Monitoring device of premixed concrete and monitoring method of monitoring device

A ready-mixed concrete and monitoring device technology, applied in the field of concrete, can solve problems such as bleeding and segregation, affecting the constructability of ready-mixed concrete, mechanical properties, structural durability, and difficulty in adjustment, and achieves the effect of accurate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention, but it should not be understood as a limitation on the protection scope of the present invention.

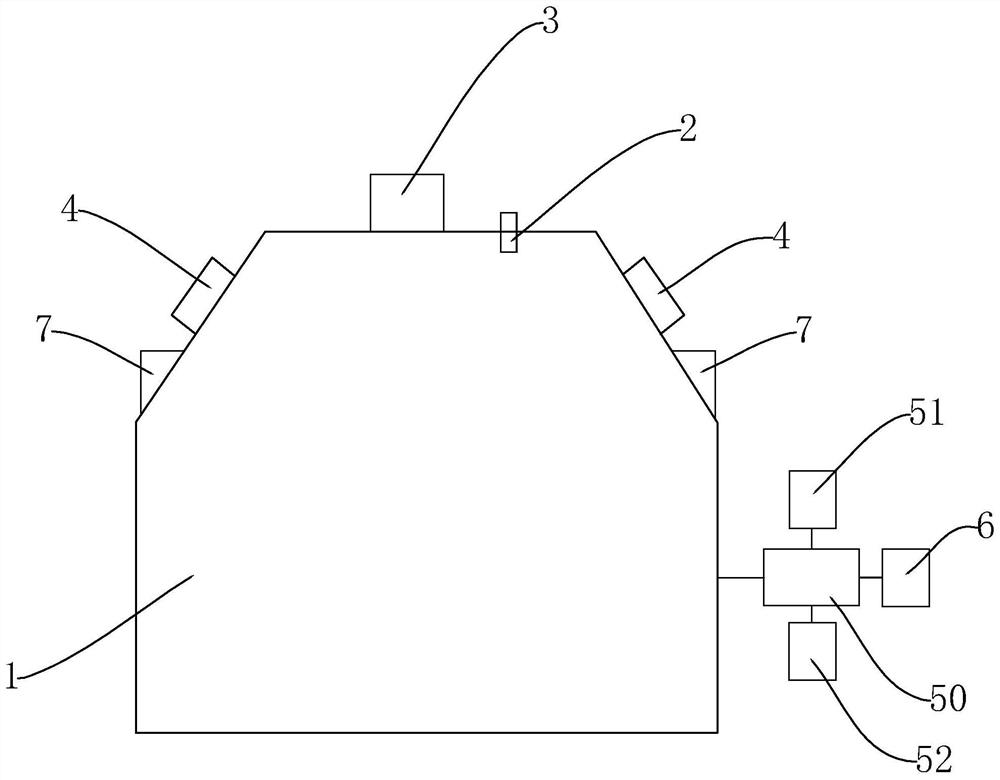

[0027] see figure 1 , a monitoring device for ready-mixed concrete, comprising: a stirring device 1 for containing and stirring concrete; a dust concentration sensor 2 arranged in the stirring device 1 for detecting the dust concentration in the stirring device 1; The device 3 is arranged on the mixing device 1 and is used to absorb the dust in the mixing device 1; the video monitoring system 4 is used to photograph the ready-mixed concrete in the mixing device 1 to monitor the workability of the ready-mixed concrete in real time; the control system 50, They are respectively electrically connected to the stirring device 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com