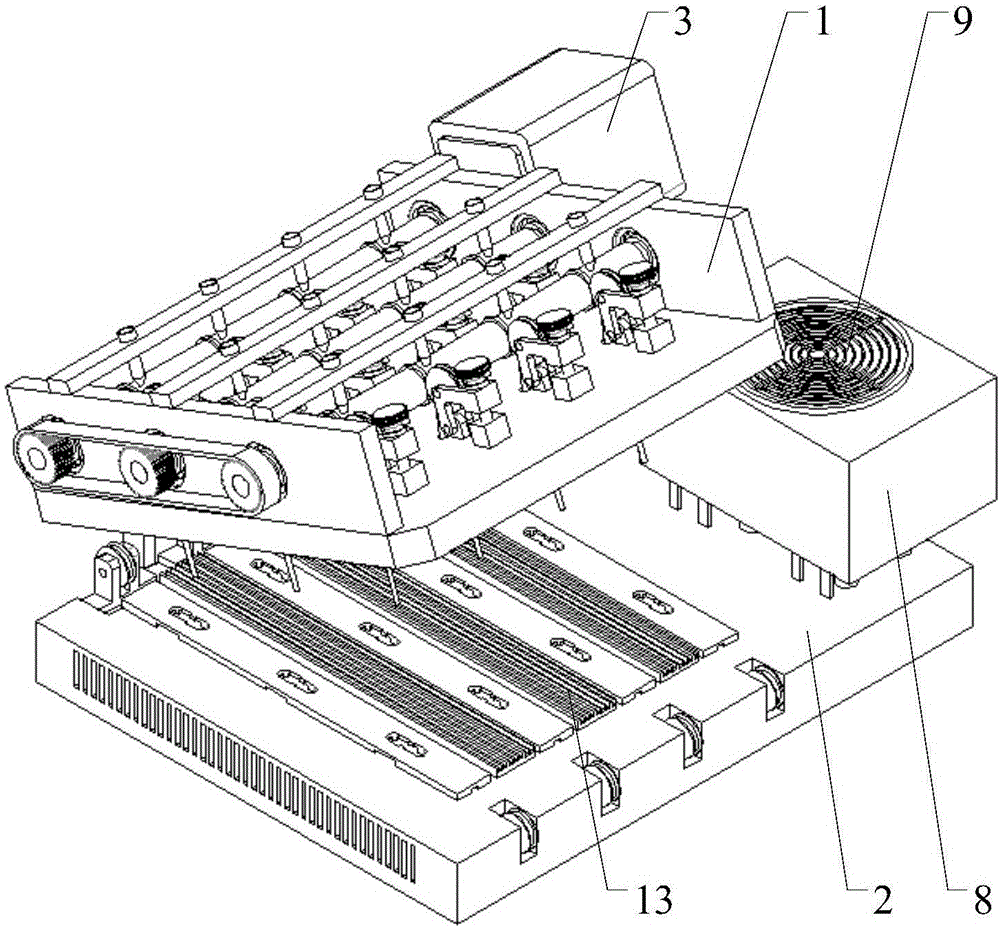

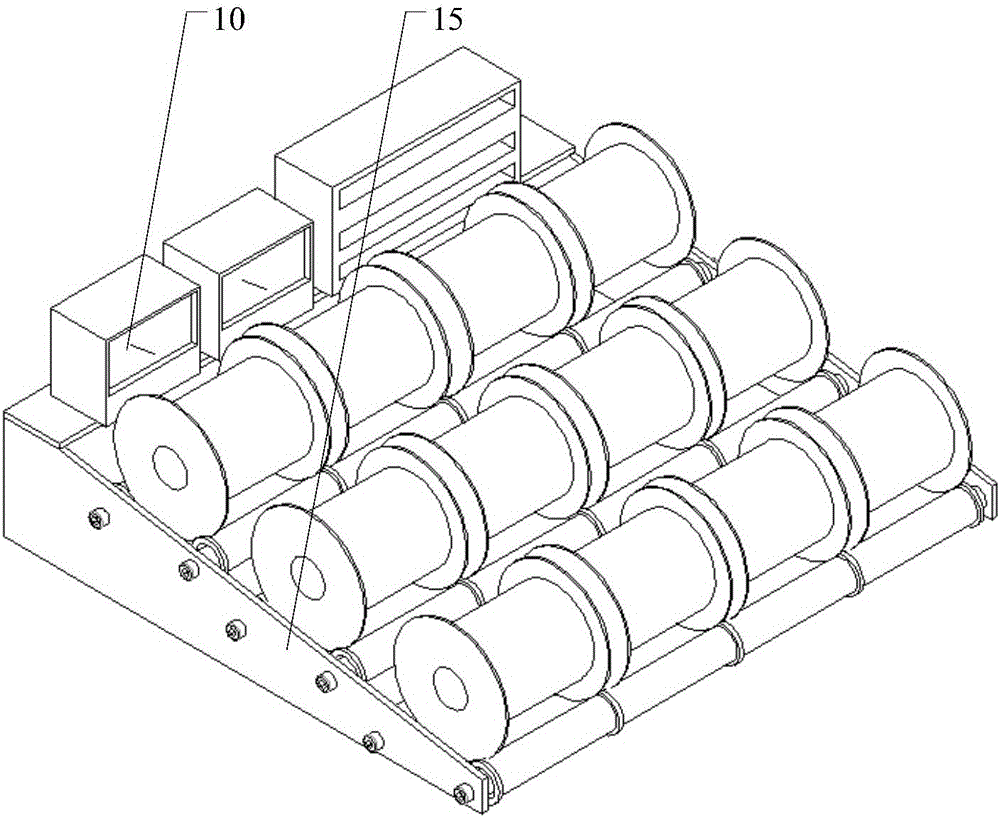

The invention provides a control method for an automatic feeding and discharging AGV. The control method is applied to an automatic feeding and discharging AGV system for hollow winding drum materials, and comprises the following steps that (1) the automatic feeding and discharging AGV automatically travels to the position of a material temporary-storage frame along guiding rails according to thestarting point position given by a dispatching instruction; (2) the automatic feeding and discharging AGV automatically takes the materials away from the material temporary-storage frame; (3) the automatic feeding and discharging AGV automatically travels to the position of production equipment along the guiding rails according to the destination point position given by the dispatching instruction; (4) the automatic feeding and discharging AGV completes the automatic feeding motion of the production equipment through coarse alignment operation of a vehicle body traveling driving device and fine alignment operation of a visual recognition assembly of cantilever shafts; and (5) otherwise, the automatic discharging motion of the production equipment is completed by obtaining materials from the production equipment and carrying the materials onto the temporary-storage frame. The control method has the advantages that the labor intensity of staff is effectively relieved, and industrial automation is realized.

Owner:湖南驰众机器人有限公司

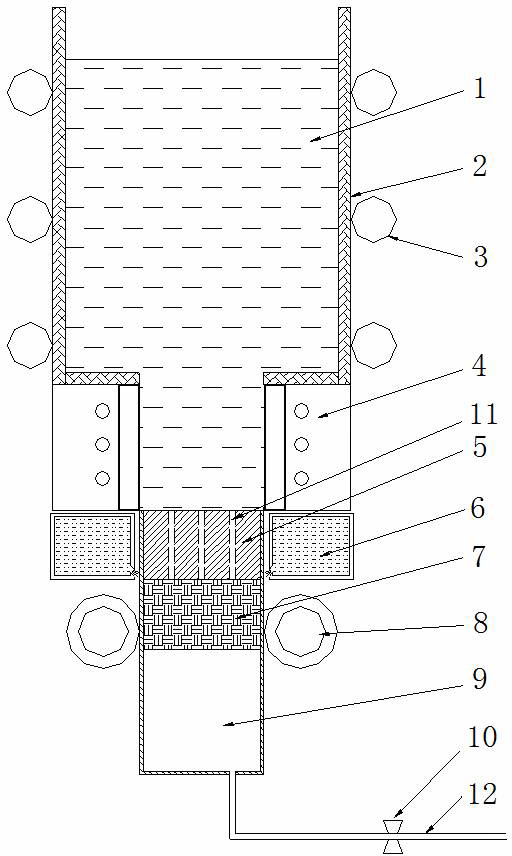

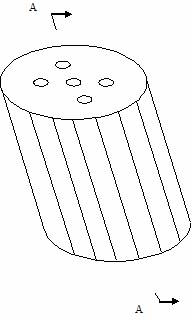

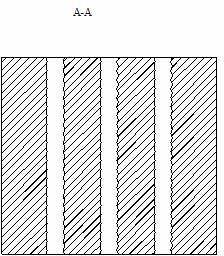

Method for preparing macroscopic through-type porous metal material and continuous casting device thereof

The invention discloses a method for preparing a macroscopic straight-through porous metal material and a continuous casting device thereof. The steps of the method are as follows: a. heating liquid metal in a crucible and keeping it warm; b. pouring the liquid metal downward into a heating type crystallizer, Keep the temperature of the liquid metal in the heating mold above the liquidus line; c. Blow gas to the liquid metal melt through the hole template, and at the same time establish a self-upper in the liquid metal melt near the dummy rod. d. Pull down the casting in the drawing direction of continuous casting through the backward displacement movement of the pulling down of the dummy bar and the upward movement of the mold, so that the liquid metal passing through the bottom of the heating mold is continuous from top to bottom Directional solidification to form a metal material casting with macroscopic straight-through porosity. The continuous casting device of the invention prepares the macroscopic straight-through directional porous metal through the method of direct blowing of the template and coupling the directional solidification of the metal melt. The equipment is simple, the operation is easy, it can be applied to a variety of metals, and the pore distribution is controllable.

Owner:SHANGHAI UNIV

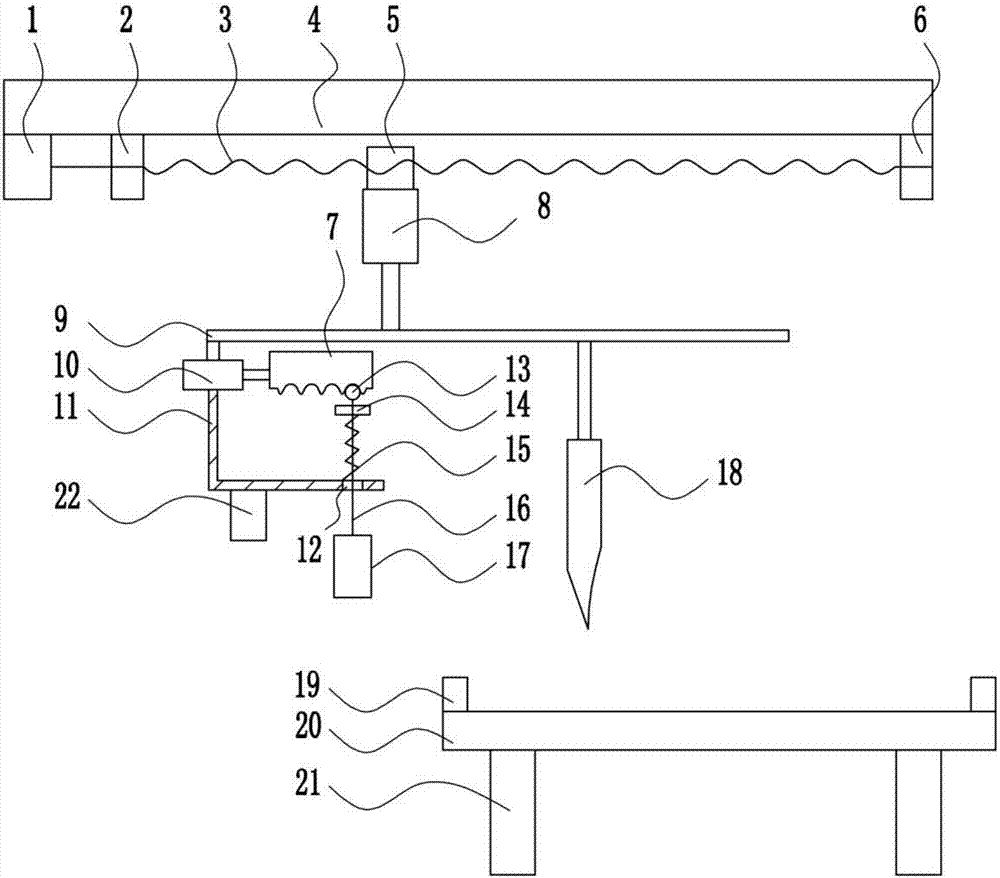

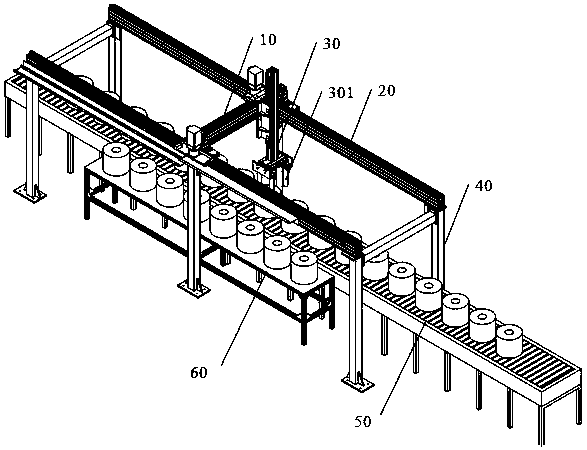

Control method for automatic guided vehicle (AGA)

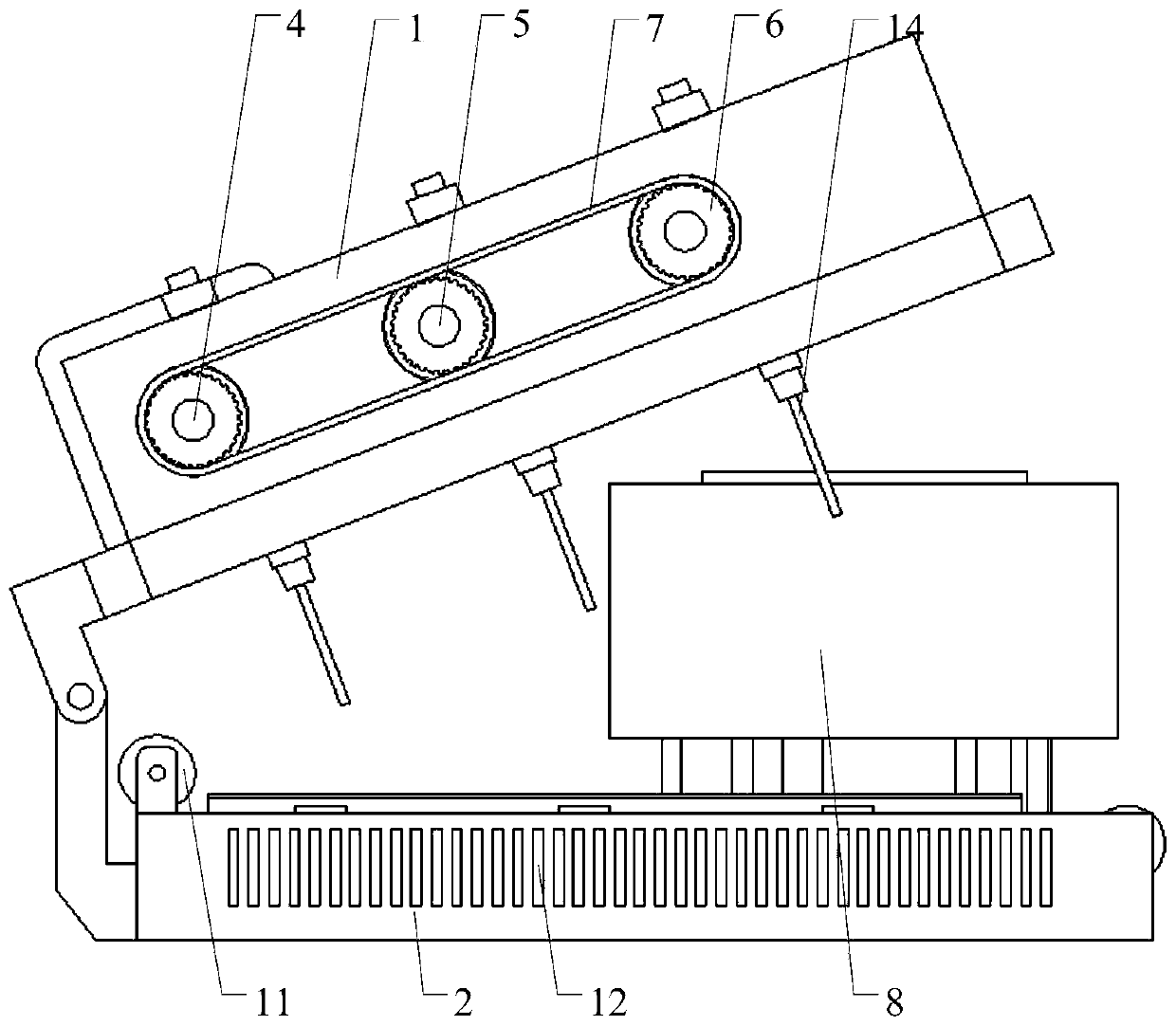

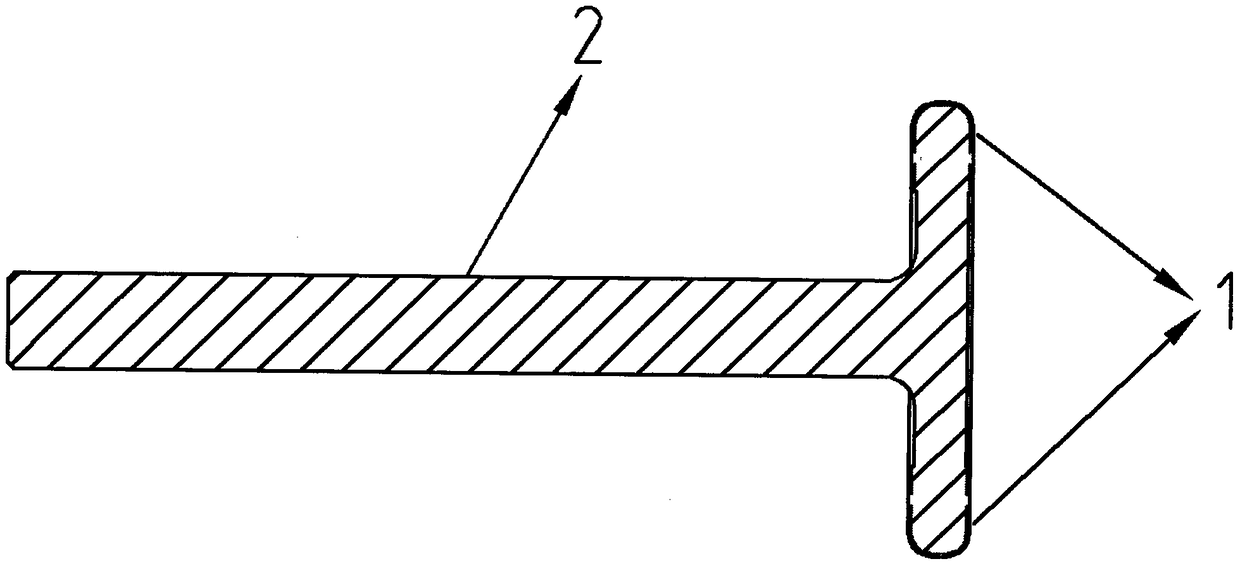

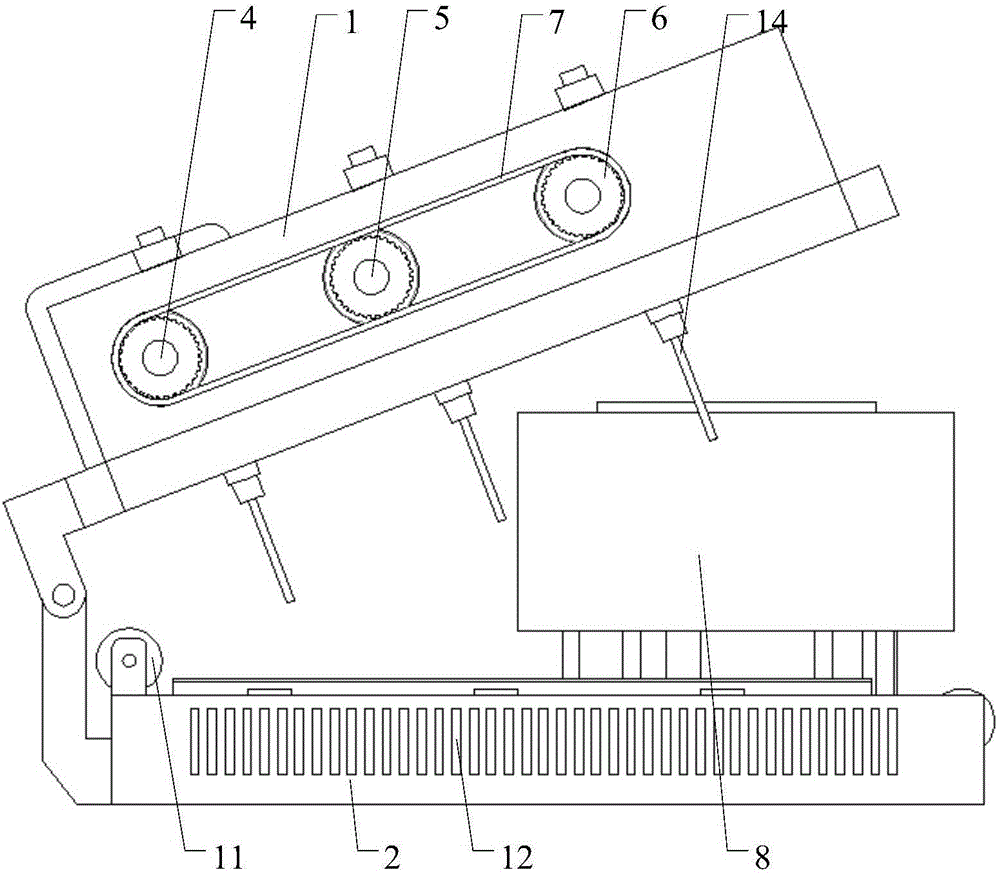

ActiveCN105417078AReduce labor intensityRealize industrial automationConveyorsControl devices for conveyorsYarnVehicle frame

The invention discloses a control method for an automatic guided vehicle (AGV). The control method is applied to an AGV system. The AGV system comprises an AGV and a butt joint truss. The AGV comprises a vehicle frame, a yarn taking mechanism and a yarn storage platform. The control method comprises the following steps that when winding of a yarn roll on a machine tool is completed, the yarn roll is taken down from the machine tool and placed on the yarn storage platform through the yarn taking mechanism; the AGV conveys the yarn roll to one side of an assembly line; the assembly line is detected by means of a sensor, continuing to wait for the time t is needed when the sensor detects that an empty position exists on the assembly line, and the yarn roll is placed on the assembly line when the sensor detects that the empty position still exists on the assembly line; and the above steps are repeated if the sensor detects that the yarn roll still exists on the assembly line. According to the control method for the AGV, the simple and efficient AGV system is adopted, the yarn roll can be conveyed onto the assembly line from the machine tool through the simple and efficient control method, the labor intensity of workers can be effectively relieved, and industrial automation is achieved.

