A method and device for testing the chlorine resistance of spandex yarn for clothing industry

A test method and test device technology, which are applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as difficulty in realizing industrial automation, unsuitable production and application problems, complicated methods, etc., and avoid fracture performance. Influence, save labor cost, realize the effect of industrial automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

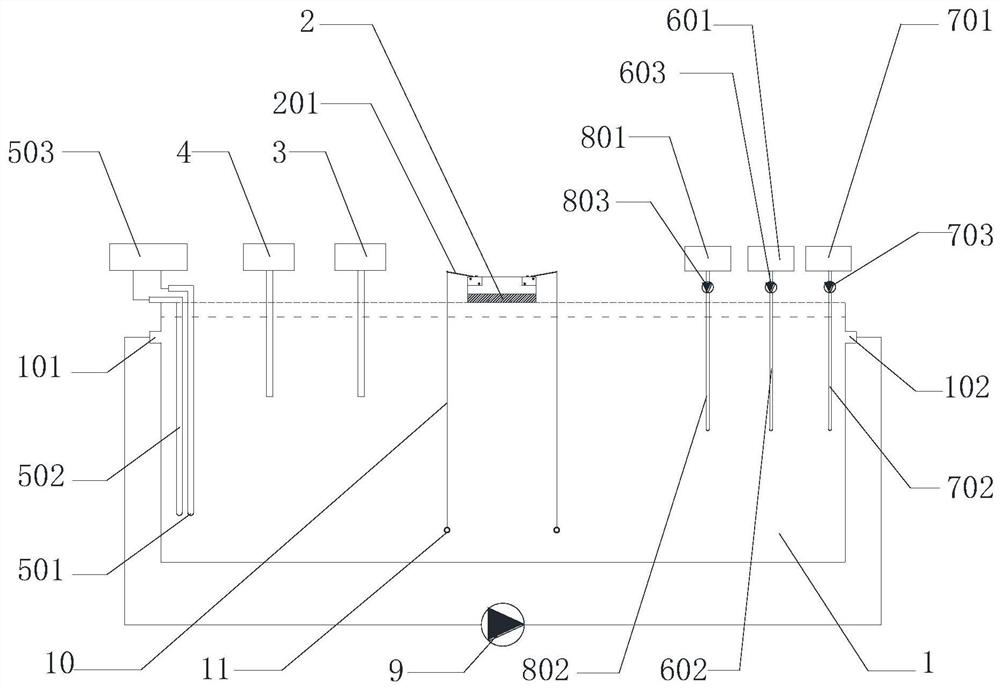

[0045] Use the above-mentioned device to measure the chlorine resistance of spandex yarn in the spandex yarn cake numbered A3 as follows:

