Kaolin gangue composite powder and application of same in premixed concrete

A technology of kaolin tailings and ready-mixed concrete, which is applied in kaolin tailings composite powder and ready-mixed concrete. In the field of kaolin tailings composite powder, it can solve the problems of no value-added tax preferential policies, lack of fly ash resources, Problems such as high transportation costs, achieving significant economic and social benefits, low manufacturing costs, and reasonable component ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Kaolin tailings from a certain place in China are used as the main raw material, and the chemical composition is as follows by weight percentage:

[0028] Element

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

K 2 O+Na 2 o

other

content

83.34

10.05

0.35

0.15

0.08

2.23

3.80

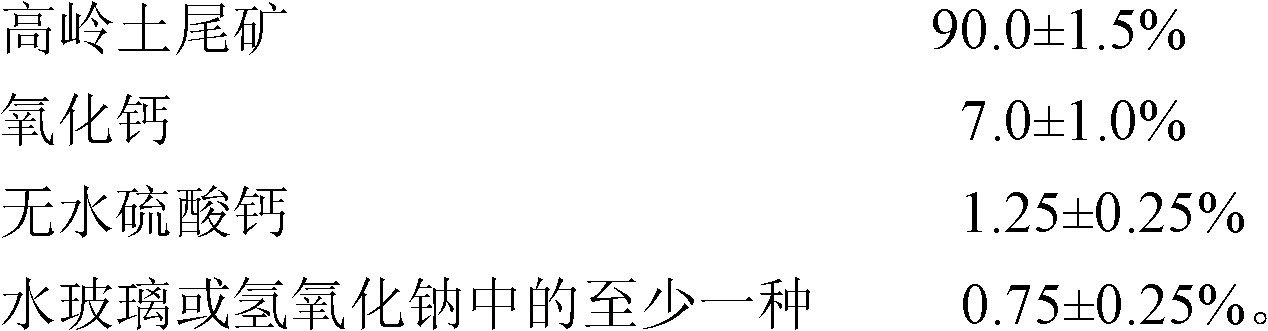

[0029] Weigh the mixture according to the following mass percentages:

[0030] (1) Kaolin tailings (moisture content <1%) 91%

[0031] (2) quicklime 7.0% (according to CaO content)

[0032] (3) Natural anhydrite 1.25%

[0033] (4) Sodium hydroxide 0.75%

[0034] Grind the mixture with a common ball mill to obtain kaolin tailings composite powder, with a fineness of 400 mesh, a sieve balance of 13.6 wt %, and a specific surface area of 550 m 2 / kg, moisture content <1%.

[0035] The obtained kaolin tailings composite powder is added to the ready-mixed concrete by 2.4% of the concrete mass; the compone...

Embodiment 2

[0046] The kaolin tailings composite powder obtained in embodiment 1 is added in the ready-mixed concrete by 4.38% of concrete quality; The component of described concrete is by weight percentage:

[0047]

[0048]

[0049] Table 3 shows the construction and mechanical performance results of the kaolin tailings composite powder prepared in this example added to the ready-mixed concrete and the ready-mixed concrete prepared by using fly ash as an admixture in the prior art.

[0050] table 3

[0051]

[0052] It can be seen from the results in Table 3 that after the kaolin tailings composite powder prepared in the example is added to the ready-mixed concrete, the overall mechanical properties of the concrete tend to be enhanced. From the point of view of this index, it can completely replace Class F Class II fly ash to prepare concrete, and its use can also improve the water retention and cohesion of the concrete mixture.

Embodiment 3

[0054] The kaolin tailings composite powder obtained in embodiment 1 is added in the ready-mixed concrete by 2.55% of concrete quality; The component of described concrete is by weight percentage:

[0055]

[0056]Table 4 shows the construction and mechanical performance results of the kaolin tailings composite powder prepared in this example added to the ready-mixed concrete and the ready-mixed concrete prepared by using fly ash as an admixture in the prior art.

[0057] Table 4

[0058]

[0059] It can be seen from the results in Table 4 that after the kaolin tailings composite powder prepared in the example is added to the ready-mixed concrete, the overall mechanical properties of the concrete tend to be enhanced. From the point of view of this index, it can completely replace Class F Class II fly ash to prepare concrete, and its use can also improve the water retention and cohesion of the concrete mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com