Owner:NANJING KANGNI PRECISION MECHANICS

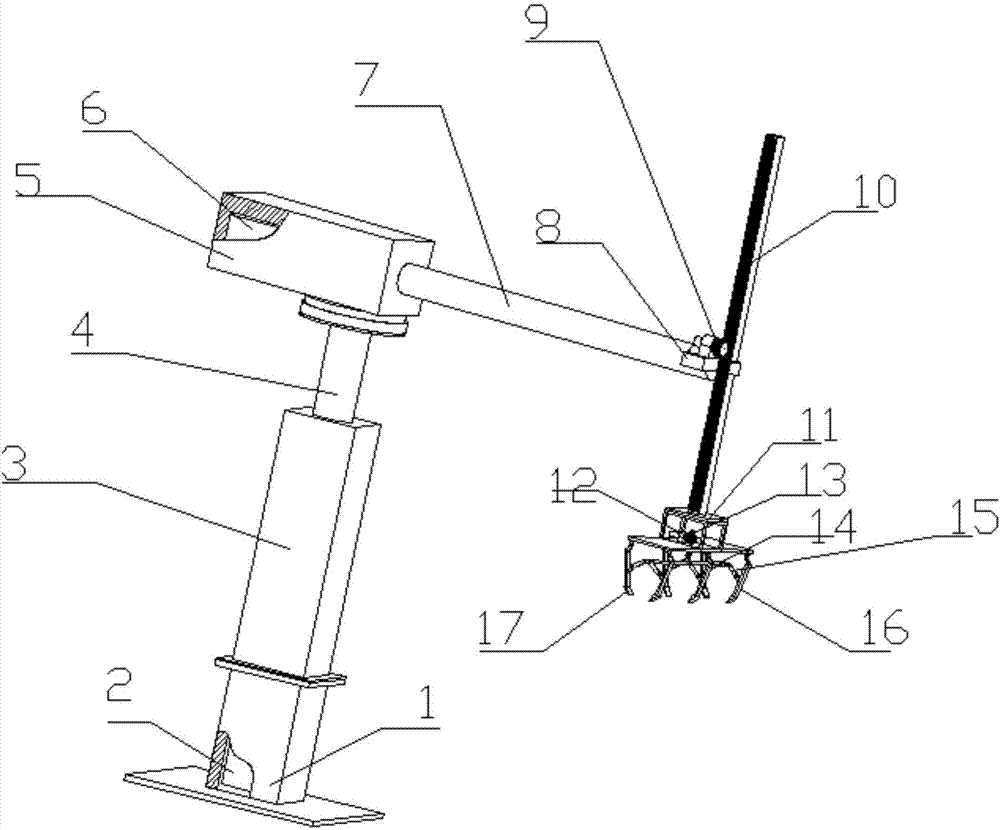

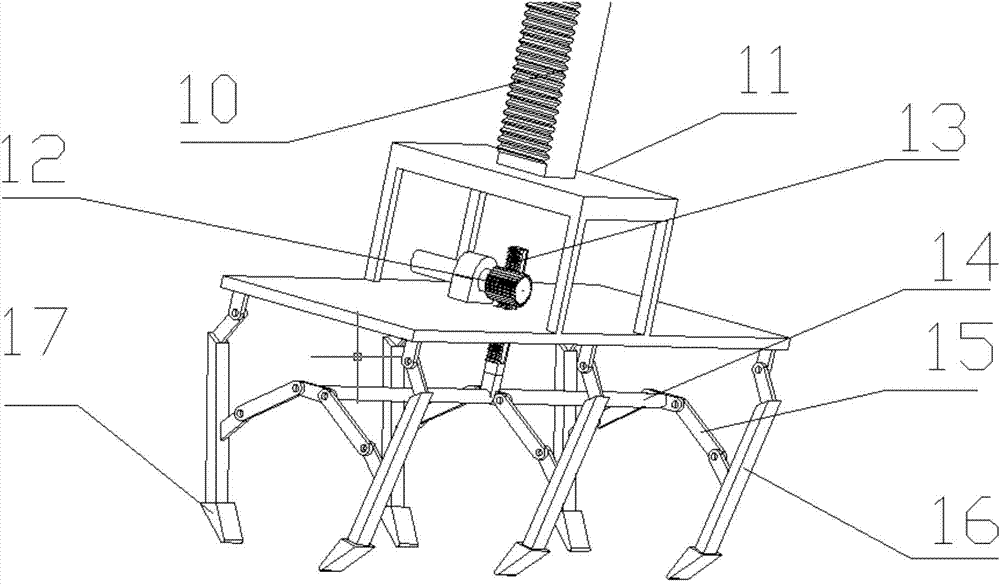

Control circuit of tree climbing robot

InactiveCN104375430ARealize industrial automationProgramme control in sequence/logic controllersEngineeringMotor control

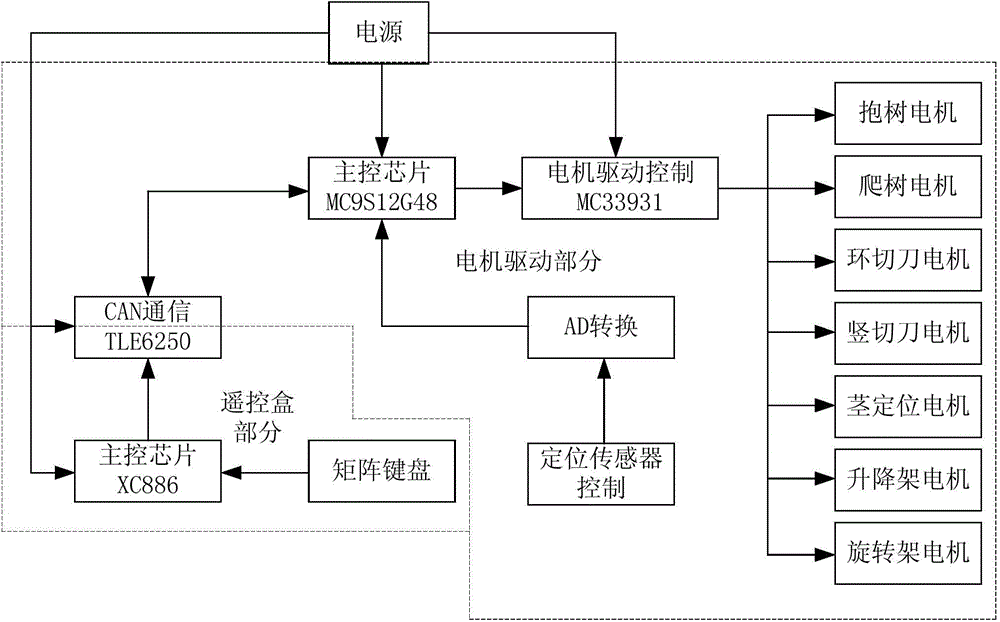

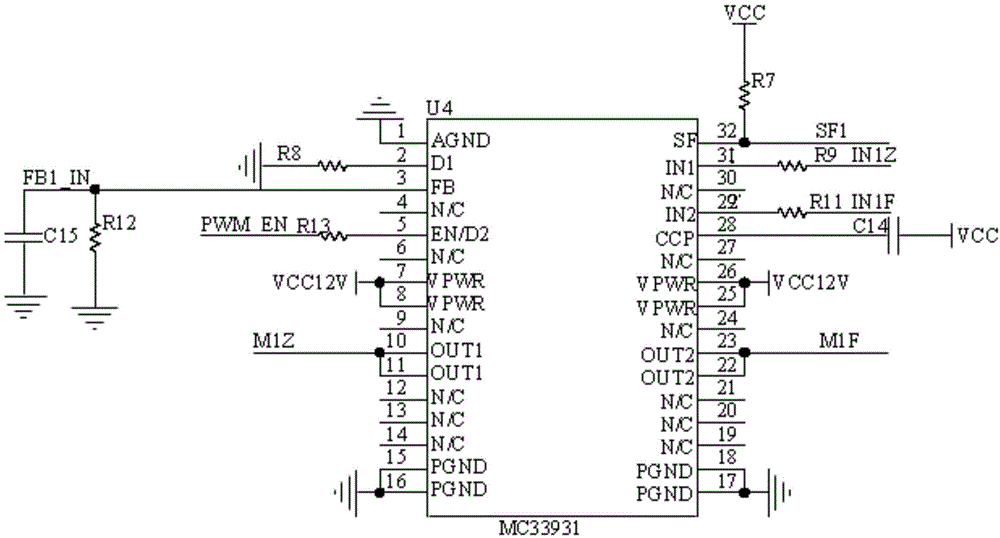

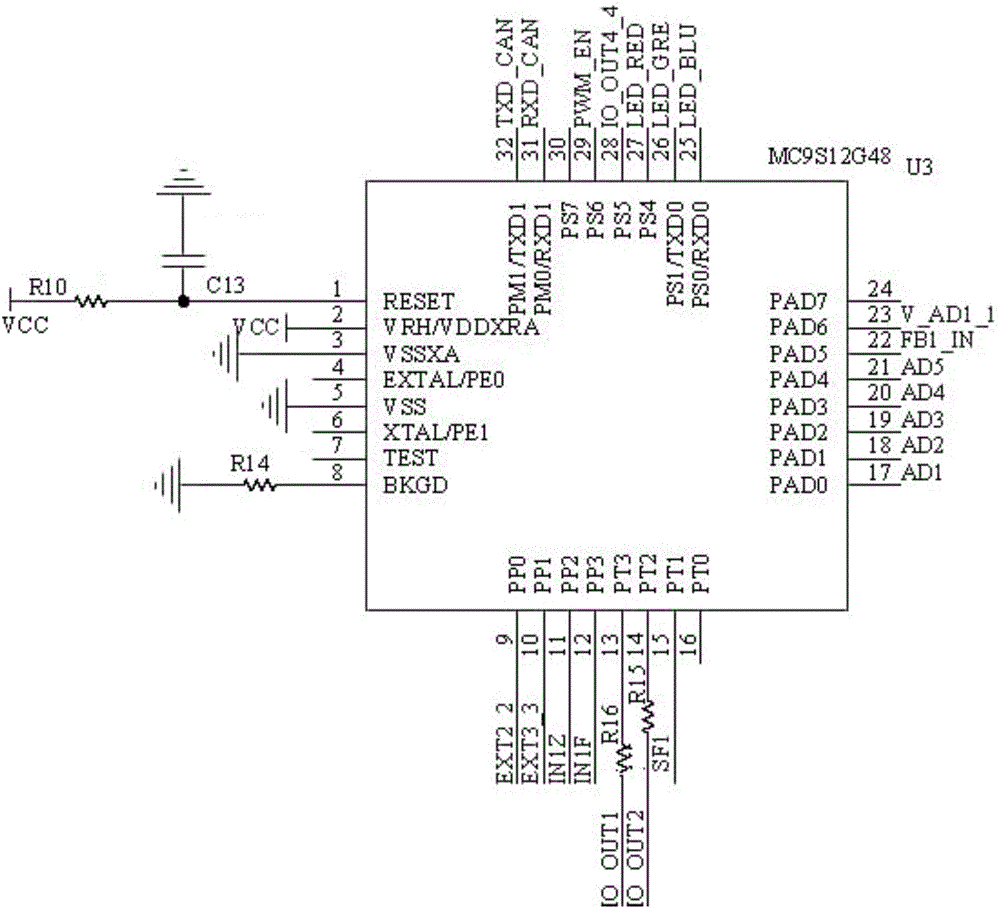

The invention provides a control circuit of a tree climbing robot. The control circuit comprises a control circuit body and a power supply. The output end of the power supply is connected with the power input end of the control circuit body. The signal input end of the control circuit body is connected with an external control device. A tree holding motor, a tree climbing motor, a girdling cutter motor, a vertical cutting cutter motor, a stem positioning motor and a lifting rack motor are provided with positioning sensors respectively, the positioning sensors send positional information, the signal output end of each positioning sensor is connected with an AD (analog-digital) converter inside a main control chip through an analog-digital conversion filter circuit, and signals are subjected to digital conversion via the AD converter inside the main control chip and then transmitted to a motor control circuit so as to control the motors to run. Manpower is replaced, industrial automation is realized, and the control circuit has broad market prospect and is applicable to the industry of electronic products.

Owner:CHONGQING NANFANG NUMERICAL CONTROL EQUIP

Bus type bus automobile digital instrument pointer function on-line monitoring method

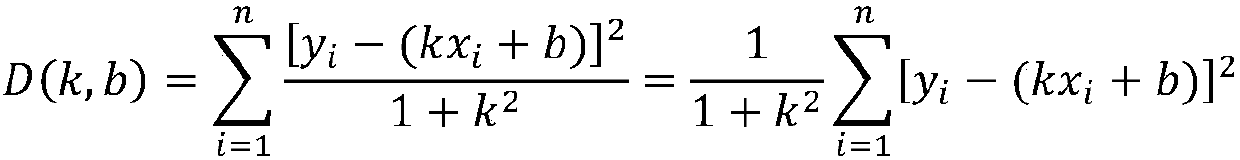

The invention discloses a bus type bus automobile digital instrument pointer function on-line monitoring method and belongs to the computer vision-based field product quality online monitoring technical field. The method can be used for automatically monitoring the function of the pointer of an automobile digital instrument and improving monitoring efficiency. The method of the invention comprises the following steps that: a pointer driving command is sent to an automobile instrument to be measured; the image of the panel of the instrument is acquired; the image is preprocessed; a pointer image is obtained through a subtraction method; the pointer image is refined; a pointer connected area is marked; by means of a minimum distance method, a pointer straight line is obtained through fitting; the pointer straight line is corrected; the reading of a pointer is calculated; and whether the reading is consistent with a preset value is judged, so that whether the function of the pointer of the instrument is qualified can be detected. The bus type bus automobile digital instrument pointer function on-line monitoring method of the invention can quickly and accurately extract the position and shape of the pointer of the automobile instrument at one time so as to realize the automatic detection of the function of the panel of the automobile digital instrument, thereby improving the efficiency and reliability of detection; and the method is suitable for digital instrument panel production line on-line detection.

