Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122 results about "Ready-mix concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ready-mix concrete is concrete that is manufactured in a batch plant, according to a set engineered mix design. Ready-mix concrete is normally delivered in two ways. First is the barrel truck or in–transit mixers. This type of truck delivers concrete in a plastic state to the site.

Lightweight concrete compositions

ActiveUS20070062415A1Other chemical processesSolid waste managementVolumetric Mass DensitySand granules

A lightweight ready-mix concrete composition that contains 8-20 volume percent cement, 11-50 volume percent sand, 10-31 volume percent prepuff particles, 9-40 volume percent coarse aggregate, and 10-22 volume percent water, where the sum of components used does not exceed 100 volume percent. The prepuff particles have an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.02 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3. The slump value of the composition measured according to ASTM C 143 is from 2 to 8 inches. After the lightweight ready-mix concrete composition is set for 28 days, it has a compressive strength of at least 1400 psi as tested according to ASTM C39.

Owner:SYNTHEON HLDG SPA

Lightweight concrete compositions

ActiveUS20080058446A1Solid waste managementOther chemical processesVolumetric Mass DensitySand granules

A lightweight ready-mix concrete composition that contains 8-20 volume percent cement, 11-50 volume percent sand, 10-31 volume percent prepuff particles, 9-40 volume percent coarse aggregate, and 10-22 volume percent water, where the sum of components used does not exceed 100 volume percent. The prepuff particles have an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.02 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3. The slump value of the composition measured according to ASTM C 143 is from 2 to 8 inches. After the lightweight ready-mix concrete composition is set for 28 days, it has a compressive strength of at least 1400 psi as tested according to ASTM C39.

Owner:SYNTHEON HLDG SPA

Lightweight concrete compositions

A lightweight ready-mix concrete composition that contains 8-20 volume percent cement, 11-50 volume percent sand, 10-31 volume percent prepuff particles, 9-40 volume percent coarse aggregate, and 10-22 volume percent water, where the sum of components used does not exceed 100 volume percent. The prepuff particles have an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.02 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3. The slump value of the composition measured according to ASTM C 143 is from 2 to 8 inches. After the lightweight ready-mix concrete composition is set for 28 days, it has a compressive strength of at least 1400 psi as tested according to ASTM C39.

Owner:NOVA CHEM (INT) SA

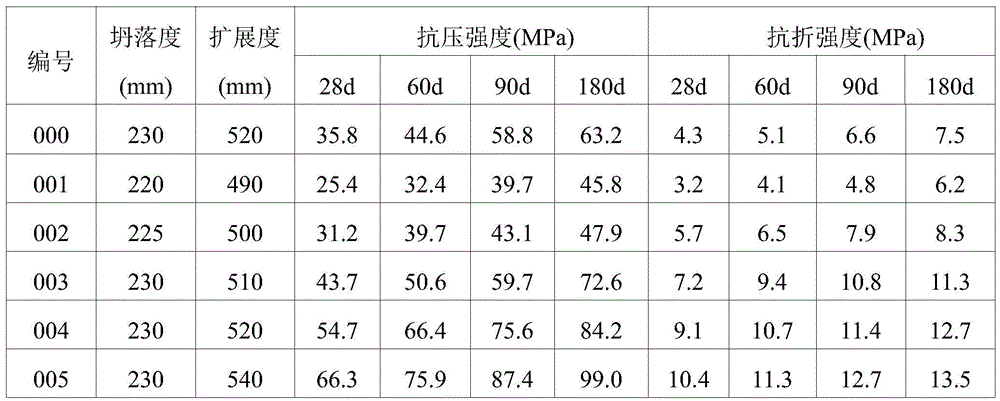

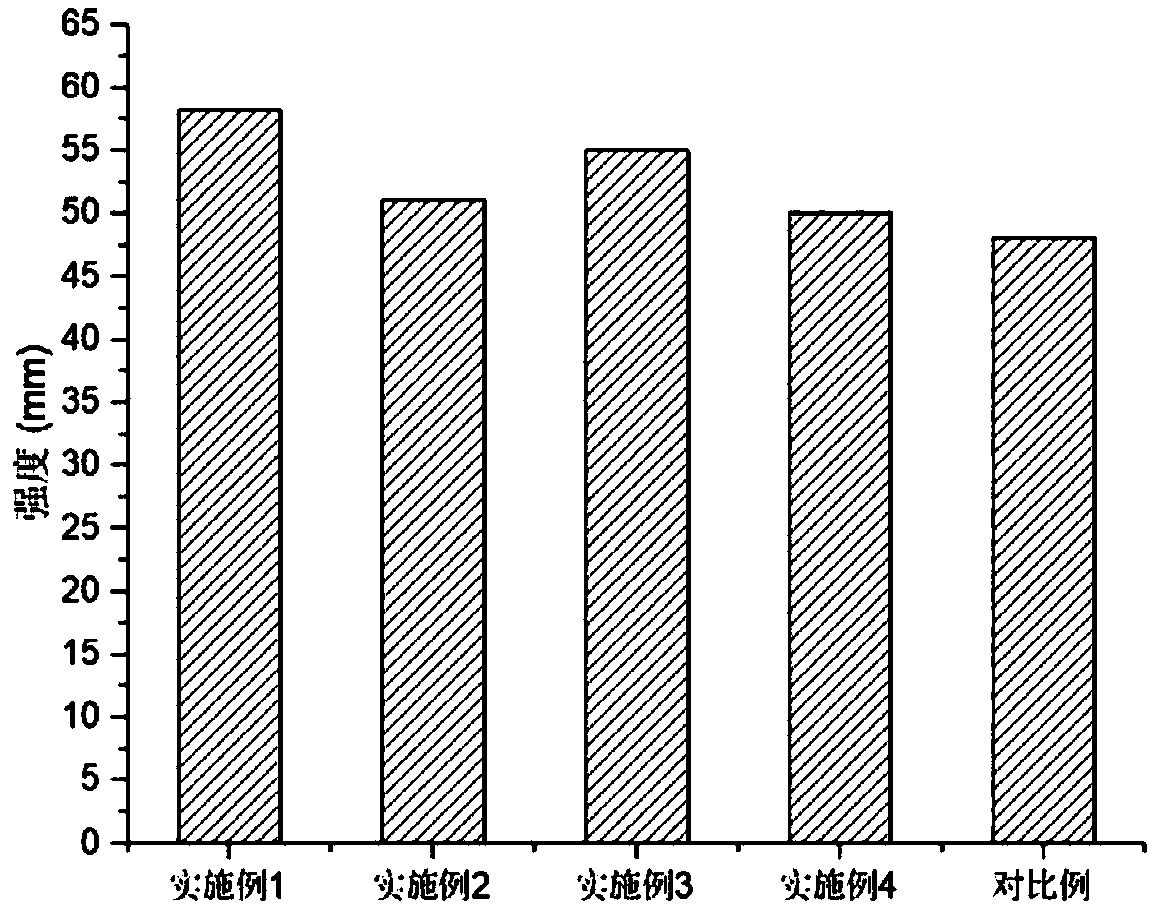

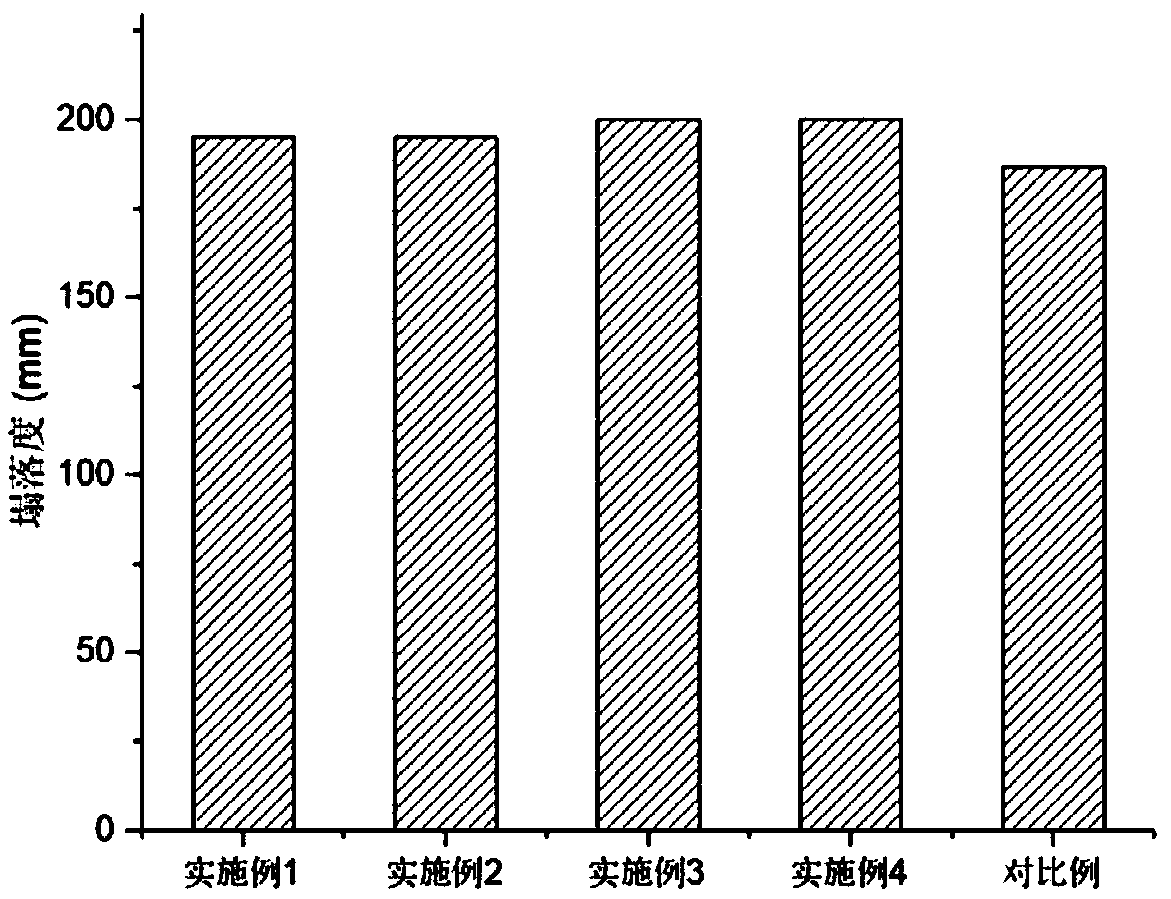

High-performance concrete with large mixing amount of mineral powder and manufacturing method of high-performance concrete

The invention discloses high-performance concrete with a large mixing amount of mineral powder and a manufacturing method of the high-performance concrete. The high-performance concrete is manufactured from cement, slag powder, coal ash, crushed stone, river sand, water, an exciting agent, and a water reducer, and comprises, by weight part: 140-170 parts of cement, 170-240 parts of slag powder, 50-100 parts of coal ash, 1010-1100 parts of crushed stone, 735-825 parts of river sand, 150-180 parts of water, 11-15 parts of an exciting agent, and 3.4-5 parts of a water reducer. Slag powder and coal ash are re-mixed into the concrete as a supplementary cementitious material, through an exciting effect of the sodium sulfate exciting agent, to manufacture the high-performance concrete with a large mixing amount of mineral powder. Long-term strength, durability, and working performance of the cement concrete are effectively improved. A large amount of industrial waste, such as mineral powder and coal ash, is utilized in the formula, thereby reducing cement consumption in pre-mixed concrete. The cost is reduced, and the method is energy-saving and eco-friendly.

Owner:武汉武新新型建材股份有限公司

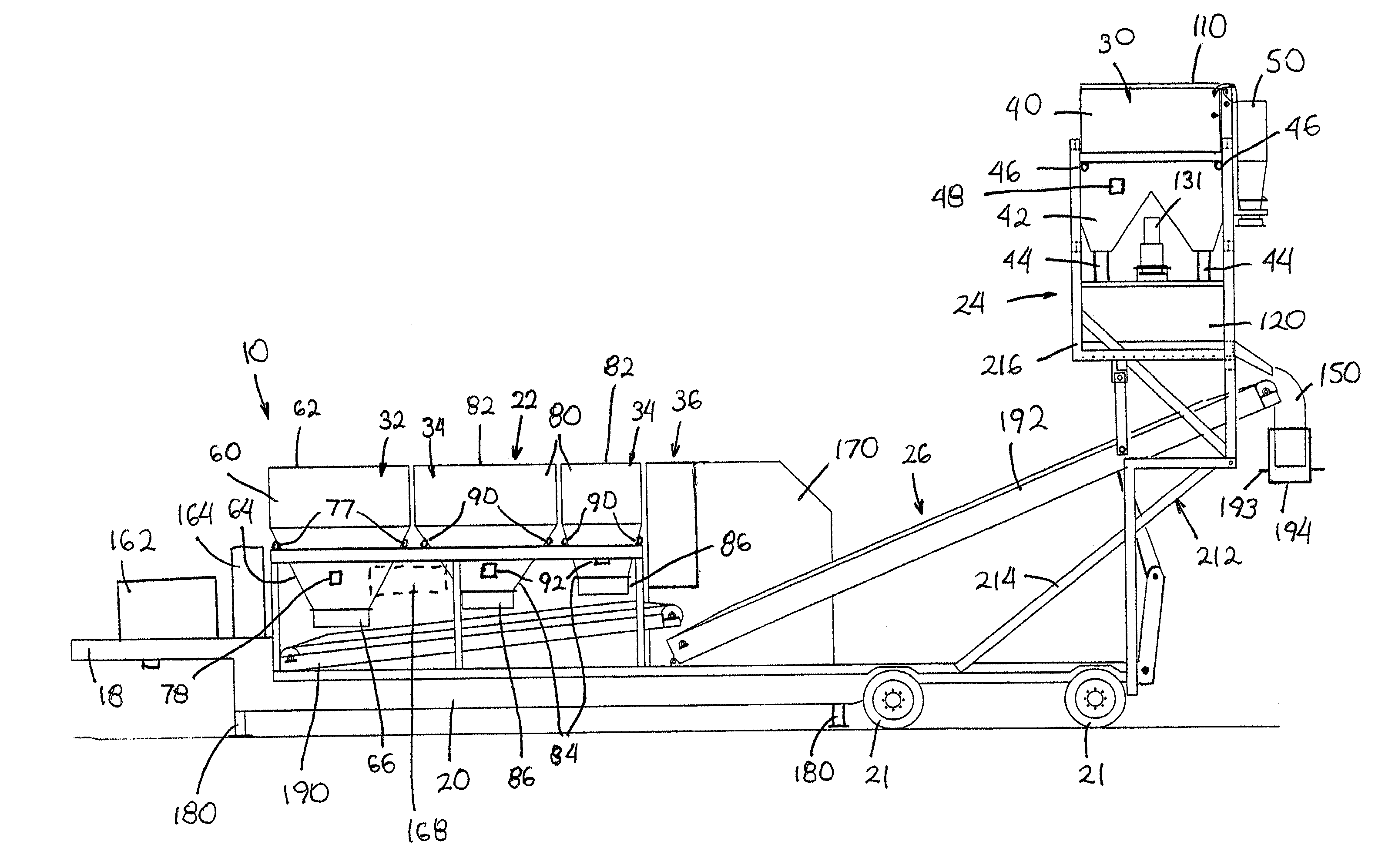

Portable concrete plant

A portable concrete plant for producing ready mix concrete proximate to a location where the ready mix concrete is used. The portable concrete plant includes storage regions for storing components used in the ready mix concrete. The portable concrete plant also includes a slurry mixer for preparing slurry that is used in the ready mix concrete. The portable concrete plant further includes conveying systems for conveying the components from the storage regions and from the slurry mixer to a system discharge port.

