Device for removing aluminum alloy shell of lithium battery

An aluminum alloy shell, lithium battery technology, applied in battery recycling, solid waste removal, recycling technology and other directions, can solve problems such as low efficiency, time-consuming and laborious, and achieve high recycling efficiency and achieve the effect of industrial automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

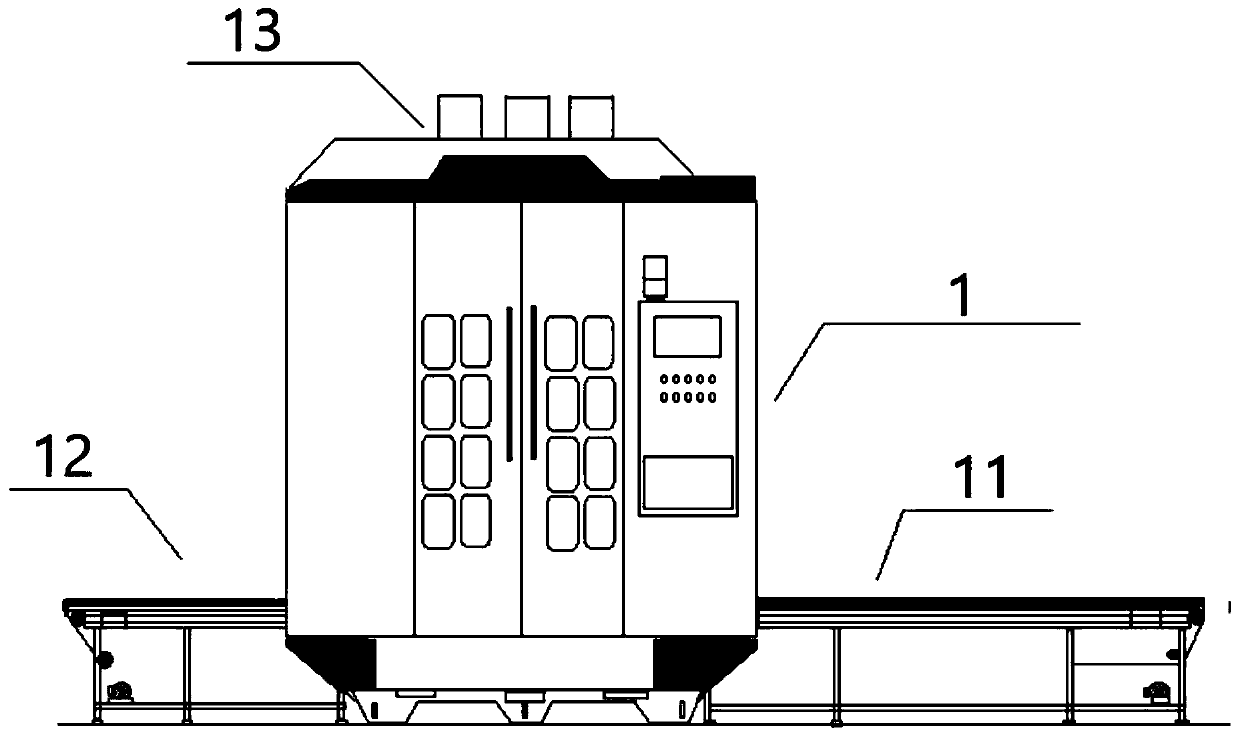

[0038] Such as figure 1 As shown, the device for removing the aluminum alloy case of a lithium battery described in this embodiment includes a shell removing unit 1, and the shell removing unit 1 is provided with a feed port 11 and a discharge port 12; the top of the shell removing unit 1 is provided with exhaust port 13;