Owner:JIANGSU UNIV

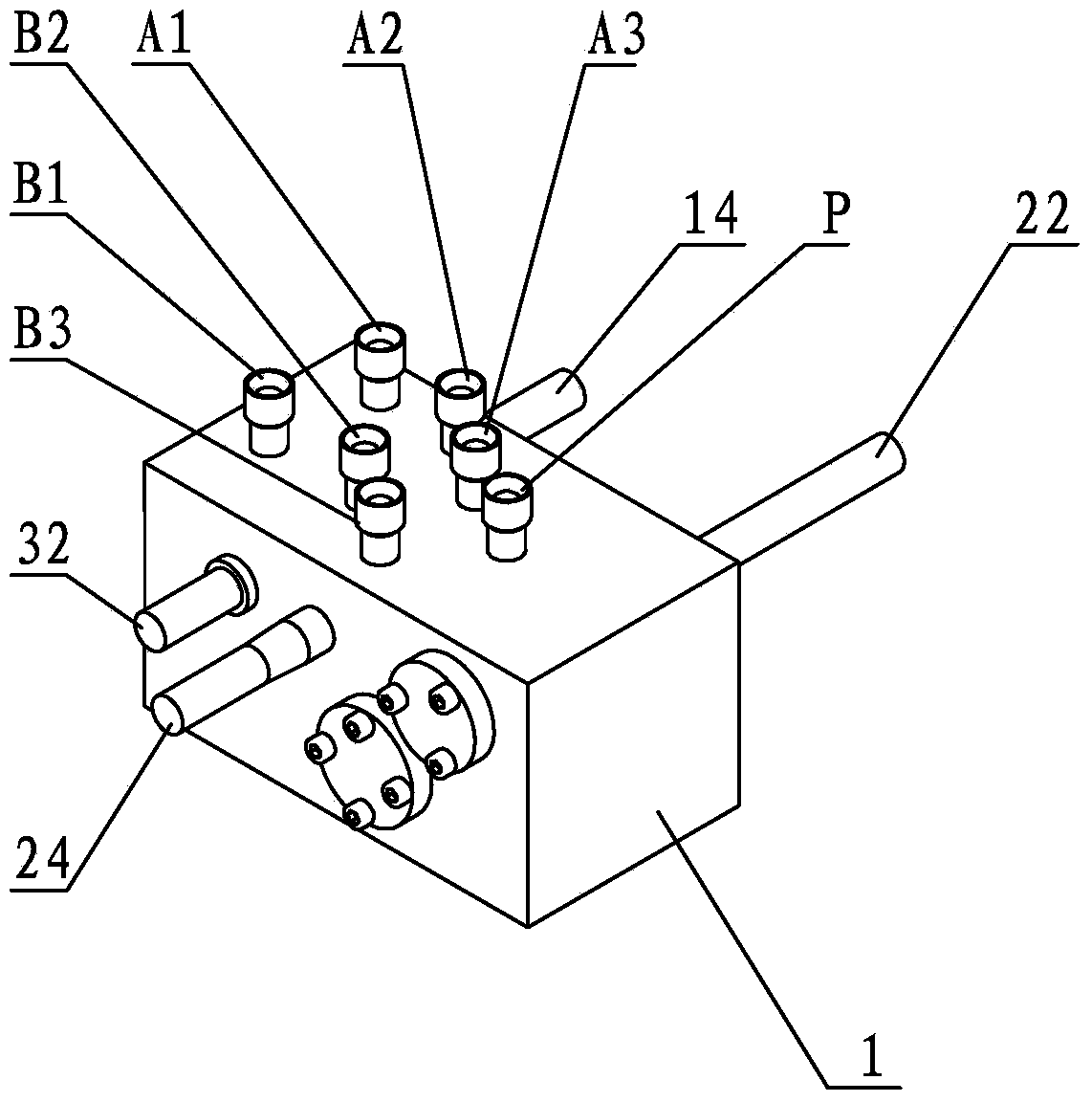

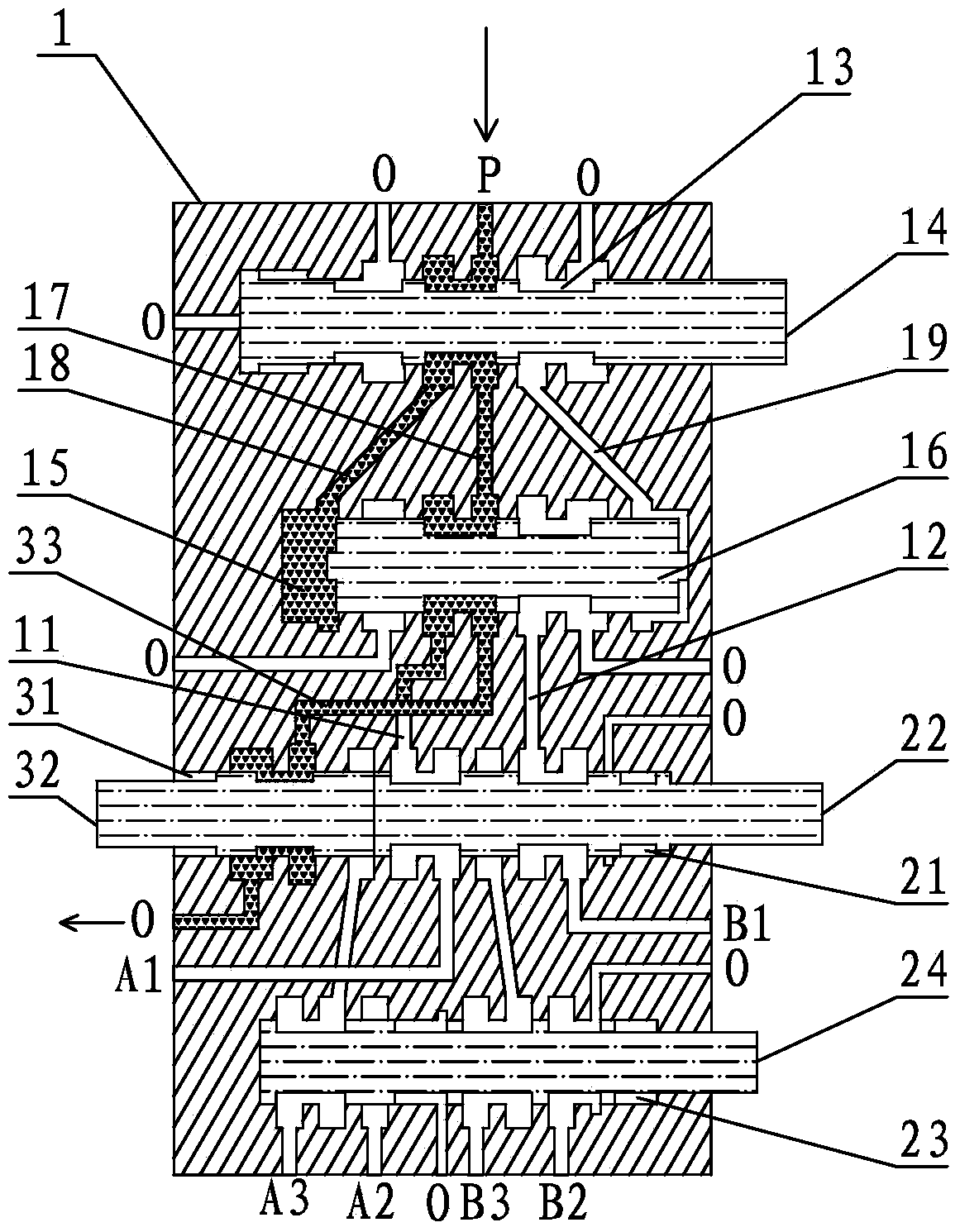

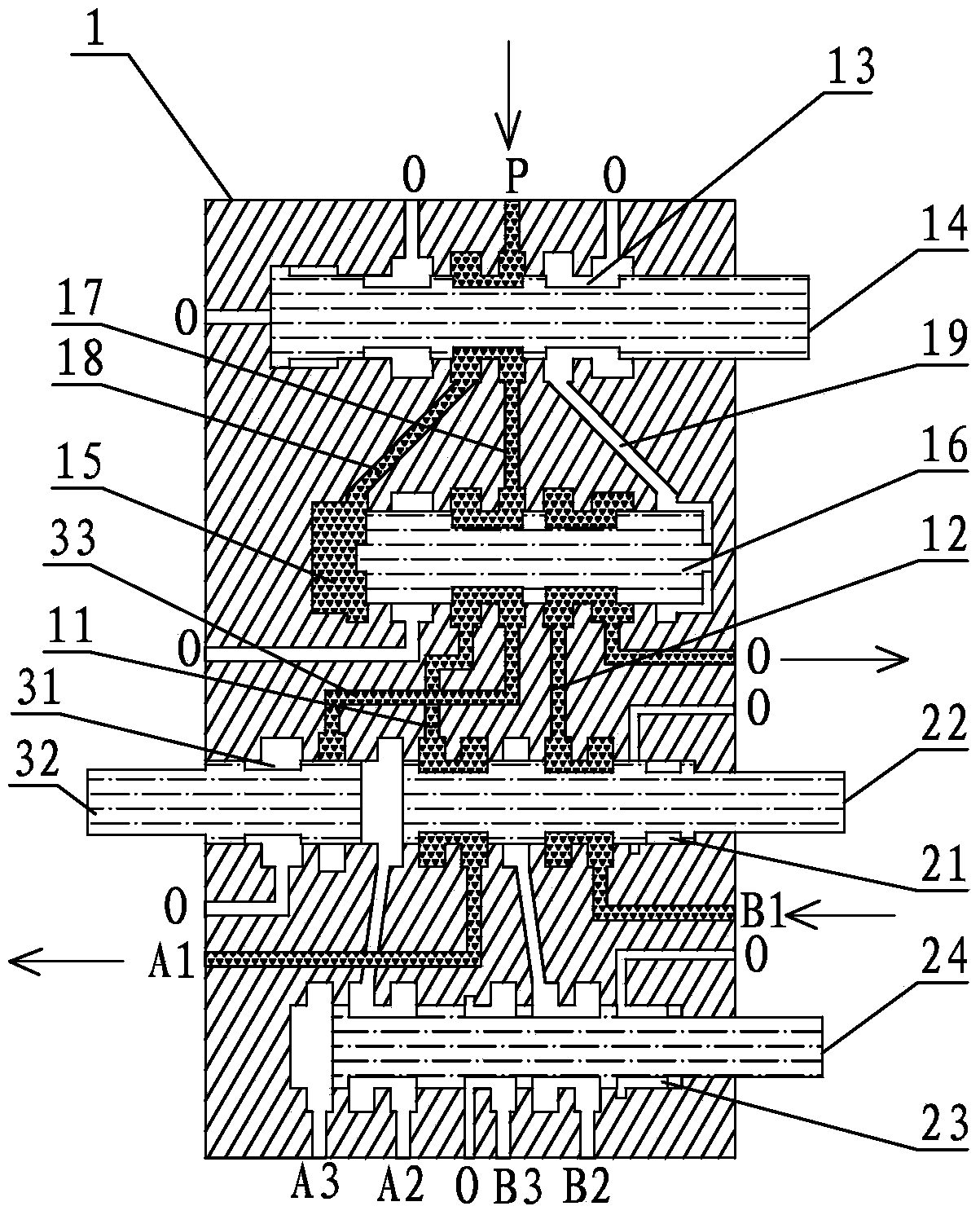

Multi-channel hydraulic control valve

ActiveCN103452937AImprove performanceEasy to controlServomotor componentsSteering controlMechanical valve

The invention discloses a multi-channel hydraulic control valve which comprises a valve body, wherein a reversing valve group and a change-over valve group are arranged in the valve body; the reversing valve group is connected with the change-over valve group through a first connecting oil passage and a second connecting oil passage; a reversing valve core in the reversing valve group acts to enable the first connecting oil passage and the second connecting oil passage to be in switching connection between an oil inlet and respective oil unloading openings respectively; a plurality of groups of oil cylinder connecting openings are formed in the change-over valve group, and change-over valve cores used for switching the oil cylinder connecting openings which are communicated with the first connecting oil passage and the second connecting oil passage are arranged on the change-over valve group. The multi-channel hydraulic control valve disclosed by the invention completely adopts a mechanical mechanism to realize the control to hydraulic oil channels, has the advantages of simple structure, low cost, stability in performance of mechanical valves and convenience for maintenance, is used for steering control of oil cylinder pistons and switching control of oil cylinders in a multi-channel hydraulic power system, facilitates the realization of automation control, and has a wide application prospect.

Owner:冯广建

Automatic stacking mechanical arm for solar glass tubes

InactiveCN104261142ARealize industrial automationSimple structureStacking articlesDe-stacking articlesHydraulic cylinderGear wheel

The invention discloses an automatic stacking mechanical arm for solar glass tubes, and belongs to the field of industrial production. The automatic stacking mechanical arm is composed of a base, a hydraulic cylinder, a base cover, a lifting rod, a gear rotary disc, a hydraulic cylinder, a telescopic rod, a gear rack seat, a lifting gear, a lifting gear rack, a claw seat, a claw gear, a claw gear rack, a pull rod, connecting rods, claws and leather sheaths. One hydraulic cylinder is arranged in the base, the bottom of the lifting rod is arranged in the base cover, the top of the lifting rod is connected with the bottom of the gear rotary disc, the other hydraulic cylinder is arranged in the gear rotary disc, the gear rack seat is fixedly connected with the telescopic rod, the lifting gear is arranged on the gear rack seat, the lifting gear rack is arranged in a groove of the gear rack seat and is meshed with the lifting gear, the top of the claw seat is fixedly connected with the bottom of the lifting gear rack, the claw gear is arranged on the claw seat, the claw gear rack is arranged in a groove of the claw seat and is meshed with the claw gear, the claws are directly connected with the claw seat through pins, the pull rod is fixedly connected with the claw gear rack, the two ends of the connecting rods are connected with the claws and the pull rod respectively through pins, and the claws are sleeved with the leather sheaths. According to the automatic stacking mechanical arm, manpower can be reduced, and automation can be achieved.

Owner:朱宝力

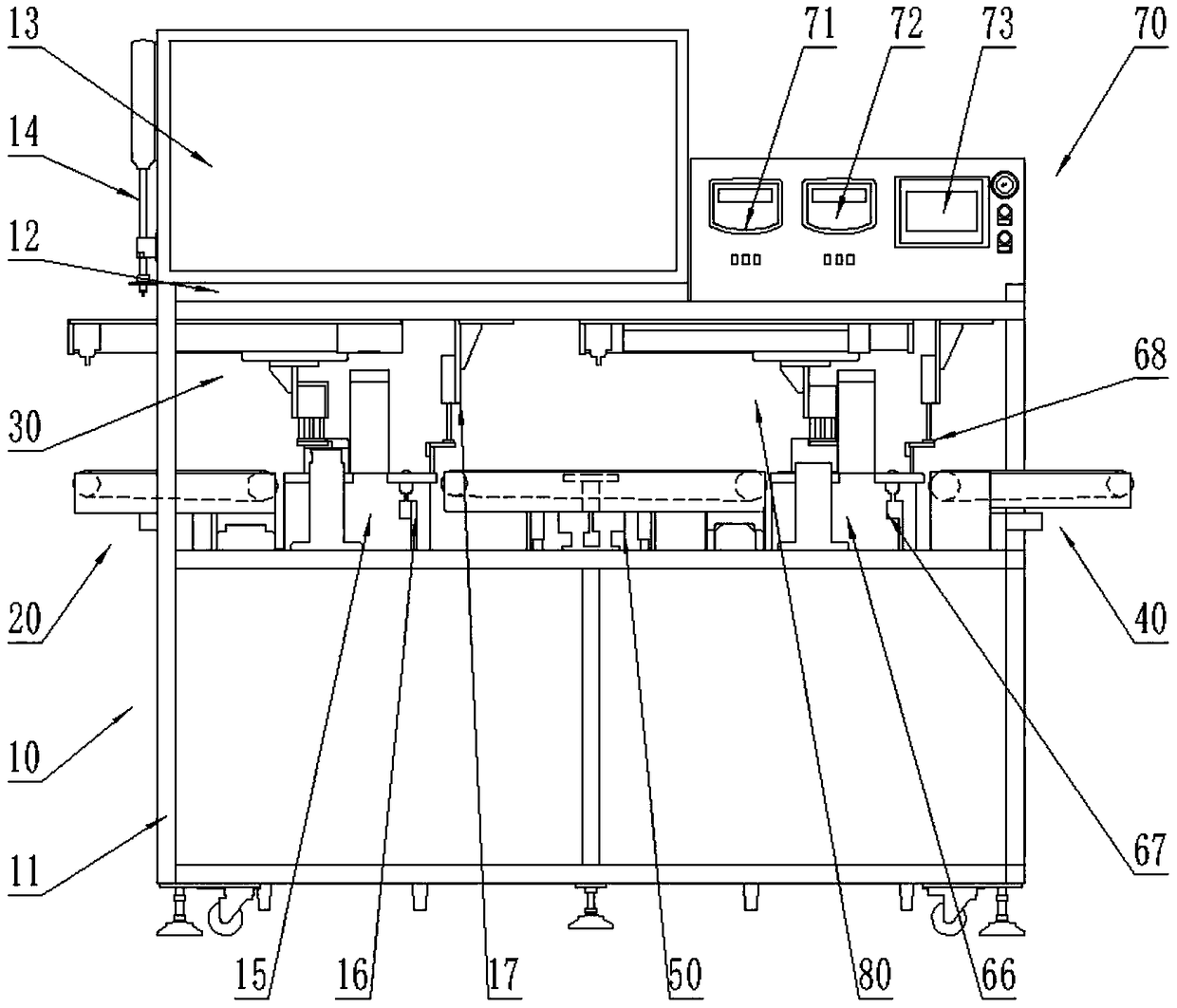

Automatic cross-shaped strapping machine for envelopes and cards

The invention discloses an automatic cross-shaped strapping machine for envelopes and cards. The automatic cross-shaped strapping machine comprises a rack, a first conveyor line, a first strapping assembly, an intermediate rotary conveyor line, a second strapping assembly, a second conveyor line and a control cabinet. The rack comprises a supporting frame and a flatly-arranged top plate arranged at the top of the supporting frame. The first conveyor line is arranged at the left end of the middle of the supporting frame, and the intermediate rotary conveyor line is arranged in the middle of thesupporting frame and located on the right side of a first blocking air cylinder. The second conveyor line is arranged at the right end of the middle of the supporting frame, and the control cabinet is arranged on the upper surface of the flatly-arranged top plate and internally provided with a first strapping controller, a second strapping controller and a human-computer interface. According to the automatic cross-shaped strapping machine for the envelopes and the cards, design is reasonable, the structure is simple, and the extremely high promotional value is achieved; and the automatic cross-shaped strapping machine can automatically conduct cross-shaped strapping on products, thus industrial automation can be achieved, worker labor force is relieved, and the strapping efficiency of theproducts is improved.