Owner:BROCKPAHLER DAVID

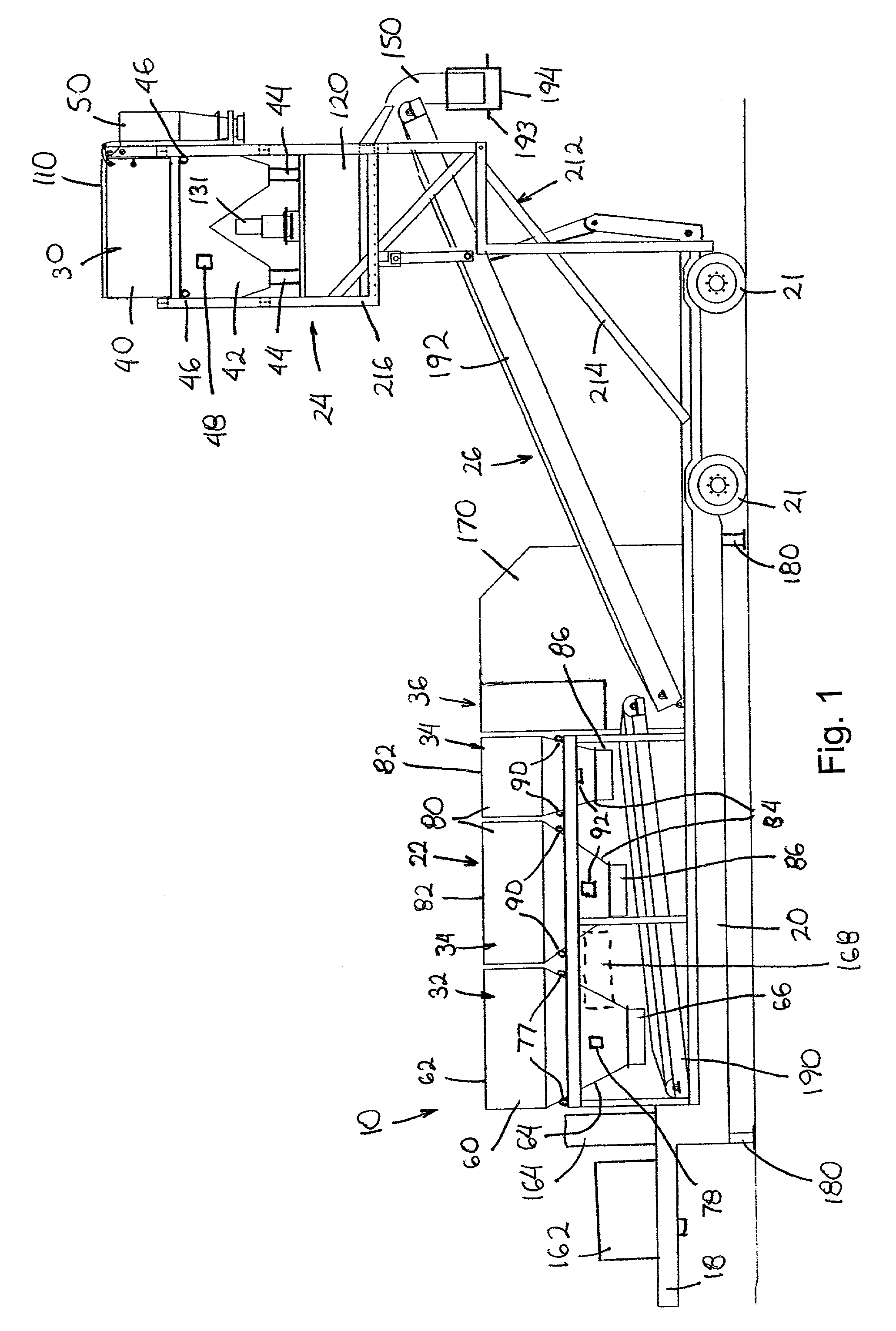

Removal of Residual Concrete from Ready Mixed Concrete Drums

ActiveUS20070079852A1Minimizing overall energy requiredMinimizing energyServomotor componentsHollow article cleaningHigh pressure waterEngineering

Residual concrete in the drum of a ready mixed concrete truck is removed by high-pressure water. A nozzle is mounted on the leading end of a torpedo-shaped nozzle housing that is hingedly mounted to an elongate boom. The boom enters the mouth of the drum at an angle that matches the angle of the drum. The hinge allows the nozzle housing to pivot with respect to the elongate boom so that the nozzle is close to the residual concrete. The boom is retracted toward the mouth with the drum rotating in the mix direction and the nozzle oscillating so that it cuts through a swath of concrete. As the boom retracts, the torpedo-shaped nozzle housing maintains the nozzle close to the residual concrete on the drum and both sides of the helical fins. The nozzle sweeps an arc from about eighty to one hundred twenty degrees as it oscillates.

Owner:BLASTERS

Sulfamate as high performance reducing water agent for building and preparing proces thereof

The invention relates to a building sulfamate high-performance water reducer and its preparing method, synthesized of benzene solfonic acid, sodium hydroxide, phenol, formaldehyde and water, and the product mainly contains the groups: -CN, benzene ring, -SO3, etc, and the average molecular weight is 4000-9500. It can make the water reduction ratio of concrete up to above 25%, improve the fluidity of concrete by a large margin, makes the loss rate of concrete slump in 2 hours less than 10%, enhances the strength by a large margin, and improves the durability of concrete. It has better adaptability to various cements. It is applied to the constructions (structures) of premixed concrete commodity, high-strength high-performance concrete, reinforced concrete, etc.

Owner:TONGJI UNIV

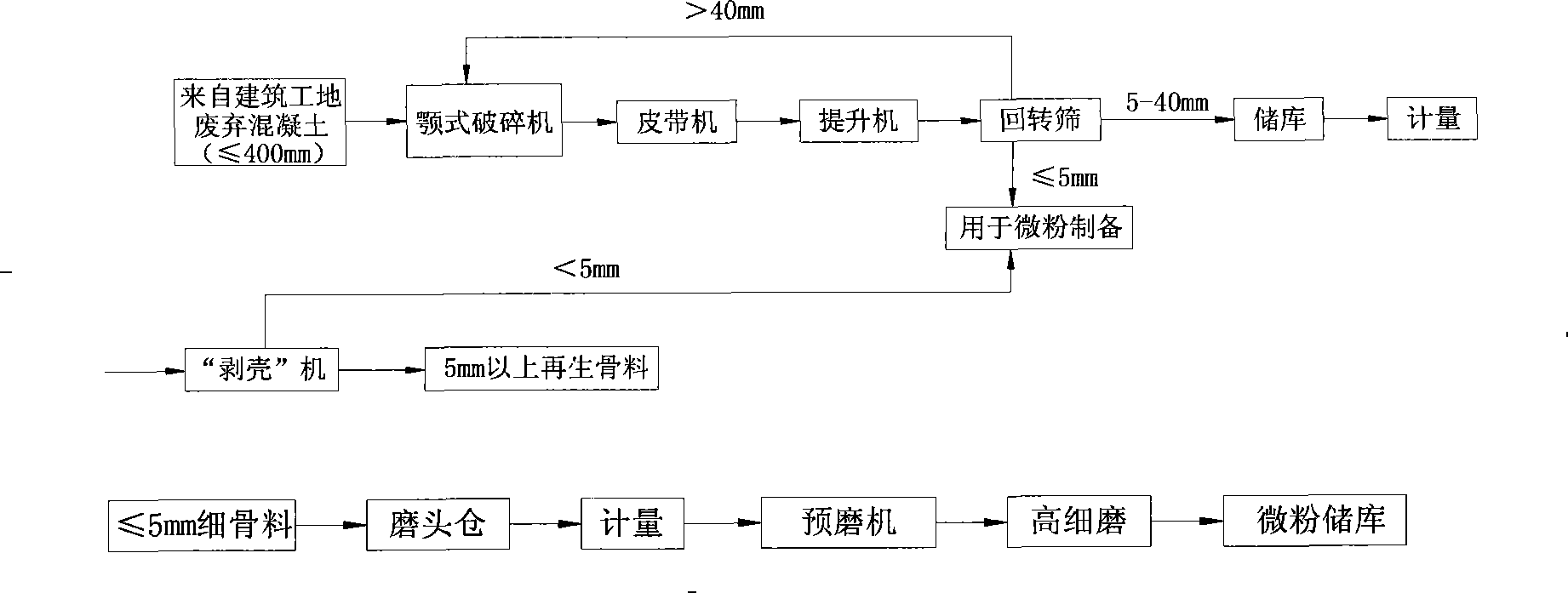

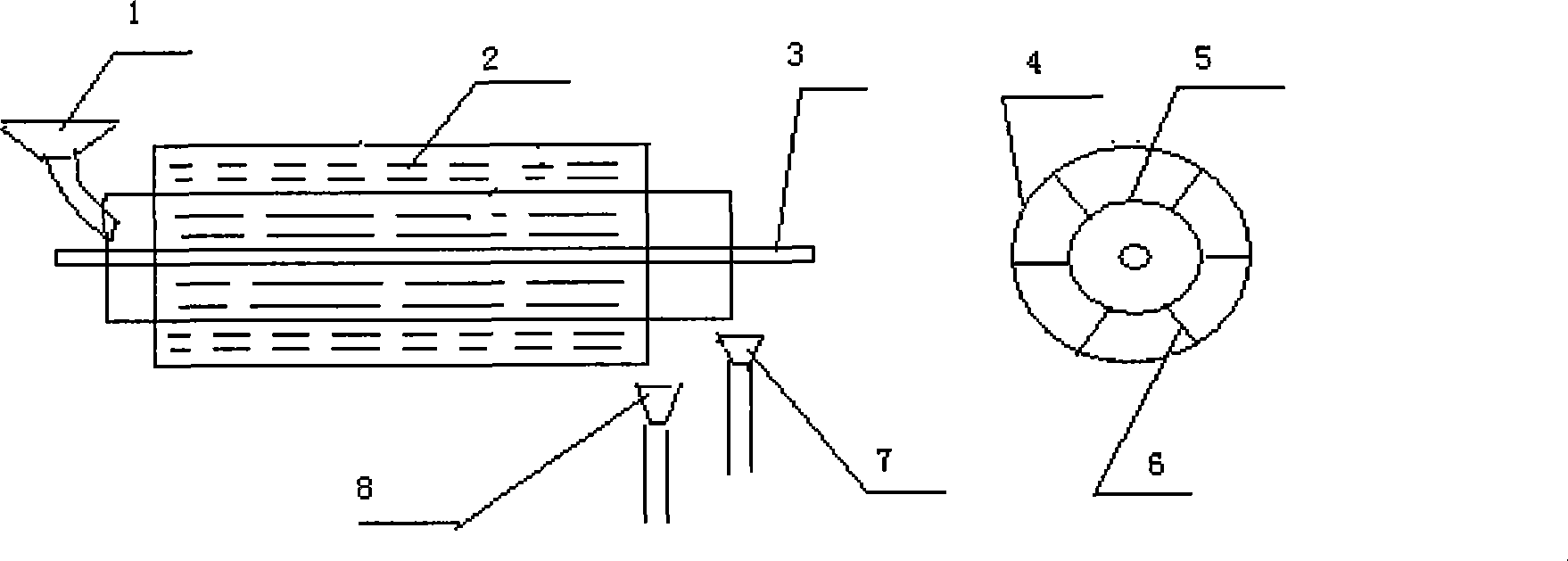

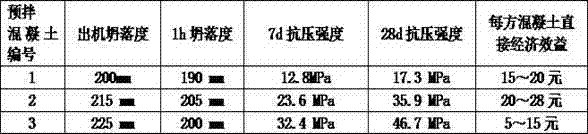

Discarded concrete reclaiming method and device

InactiveCN101250033AEffective "shelling" separationEasy constructionSolid waste managementRecovery methodGranularity

The invention discloses a recovery method of waste concrete and a device. The steps of the method comprise employing a crusher to crush waste concrete, wherein steel bars of the waste concrete are removed, the grain size of the waste concrete is about 400mm, after crushing, the largest grain size is no more than 50mm, then sending the waste concrete to a rotary sieve for selecting, selecting three grain diameters of 40mm, 5-40mm and being less than 5mm, sending a portion of waste concrete grain diameter of which is larger than 40mm to continue to crush, separating thick and fine aggregates which are bonded firmly of a portion of waste concrete grain diameter of which is 5-40mm by employing rubbing way, then obtaining 5-25mm clean gravels and fine aggregates grain diameter of which is smaller than 5mm, and a portion of waste concrete grain diameter of which is smaller than 5mm is in ultra-fine grinding treatment. The invention separates and restores original thick and fine aggregates which are bonded firmly of the waste concrete to obtain clean gravels, finely-crushing hardened mortar and a portion of stone waste, the gravels is used for thick aggregates mixed with the waste concrete, the finely-crushing hardened mortar and a portion of stone waste are grinded and processed further to produce micro powder, the micro powder is utilized as admixture of premixed concrete to instead of a portion of cement, thereby improving construction and service performance of the premixed concrete.

Owner:LUOYANG INST OF SCI & TECH

Method utilizing tailing sand to carry out sand gradation improvement

The invention discloses a method utilizing tailing sand to carry out sand gradation improvement, and belongs to the field of construction material preparation. The method comprises the following steps: (1) screening the tailing sand, and calculating the fineness modulus; (2) screening the sand needed to be improved, and calculating the fineness modulus; (3) mixing the tailing sand and the sand needed to be improved according to a ratio of a to b, and then screening the mixed sand; (4) determining the mixed sand. The method has the advantages that ore tailing wastes are utilized and high quality premixed concrete is obtained at the same time. The invention provides a method utilizing tailing sand to carry out sand gradation improvement. In the method, the tailing sand is mixed with sand needed to be improved according to a certain ratio, the tailing sand with low fineness modulus is used to modify the sand with high fineness modulus, thus the gradation of the obtained mixed sand meets the requirements of II zone middle sand, and the premixed concrete made of the improved mixed sand is accord withrelated criteria.

