Tailing aggregate concrete and preparation method thereof

A tailings aggregate and concrete technology, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of low utilization rate of tailings, achieve high density, alleviate pollution, and combine well Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

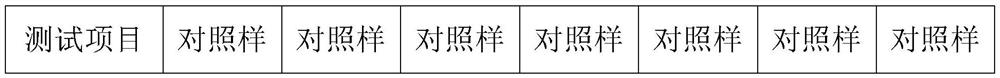

Image

Examples

preparation example 1

[0043]Wheat straw fibers were cooked in a sodium hydroxide solution with a mass concentration of 10% and a temperature of 90 degrees Celsius for 30 minutes, and then crushed by a gyratory crusher to obtain modified wheat straw fibers with a length of 3 mm.

preparation example 2

[0045] Wheat straw fibers were cooked in a sodium hydroxide solution with a mass concentration of 13% and a temperature of 95 degrees Celsius for 35 minutes, and then crushed by a gyratory crusher to obtain modified wheat straw fibers with a length of 5 mm.

preparation example 3

[0047] Wheat straw fibers were cooked in a sodium hydroxide solution with a mass concentration of 15% and a temperature of 100 degrees Celsius for 40 minutes, and then crushed by a gyratory crusher to obtain modified wheat straw fibers with a length of 7 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com