Owner:广州坤林自动化科技有限公司

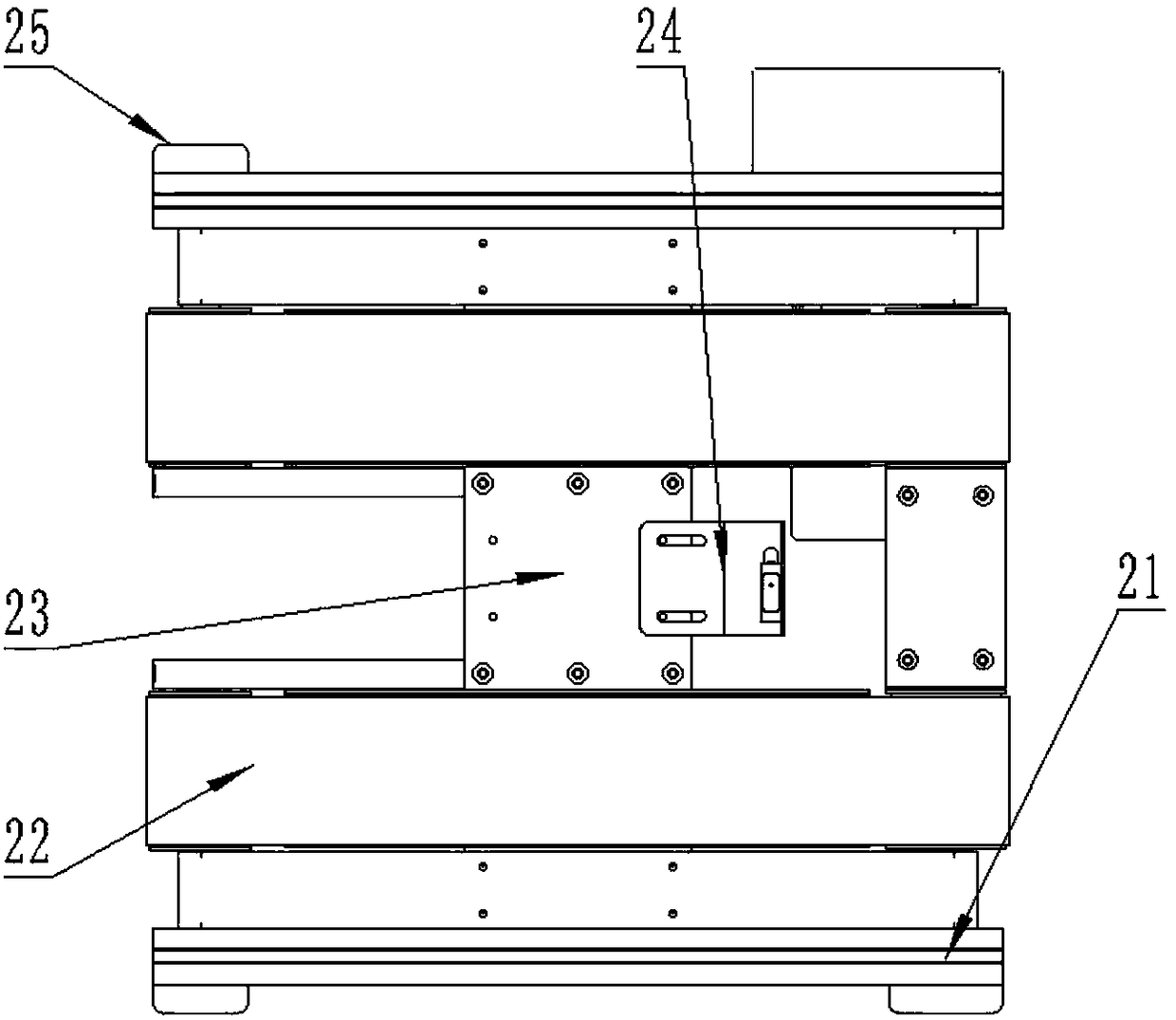

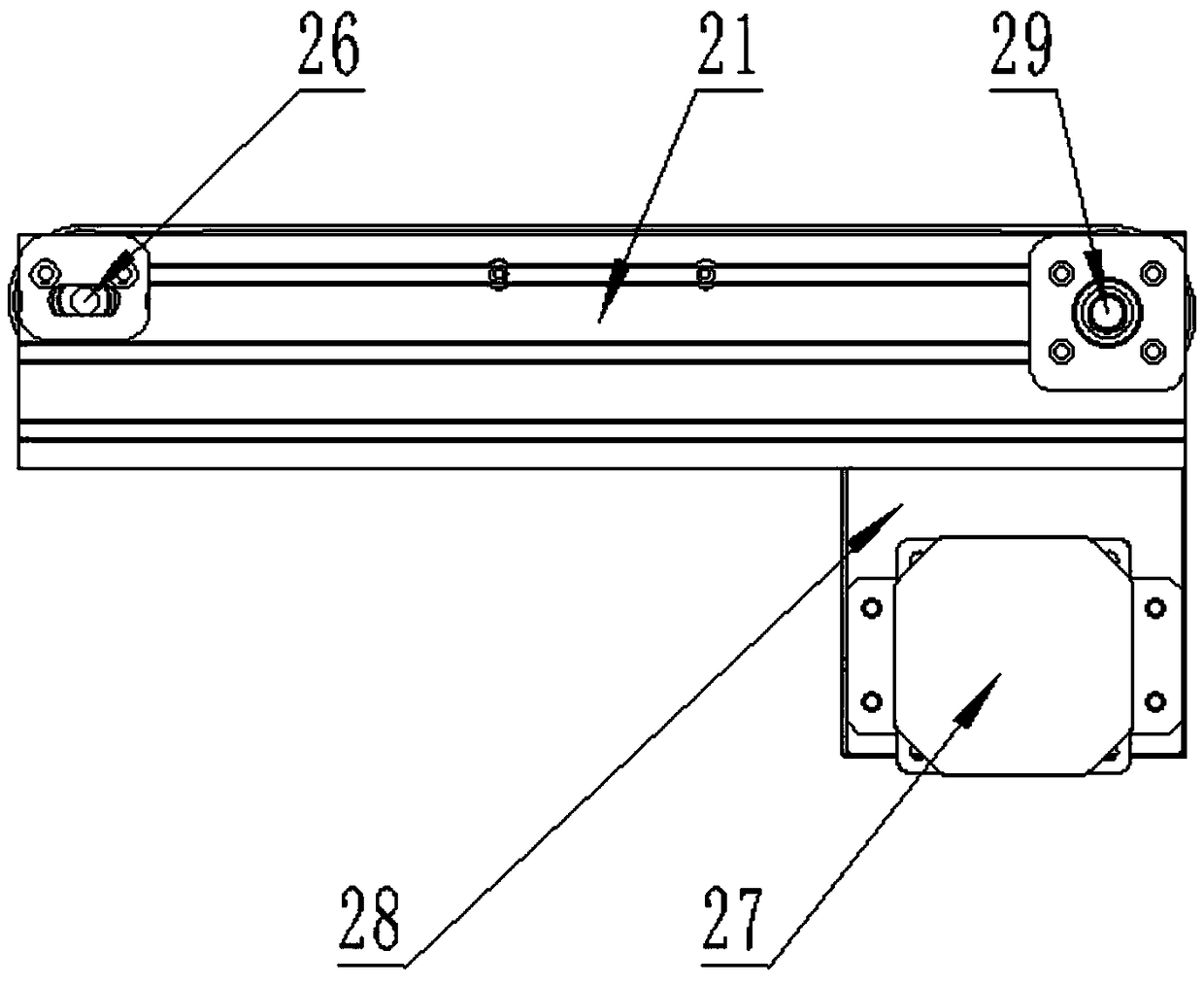

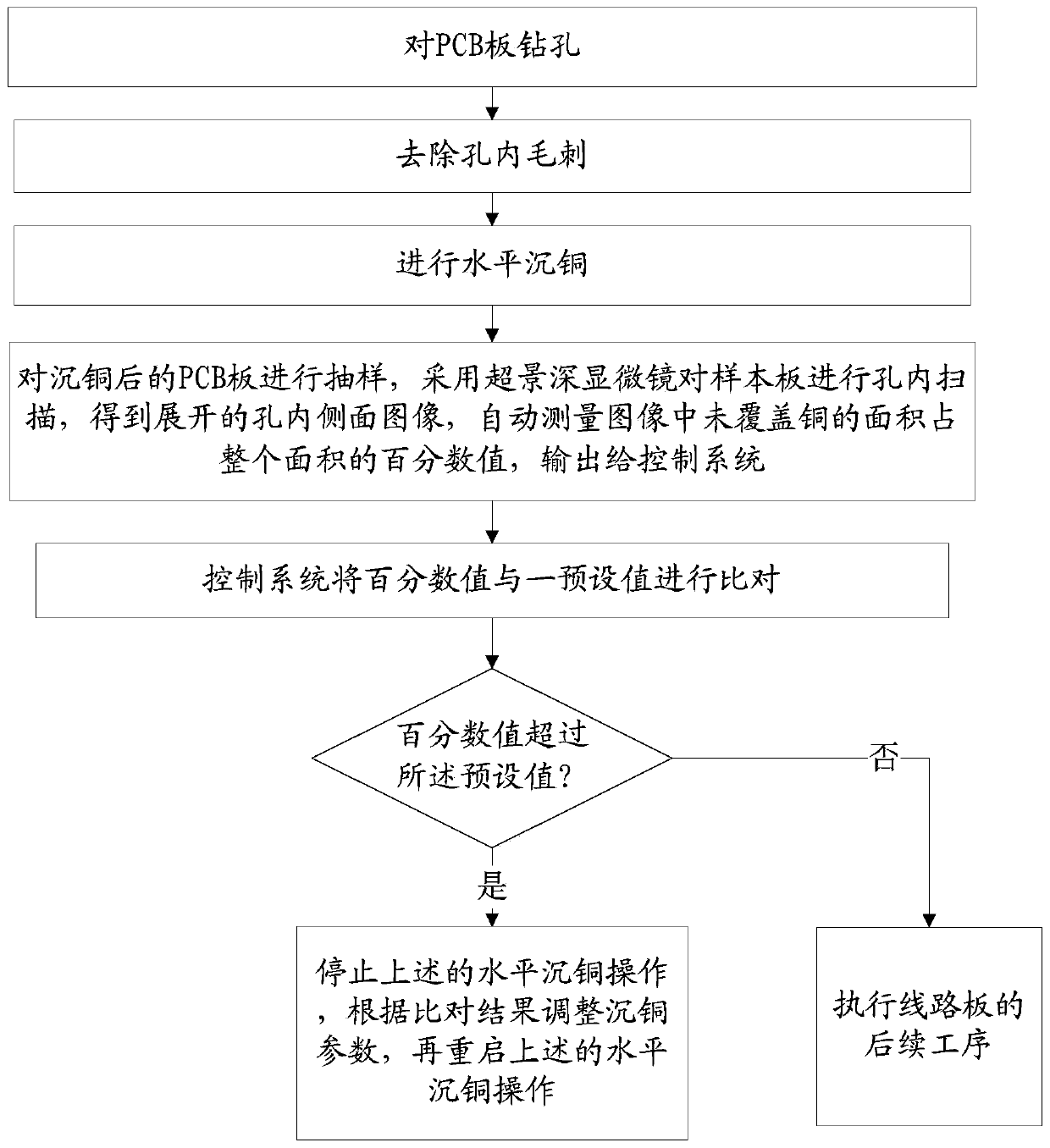

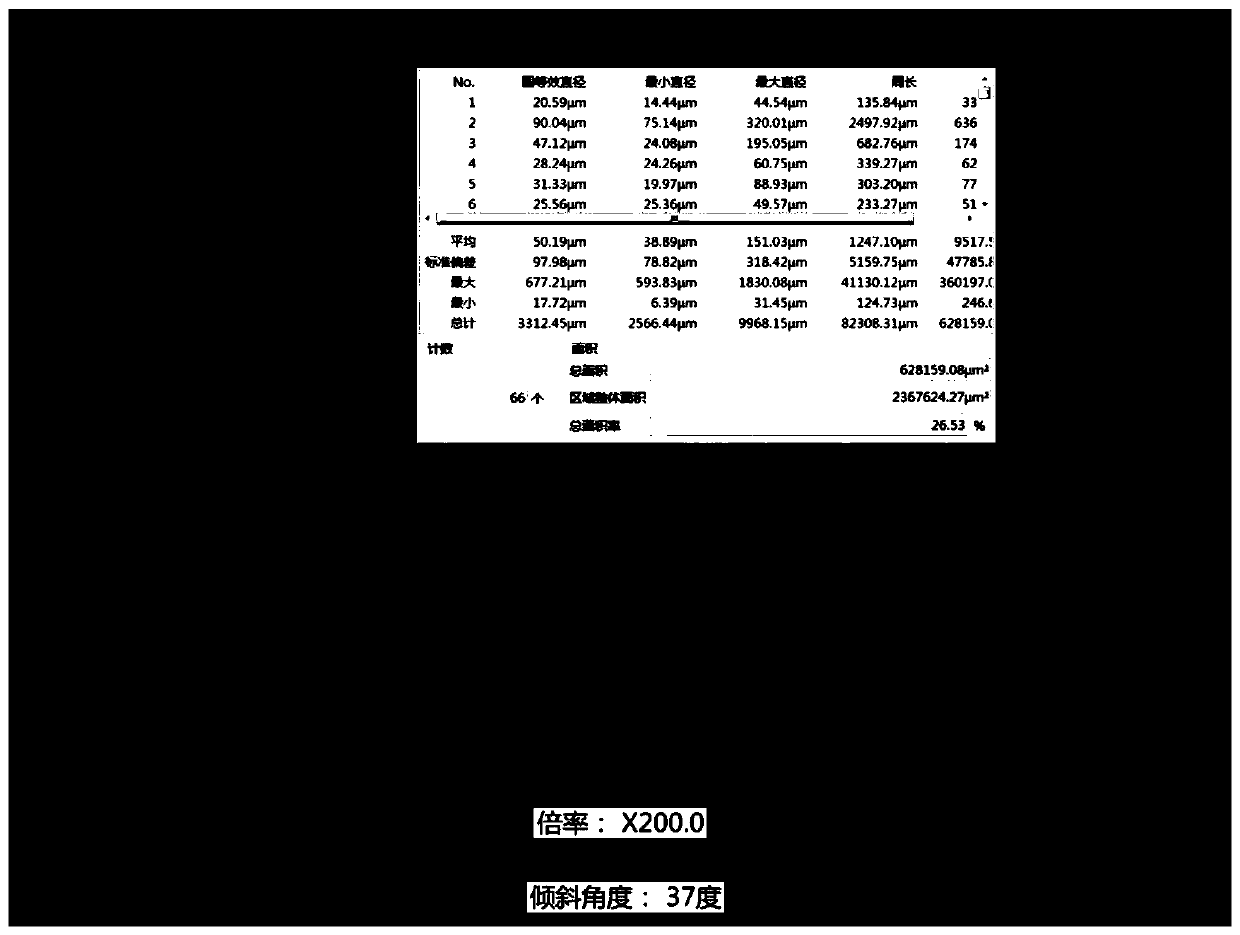

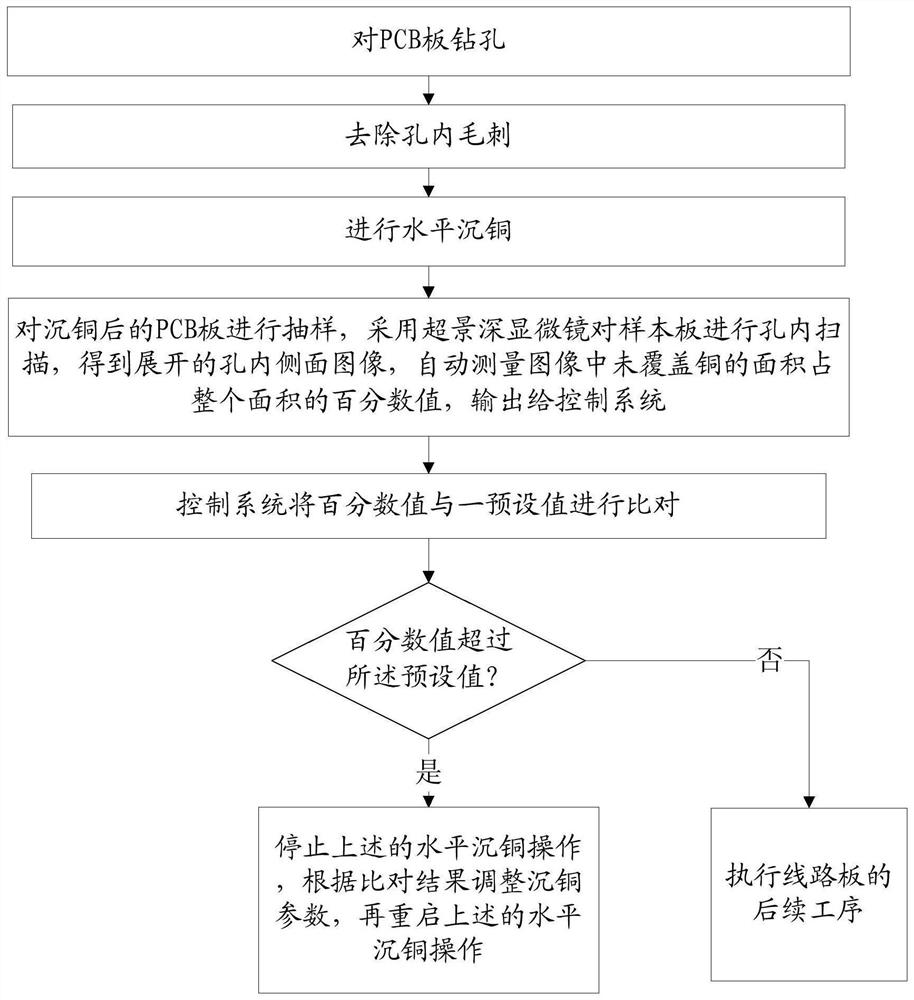

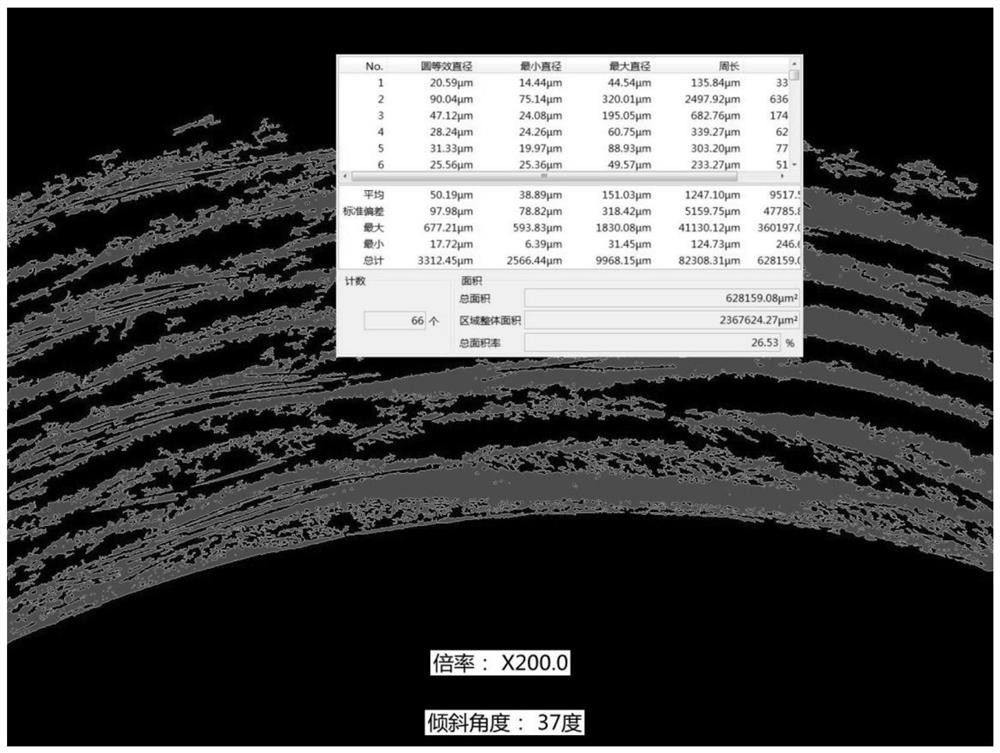

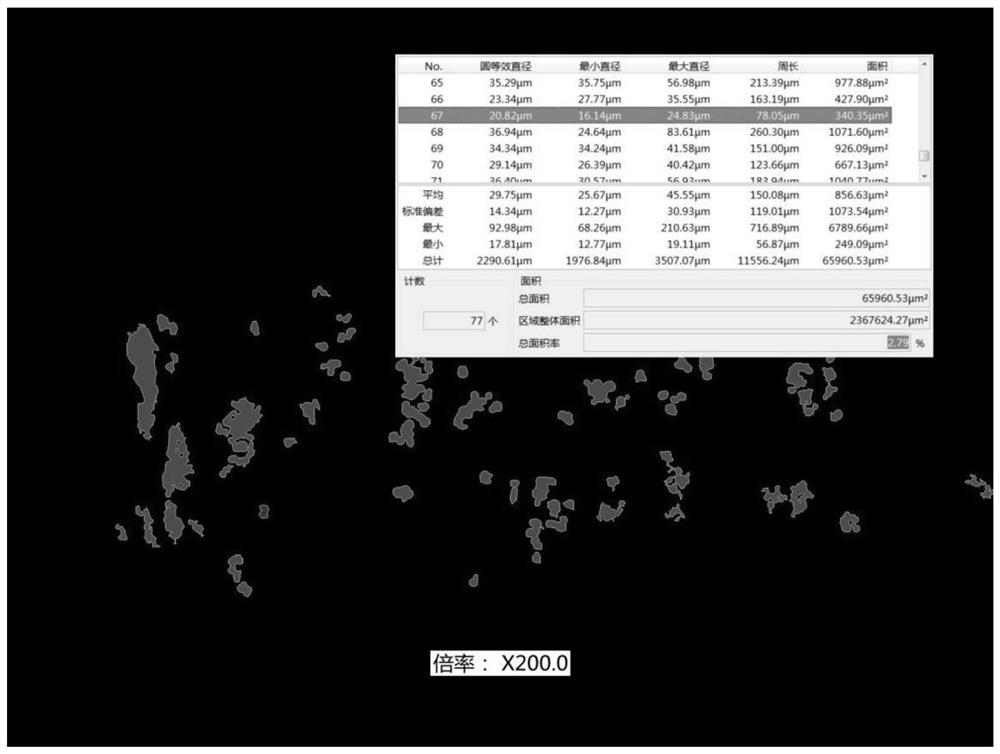

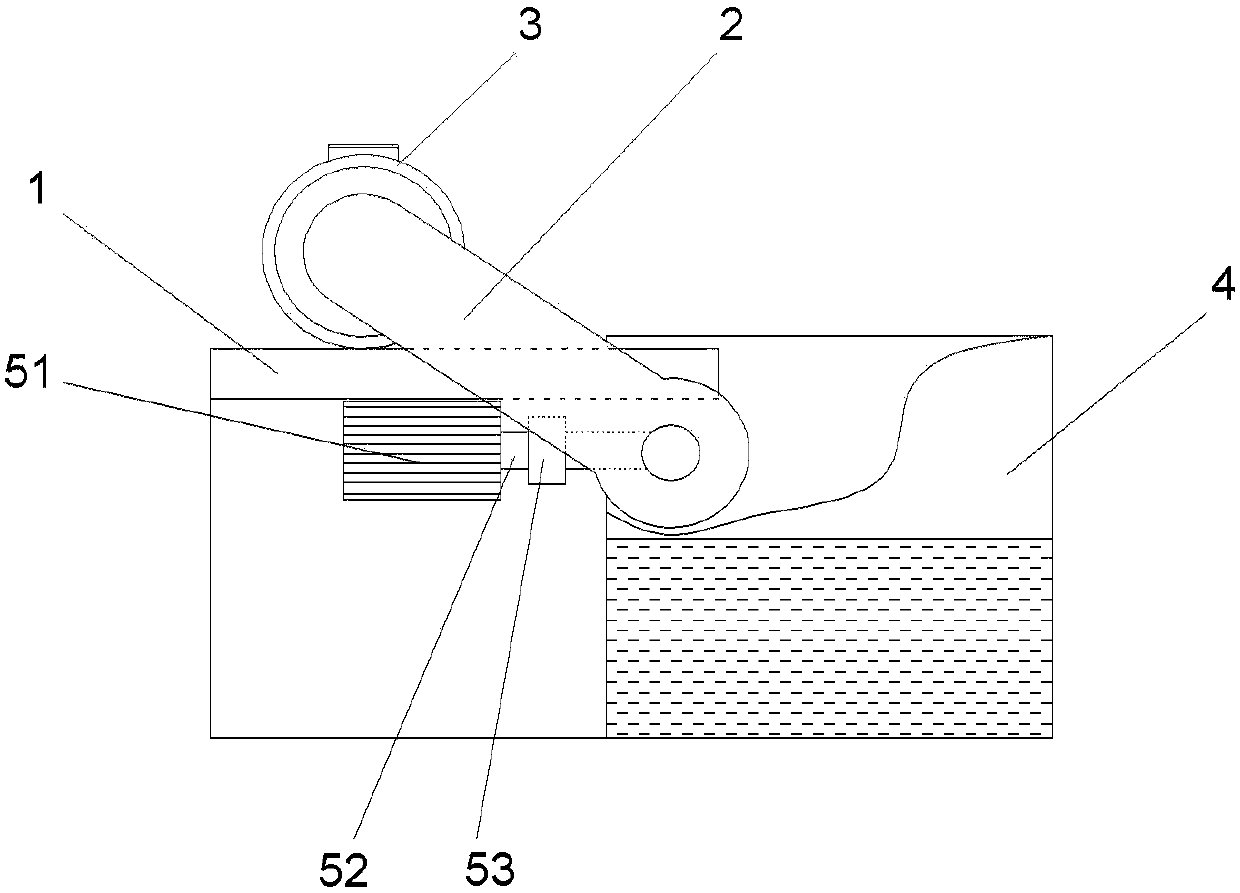

Automatic copper deposition control process for printed circuit board

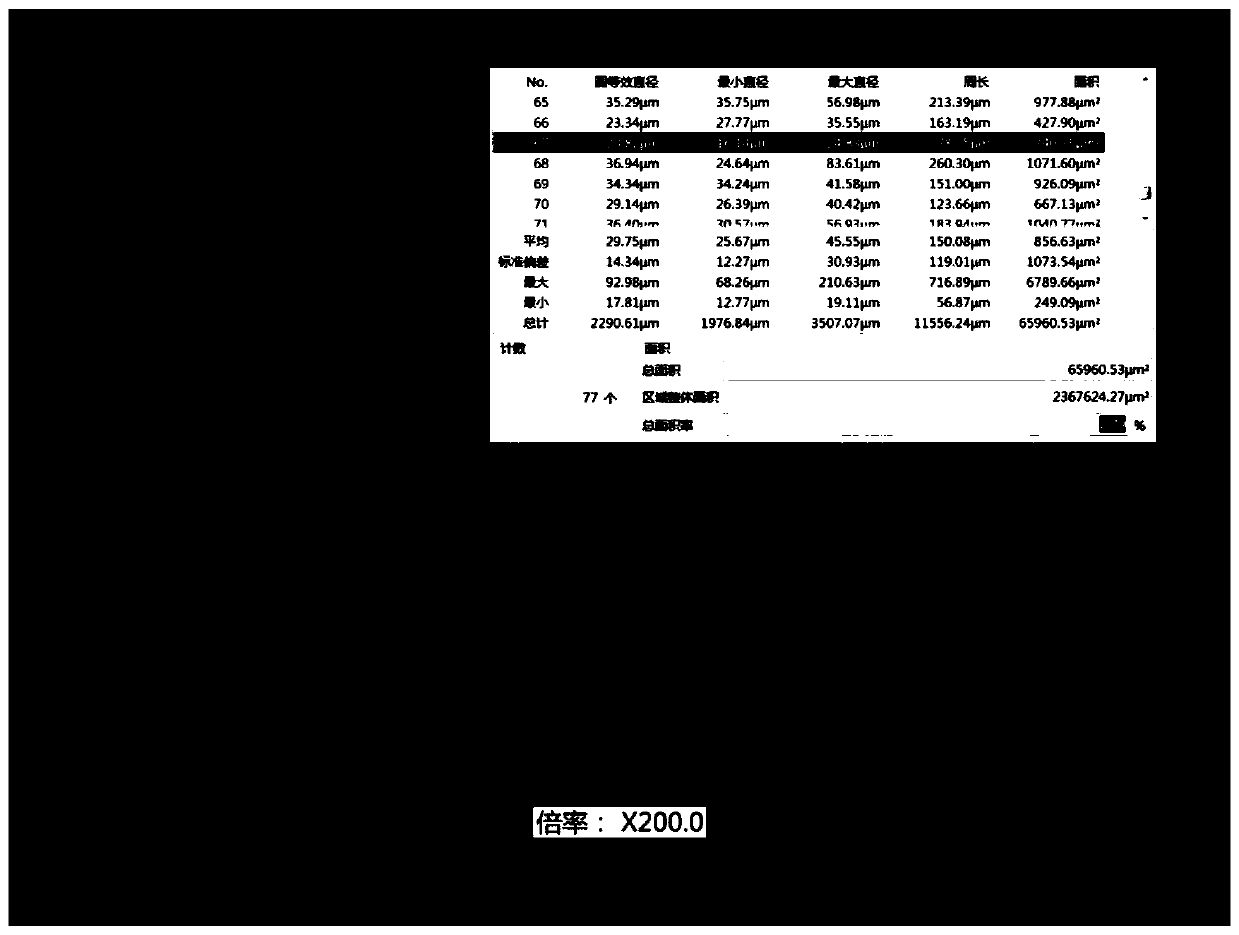

ActiveCN110461105AHigh precisionQuantification of light transmission pointsInsulating layers/substrates workingPrinted element electric connection formationControl system3d image

The invention provides an automatic copper deposition control process for a printed circuit board. A super scene depth microscope and a control system are required. The super scene depth microscope isconnected with the control system and controlled by the control system. The process comprises steps: drilling is carried out on the PCB; burrs in the hole are removed; horizontal copper deposition iscarried out; PCBs after copper deposition are sampled, the super scene depth microscope is adopted to perform in-hole scanning on sample boards, an unfolded in-hole side image is obtained, the percentage value of the area without copper covering in the image in the whole area is automatically measured, and the percentage value is outputted to the control system; if the percentage value exceeds apreset value, the above horizontal copper deposition operation is stopped, copper deposition parameters are adjusted according to a comparison result, and the above horizontal copper deposition operation is restarted; and if the percentage value does not exceed the preset value, the subsequent steps of the circuit board are performed. Through introducing a 3D imaging technology to circuit board making, quantitative detection of light transmission points is realized, the backlight determination accuracy and the detection speed are improved, industrial automation is realized, and the productionefficiency and the quality are improved.