Owner:SHANDONG JIANZE CONCRETE

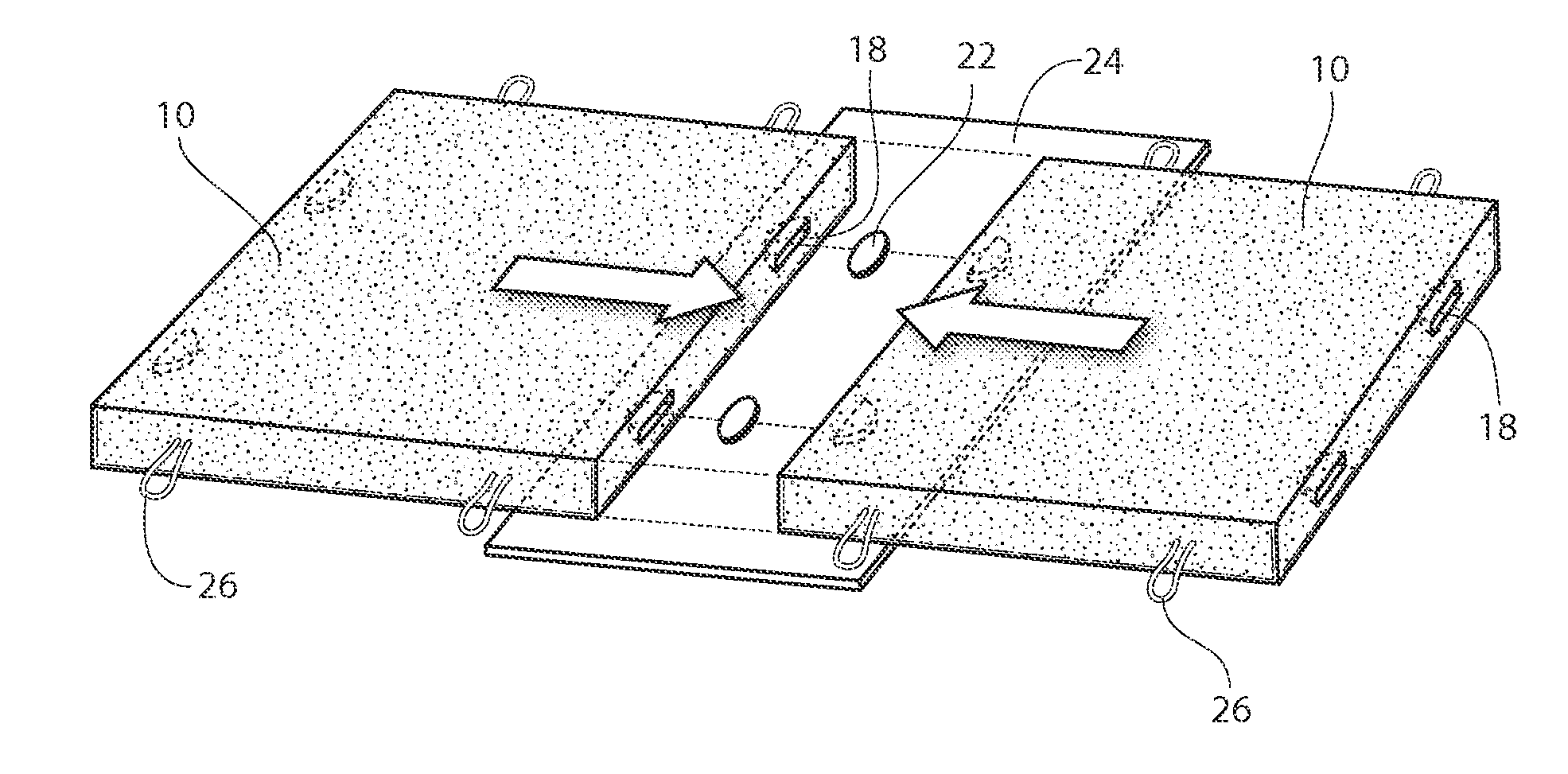

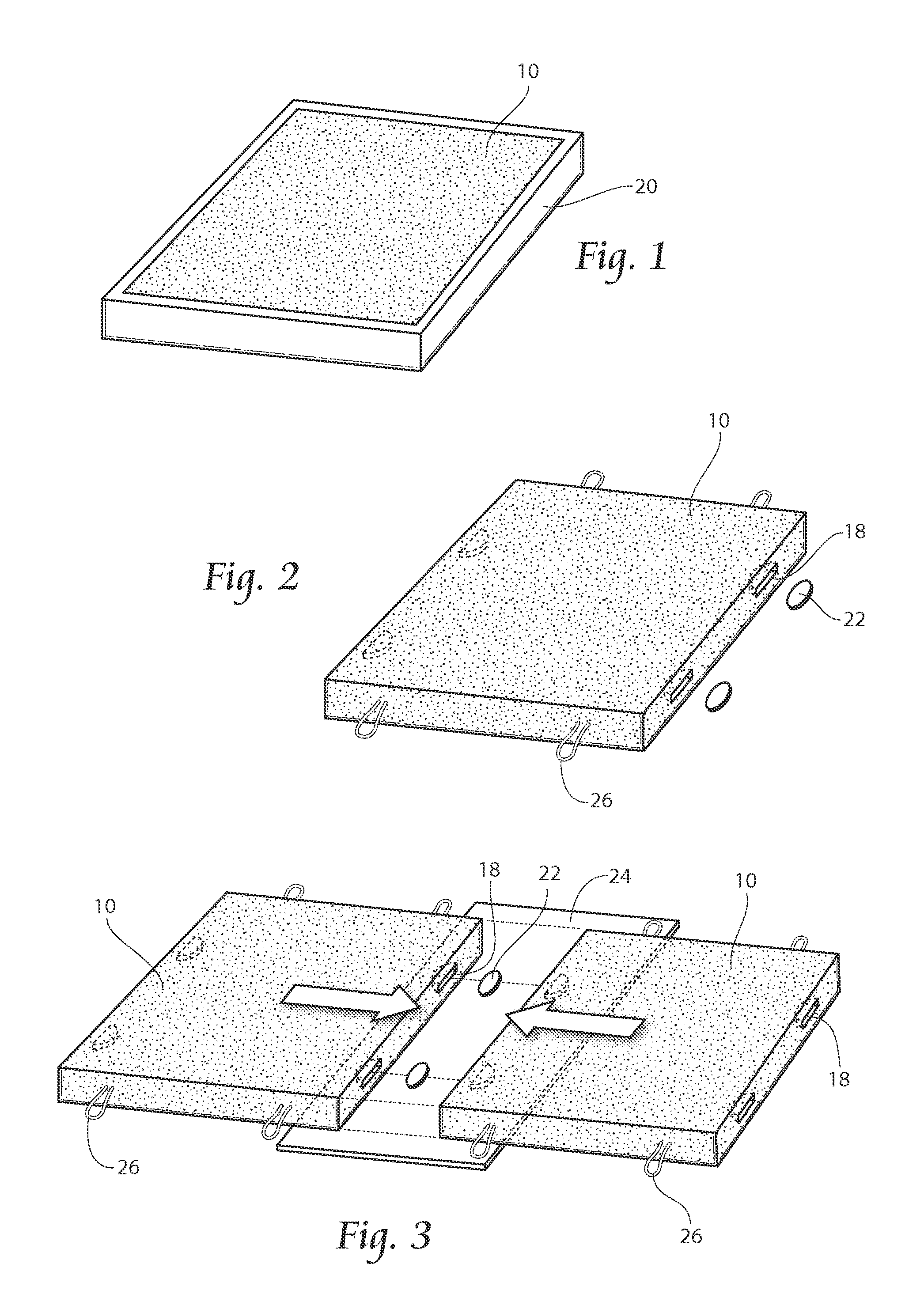

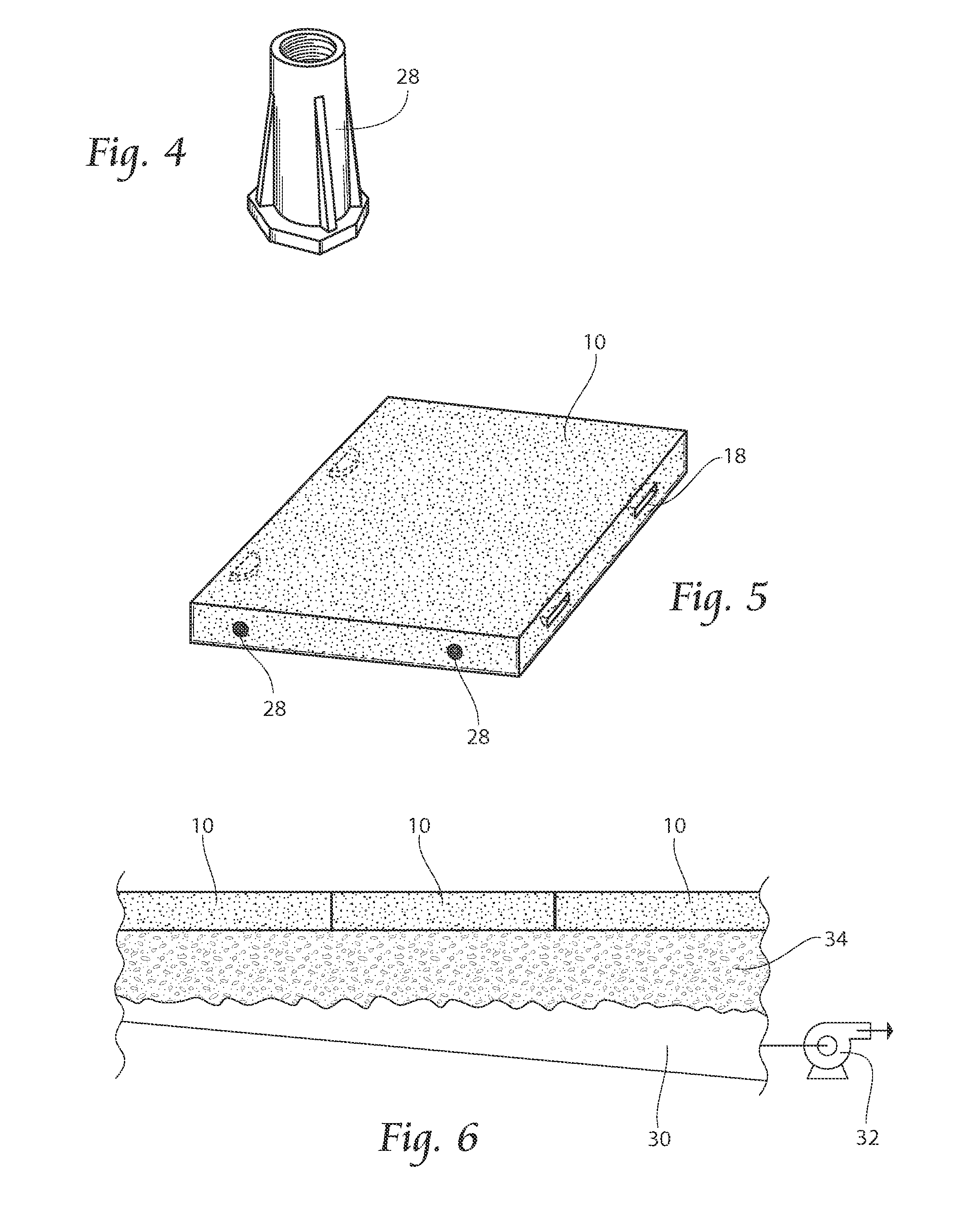

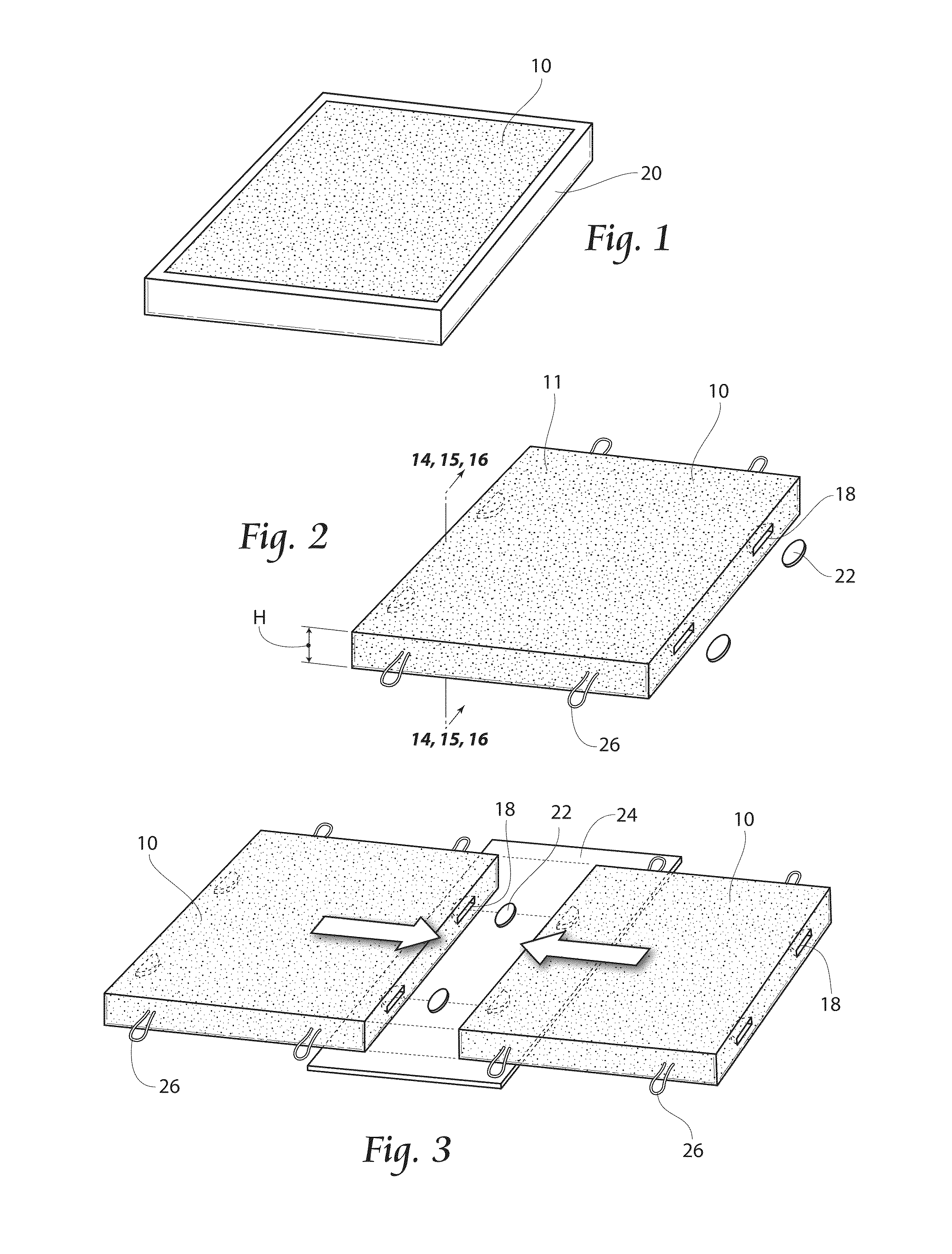

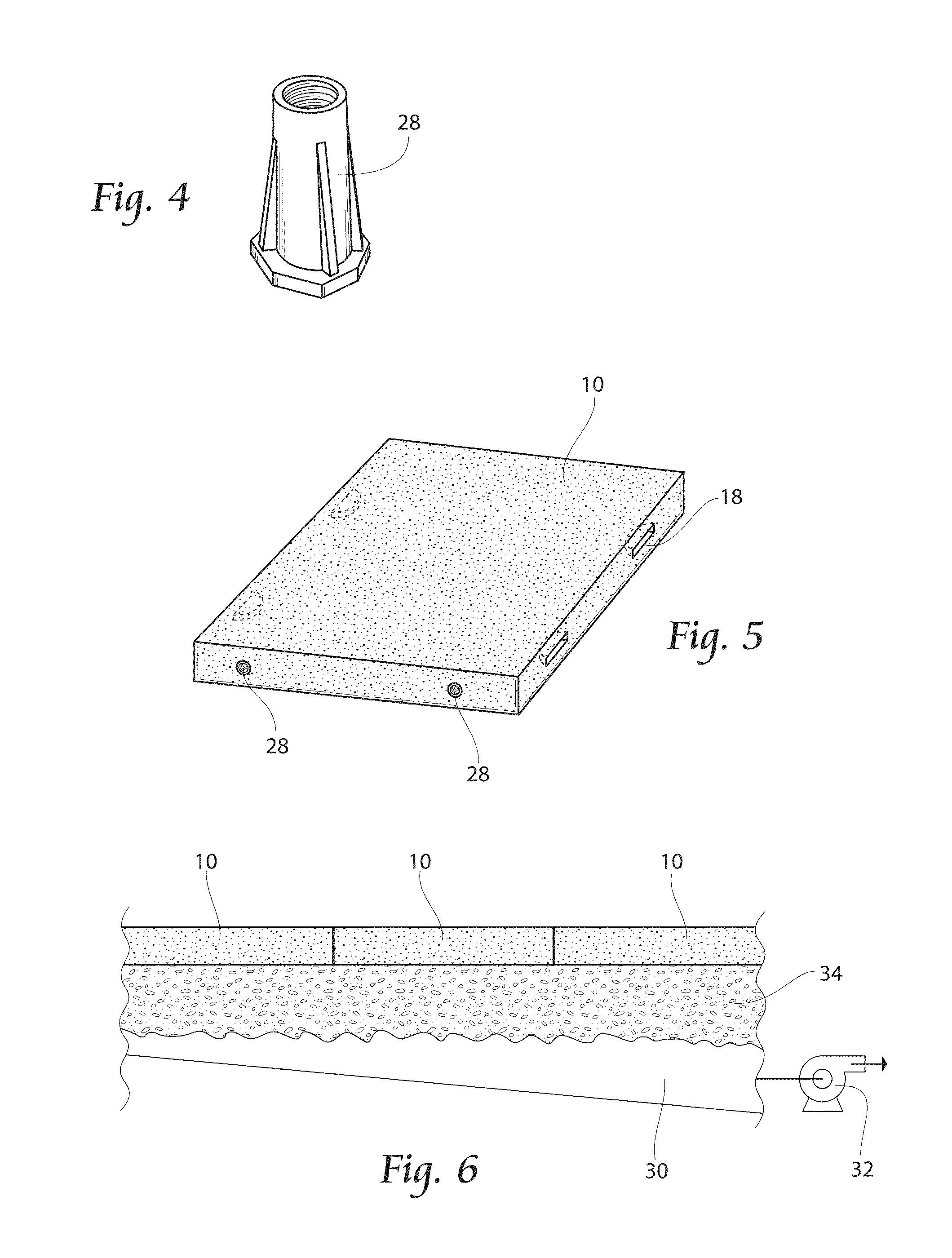

Precast pervious concrete panels

InactiveUS20130326966A1Easy to transportConstruction materialSingle unit pavingsCollection systemReady-mix concrete

A precast pervious concrete panel is formed in a containment vessel under controlled conditions and allowed to reach an acceptable strength before removal from the containment vessel, thereby producing standard sizes or shapes for installation in the field. Each piece of pervious concrete may include slots cut into the piece at predetermined locations allowing installation of a joint connector; either dry or with a bonding material thereby allowing connection of multiple pieces into a solid slab. A strip material may be used under the slab joints to dissipate load bearing and allow the panels to slide together when picked up by the embedded lifting device. Multiple pervious concrete pieces can be combined with a collection system allowing collection / reuse of water passing through the panels. Precast pervious concrete panels can be used as inserts in ready mix or cast in place concrete frames allowing for easy replacement of the pieces.