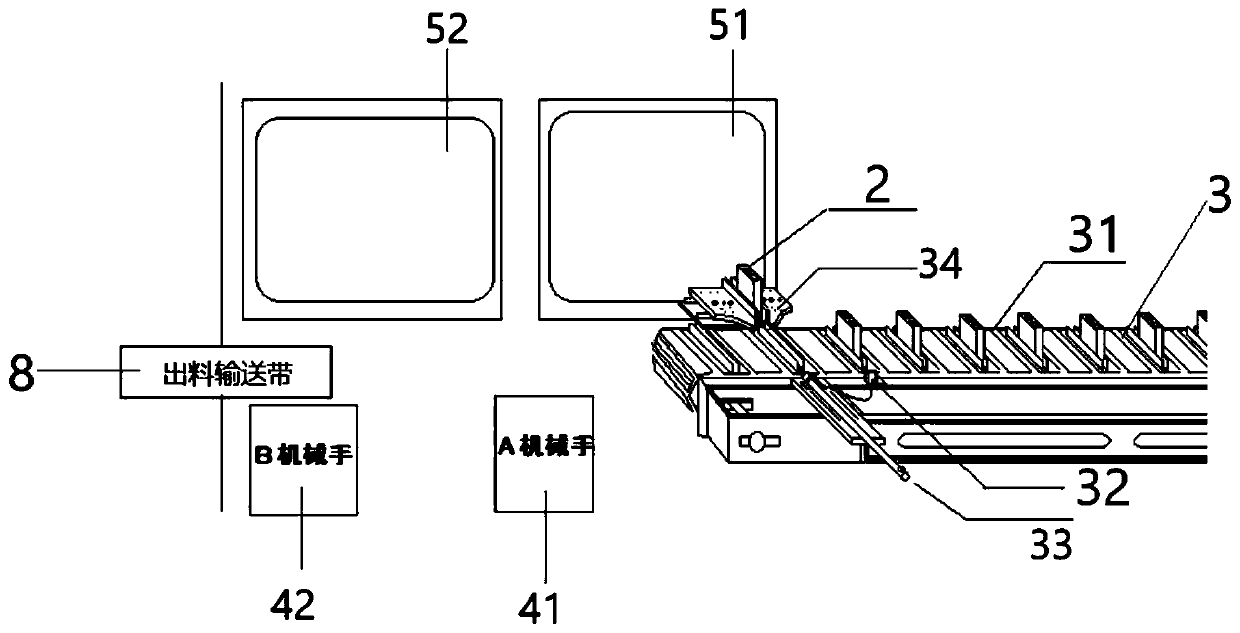

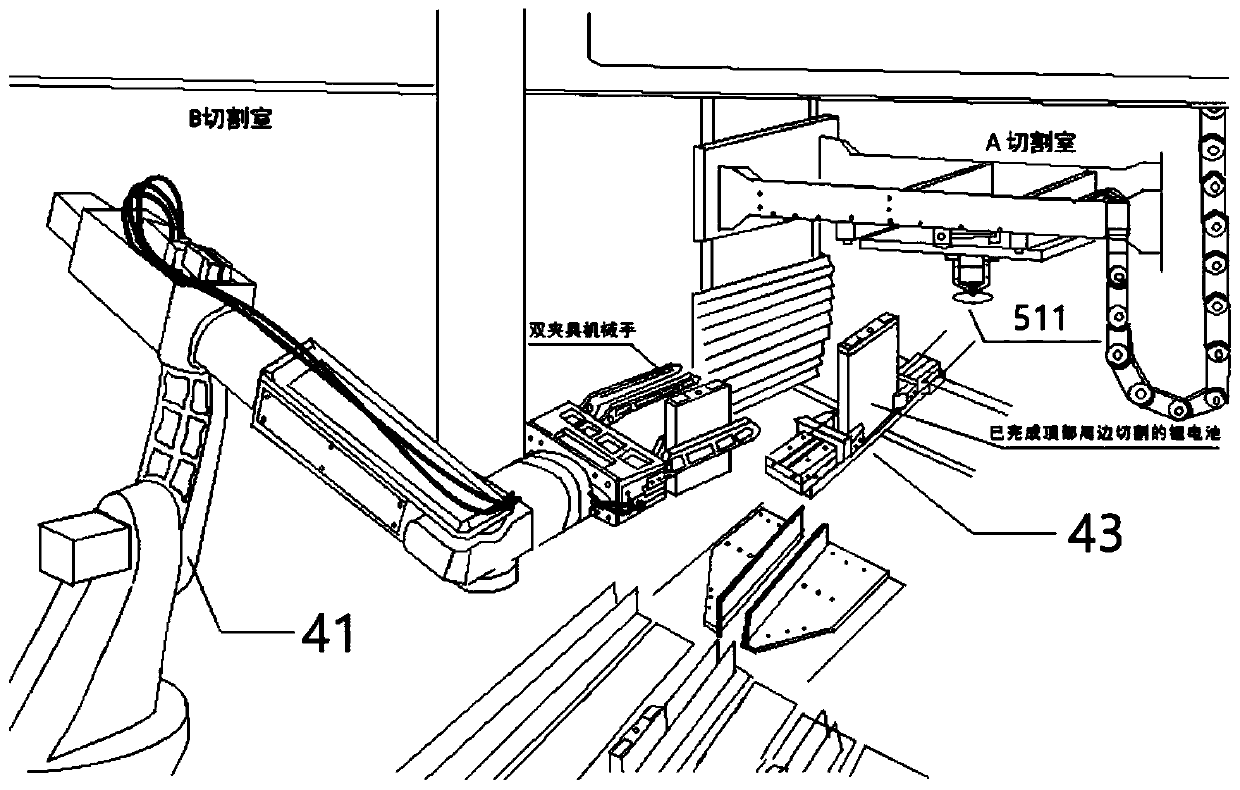

[0039] It also includes a control module, and a conveyor belt feeding module 3, a manipulator feeding module, a cutting module, a winding core extracting module, a lug cutting module, and a material sending module that are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com