Owner:福州瑞华印制线路板有限公司

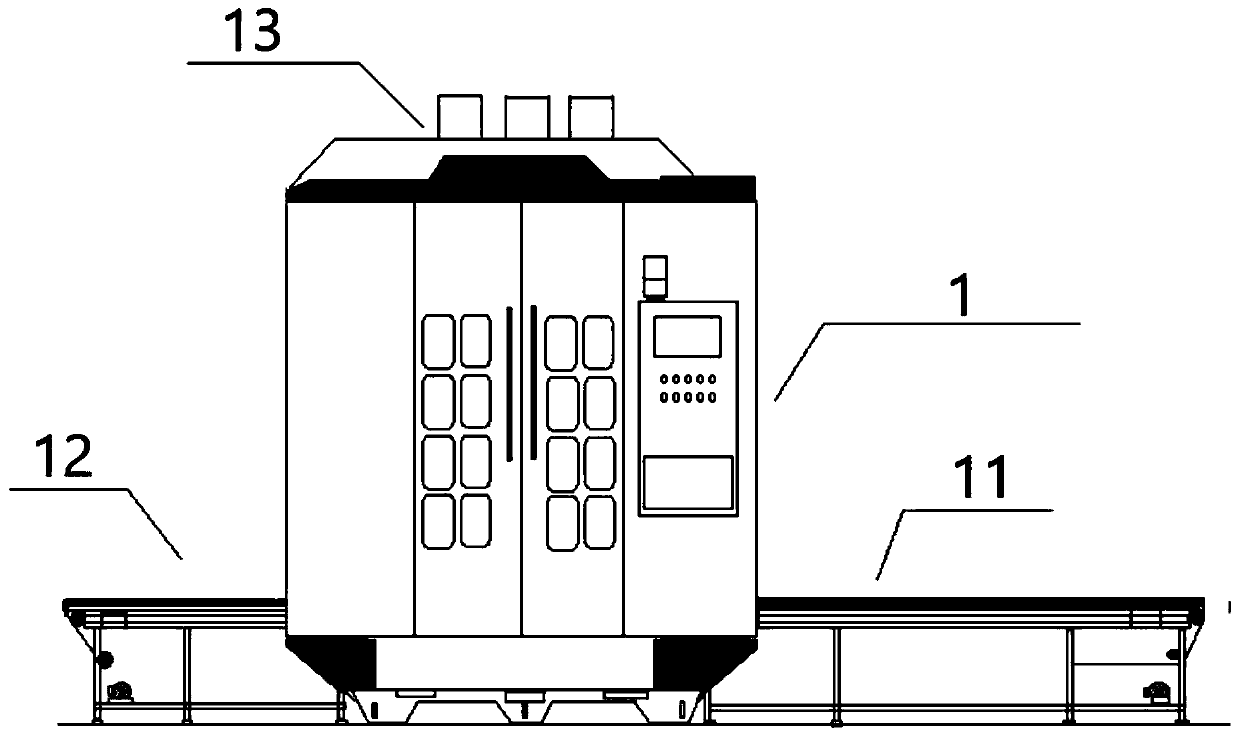

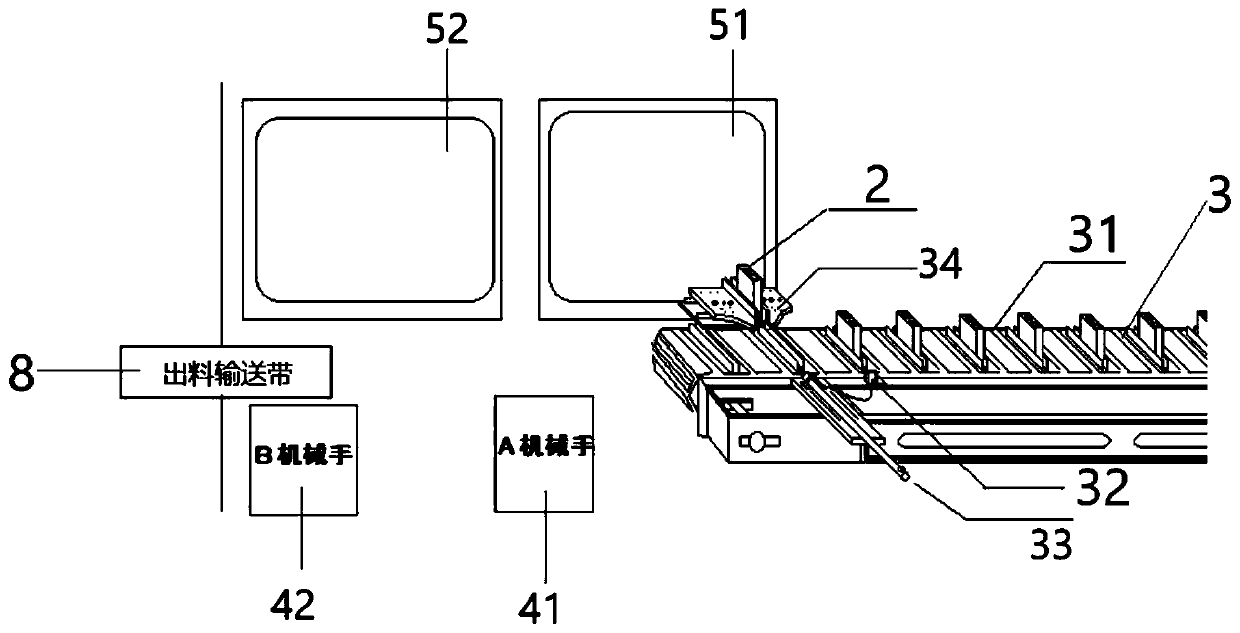

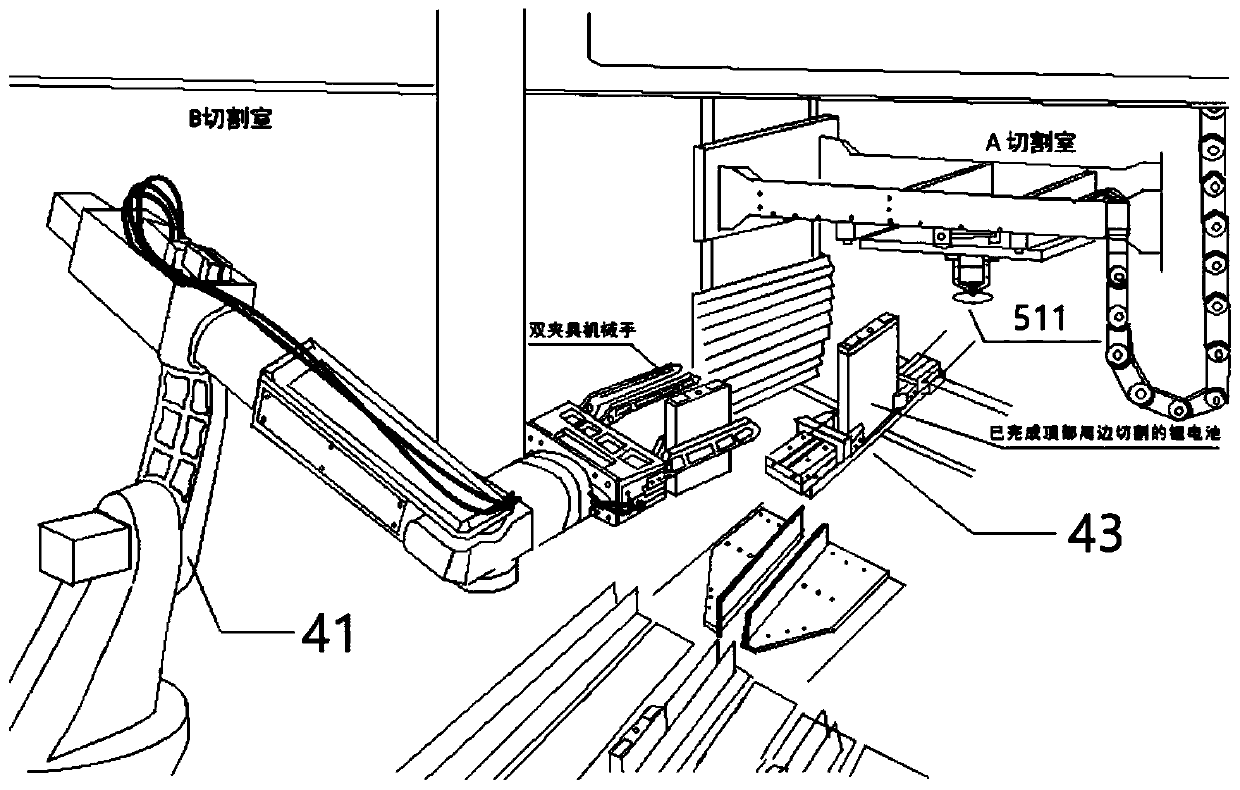

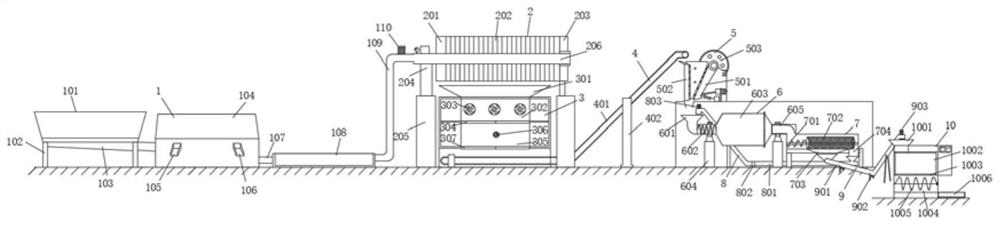

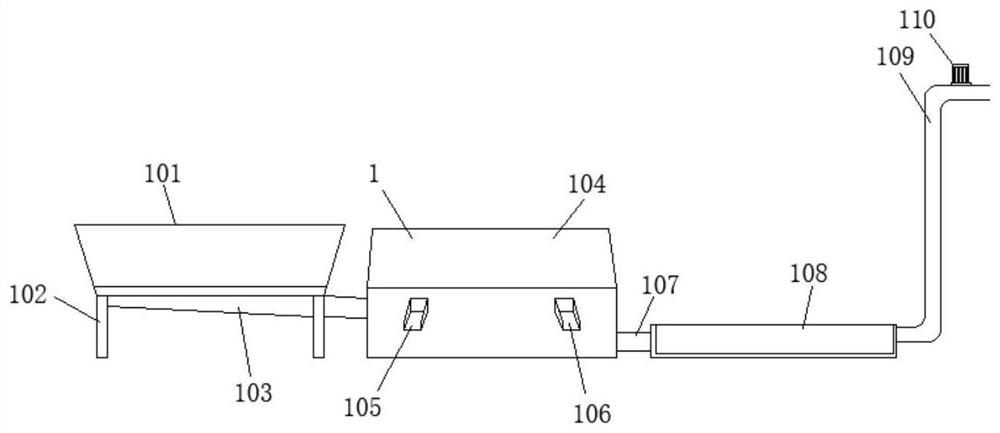

Device for removing aluminum alloy shell of lithium battery

PendingCN111146524ARealize industrial automationImprove recycling efficiencySolid waste disposalWaste accumulators reclaimingEngineeringMechanical engineering

A device for removing an aluminum alloy shell of a lithium battery can solve the technical problems that manual removal of the aluminum alloy shell of the lithium battery wastes time and labor and islow in efficiency. The device comprises a shell removing unit, wherein the shell removing unit is provided with a feeding port and a discharging port. The device also comprises a control module; a conveying belt feeding module, a mechanical arm feeding module, a cutting module, a roll core extracting module, a tab cutting module and a material sending-out module which are in communication connection with the control module. The conveying belt feeding module and the conveying belt material sending-out module are arranged outside the shelling unit, the conveying belt feeding module corresponds to the feeding port, and the material sending-out module corresponds to the discharging port. The mechanical arm feeding module, the cutting module, the roll core extracting module and the tab cuttingmodule are arranged in the shell removing unit and are sequentially arranged in a butt joint manner. According to the invention, the device employs the automatic control, the aluminum alloy shell of the lithium battery is mechanically removed according to the set process, the industrial automation is achieved in the whole recycling process, and the recycling efficiency is high.

Owner:安徽巡鹰动力能源科技有限公司

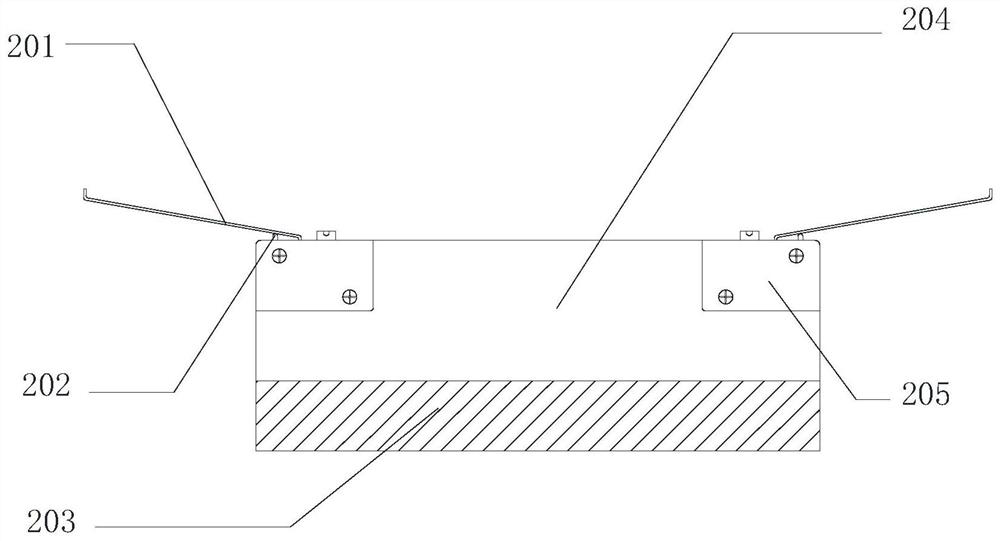

An online tin coating equipment for spotlight welding strip

ActiveCN106191734BRealize tin coating workImprove welding effectHot-dipping/immersion processesSemiconductor devicesEngineeringSilicon cell

The invention discloses online tin coating equipment for a light condensation welding strip. The online tin coating equipment comprises a heating control device, an upper plate and a lower plate, wherein one side of the upper plate is hinged to one side of the lower plate. The upper plate is provided with a tin wire feeding mechanism and a through hole allowing a tin wire to pass through. The lower plate communicates with a heat dissipation mechanism and is provided with an induction coil and a welding strip guide plate. The induction coil and the heating control device are electrically connected. The tin wire penetrates through the through hole and moves to the position a certain distance away from the lower plate through the tin wire feeding mechanism, the tin wire and the induction coil generate electromagnetic induction, the tin wire melts, and a tin coating is formed on the surface of the light condensation welding strip. After tin coating is completed, the tin wire retracts by a certain distance through the tin wire feeding mechanism so as to be separated from the electromagnetic induction area for use next time. Through the structural design, the tin coating work before welding of the light condensation welding strip and a solar crystal silicon cell is achieved, and the light condensation welding strip without tin coatings can be well welded to the back face of the cell.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

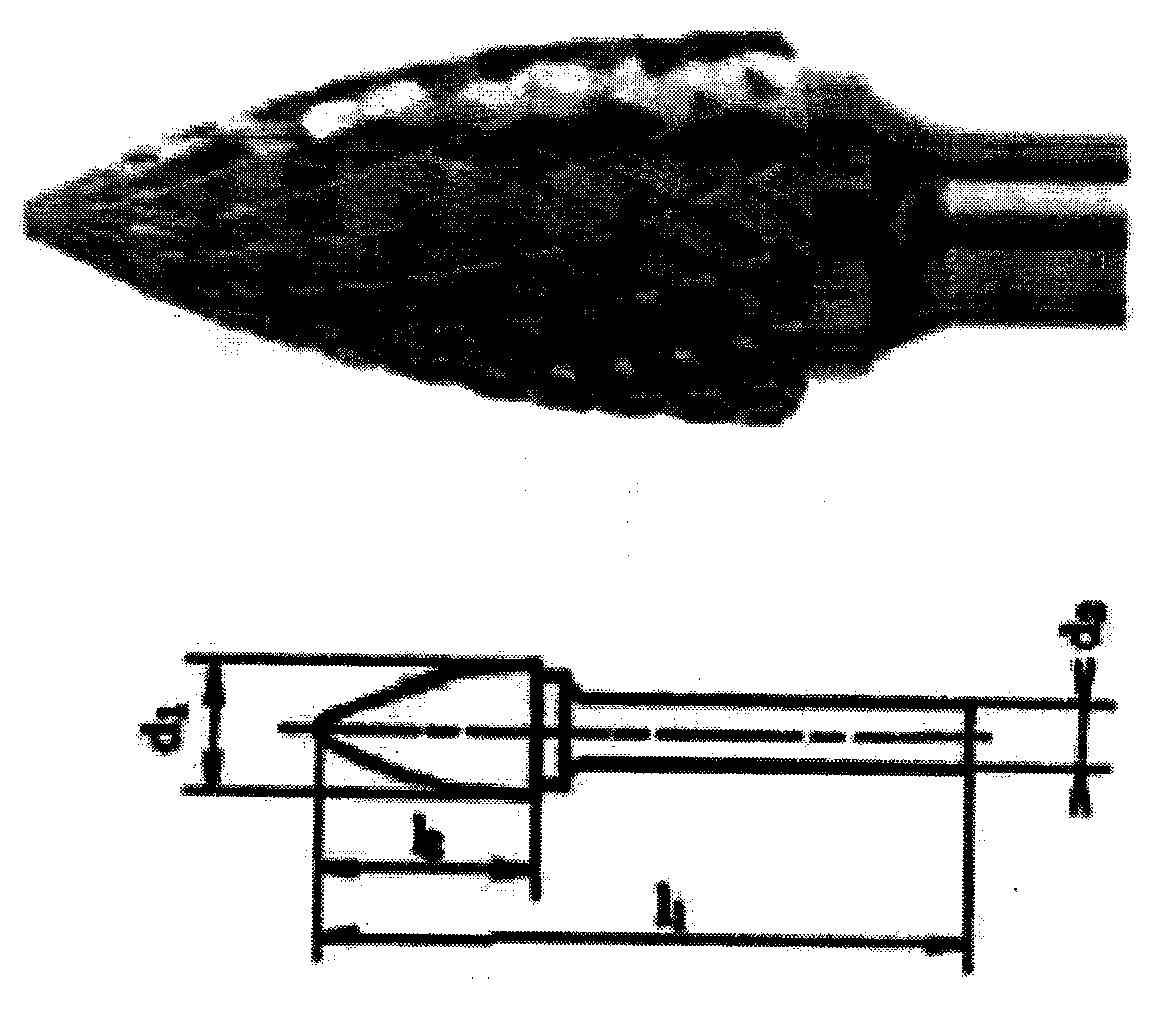

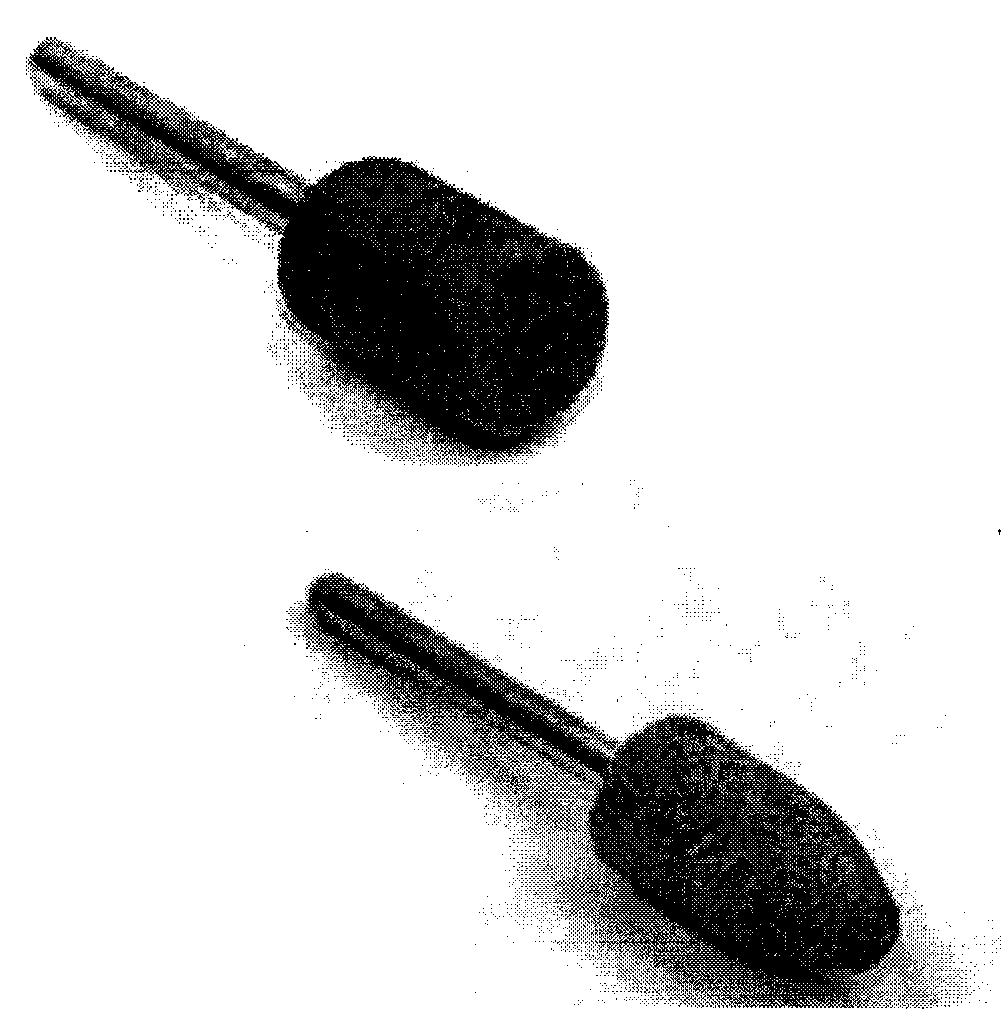

Novel engine cylinder robot grinding head

The invention relates to a novel engine cylinder robot grinding head which comprises a base body made of hardened and tempered bearing steel, and a grinding material layer electroplated through a sandburying method. Compared with traditional manual grinding, the novel engine cylinder robot grinding head has the advantages of high grinding efficiency, good accuracy, long service life, less harm ona human body and the like, and can better promote the industry modernization process.