Owner:THE SPANCRETE GROUP

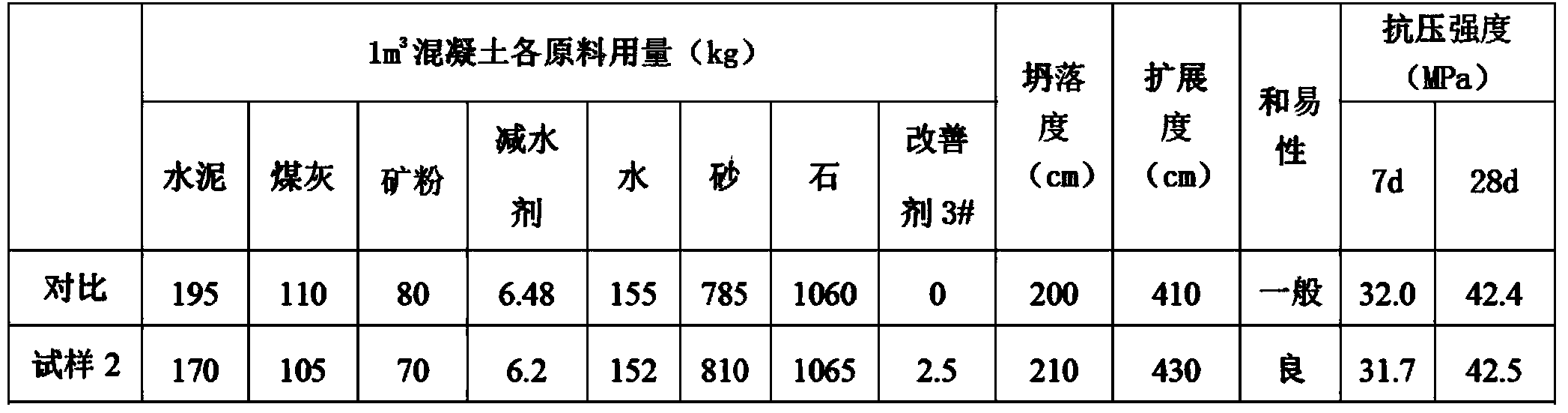

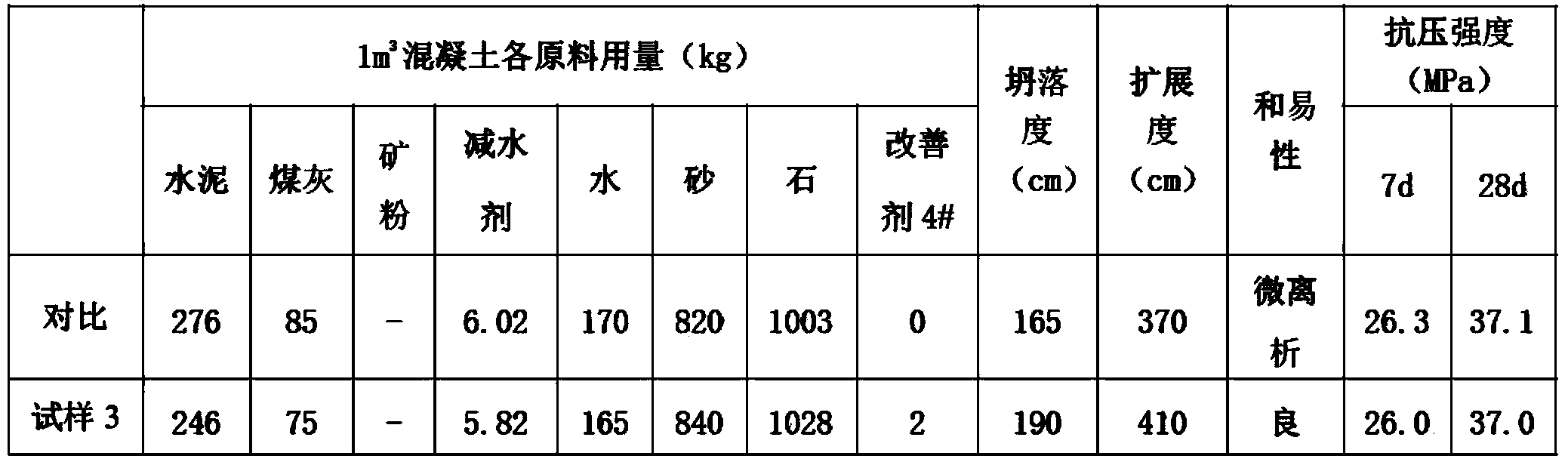

Energy-efficient and environment-friendly fresh ready-mix concrete improving agent

The invention discloses an energy-efficient and environment-friendly fresh ready-mix concrete improving agent, comprising the following components: organic alcohol, a stabilizer, a polyvinyl alcohol and / polyvinyl chloride, a dispersant and water, and also comprising a thickening agent. The improving agent disclosed by the invention is applied to fresh ready-mix concrete, so that free water of an aggregate surface can be reduced, the binding power of set cement and aggregate is increased, the strength and the lasting quality of the concrete are improved, and the service life is prolonged. Meanwhile, the grade strength of the concrete is kept and the construction workability is improved on the basis that the economic benefit targets of reducing the dosage of a water reducer and saving a cementing material are achieved, and the targets of saving energy and protecting environment are achieved.

Owner:GUANGZHOU WENJIAN HIGH TECH MATERIAL TECH

Lightweight concrete compositions

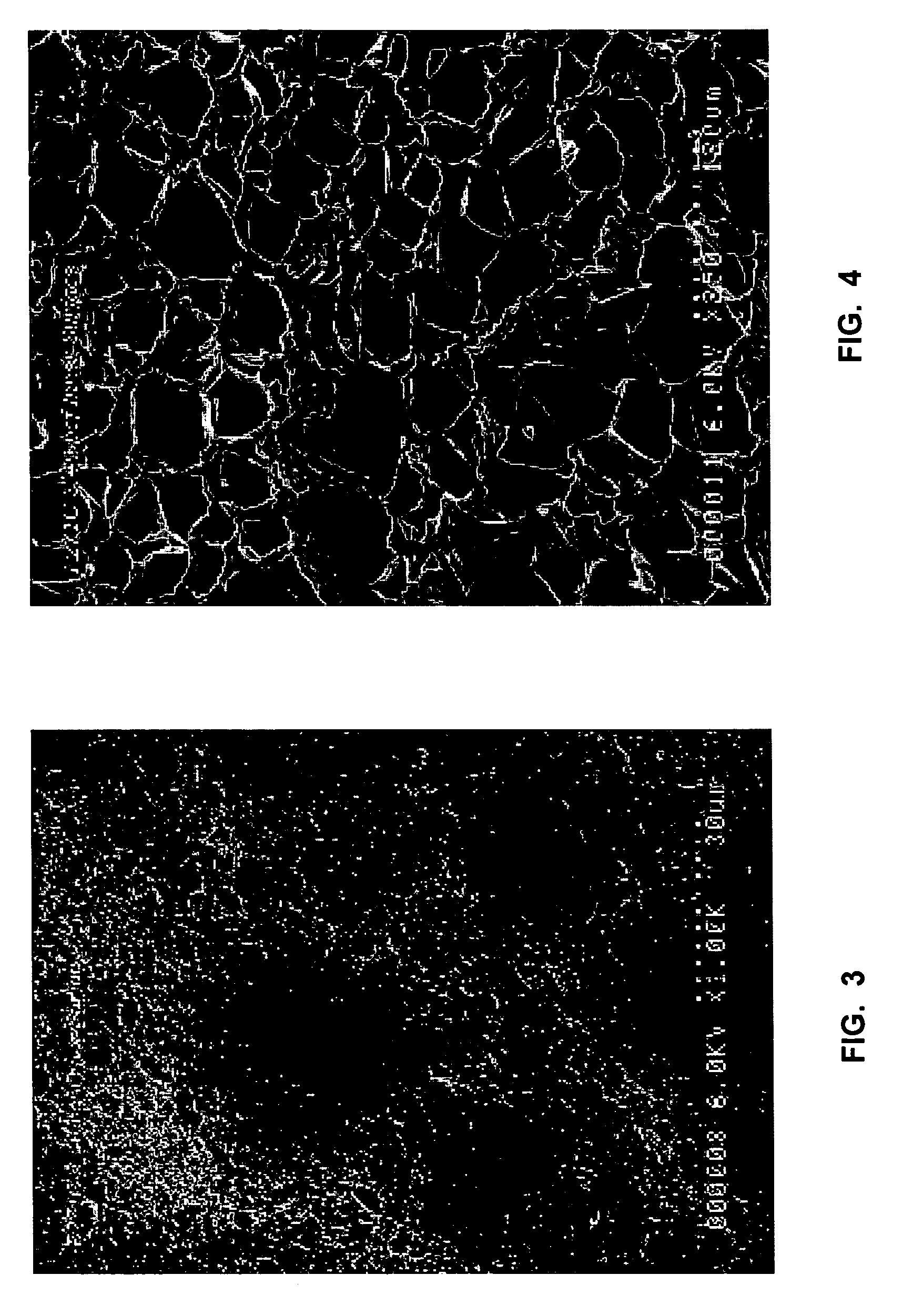

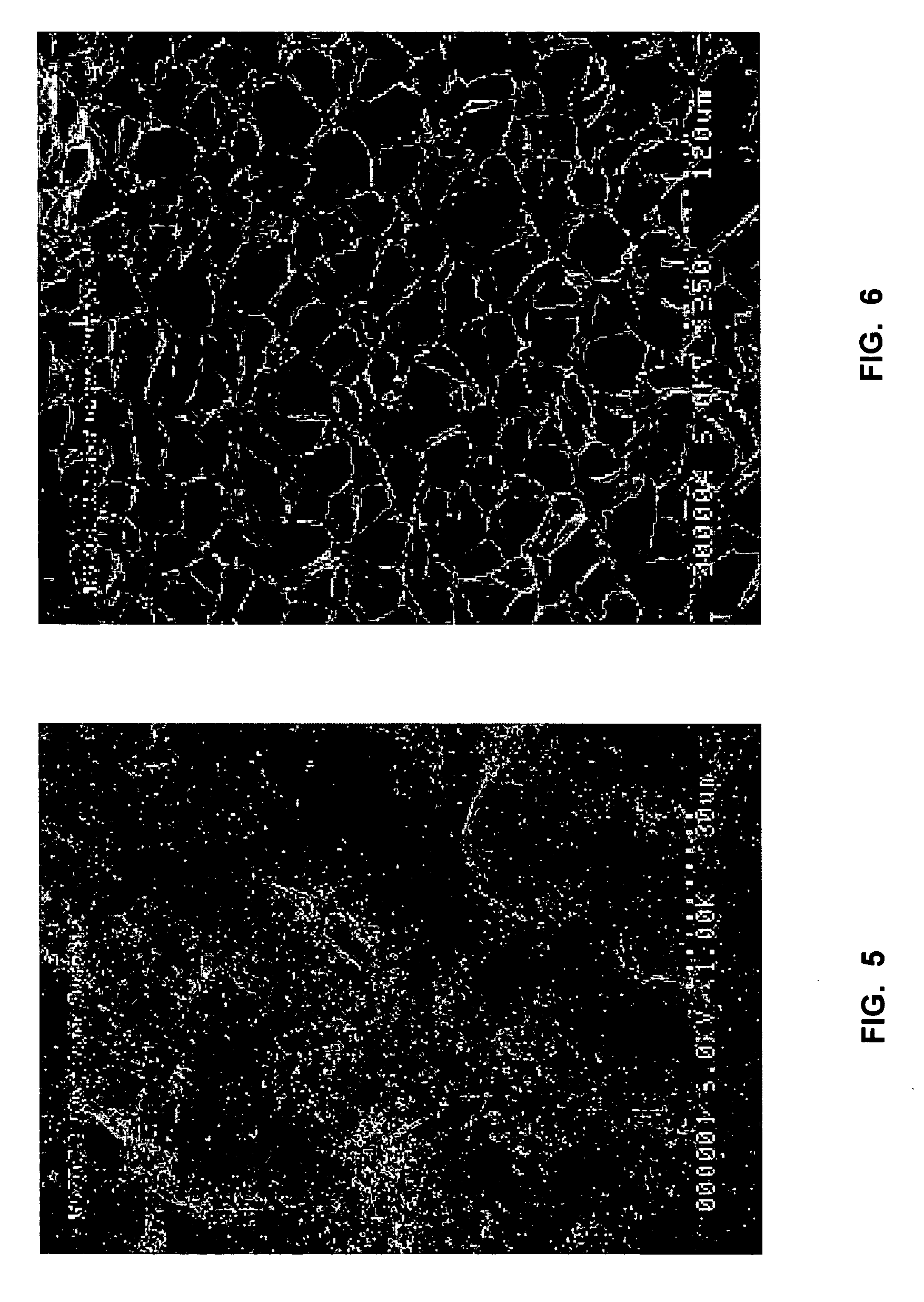

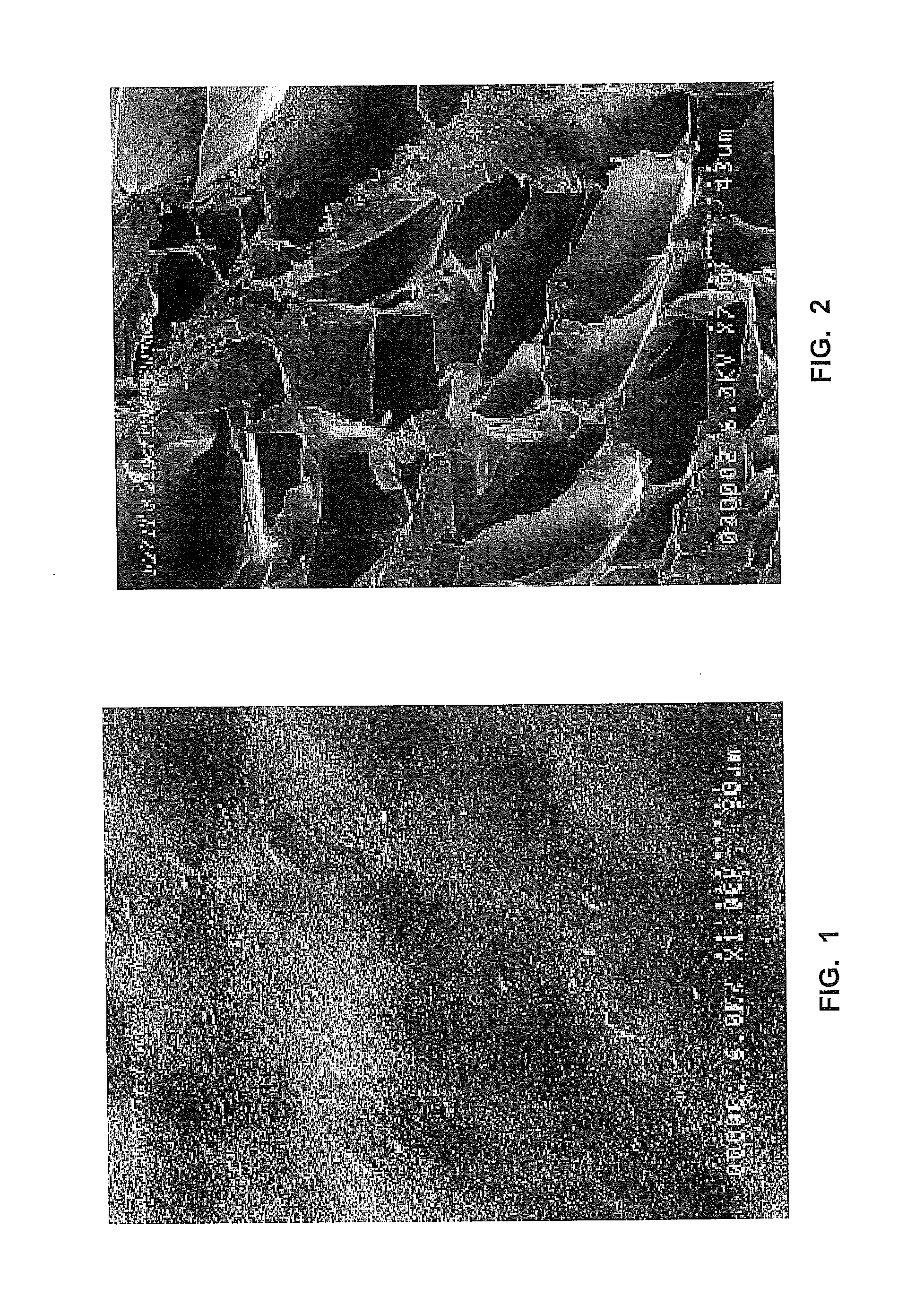

ActiveUS7648574B2Other chemical processesSolid waste managementCompressive strengthReady-mix concrete

A lightweight ready-mix concrete composition that contains 8-20 volume percent cement, 11-50 volume percent sand, 10-31 volume percent prepuff particles, 9-40 volume percent coarse aggregate, and 10-22 volume percent water, where the sum of components used does not exceed 100 volume percent. The prepuff particles have an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.02 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3. The slump value of the composition measured according to ASTM C 143 is from 2 to 8 inches. After the lightweight ready-mix concrete composition is set for 28 days, it has a compressive strength of at least 1400 psi as tested according to ASTM C39.

