Tobacco frame tobacco leaf grade determination method based on deep learning

A deep learning and judgment method technology, applied in the field of level judgment, can solve the problems of irregular results and low efficiency, and achieve the effect of speeding up industrial processes, high robustness, and reducing manual workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

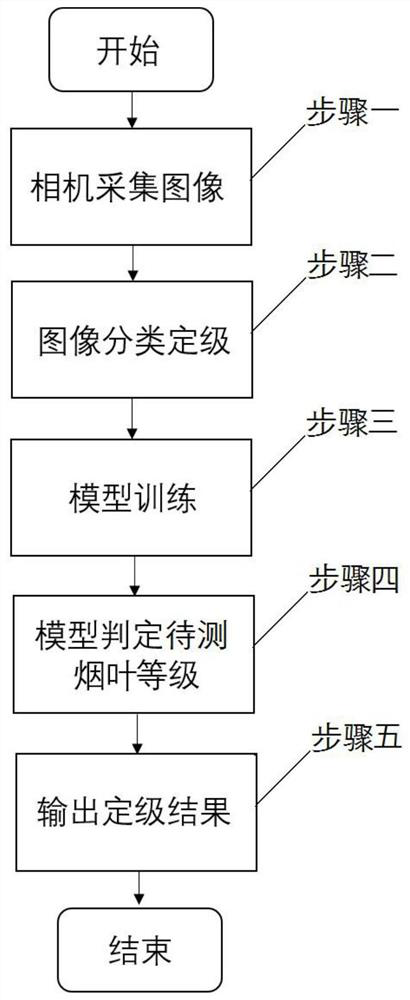

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments will specifically illustrate the technical solutions of the present invention in conjunction with the accompanying drawings.

[0028]

[0029] In this example, framed tobacco leaves are used as the test object, and a method for judging the grade of framed tobacco leaves based on deep learning is described in detail.

[0030] The method for judging the grade of cigarette frame tobacco leaves based on deep learning comprises the following steps:

[0031] Step 1: select a number of tobacco leaves of different grades as samples, and collect tobacco leaf images of the samples in the cigarette frame.

[0032] The imaging equipment used in the acquisition process includes online industrial cameras and light sources. The line industrial camera used is model BES-PGE-122S6C-C (FILR, USA), 12 million global exposure color cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com