Owner:深圳西斯特科技有限公司

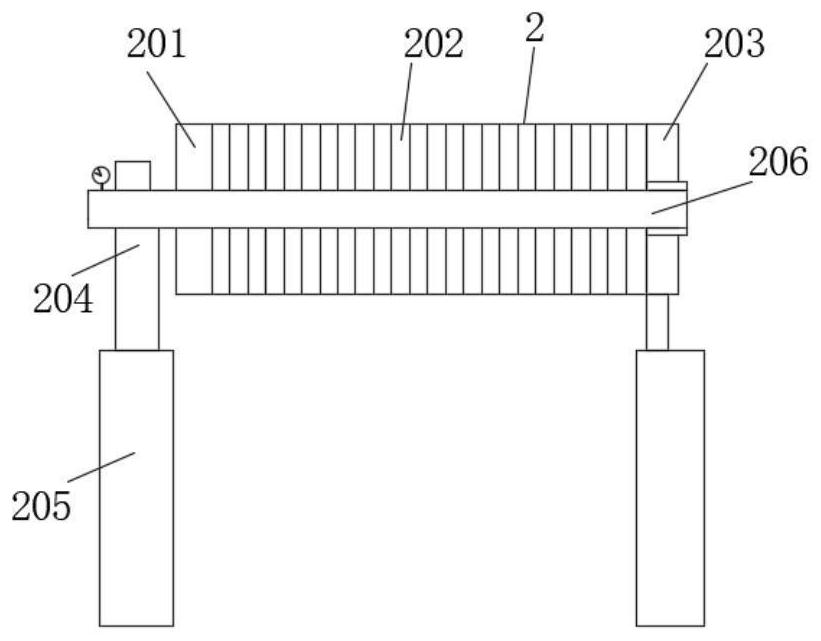

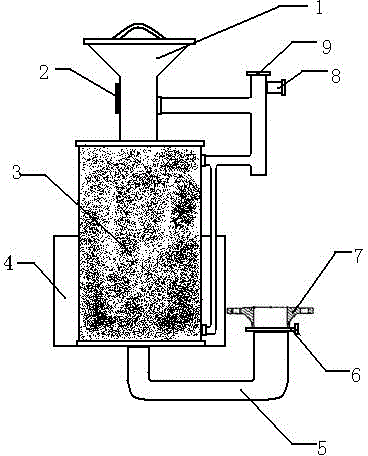

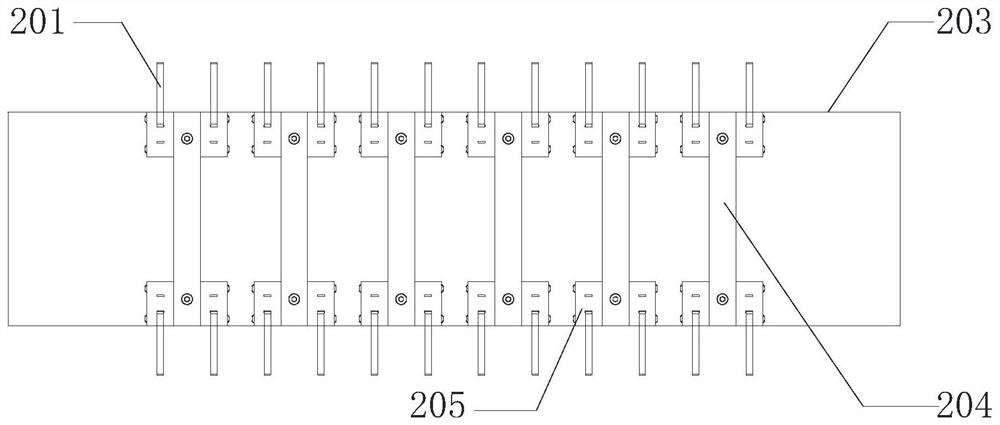

Whole substrate glass multi-piece crushing device and multi-piece crushing method

ActiveCN112337631AImprove crushing efficiencyRealize continuous operationGlass recyclingGrain treatmentsStructural engineeringManufacturing engineering

The invention discloses a whole substrate glass multi-piece crushing device and a multi-piece crushing method. The device comprises a frame body, a vacuum generation device and sucker arms, the framebody is provided with a moving mechanism used for driving the sucker arms to move, the moving mechanism is connected with a plurality of rows of sucker arms arranged in parallel in a hinged mode, a plurality of suckers arranged at intervals in the length directions of the sucker arms are arranged on the suction surfaces of the sucker arms, extraction openings of the suckers are connected to the output end of the vacuum generation device, and the vacuum generation device is arranged on the frame body. According to the device and the method, suction of multiple layers of glass is achieved, the problem of suction of a single piece of glass in the prior art is solved, the suction of the multiple layers of glass meets the requirement for crushing the multiple layers of glass, the glass crushingefficiency is improved, continuous operation of glass crushing is achieved, the working efficiency of personnel is greatly improved, the blank of equipment of this kind in China is filled, and the very high promotional value is achieved.

Owner:IRICO

Online tin coating equipment for light condensation welding strip

ActiveCN106191734ARealize tin coating workImprove welding effectHot-dipping/immersion processesSemiconductor devicesEngineeringElectromagnetic induction

The invention discloses online tin coating equipment for a light condensation welding strip. The online tin coating equipment comprises a heating control device, an upper plate and a lower plate, wherein one side of the upper plate is hinged to one side of the lower plate. The upper plate is provided with a tin wire feeding mechanism and a through hole allowing a tin wire to pass through. The lower plate communicates with a heat dissipation mechanism and is provided with an induction coil and a welding strip guide plate. The induction coil and the heating control device are electrically connected. The tin wire penetrates through the through hole and moves to the position a certain distance away from the lower plate through the tin wire feeding mechanism, the tin wire and the induction coil generate electromagnetic induction, the tin wire melts, and a tin coating is formed on the surface of the light condensation welding strip. After tin coating is completed, the tin wire retracts by a certain distance through the tin wire feeding mechanism so as to be separated from the electromagnetic induction area for use next time. Through the structural design, the tin coating work before welding of the light condensation welding strip and a solar crystal silicon cell is achieved, and the light condensation welding strip without tin coatings can be well welded to the back face of the cell.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

A printed circuit board automatic control copper sinking process

ActiveCN110461105BHigh precisionQuantification of light transmission pointsInsulating layers/substrates workingPrinted element electric connection formationAutomatic control3d image

The invention provides an automatic control copper sinking process for a printed circuit board, and a super-depth-of-field microscope and a control system need to be provided. The super-depth-of-field microscope is connected with the control system and is controlled by the control system. The process includes: drilling a PCB board; removing the Burr in the hole; horizontal copper sinking; sample the PCB board after copper sinking, scan the sample board with an ultra-depth-of-field microscope, and obtain an image of the inner side of the hole. The percentage value is output to the control system; if the percentage value exceeds the preset value, stop the above-mentioned horizontal copper sinking operation, adjust the copper sinking parameters according to the comparison result, and restart the above-mentioned horizontal copper sinking operation; if it does not exceed the preset value , the subsequent steps of the circuit board are performed. By introducing 3D imaging technology into circuit board production, the invention realizes quantitative detection of light transmission points, improves the accuracy and detection speed of backlight determination, realizes industrial automation, and improves production efficiency and quality.

Owner:福州瑞华印制线路板有限公司

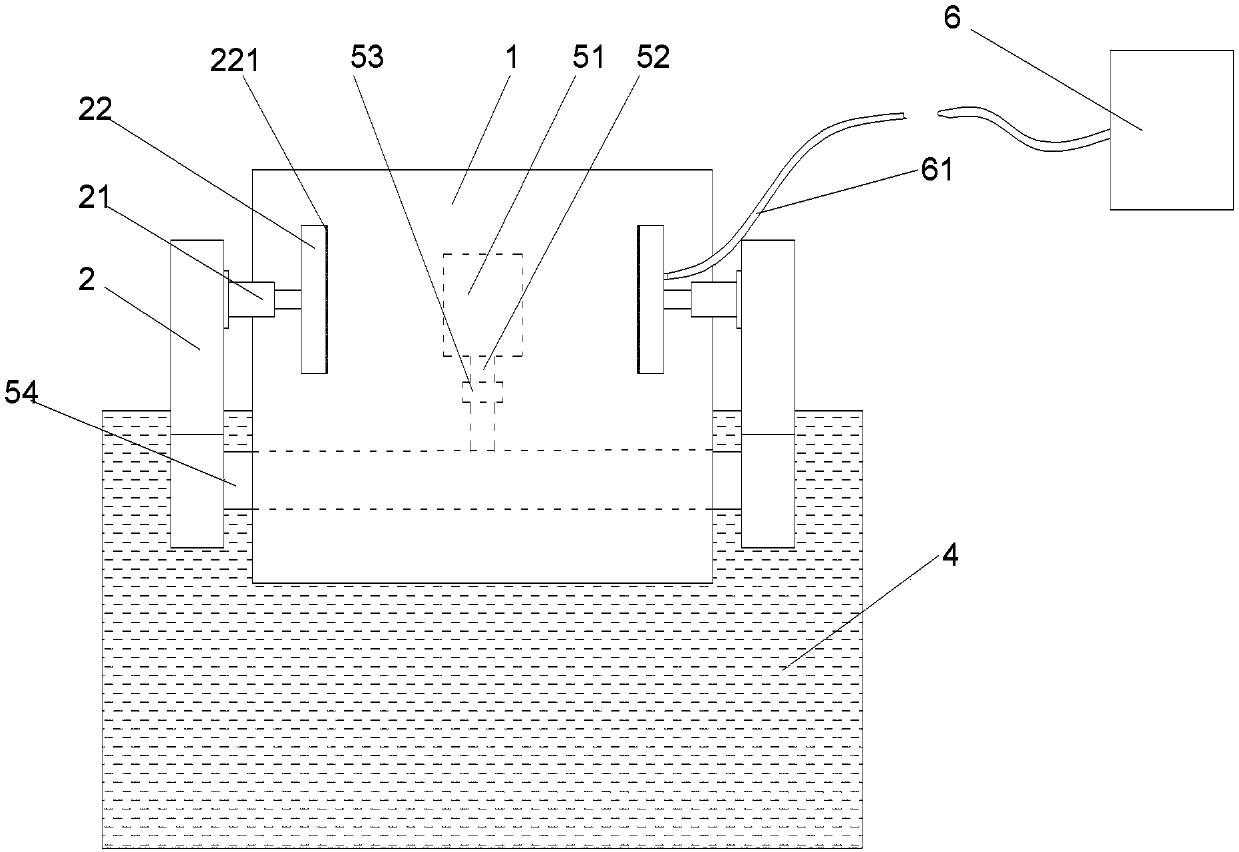

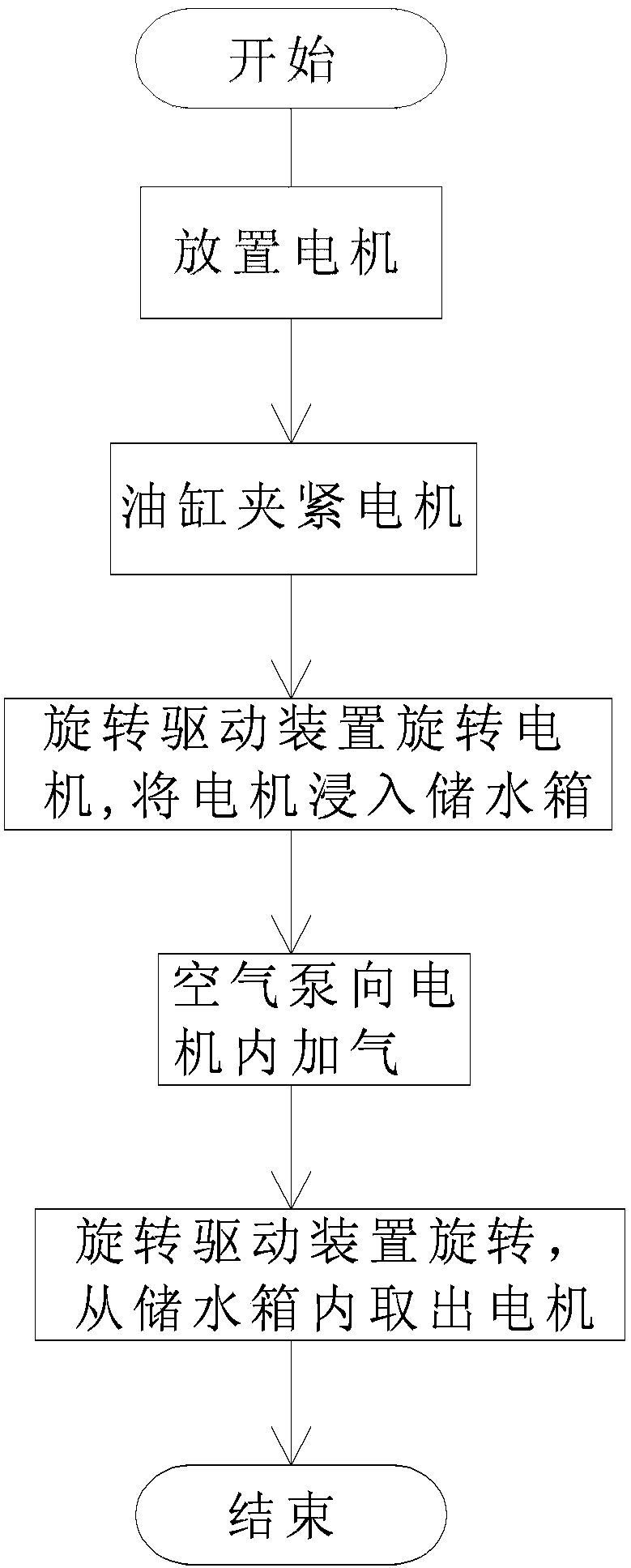

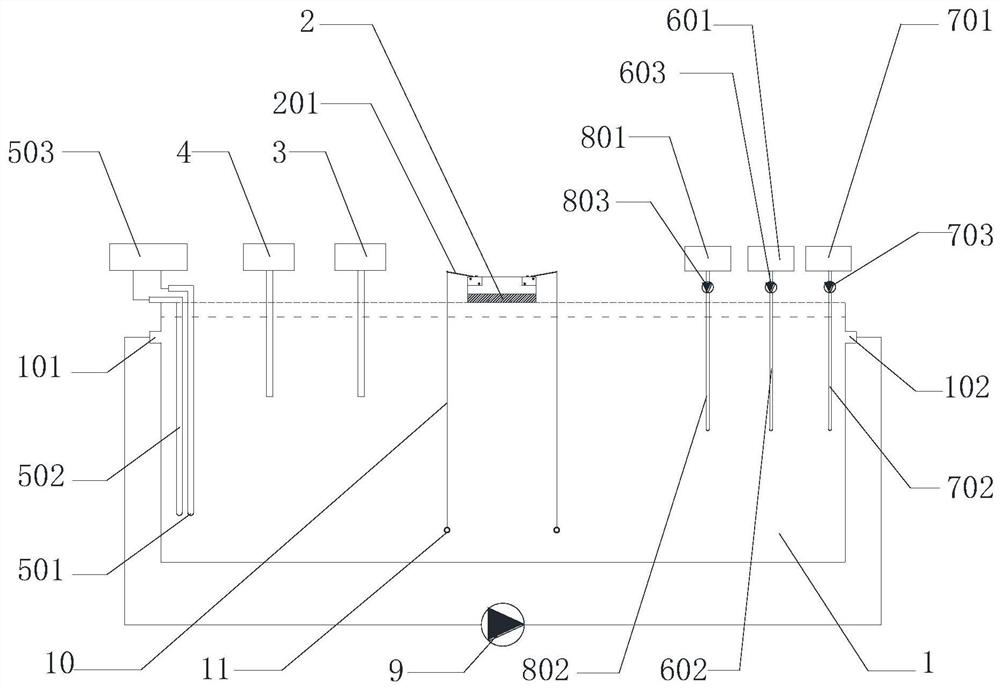

Testing system for sealing performance of motor and control method thereof

InactiveCN107702863AAvoid the seal lock stepSave human effortDetection of fluid at leakage pointWater storage tankHuman power

The invention provides a testing system for the sealing performance of a motor. The system is composed of a material platform, sealing clamps, an air pump and a water storage tank. A motor is arrangedhorizontally on the material platform. The sealing clamps are respectively arranged at the two sides of the axial direction of the motor and include clamping plates and rotating driving units. The air pump has an air filling pipe that is connected to the inside of the motor by a clamp head. The water storage tank is arranged below one side of the material platform. In addition, the invention alsoprovides a control method of the testing system for the sealing performance of a motor. The method comprises the following steps that: (1), a motor is placed on a material platform; (2), a telescopicoil cylinder drives the clamp head to be compressed on the axial end surface of the motor; (3), the rotating driving units drive the motor to be immersed into the water storage tank; (4), the air pump refills the motor with air; and (5), the rotating driving units drive the motor to be taken out of water. The testing system and the control method have the following advantages: the two ends of themotor are compressed automatically by using the pressure generated by the oil cylinder, so that the tedious sealing and locking steps are reduced; the manpower is saved; the production time is reduced; and the automation degree is improved.

Owner:JIANGSU WEITELI MOTORS MFG

Integrated device for preparing recycled cement paste powder by using waste premixed concrete

PendingCN113135674AAdd processing systemRealize the preparation of integrated industrializationSievingScreeningReclaimed waterCement paste

An integrated device for preparing recycled cement paste powder from waste premixed concrete is characterized in that an inlet of a separation device is connected with a first feed port for feeding the waste premixed concrete, and an outlet of a conveying pipeline of the separation device is connected with an inlet of a filter pressing device. A lower outlet of the filter pressing device is located above a second feeding port in the uppermost portion of the air drying device, a second discharging port of the air drying device is connected with an inlet of a first conveying device, an outlet of the first conveying device is connected with an inlet of a crushing device, and an outlet of the crushing device is connected with a third feeding port of a ball milling device. A third discharging port of the ball milling device is connected with an inlet of a screening device, the screening device is provided with a coarse material outlet and a fine material outlet, the coarse material outlet is connected with a third feeding port of the ball milling device through a second conveying device, the fine material outlet is connected with a fourth feeding port of the calcining device through a third conveying device, and an outlet of the calcining device is connected with a collecting box. According to the invention, integrated and industrial production of the regenerated cement paste powder is realized.