Owner:SYNTHEON HLDG SPA

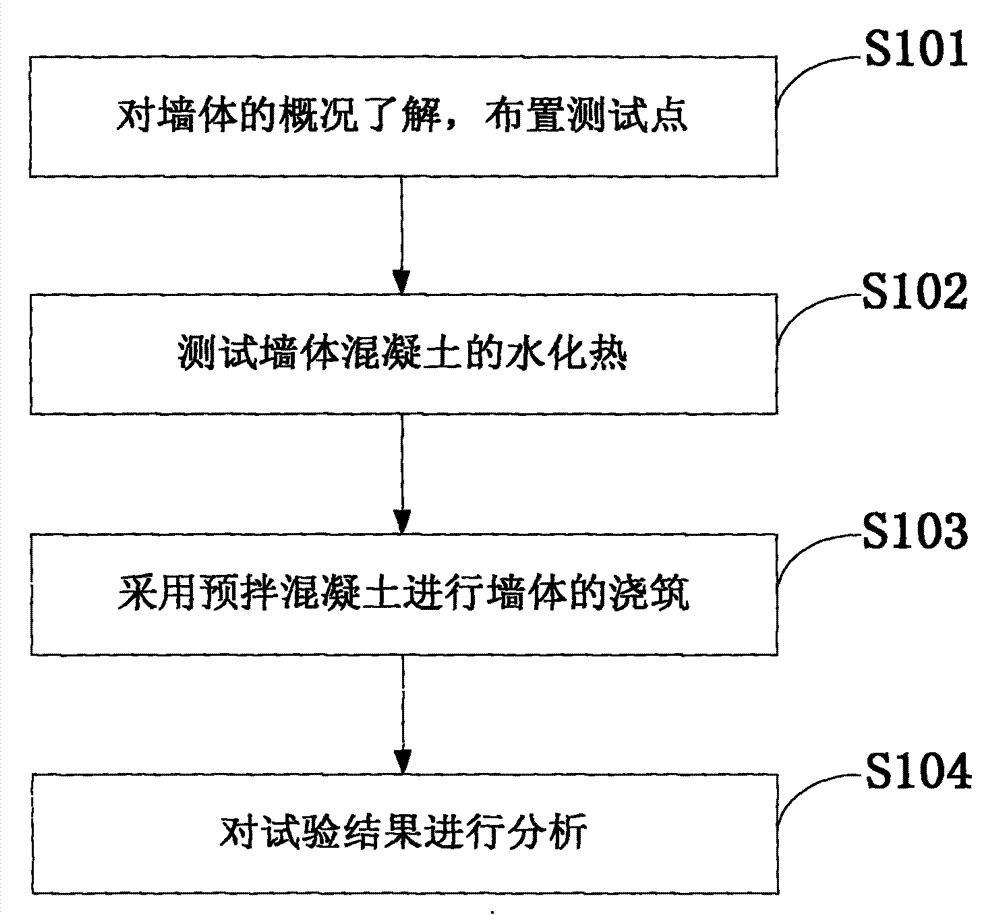

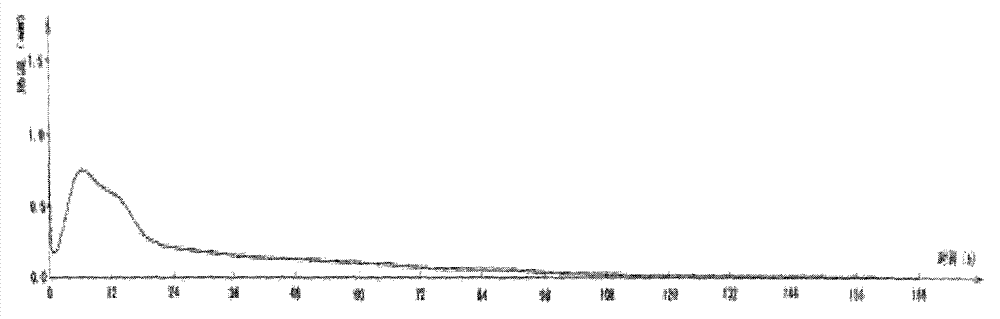

Method for testing early stage shrinkage and anti-cracking performances of premixed concrete wall

InactiveCN103499682ASolve problems that cannot be researched in the laboratoryMaterial testing goodsOriginal dataRebar

The invention discloses a method for testing early stage shrinkage and anti-cracking performances of a premixed concrete wall. The method for testing the early stage shrinkage and anti-cracking performances of the premixed concrete wall comprises the following steps: firstly, knowing general situation of a wall, and arranging test points; secondly, testing hydration heat of concrete of the wall; thirdly, pouring the wall by adopting premixed concrete; fourthly, analyzing test results. According to the method for testing the early stage shrinkage and anti-cracking performances of the premixed concrete wall, testing on the early stage shrinkage and anti-cracking performances of the premixed concrete wall is carried out on an engineering practical wall, concrete shrinkage deformation, reinforcing steel bar deformation and temperature variation are determined at the same time in the concrete wall, shrinkage change rules of practical wall concrete are explored, and influence rules of adjacent component constraint, constraint in the reinforcing steel bar and a construction sequence and method to shrinkage and cracking of concrete of a component are analyzed; meanwhile, the original data is accumulated, and test data foundation is provided for possible mechanical calculation and analysis; besides, relation between laboratory data and engineering practical data is obtained, so that laboratory basic data can guide engineering application more directly and effectively.

Owner:范洁群

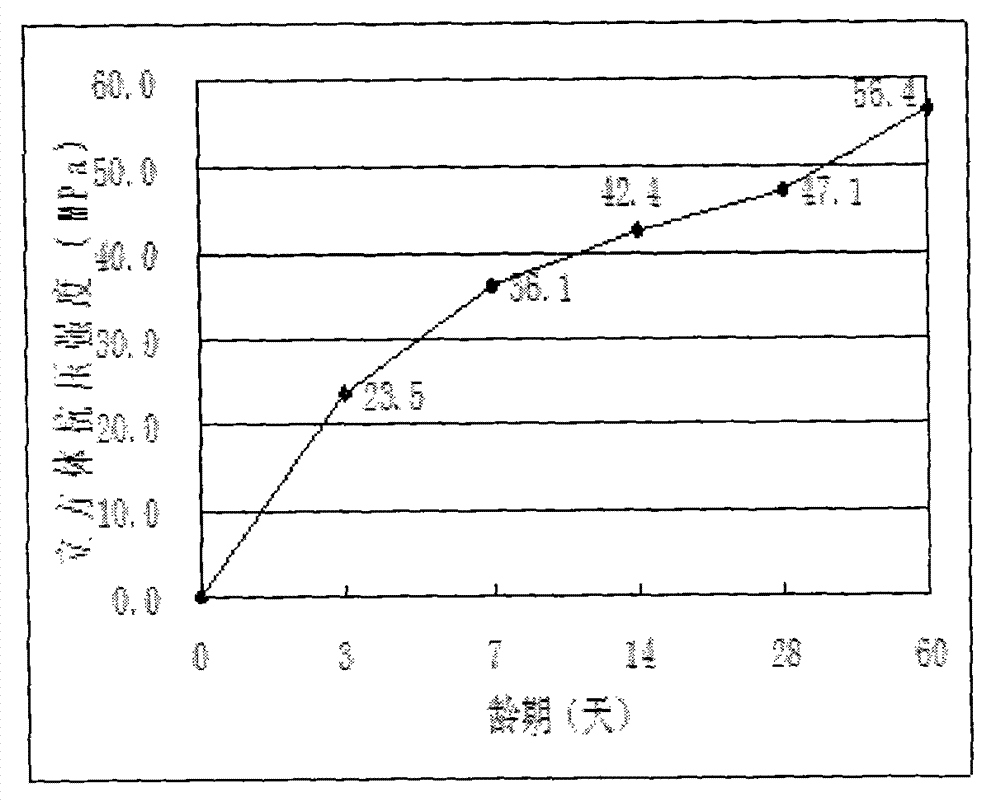

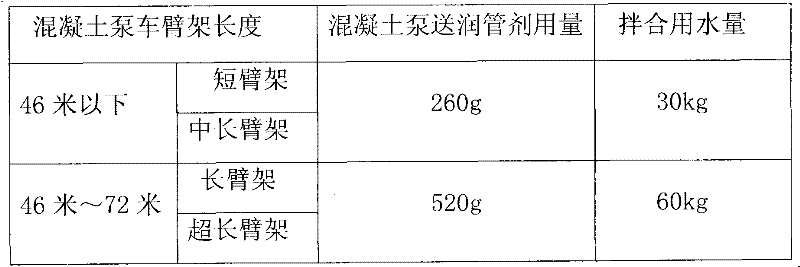

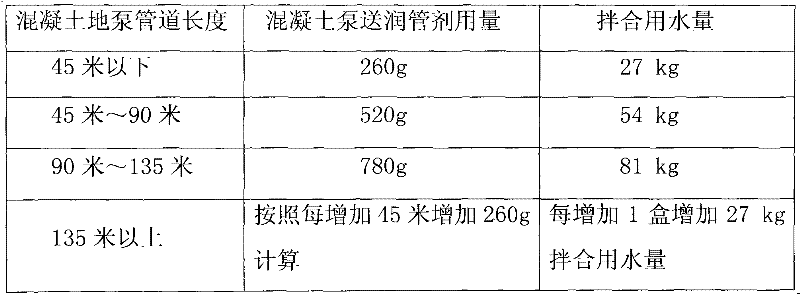

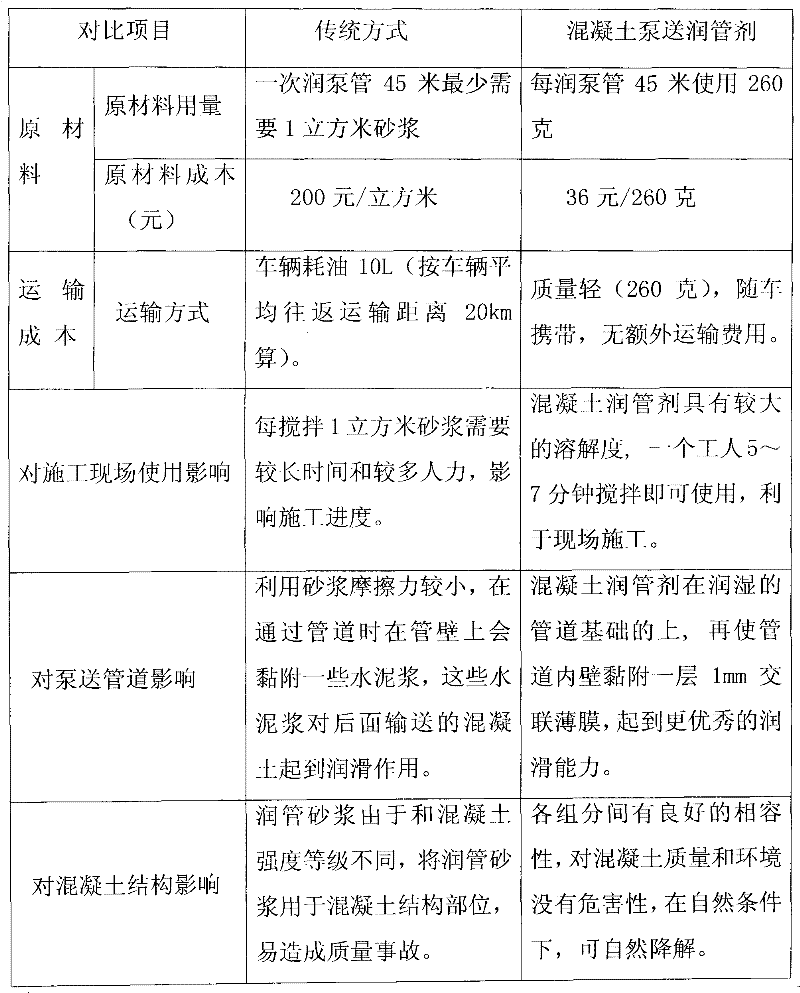

Concrete pumping pipe lubricating agent and preparation method and application method thereof

InactiveCN102533415APerformance is not affectedLow costPipeline systemsLubricant compositionPolyethylene vinyl acetateStearate

The invention discloses a concrete pumping pipe lubricating agent and a preparation method and an application method thereof. The pipe lubricating agent comprises the following components by mass percentage: 30-43 percent of stearate, 15-20 percent of thickener, 17-25 percent of solid-state wax, 16-20 percent of polyethylene vinyl acetate, 0.5-1 percent of defoamer and 4-7 percent of calcium carbonate. The preparation method comprises two steps. The inner walls of delivery pipes of a pump, a ground pump and other related machines are lubricated prior to pumping of pre-mixed concrete, so as to improve the surface tension, viscosity, adhesion and lubricity and to prevent the pumps from being blocked. The preparation method and the application method of the concrete pumping pipe lubricating agent are simple, and the traditional pipe lubricating mortar can be replaced completely. The invention has the advantages that the pipe lubricating agent is non-toxic, odorless and easy to decompose, the performance of commercial concrete cannot be affected, and the cost is low.

