Integrated device for preparing recycled cement paste powder by using waste premixed concrete

A technology for ready-mixed concrete and reclaimed water, applied in cement production, solid separation, chemical instruments and methods, etc., can solve the problems of lack of integrated industrial processing and preparation devices, reduce the problem of increasing shortage of limestone resources, increase fineness, reduce The effect of carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

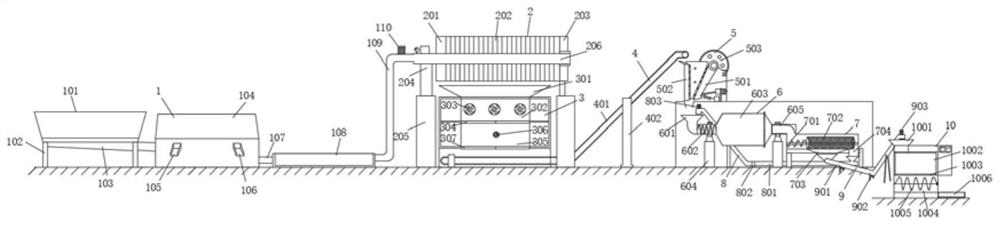

[0039] refer to Figure 1 to Figure 11 , an integrated device for preparing recycled cement slurry powder by using waste ready-mixed concrete, comprising a separation device 1, a filter press device 2, an air-drying device 3, a first conveying device 4, a crushing device 5, a ball milling device 6, Screening device 7 , second conveying device 8 , third conveying device 9 and calcining device 10 .

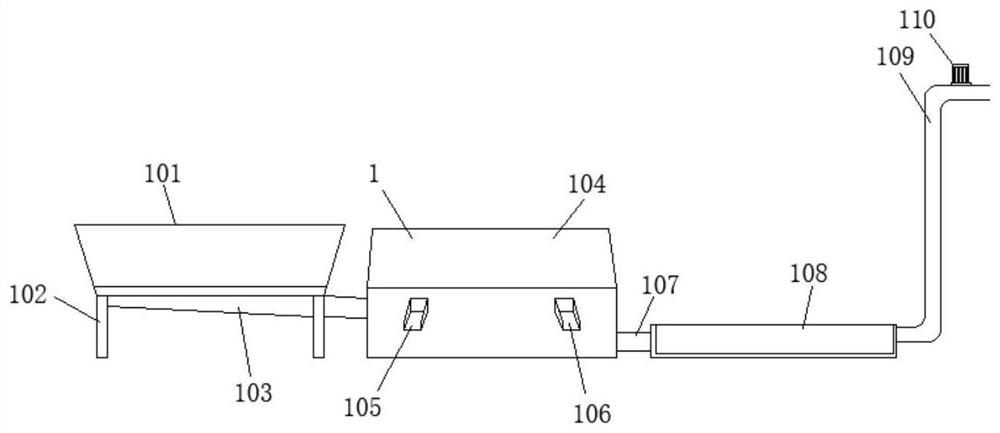

[0040] Such as figure 2 As shown, the separation device 1 is composed of a first material inlet 101 , a sand separator 104 , and a sedimentation tank 108 , which are connected by a second pipeline 103 and a third pipeline 107 . Below the first material inlet 101 is a separation base 102; the front part of the sand separation system 104 is provided with a stone outlet 105 and a sand outlet 106; Pump 110.

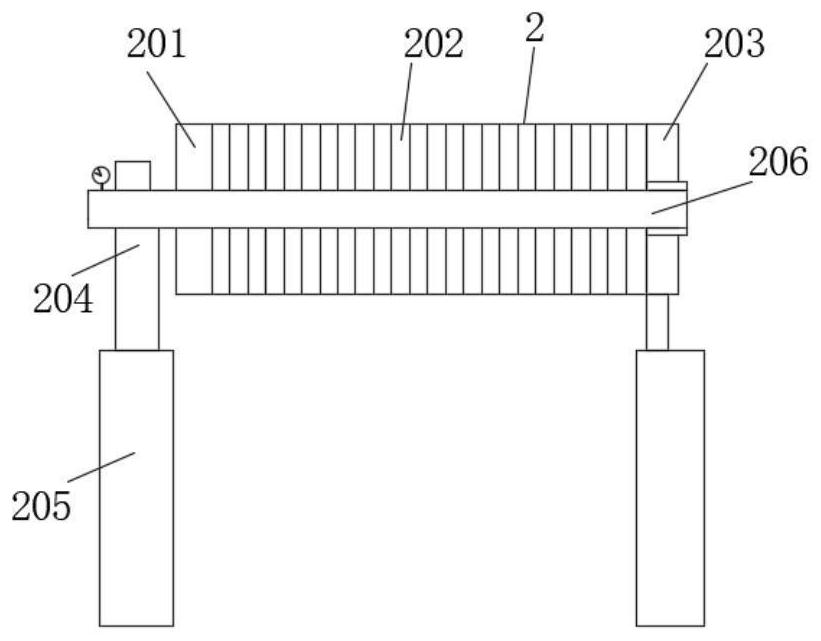

[0041] Such as image 3 As shown, the filter press device 2 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com