Owner:浙江永坚新材料科技股份有限公司

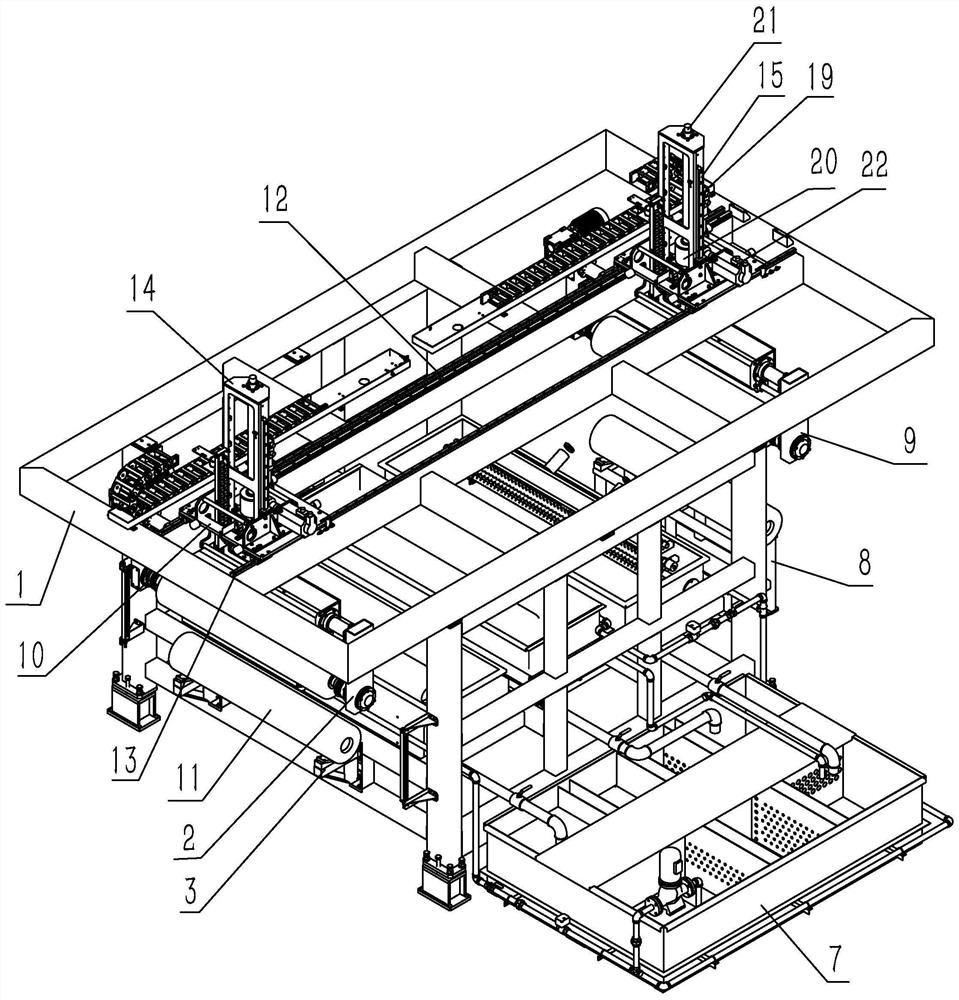

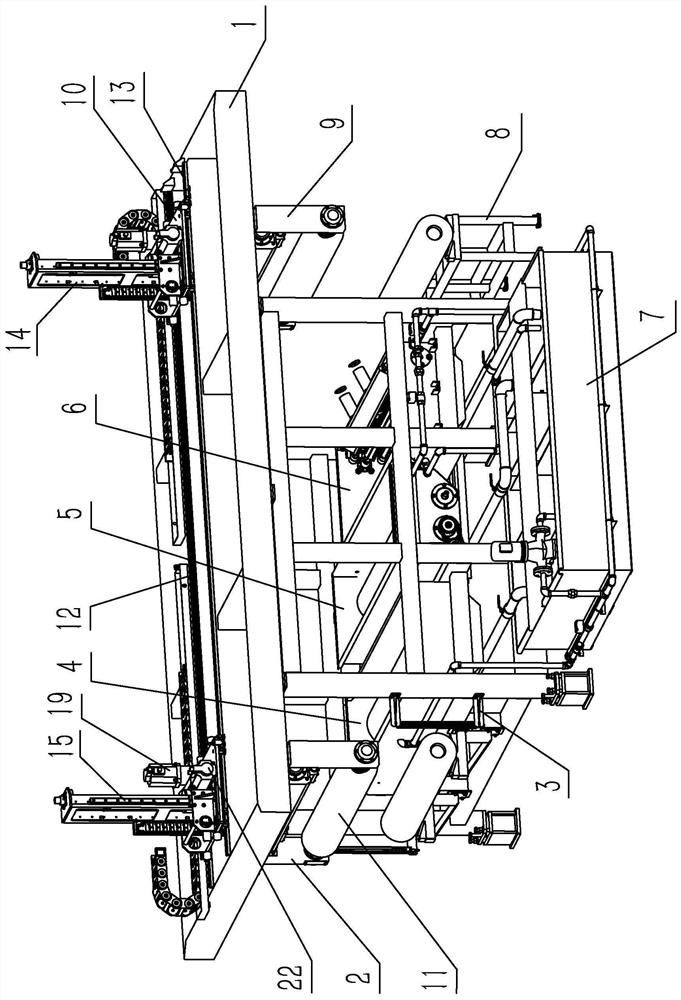

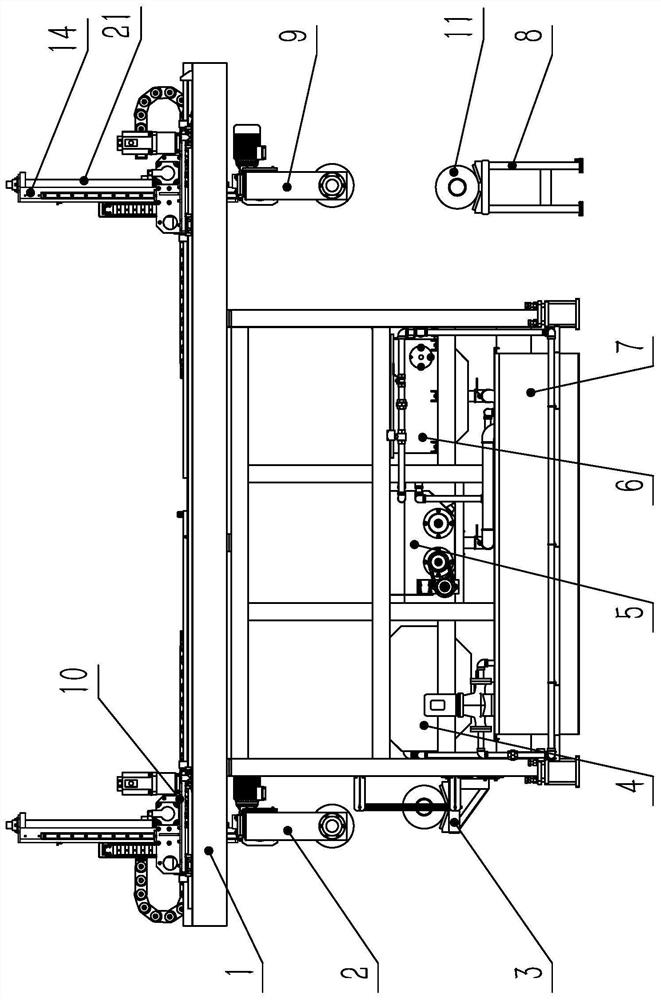

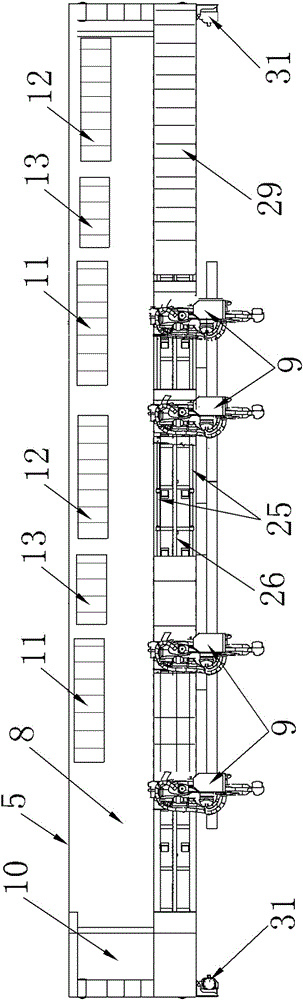

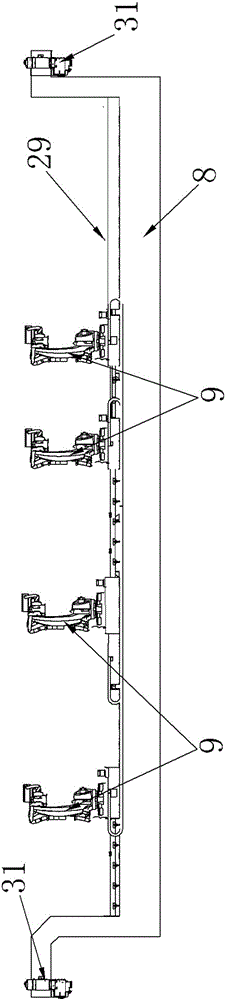

Automatic cleaning machine for gravure rollers of printing machine

PendingCN112829458AFast cleaningImprove cleaning qualityDrying gas arrangementsPrinting press partsWater useManufacturing engineering

The invention relates to the field of large gravure press corollary equipment. According to the technical scheme, an automatic cleaning machine for gravure rollers of a printing machine is characterized by comprising a rack, two supporting frames, two self-rotation mechanical arms, three cleaning assemblies and circulating water treatment equipment, wherein the two supporting frames are horizontally and slidably positioned on the upper portion of the rack in the left-right direction through first transmission assemblies correspondingly, the two self-rotation mechanical arms are vertically and slidably positioned on the two supporting frames through second transmission assemblies correspondingly, the three cleaning assemblies are arranged on the lower portion of the rack to clean and dry the gravure rollers, and the circulating water treatment equipment is used for providing cleaning water and collecting and treating sewage; the three cleaning assemblies are a rough cleaning tank, an ultrasonic plate cleaning tank and a cleaning and blow-drying device which are sequentially arranged from left to right; a feeding transfer frame used for containing the to-be-cleaned gravure rollers is installed on the side face of the rough cleaning tank; and a transfer table used for containing the clean gravure rollers is installed on the side face of the cleaning and blow-drying device. According to the automatic cleaning machine, the cleaning efficiency and the cleaning quality of the gravure rollers can be improved, manpower is greatly saved, and the production cost is reduced.

Owner:ZHEJIANG MEIGE MACHINERY

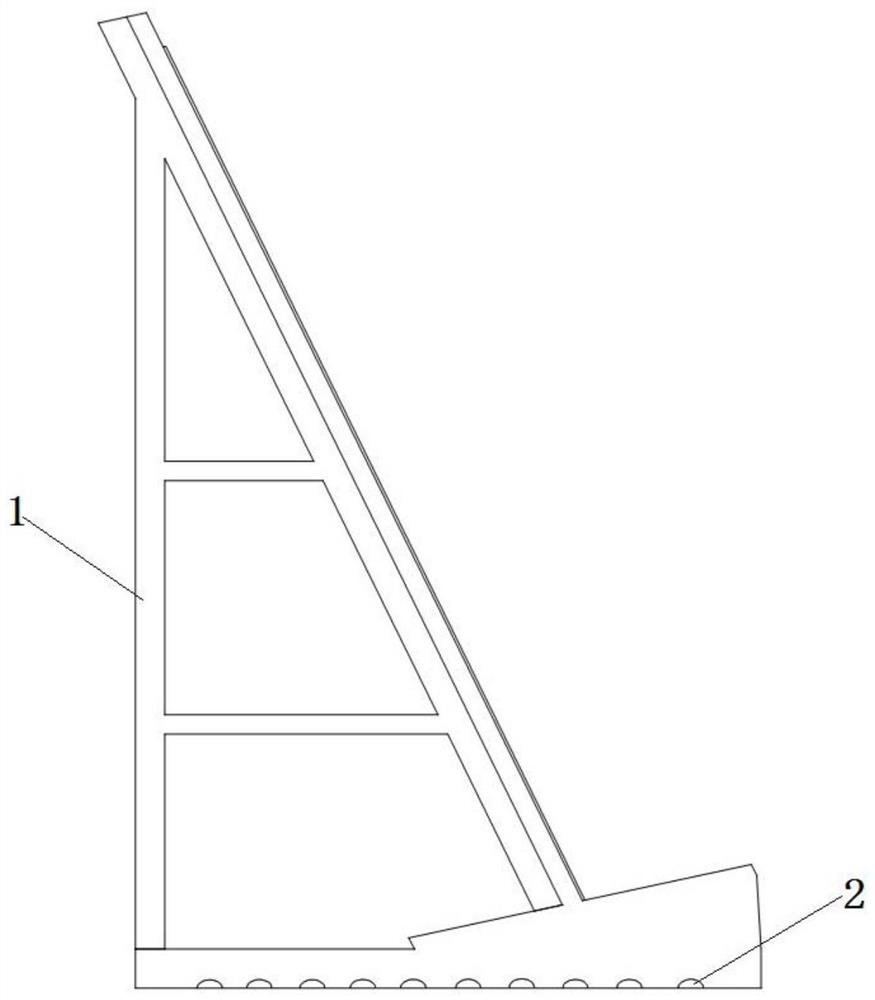

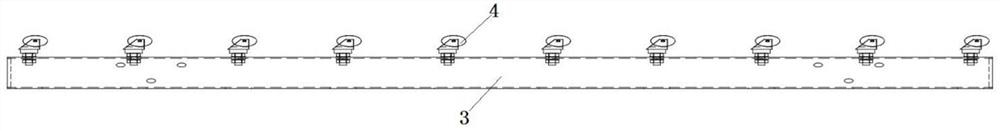

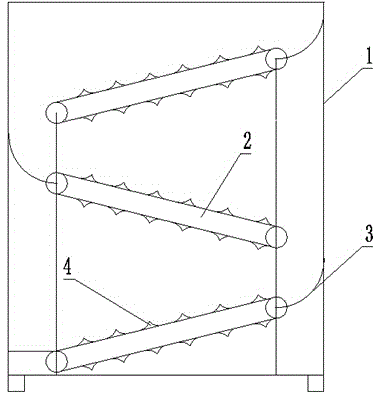

Storage shelf

The invention relates to a storage shelf and belongs to the technical field of storage equipment. The storage shelf comprises a shelf frame 1 and a conveying track 2 which is of a conveyor belt structure with multiple layers separated. A baffle 3 is arranged at the top end of the conveying track 2. A counter is arranged at an outlet of the shelf. A switch for controlling the conveying track 2 is fixedly installed on the shelf frame 1. Conveyor belt interlayers are arranged in the shelf for conveying goods and replace a traditional fixed structure; the counter is arranged at the outlet and can count numbers automatically when goods are fetched automatically; a displayer displays instant messages including the total quantity, the balance, the fetching quantity and the like, so that workers check the messages conveniently; industrial automation and mechanical operation are achieved; the problems that storage structures in the prior art are of a fixed structure, goods are difficult to fetch, and manual assisting is needed are solved.

Owner:WUHU YANGYU ELECTROMECHANICAL TECH DEV

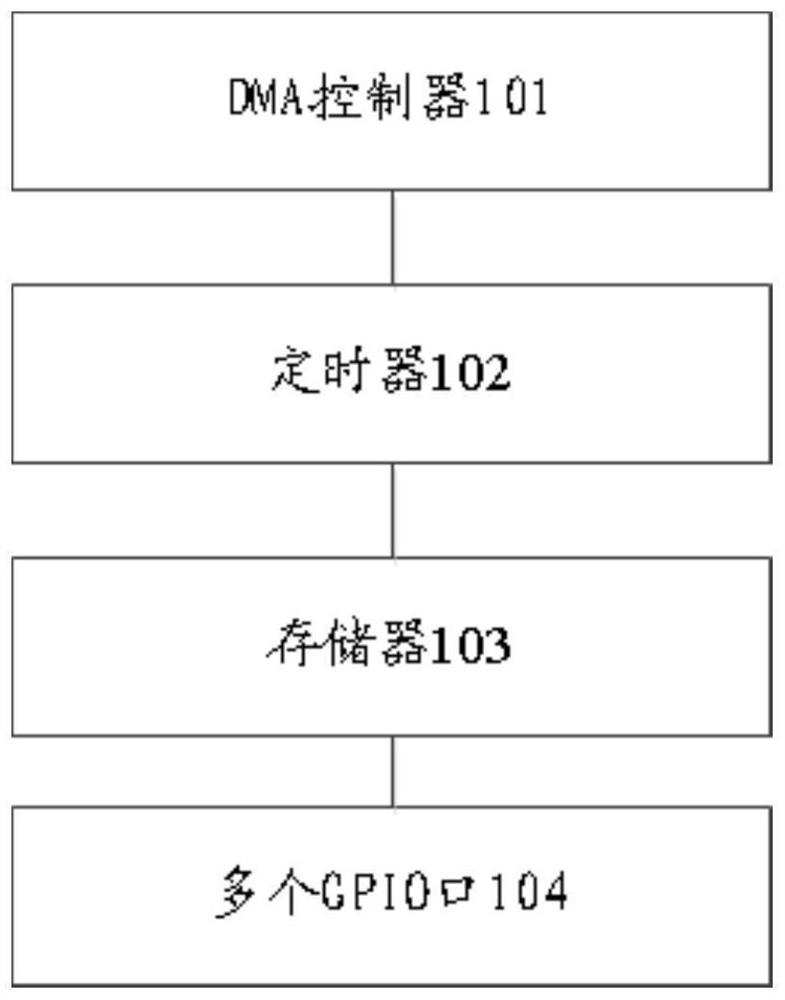

Calibration control device, method and system

PendingCN114252101AImprove calibration efficiencyRealize industrial automationInstrumentsComputer hardwareEngineering

The invention provides a calibration control device, method and system, and the device comprises a DMA controller, a timer, a memory, and a plurality of GPIO ports. Test data for testing the sensor to be calibrated is pre-stored in the memory; a first time interval for outputting data and a second time interval for reading data are preset in the timer; the GPIO ports are used for being connected with at least one external sensor to be calibrated; the DMA controller is used for outputting the test data to the sensor to be calibrated through the GPIO port according to the first time interval when a first starting instruction is received, so that the test data is processed through the sensor to be calibrated to obtain result data; the DMA controller is also used for calibrating the sensor to be calibrated based on the test data and the result data.

A method for automatic piecing of ring spinning frame

ActiveCN112111817BAutomatic splice implementationRealize fully automatic detectionContinuous wound-up machinesOpen-end spinning machinesProcess engineeringMachine

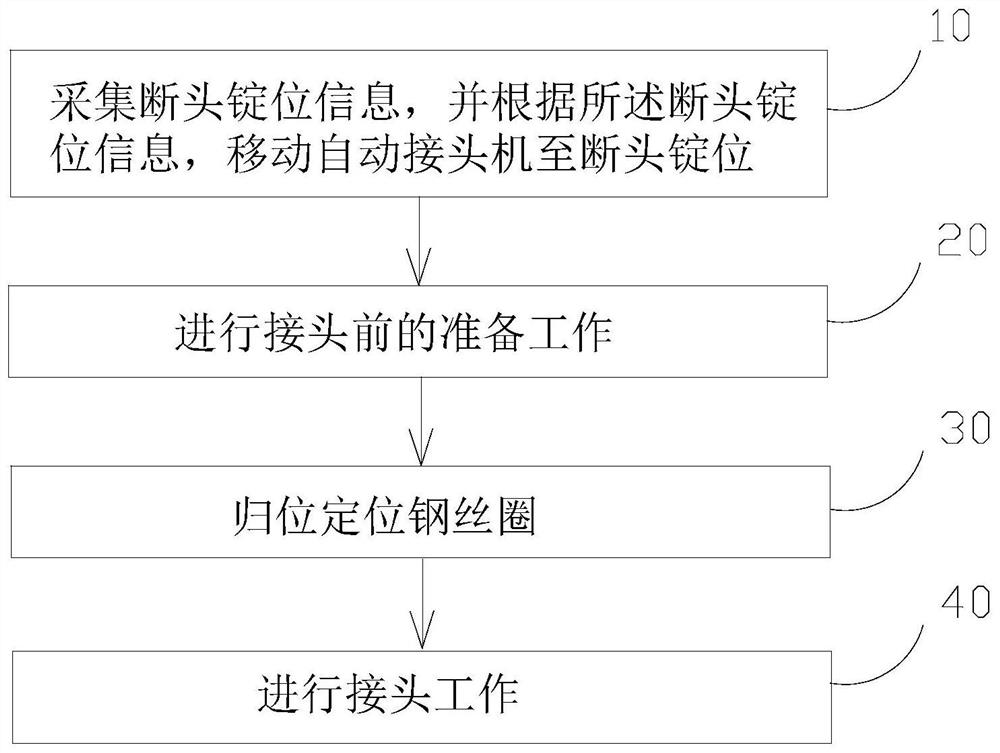

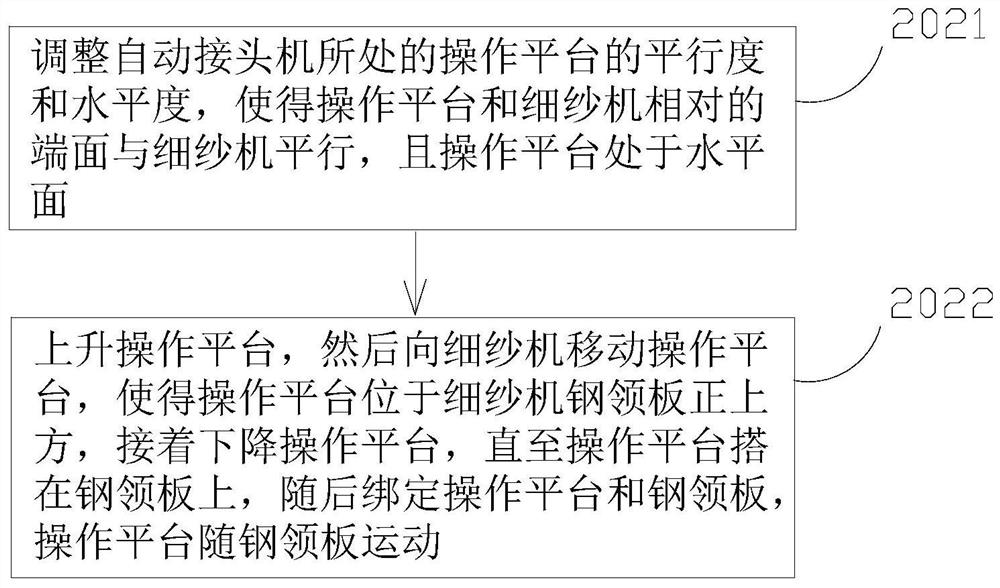

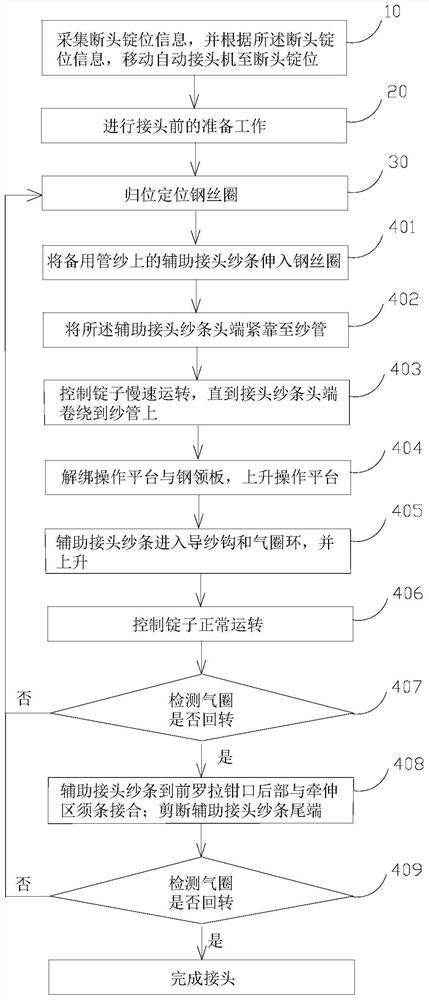

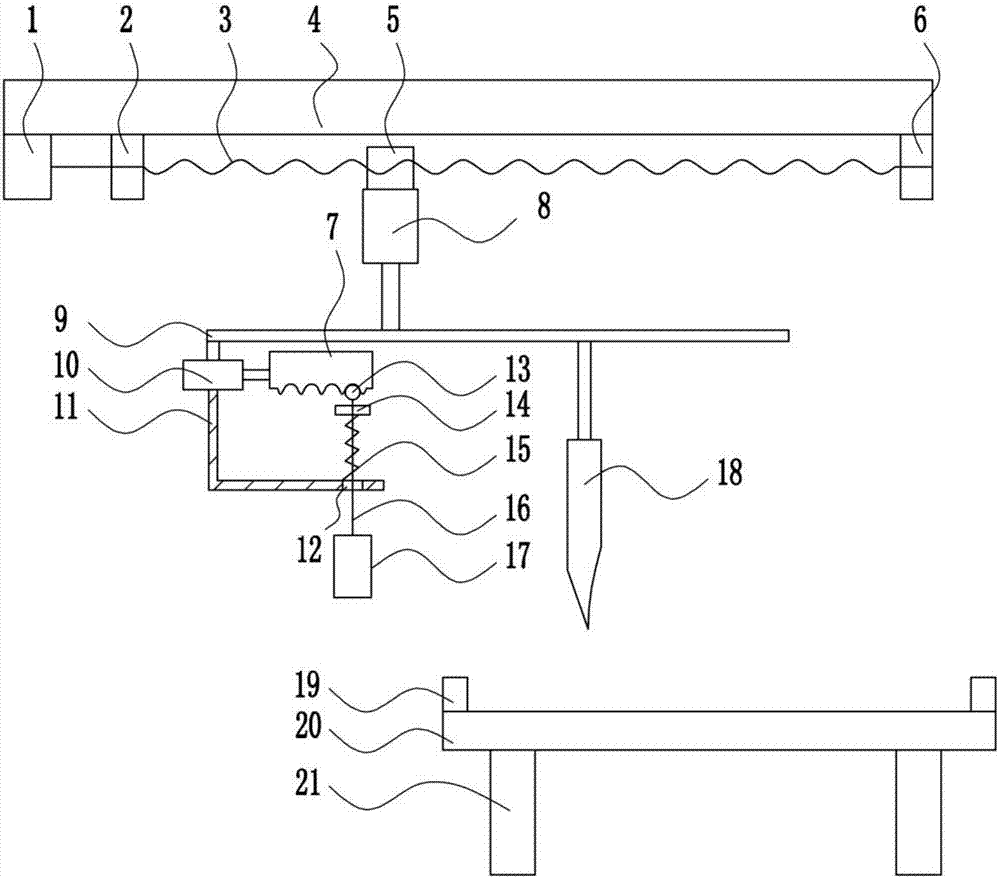

The invention discloses an automatic jointing method for a ring spinning frame, which realizes automatic jointing and improves jointing efficiency. The automatic splicing method of the ring spinning frame includes: step 10) collecting the broken end spindle position information, and moving the automatic splicing machine to the broken end spindle position according to the broken end spindle position information; step 20) performing preparations before splicing Work; step 30) homing and positioning the traveler; step 40) performing joint work.