Owner:QINGDAO MEILONG READY MIXED MORTAR TECH +1

Low viscosity large flowing degree C60 super high-rise pump concrete based on ultrafine sand compounding

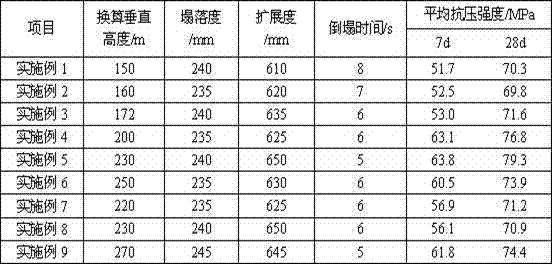

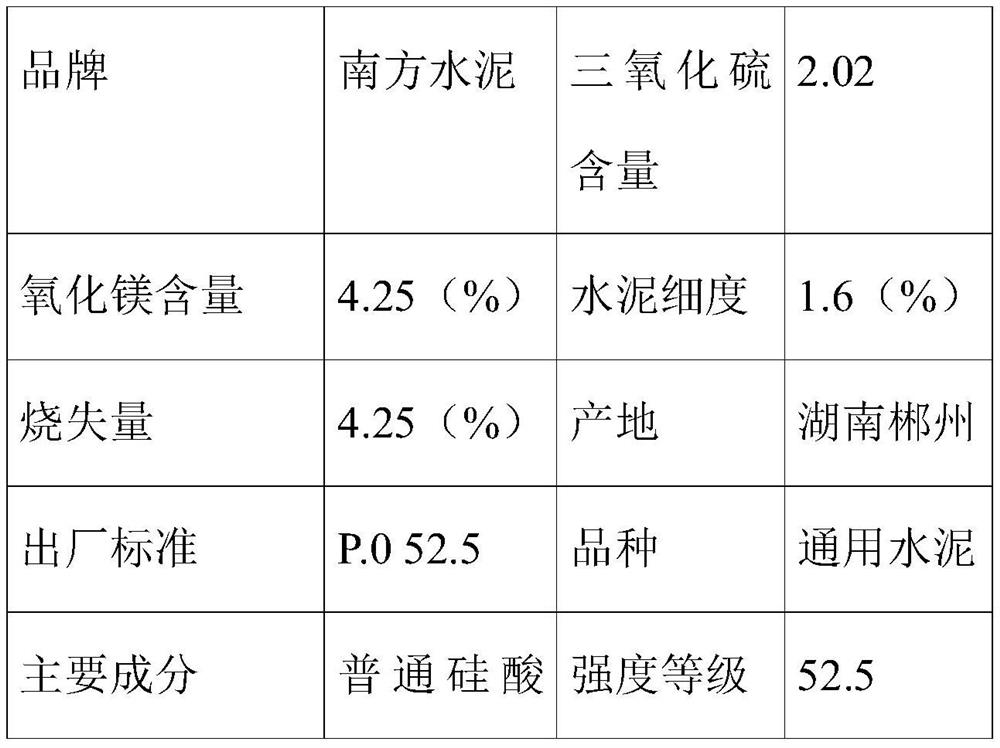

The invention discloses a low viscosity large flowing degree C60 super high-rise pump concrete based on ultrafine sand compounding. The super high-rise pump concrete comprises cement, mineral powder, fly ash, ultrafine natural sand, machine-made sand, broken stone, additives, and water. The super high-rise pump concrete can be prepared by a conventional method. The concrete is characterized in that according to the characteristics of premixed concrete in Sichuan and Chongqing areas, ultrafine natural sand and machine-made sand are compounded to obtain second grade medium sand; pebble and broken pebble are compounded according to a certain ratio to 5-25 continuous grading; 28d compressive strength can reach 70 MPa or more; the slump is not less than 240 mm, the slump flow is not less than 620 mm; the slump cone time is not more than 9 seconds, and the concrete has the characteristics of high strength, low viscosity, large flowing degree, easy operation of production mode, and suitability for the pumping of a super high-rise building with a vertical height more than 350 meters.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

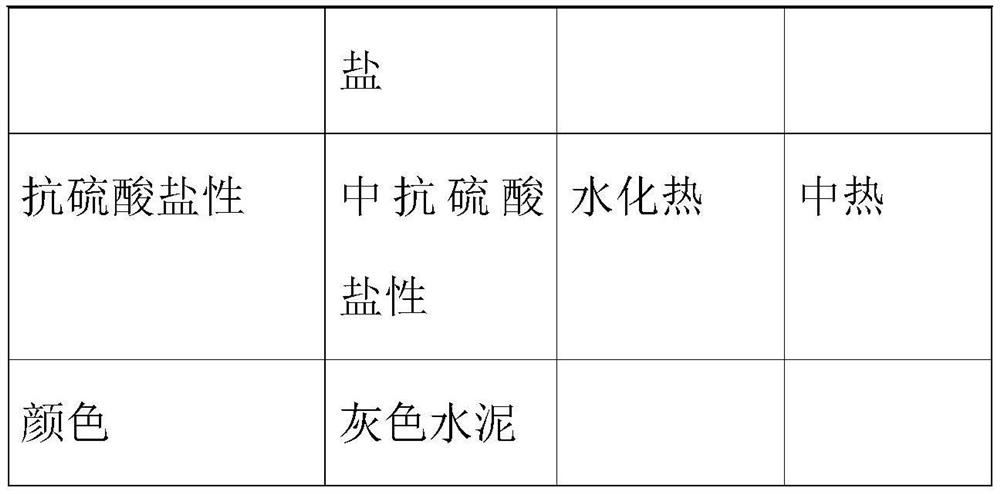

Concrete accelerator and preparation method thereof

The invention provides a concrete accelerator. The concrete accelerator is prepared from the following raw materials: aluminum sulfate, aluminum nitrate, phosphoric acid, ammonia water, a halloysite nanotube modified alkylol amine polymer grinding aid, a stabilizer, magnesium fluorosilicate, a tackifier and water. Various coagulation accelerating components are compounded, the coagulation time ofsprayed concrete can be further shortened, the comprehensive performance of cement is improved, a good coagulation accelerating effect is achieved on premixed concrete subjected to initial hydration,the coagulation time of the concrete can be obviously shortened, the early strength is improved, the stability, durability and safety of the concrete can be remarkably improved, and the cost is low. The concrete accelerator is particularly suitable for premixed concrete spraying construction of long-time and long-distance transportation.

Owner:海南佳益混凝土有限公司

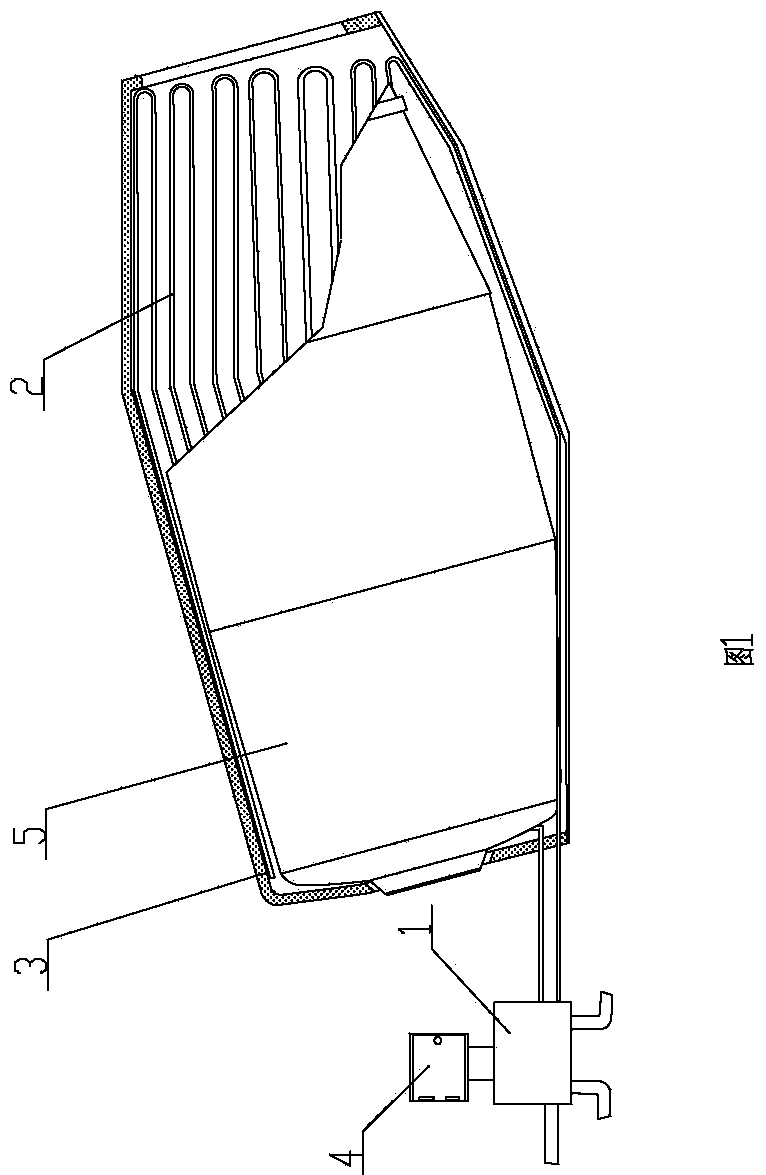

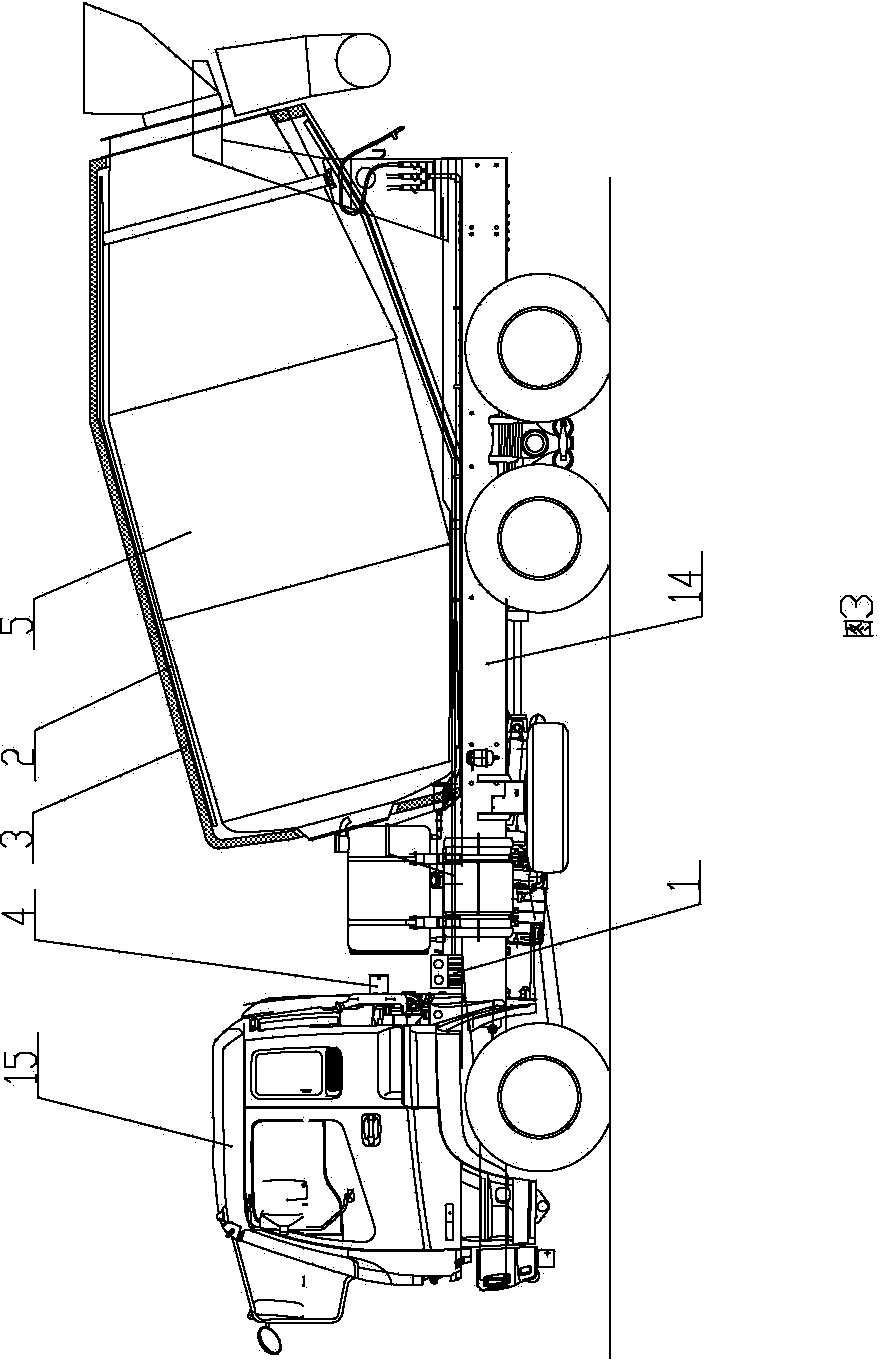

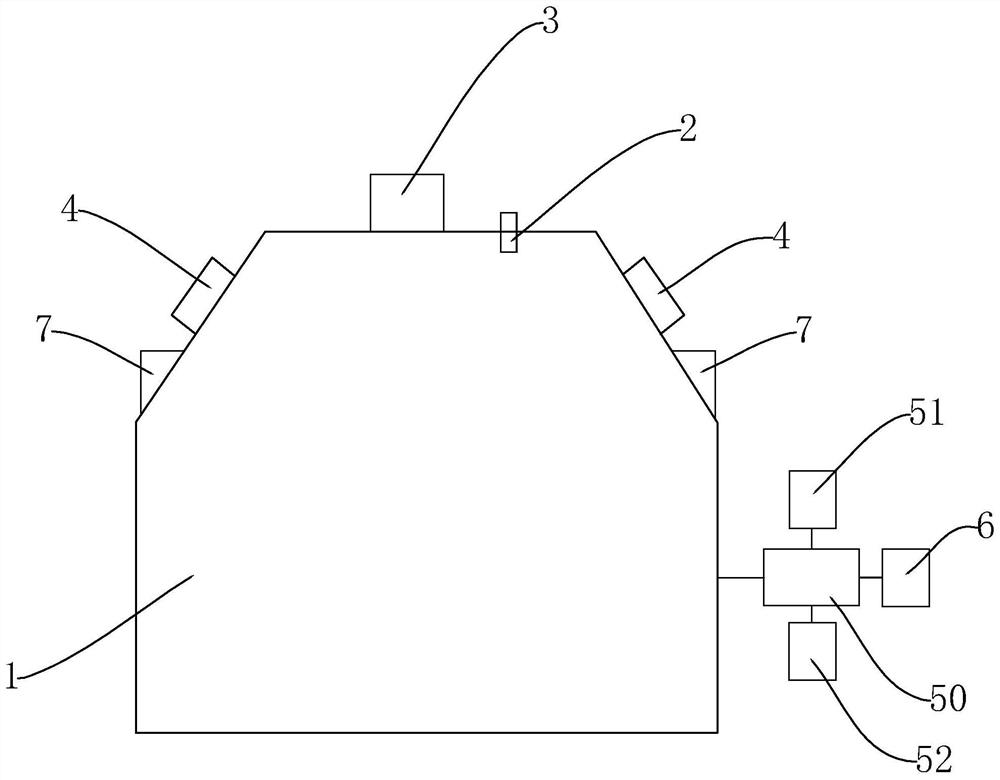

Concrete mixer truck tank body temperature-control heat insulation device

InactiveCN103737723AWith heat preservation functionRealize the cooling effectCement mixing apparatusControl apparatusTank truckProcess engineering

The invention relates to the technical field of concrete transportation devices, particularly a concrete mixer truck tank body temperature-control heat insulation device which comprises a tank truck chassis, a rotatable tank body installed on the tank truck chassis, a cold / heat source, an energy converter, a cold / heat medium coil pipe, a heat insulation sleeve and a controller, wherein the cold / heat medium coil pipe is fixed on the inner wall of the heat insulation sleeve; the heat insulation sleeve is fixedly arranged on the tank truck chassis and coated on the outer side of the tank body; a rotating clearance is arranged between the cold / heat medium coil pipe and the outer wall of the tank body; the cold / heat source is connected with the cold / heat medium coil pipe through the energy converter; and the energy converter is controlled by the controller. The device is reasonable and compact in structure and convenient to use, can maintain the concrete in the tank body of the premixed concrete tank truck at proper temperature and ensure the product quality on the premise of not consuming extra energy sources, is more energy-saving and environment-friendly, and saves the cost.

Owner:XINJIANG JINYUXIN NEW MATERIAL CO LTD

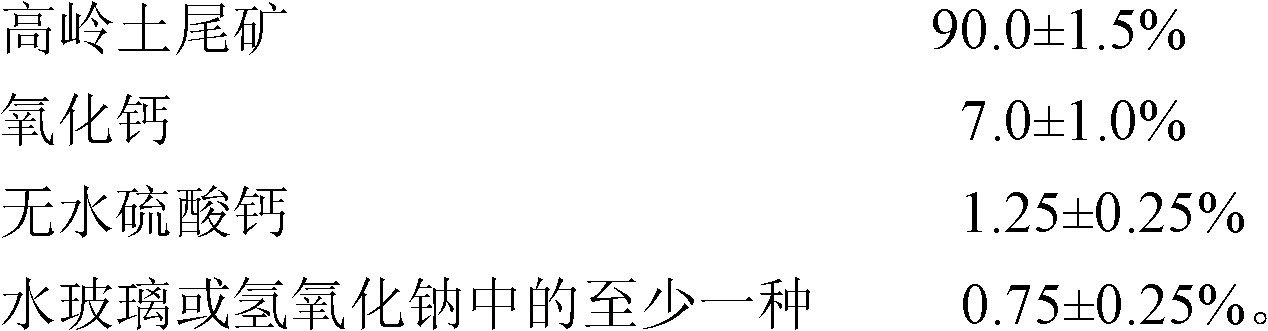

Kaolin gangue composite powder and application of same in premixed concrete

InactiveCN102617060AHigh in calciumImprove hydraulic hardnessSolid waste managementAnhydrous Calcium SulfateCoal

The invention provides kaolin gangue composite powder and the application of the same in premixed concrete. A powder body comprises the following components: kaolin gangue, calcium oxide, dried gypsum and at least one of sodium silicate or sodium hydroxide. The powder body is formed by mechanically and finely grinding the raw materials according to certain mass ratio. Application of the powder in the premixed concrete is that kaolin gangue composite powder occupying 2.4% to 4.5% of concrete in mass is added into the concrete. The powder body can completely replace coal ash to prepare common concrete for construction, and the mixture has better water-retaining performance and sticky polymerization performance and cannot affect mechanical performance and durability of the concrete. The powder is reasonable in component proportion and capable of replacing F-class coal ash, and preparation of the powder can meet requirements for concrete strength, peaceability and durability. The powder is suitable for concrete preparation in projects such as hydroelectric dams, roads, port docks and public / civil buildings, resolves the problem of unbalanced supply and demand in coal ash areas, is low in preparation cost and environment-friendly and has remarkable economical and social benefits.

