High-performance concrete with large mixing amount of mineral powder and manufacturing method of high-performance concrete

A high-performance concrete and high-volume technology, which is applied in the field of high-performance building material preparation, can solve the problems of limited contribution to energy saving and emission reduction, increase of peak heat release of cement, and unfavorable concrete strength, etc., so as to reduce cement consumption and reduce temperature difference Cracks, improve the effect of bleeding segregation and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

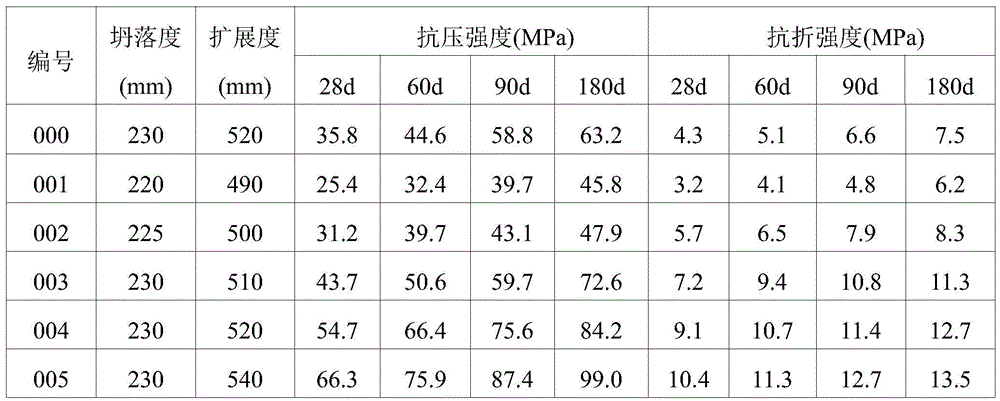

Examples

Embodiment Construction

[0022] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

[0023] The preparation process of the large-volume slag powder high-performance concrete of the present invention is as follows:

[0024] Parts by weight: 140-170 parts of cement, 170-240 parts of slag powder, 50-100 parts of fly ash, 1010-1100 parts of crushed stone, 735-825 parts of river sand, 150-180 parts of water, activator 11-15 parts, 3.4-5 parts of water reducing agent; the cementitious material is composed of ordinary Portland cement, slag powder and fly ash, slag powder accounts for 50-60% of the total mass of the cementitious material, and the mass of fly ash It is 15-30% of the total mass of the gelling material. Slag powder is S95 grade slag powder with an average particle size of 2.36-4.75mm and a specific surface area of not less than 400㎡ / kg. Fly ash is Class I fly ash with a sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com