Owner:TONGLING SOBONE INTELLIGENT EQUIP +1

A high-efficiency grinding and cutting machine for mosaic tiles

ActiveCN106239746BImprove cleanlinessImprove cutting and grinding efficiencyWorking accessoriesStone-like material working toolsEngineeringPulp and paper industry

The invention relates to a cutting machine, in particular to an efficient grinding and cutting machine for mosaic tiles. The efficient grinding and cutting machine for the mosaic tiles aims at achieving the technical effect that cutting and grinding efficiency is high. The efficient grinding and cutting machine for the mosaic tiles comprises a servo motor, a left bearing seat, a screw rod, a top plate, a nut, a right bearing seat, a wedge block, an air cylinder, a supporting rod, an electric push rod, a guide plate, a contact wheel, a fixed block, an elastic part, a lifting rod, a grinding tool, a cutting knife, limiting blocks, an operating platform and support rods. The operating platform is arranged at the tops of the support rods. The limiting blocks are arranged at the top of the operating platform. The top plate is arranged above the operating platform. The efficient grinding and cutting machine achieves the effects that cutting and grinding efficiency is high, the device is long in service life and high in automation degree, and it is convenient for an enterprise to achieve industrial automation due to the fact that the efficient grinding and cutting machine further comprises a suction device.

Owner:THE ARCHITECTURAL DECORATION ENG OF CHINA RAILWAY NO 2 ENG GRP SICHUAN

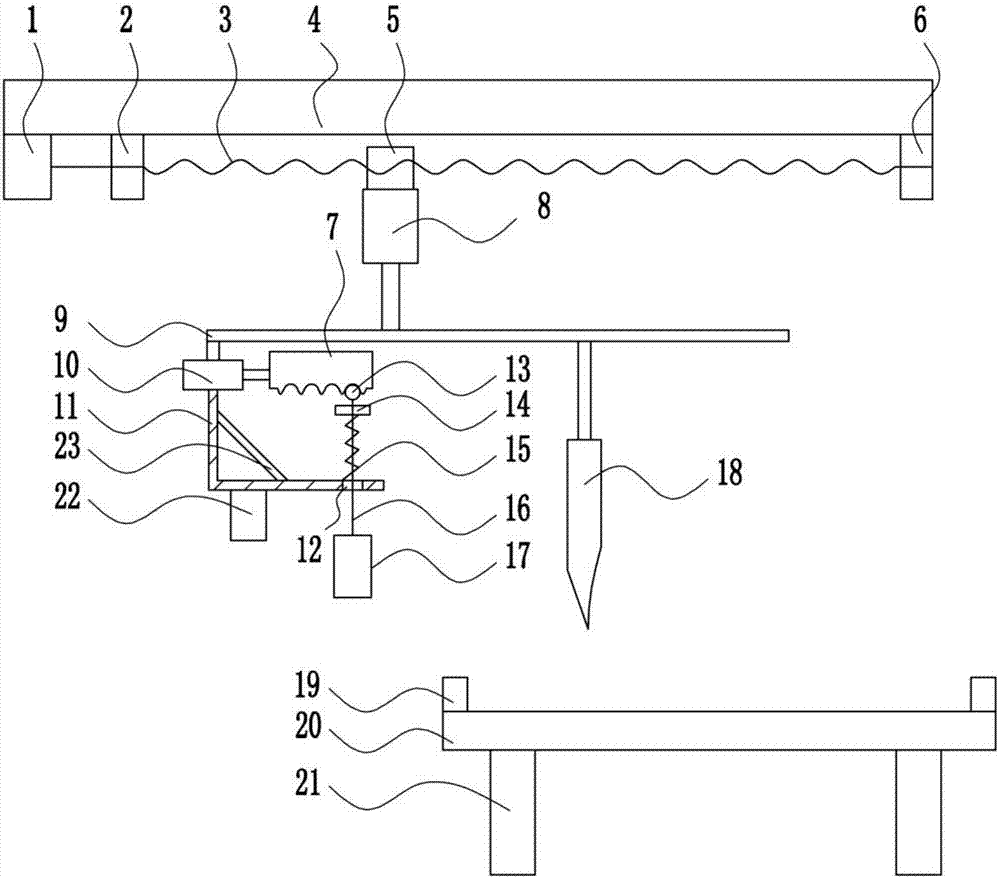

Vaporific parting liquid separation mold device

InactiveCN105328134AReasonable structureRealize industrial automationMoulding machinesControl flowWorking environment

Provided is a vaporific parting liquid separation mold device. The vaporific parting liquid separation mold device is characterized in that the vaporific parting liquid separation mold device comprises a liquid injection hopper, a flowmeter, a tank, a supporting seat, a high-pressure air pipe, a pressure regulating valve, a flange, a nozzle and an opening degree regulating valve; the tank of the device is fixed to the supporting seat, the parting liquid injection hopper is arranged on the tank, and the high-pressure air pipe is arranged at the lower end of the tank and connected with an outside high-pressure air source; and the flange and the pressure regulating valve are arranged at the joint of the high-pressure air pipe and the outside high-pressure air source, the flowmeter for controlling flow is arranged below the liquid injection hopper, the other side of the liquid injection hopper is communicated with the nozzle, and the opening degree regulating valve is arranged on the nozzle. The vaporific parting liquid separation mold device has the beneficial effects that the structure is reasonable, industrial automation is achieved, the work efficiency can be improved, and the labor intensity of workers can be lowered; and air pollution can be avoided, and the work environment can be improved.

Owner:赵丹

Automatic batching control system

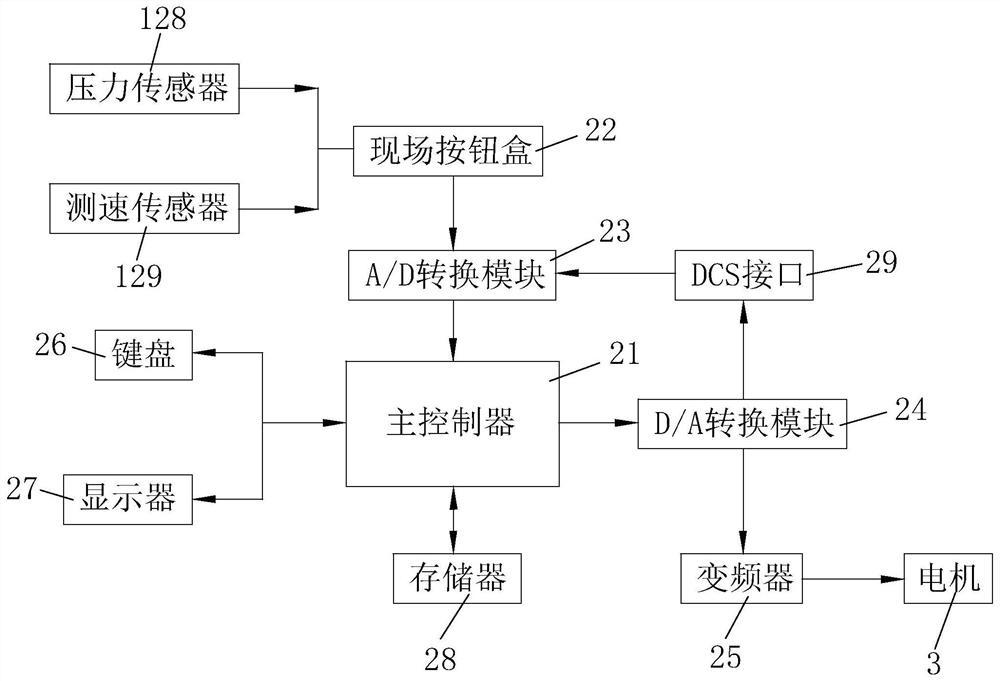

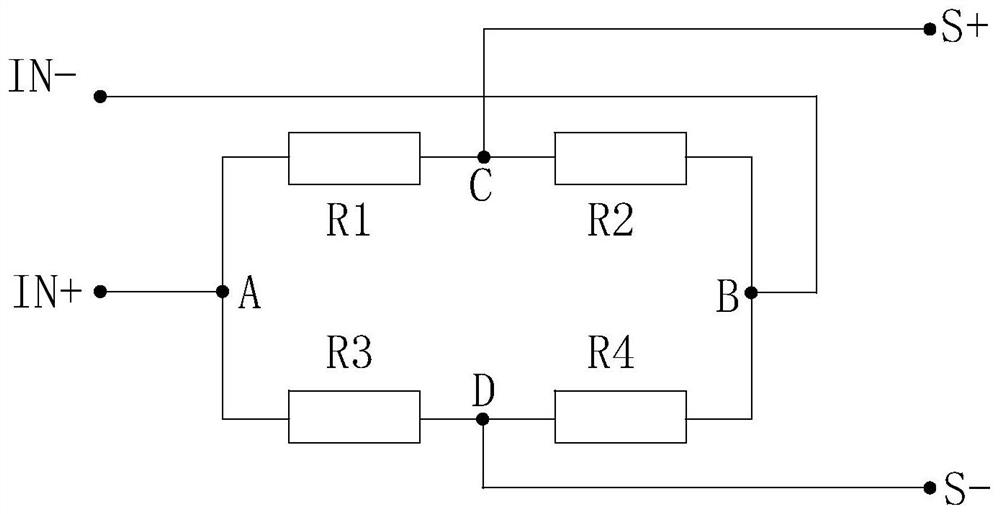

PendingCN113311794AStable internal combustion valueHigh precisionTotal factory controlProgramme total factory controlFrequency changerControl system

The invention relates to an automatic batching control system which comprises an automatic batching machine and a control module in control connection with the automatic batching machine. The control module comprises a main controller, a field button box, an A / D conversion module, a D / A conversion module and a frequency converter. The field button box is connected with the automatic batching machine and the A / D conversion module. The main controller is respectively connected with the A / D conversion module and the D / A conversion module. The frequency converter is respectively connected with the D / A conversion module and a motor of the automatic batching machine. After the field button box receives a pressure signal and a speed signal from the automatic batching machine, the pressure signal and the speed signal are transmitted to the main controller through the A / D conversion module to be calculated and adjusted, a proper control value is output and transmitted to the frequency converter through the D / A conversion module, and the frequency converter controls operation of the motor. The metering and proportioning precision is high, the operation is convenient, manpower and material resources are saved, real industrial automation is achieved, and the product quality and productivity are improved.

Owner:赣州科帕机电自动化有限公司

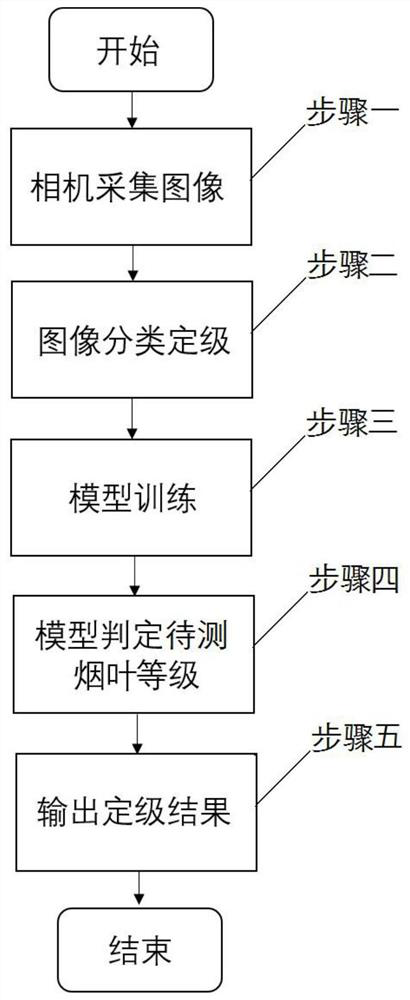

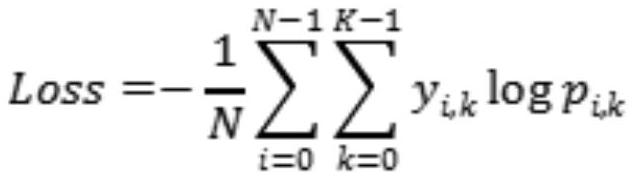

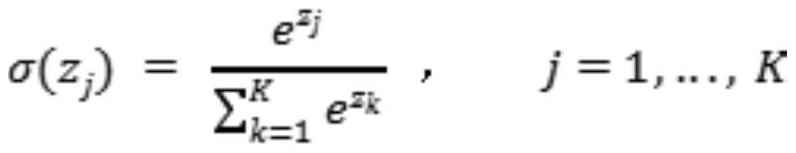

Tobacco frame tobacco leaf grade determination method based on deep learning

PendingCN114022666ASpeed up industrial processesRealize industrial automationCharacter and pattern recognitionNeural architecturesHorticultureTobacco leaf

The invention provides a tobacco frame tobacco leaf grade determination method based on deep learning. The method comprises the following steps: 1, selecting a plurality of different grades of tobacco leaves as samples, and collecting tobacco leaf images of the samples in a tobacco frame; 2, classifying and storing the acquired tobacco leaf images according to different grades; 3, constructing a prediction model, preprocessing the classified tobacco leaf images, inputting the preprocessed tobacco leaf images into the prediction model, and training the preprocessed tobacco leaf images to obtain a trained prediction model; 4, determining the grade of the tobacco leaves in the to-be-detected tobacco frame, firstly collecting the tobacco leaf image of the tobacco leaves in the to-be-detected tobacco frame, carrying out the same preprocessing as the step 3 on the collected image, and then predicting by utilizing the trained prediction model to obtain a tobacco leaf grade determination result; and 5, outputting a judgment result. The method is used for judging the grade of the tobacco leaves, reduces the manual workload and improves the production efficiency.

Owner:SHANGHAI MICRO VISION TECH

A control method for an AGV trolley

ActiveCN105417078BReduce labor intensityRealize industrial automationConveyorsControl devices for conveyorsYarnVehicle frame

Owner:NANJING KANGNI PRECISION MECHANICS

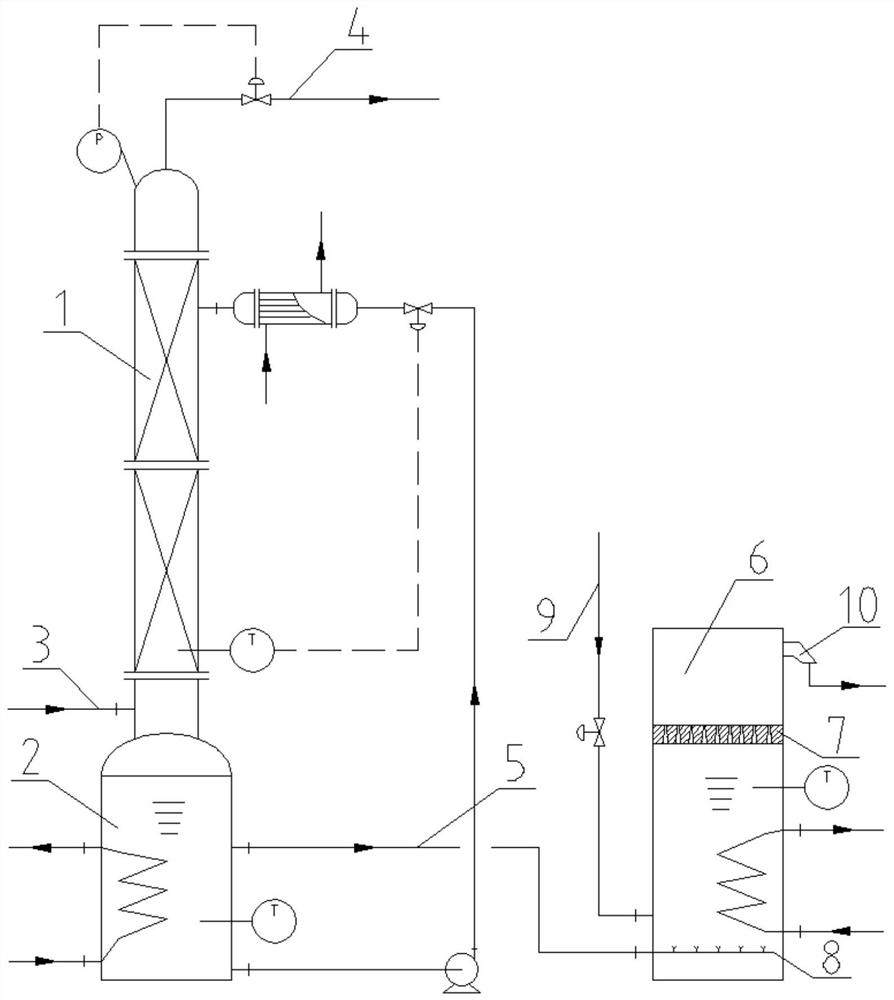

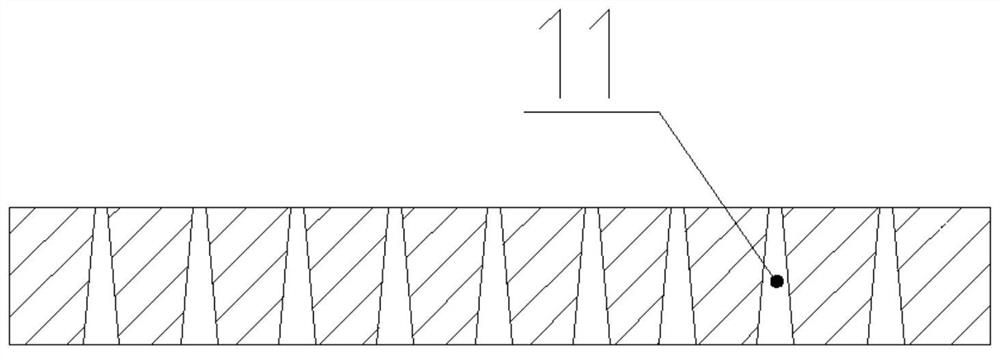

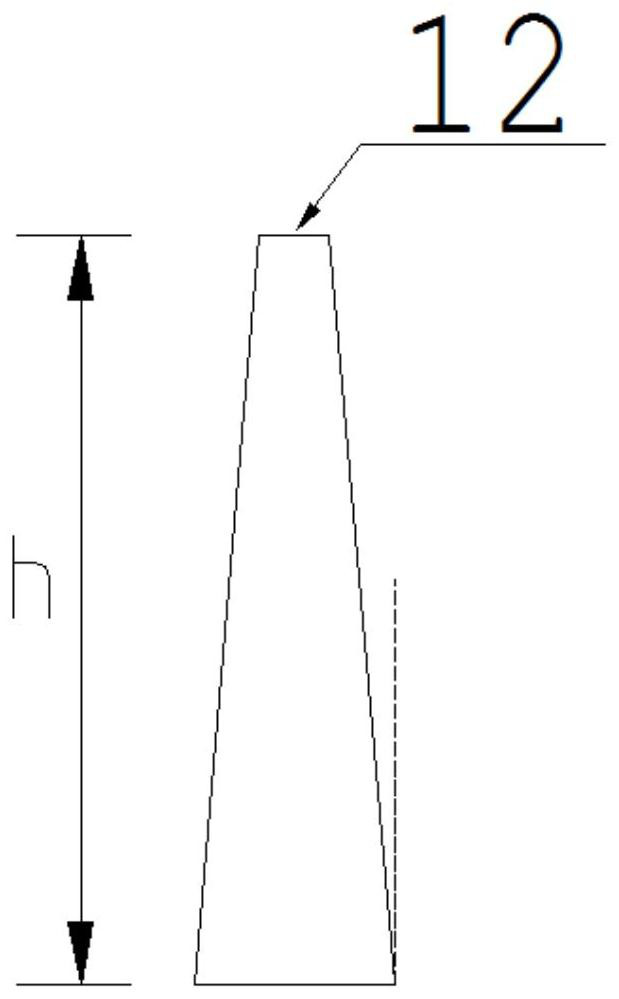

Method and device for purifying tetrafluoroethylene polymerization reaction kettle recovery gas

ActiveCN114642942AAchieve purificationRealize industrial automationDispersed particle separationHalogenated hydrocarbon separation/purificationChemical industryTetrafluoroethylene

The invention belongs to the technical field of fluorine chemical industry, particularly discloses a purification method of tetrafluoroethylene polymerization reactor recovery gas, and also discloses a purification device. According to the purification method of the tetrafluoroethylene polymerization reaction kettle recovered gas, the purified recovered gas is obtained through separation of the spray tower, the purified recovered gas comes out of the top of the spray tower and then returns to a tetrafluoroethylene monomer device to be reused, and paraffin liquid is obtained through separation in a tower kettle of the spray tower; and then the paraffin liquid is granulated, natural buoyancy is utilized, and the paraffin particles with high purity are obtained through extrusion of the small holes and can be reused. According to the purification method, on one hand, high-purity recycled gas is obtained, the phenomenon that instruments, pipelines and the like are blocked due to the fact that paraffin exists in the recycled gas can be avoided, paraffin particle products are obtained, and good economic benefits are created.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

A mobile platform system for automatic production of electrolytic manganese post-processing section

InactiveCN104451769BRealize automated productionRealize industrial automationElectrolysis componentsPhotography auxillary processesMachineProcess engineering

Owner:深圳市博利昌智能装备有限公司

A method and device for testing the chlorine resistance of spandex yarn for clothing industry

ActiveCN110376120BIn line with the actual applicationImpact on Fracture PropertiesWeather/light/corrosion resistanceYarnTemperature control

The invention discloses a method and a device for testing the chlorine resistance of spandex yarn used in the clothing industry. The drug module is provided with an elastic support and a pressure sensor under the elastic support on the sample frame. Test method: keep the residual chlorine value, pH value and temperature of the test water stable through the first, second and third dosing modules and the temperature control module; wind the spandex yarn into a sample ring and hang it with a heavy vertical iron ring Fixed on the elastic support, the elastic support is in contact with the pressure sensor; when the sample ring breaks, the elastic support leaves the pressure sensor; read the contact time between the elastic support and the pressure sensor, which is the chlorine resistance time. The invention can effectively detect the chlorine resistance time of the spandex yarn, provide an effective reference for the application of the spandex yarn in the garment industry, save manual operation costs and realize industrial automation.

Owner:杭州青云新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com