Owner:CENT SOUTH UNIV +1

Preparation method of steel fiber self-compacting premixed concrete

ActiveCN111056793AHigh compressive strengthImprove bonding performanceCrack resistanceStructural engineering

The invention discloses a preparation method of steel fiber self-compacting premixed concrete, wherein the method adopts a specific feeding sequence and mixing conditions as well as specific types ofsteel fibers and component proportions, so that the properties such as compressive strength, tensile strength and the like of the formed concrete can be further improved, and the crack resistance anddurability are improved. In addition, the invention also discloses the steel fiber self-compacting premixed concrete prepared by the preparation method.

Owner:深圳市恒星建材有限公司

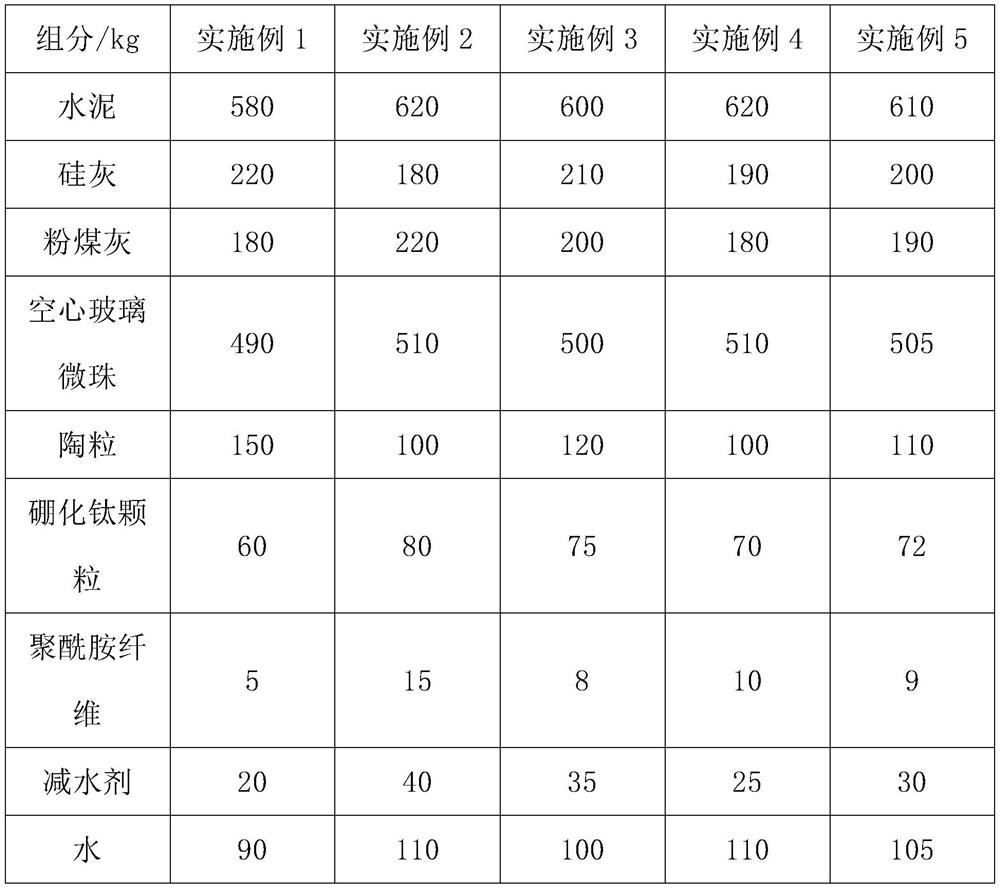

Lightweight high-strength concrete and preparation method thereof

The invention relates to the technical field of concrete preparation, and particularly discloses lightweight high-strength concrete and a preparation method thereof. The lightweight high-strength concrete comprises the following components: cement, silica fume, fly ash, hollow glass beads, ceramsite, titanium boride particles, polyamide fibers, a water reducing agent and water. The preparation method comprises the following steps: 1, uniformly mixing cement, silica fume, fly ash, hollow glass beads and water to obtain premixed concrete; and 2, adding ceramsite, titanium boride particles, fibers and a water reducing agent into the premixed concrete, and stirring for 45 minutes to obtain the uniformly stirred lightweight high-strength concrete. The lightweight high-strength concrete can be used in the construction fields of super high-rise buildings, bridges and the like, and has the advantages of small volume weight, high compressive strength and stable working performance.

Owner:中建西部建设北方有限公司 +1

Tailing aggregate concrete and preparation method thereof

The invention relates to the technical field of concrete preparation, and particularly discloses tailing aggregate concrete and a preparation method thereof. The tailing aggregate concrete comprises the following raw materials in parts by weight: 180-220 parts of cement, 70-90 parts of mineral powder, 0-45 parts of fly ash, 45-90 parts of limestone powder, 10-35 parts of modified wheat straw fiber, 500-750 parts of tailing sand, 200-400 parts of tailing stone chips, 900-1100 parts of tailing ore, 3-5 parts of a polycarboxylic acid high-efficiency water reducing agent and 160-180 parts of water; The preparation method comprises the following steps: step 1, mixing and stirring the cement, the mineral powder, the fly ash, the limestone powder, the wheat straw fibers, the tailing sand, the tailing chips and the tailings for 60-90s to obtain uniformly stirred premixed concrete; and 2, mixing and stirring other raw materials and the premixed concrete for 90-120 seconds to obtain the tailingaggregate concrete. The tailing aggregate concrete can be used in constructional engineering construction, and has the advantages of good fluidity, stable working performance and low production cost.

Owner:中建西部建设北方有限公司 +1

Steel slag doped premixed concrete and preparation method thereof

ActiveCN111792883ALow hydroxyl contentImprove water resistanceBacteriaHollow filament manufactureReady-mix concretePolypropylene

The invention discloses a steel slag doped premixed concrete and a preparation method thereof. The preparation method comprises the steps that citral is added into a polypropylene glycol solution to modify polypropylene glycol, then calcium carbonate, hydrochloric acid, steel slag, rubber powder and other substances are added to improve the mechanical property of polypropylene glycol, and porous fibers are prepared through electrostatic spinning; the porous fibers are modified by using a silane coupling agent, and microorganisms are loaded on the modified fibers to obtain modified fibers; calcium lactate is wrapped with urea-formaldehyde resin to prepare calcium lactate microcapsules; and calcium lactate microcapsules, modified fibers, cement and other materials are mixed and stirred to prepare the steel slag doped premixed concrete. The invention provides a steel slag doped premixed concrete and a preparation method thereof. The ratio and reaction time are reasonably controlled in thepreparation process, the mechanical properties and impermeability of the prepared concrete sample are effectively improved, and meanwhile, the steel slag doped premixed concrete also has certain self-repairing capability, so that manpower, material resources and financial resources are greatly saved, and the practicability is relatively high.

Owner:江阴市新远见工程有限公司

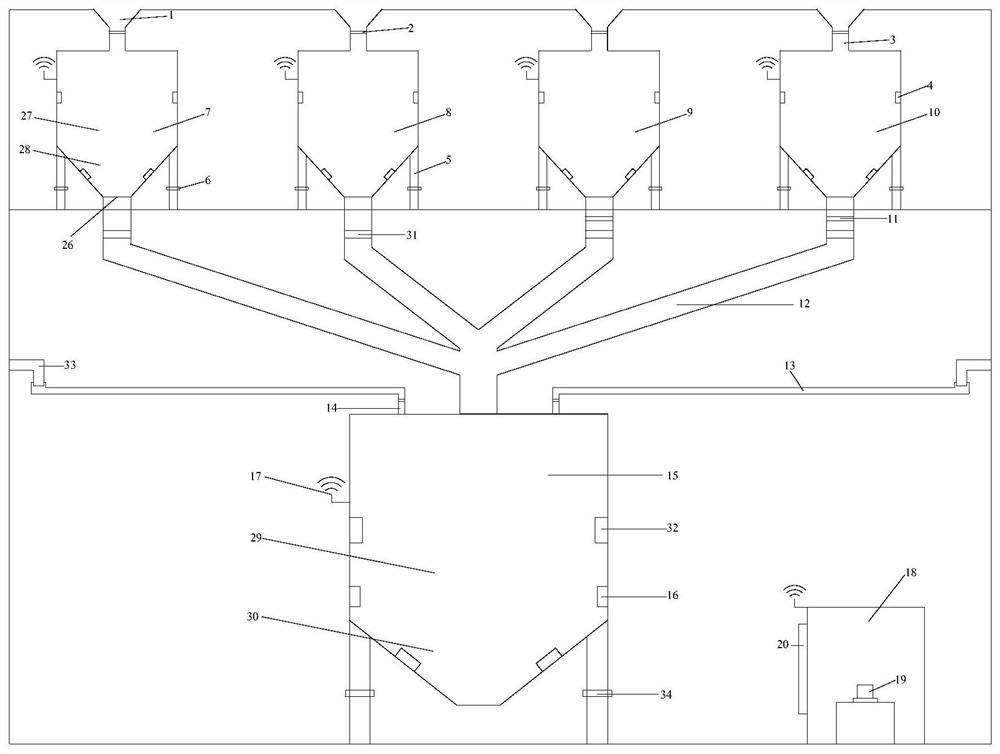

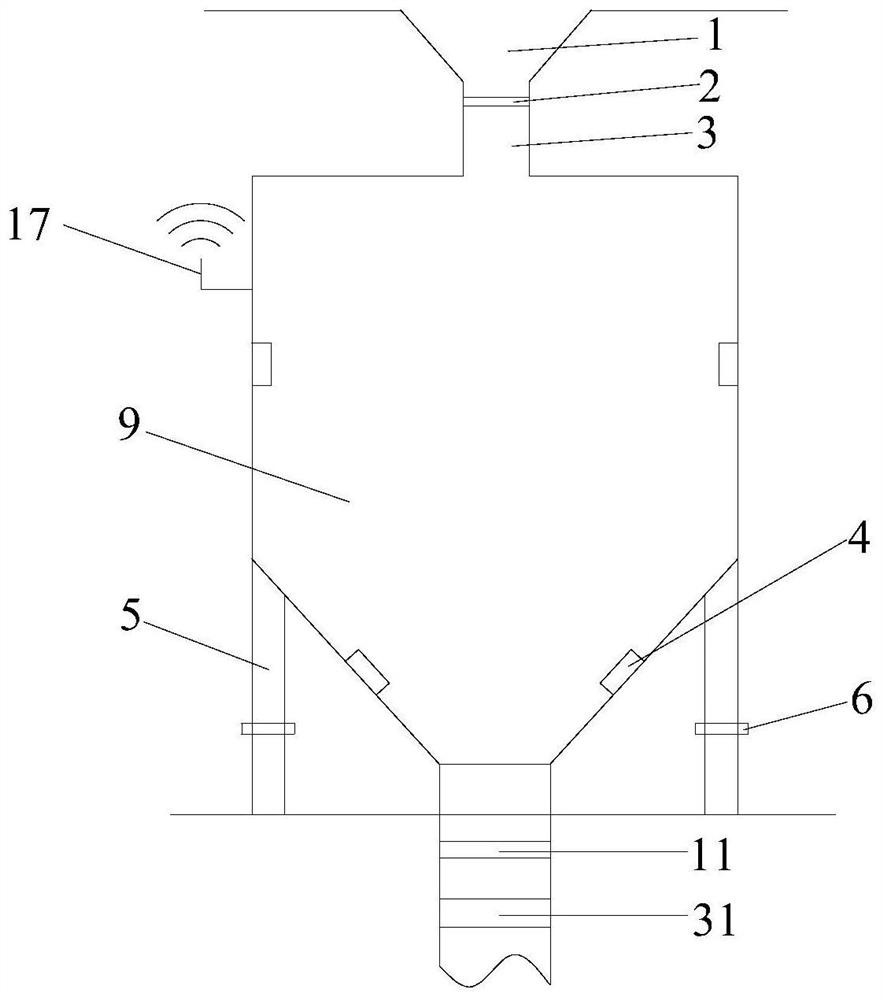

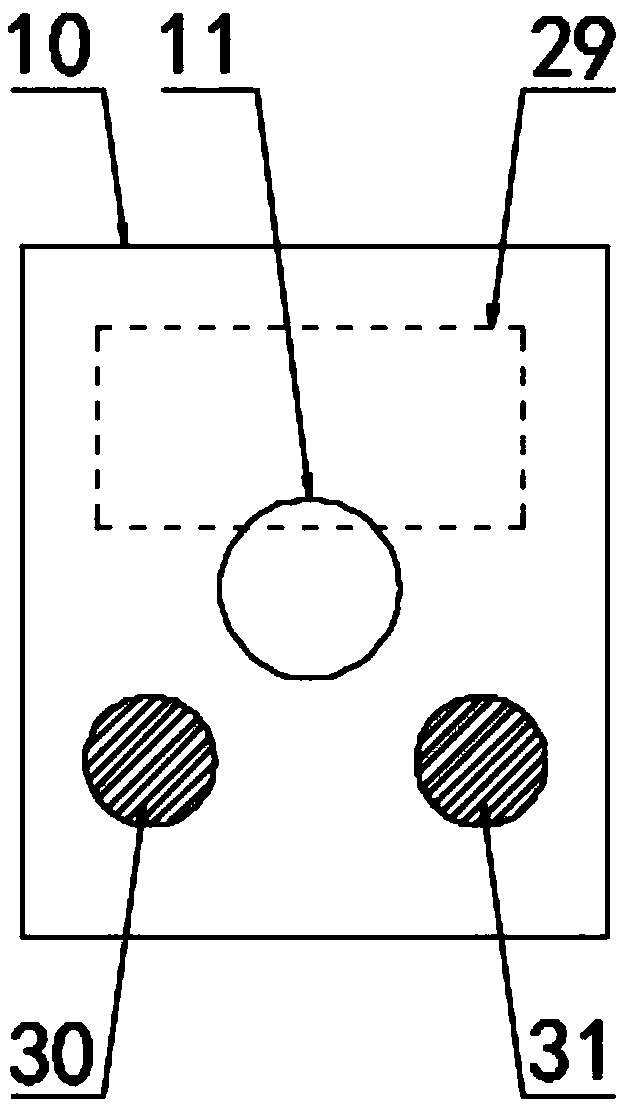

Automatic metering device for premixed concrete aggregate and operation method

InactiveCN112388832APrecise feedingReduce labor costsMixing operation control apparatusControl apparatusStructural engineeringReady-mix concrete

The invention relates to the field of concrete construction, in particular to an automatic metering device for a premixed concrete aggregate and an operation method. The construction steps are as follows: concrete material transportation, hopper feeding, hopper quality measurement, concrete mixing material quality control, mixing bin feeding, mixing bin quality monitoring, mixing bin water contentmonitoring, and concrete mixing and conveying, wherein the weight of a hopper and the weight of a concrete mixing bin are measured through a mass sensor, pressure changes of the inner side wall of the hopper and the inner side wall of the concrete mixing bin are measured through a pressure sensor, and therefore the feeding amount of the mixing bin is calculated; the water content of concrete in the mixing bin is measured through a water content sensor arranged on the side wall of the concrete mixing bin, and the water content is fed back to a computer through wireless signal transmission to control water inflow; and intelligent and accurate feeding of premixed concrete can be achieved, high-quality premixed concrete is produced, the labor cost is saved, and the production efficiency is improved.