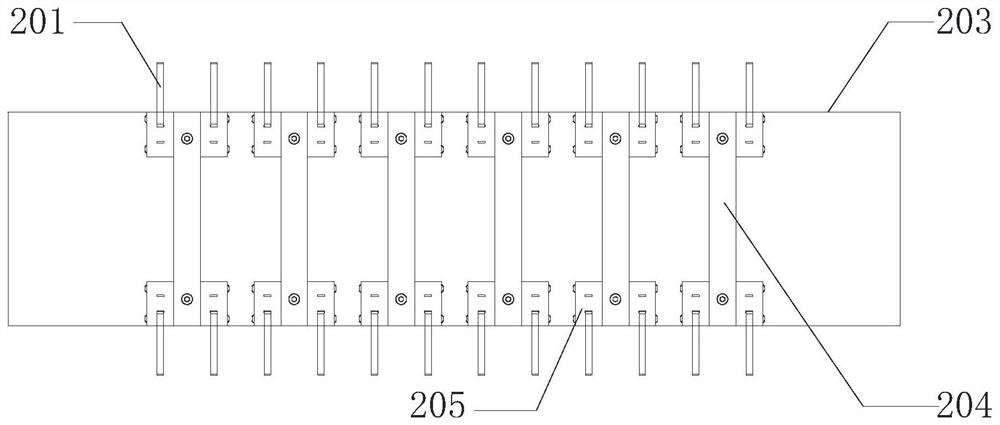

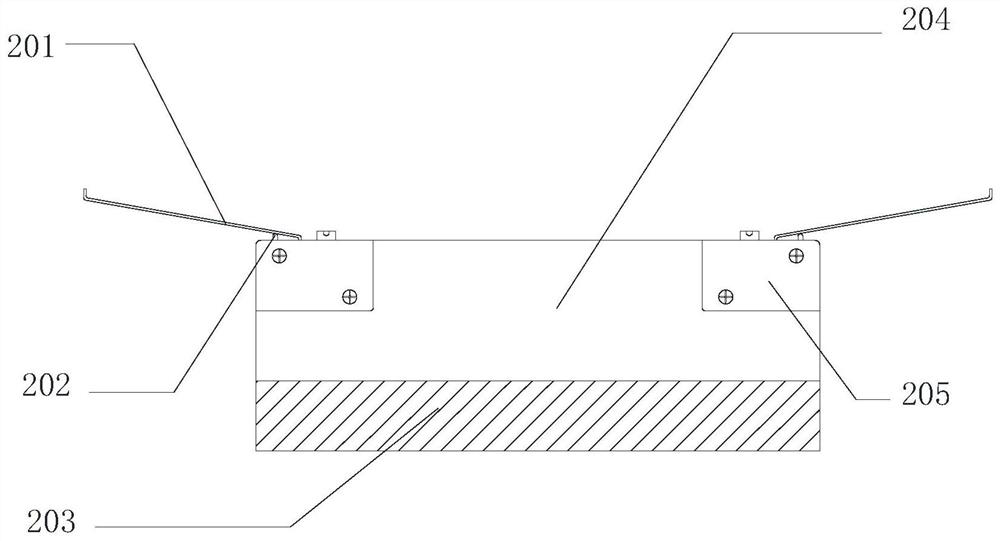

[0046] (1) Take the spandex yarn cake to be tested, and make 6 sample circles 10 with a diameter of 15±2cm by winding the spandex yarn in the spandex yarn cake for 2 circles, respectively numbered as A31, A32, A33, A34, A35, A36;

[0047] (2) Hang a heavy vertical iron ring 11 with a mass of 5.8g on each sample ring, and fix the sample ring with the heavy vertical iron ring on the elastic support of the sample frame;

[0048] (3) Add 180L of test water into the measuring pool, add residual chlorine adjusting solution through the first dosing module, add acid and / or alkaline pH adjusting solution to the second and / or third dosing module, and use the remaining test water. The chlorine value is kept at 3.5±0.5mg / L, the pH value is kept at 7.6±0.5, and the residual chlorine adjustment solution is the mass fraction of available chlorine (calcu...

Embodiment 2

[0054] Use the above-mentioned device to measure the chlorine resistance of spandex yarn in the spandex yarn cake numbered B3 as follows:

[0055] (1) Take the spandex yarn cake to be tested, and wrap the spandex yarn in the spandex yarn cake twice to make 6 sample circles with a diameter of 15±2cm, which are numbered as B31, B32, B33, B34, B35, B36 ;

[0056] (2) Hang a heavy vertical iron ring with a mass of 5.8g on each sample ring, and fix the sample ring with the heavy vertical iron ring on the elastic support of the sample frame;

[0057] (3) Add 180L of test water into the measuring pool, add residual chlorine adjusting solution through the first dosing module, add acid and / or alkaline pH adjusting solution to the second and / or third dosing module, and use the remaining test water. The chlorine value is kept at 3.5±0.5mg / L, and the pH value is kept at 7.6±0.5. The residual chlorine adjustment solution is to make the mass fraction of available chlorine (calculated as Cl...

Embodiment 3

[0063] Use the above-mentioned device to measure the chlorine resistance of spandex yarn in the spandex yarn cake numbered C3 as follows:

[0064] (1) Take the spandex yarn cake to be tested, and wrap the spandex yarn in the spandex yarn cake twice to make 6 sample circles with a diameter of 15±2cm, numbered C31, C32, C33, C34, C35, C36 respectively ;

[0065] (2) Hang a heavy vertical iron ring with a mass of 5.8g on each sample ring, and fix the sample ring with the heavy vertical iron ring on the elastic support of the sample frame;

[0066] (3) Add 180L of test water into the measuring pool, add residual chlorine adjusting solution through the first dosing module, add acid and / or alkaline pH adjusting solution to the second and / or third dosing module, and use the remaining test water. The chlorine value is kept at 3.5±0.5mg / L, and the pH value is kept at 7.6±0.5. The residual chlorine adjustment solution is to make the mass fraction of available chlorine (calculated as Cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com