Owner:四川兴城港瑞建材有限公司

System for realizing zero emission of wastewater and waste residues of pre-mixed concrete industry

The invention discloses a system for realizing zero emission of wastewater and waste residues of a pre-mixed concrete industry. The system comprises a scrubbing stirring vehicle, wherein an input endof the scrubbing stirring vehicle is provided with a clean water tank and an output end of the scrubbing stirring vehicle is provided with a sand-stone separation machine; the output end of the sand-stone separation machine is provided with a NO. 1 first-grade slurry tank and a NO. 2 first-grade slurry tank; the output end of the NO. 1 first-grade slurry tank is provided with a fine sand separation machine, a second-grade slurry tank, a slurry storage tank and a mixing plant, which are connected in sequence through a pipeline; the input end of the fine sand separation machine is connected witha clean water tank; the input end of the second-grade slurry tank is connected with the scrubbing stirring vehicle and the fine sand separation machine through a three-way pipeline. According to thesystem disclosed by the invention, washing water of the scrubbing stirring vehicle is directly introduced into the system and concrete slurry is treated through the sand-stone separation machine and the fine sand separation machine respectively, and coarse sand, stones and fine sand are filtered; the coarse sand, the stones and the fine sand are recycled and obtained slurry is recycled into the NO. 1 first-grade slurry tank and the NO. 2 first-grade slurry tank for storing and then is conveyed to the slurry storage tank; finally, the slurry is recycled into the mixing plant for recycling.

Owner:淮北砼友乐环保科技有限公司

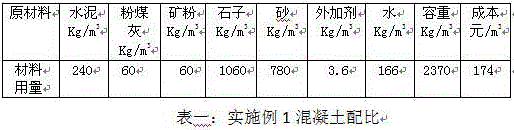

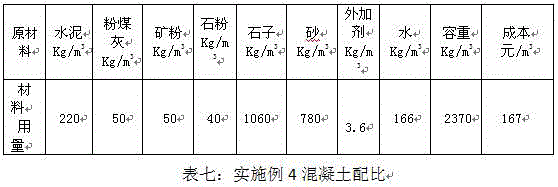

Application of tailing machine-made sand winnowing powder in premixed concrete

The invention provides application of tailing machine-made sand winnowing powder in premixed concrete. The concrete at least comprises cement, coal ash, mineral powder, stone powder, stone, sand and additives. Each cubic meter of concrete comprises 210-230 kg of cement, 40-60 kg of coal ash, 40-60 kg of mineral powder, 20-40 kg of stone powder, 1000-1060 kg of stone, 750-780 kg of sand and 3-3.6 kg of additives. The invention provides application of a novel mineral mixing material in concrete. The cement consumption is saved, the workability of concrete is improved, the hydration heat, contraction and the like are reduced, technological performance is good, economic benefits are remarkable, and the concrete conforms to the energy conservation, emission reduction and resource recycle related strategies promoted by China.

Owner:NANTONG TIEYUE BUILDING MATERIAL TECH CO LTD

Monitoring device of premixed concrete and monitoring method of monitoring device

PendingCN111730758AAccurate measurementImprove accuracyTelevision system detailsFlow propertiesVideo monitoringRaw material

The invention discloses a monitoring device of premixed concrete and a monitoring method of the monitoring device. The monitoring device comprises a stirring device, a dust concentration sensor arranged in the stirring device, a dust collection device, a video monitoring system and a control system, wherein the control system comprises a data storage system and an image analysis system, the data storage system stores a database of relations between the images and slumps of the premixed concrete, and the image analysis system analyzes the similarity between real-time monitored images and the images prestored in the data storage system in real time to obtain predicted slumps corresponding to the real-time monitored premixed concrete. The monitoring method includes the steps of preparing rawmaterials, stirring the raw materials and the collecting dust, shooting the real-time images and analyzing the similarity and displaying the predicted slumps on a display screen. By using the monitoring device and the monitoring method, the predicted slump value can be displayed in real time so as to adjust the premixed concrete in time and the waste of resources and economic losses caused by thequality failing to meet the design requirements after unloading are avoided.

Owner:珠海春禾新材料研究院有限公司

Green and environment-friendly compound admixture for concrete

InactiveCN107021656AIn line with the sustainable development strategyReduce manufacturing costSolid waste managementWastewaterNational standard

The invention discloses a green and environment-friendly compound admixture for concrete. The green and environment-friendly compound admixture is prepared from the following components in percentage by mass: 5 percent to 20 percent of cement clinker, 10 percent to 80 percent of concrete filter residue, 10 percent to 80 percent of a waste concrete test block and 0.1 percent to 0.5 percent of a grinding aid; the sum of the mass percent of all the components is 100 percent; the concrete filter residue is filter residue formed by recycling wastewater of a pre-mixed concrete production enterprise, precipitating, carrying out filter pressing and dehydrating; the waste concrete test block is a waste material formed by detecting and testing a test piece which is molded by the concrete and is used for detecting the compressive strength. According to the compound admixture disclosed by the invention, the green and environment-friendly compound admixture for the concrete, which meets national standard technical specifications, is manufactured with low cost by utilizing a lot of wastes and the like.

Owner:张建 +1

Precast Pervious Concrete Panels

ActiveUS20150184384A1Construction materialSingle unit pavingsCollection systemStructural engineering

Systems and methods directed to a precast pervious concrete panel. Each pervious concrete panel has a plurality of layers of concrete mixture, wherein the aggregate used in each layer may be a different size. The panels have slots at predetermined locations allowing installation of a joint connector; either dry or with a bonding material thereby allowing connection of multiple panels into a solid slab. Multiple pervious concrete panels can be combined with a collection system allowing collection / reuse of water passing through the panels. Precast pervious concrete panels can be used as inserts in ready mix or cast in place concrete frames allowing for easy replacement of the pieces.

Owner:THE WELLS COMPANY

Method for preparing recycled concrete by using unqualified ready-mixed concrete and recycled powder

The invention relates to a method for preparing recycled concrete by using unqualified ready-mixed concrete and recycled powder. The method includes the following steps: mixing a retarder with the mass accounting for 0.06-0.13% of the unqualified ready-mixed concrete into the unqualified ready-mixed concrete for preservation; preparing new concrete according to the standard and mixing the unqualified ready-mixed concrete into new concrete by 10-50% mass ratio; then mixing a water reducer accounting for 0.16-0.31% of the total mass of a mixture and regenerated powder accounting for 10-40% of the total mass of the mixture, mixing mechanically and uniformly to obtain the recycled concrete. The concrete can better solve the problem of unqualified ready-mixed concrete treatment in concrete production, does not pollute the environment, and reduces the amount of materials used in concrete production. The recycled concrete can meet the performance requirements of the concrete replaced. Therefore, the method has significant economic benefits, environmental benefits and social benefits.

Owner:TONGJI UNIV

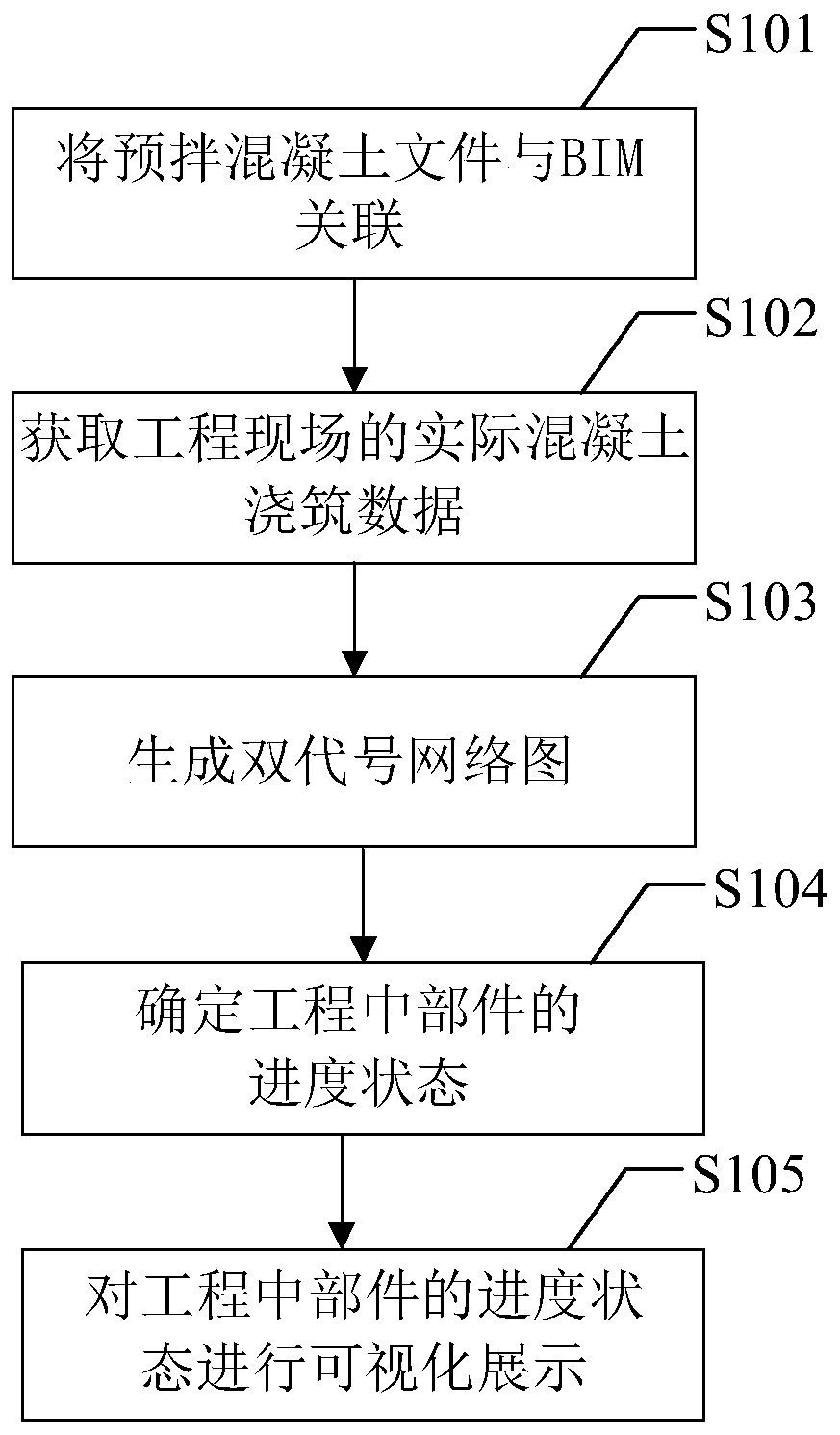

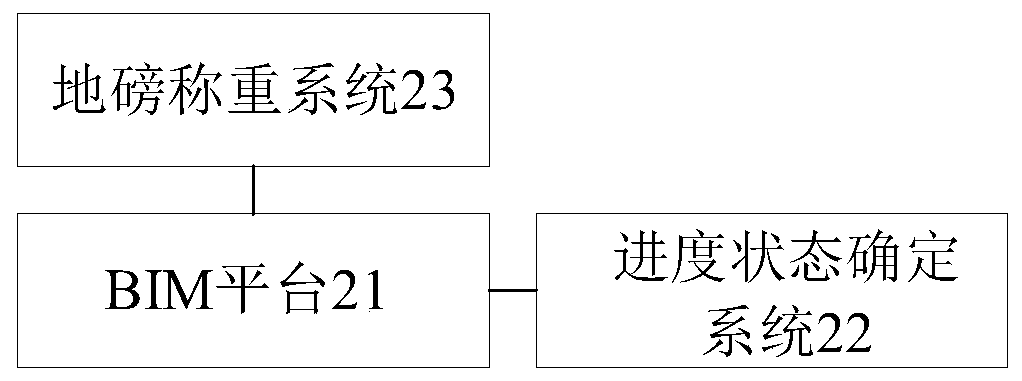

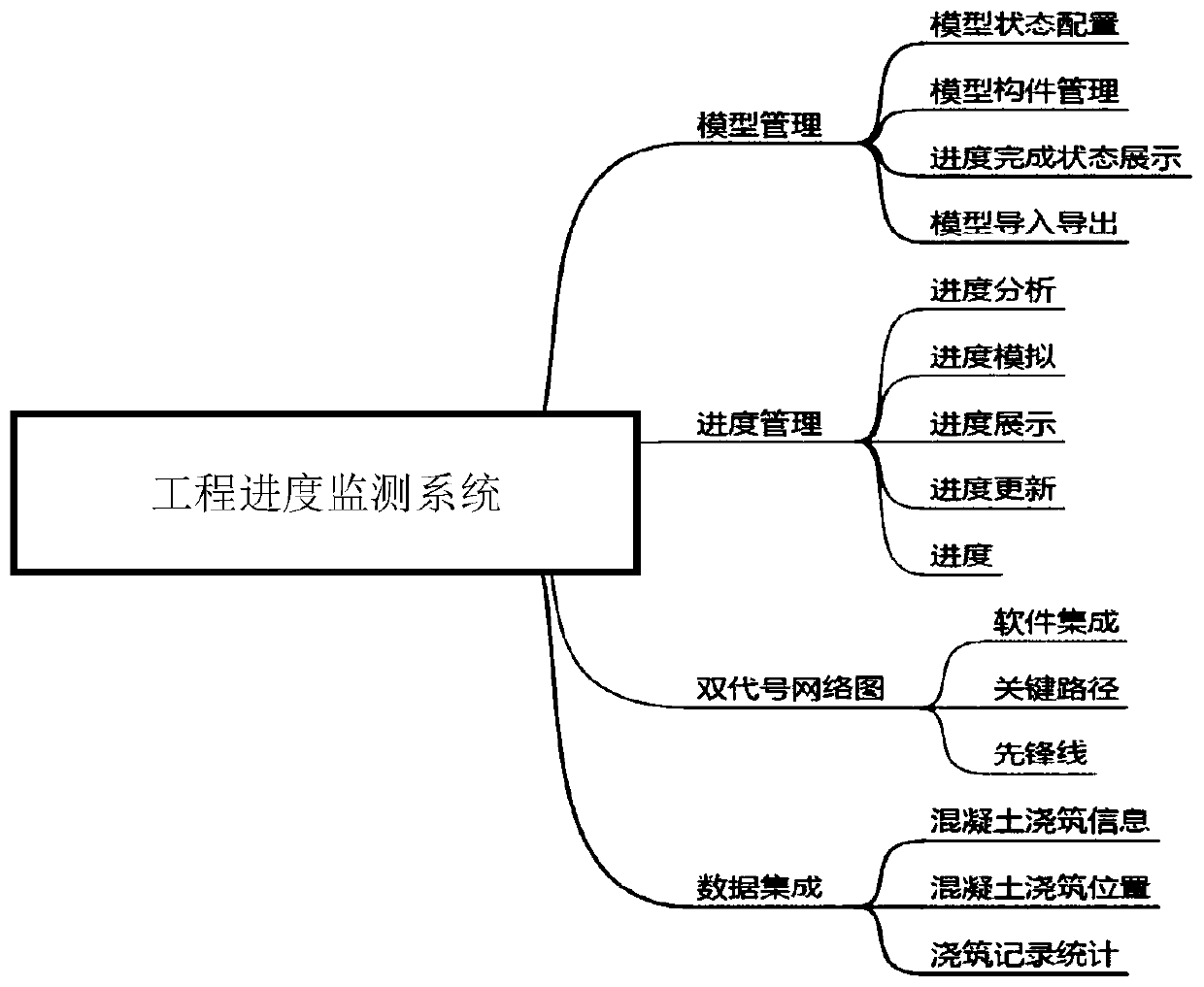

Project progress monitoring method and system

PendingCN111242444AImprove integrityRealize dynamic progress managementOffice automationOther databases indexingInformation integrationReady-mix concrete

The invention discloses a project progress monitoring method and system. In one embodiment of the invention, the project progress monitoring method can comprise the steps: associating a premixed concrete file of a project with a pre-created building information model, wherein the premixed concrete file comprises planned concrete pouring data of different parts in the project; acquiring actual concrete pouring data of the engineering field; generating a double-code network diagram by utilizing actual concrete pouring data and planned concrete pouring data of corresponding components in the building information model; determining a progress state of a component in a project by utilizing the dual-code network diagram; and visually displaying the progress state of the component in the project.The dynamic progress management of the project is realized, the timeliness is good, the information integrity is strong, the accuracy is high, and the implementation situation of the project can be conveniently supervised and managed by related personnel according to the project progress state.

Owner:CHINA RAILWAY CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com