Automatic batching control system

An automatic batching and control system technology, applied in the field of control systems, can solve problems such as large proportion errors, affecting product quality and productivity, and unqualified finished products, and achieve the effects of improving quality and productivity, saving manpower and material resources, and stabilizing the internal combustion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

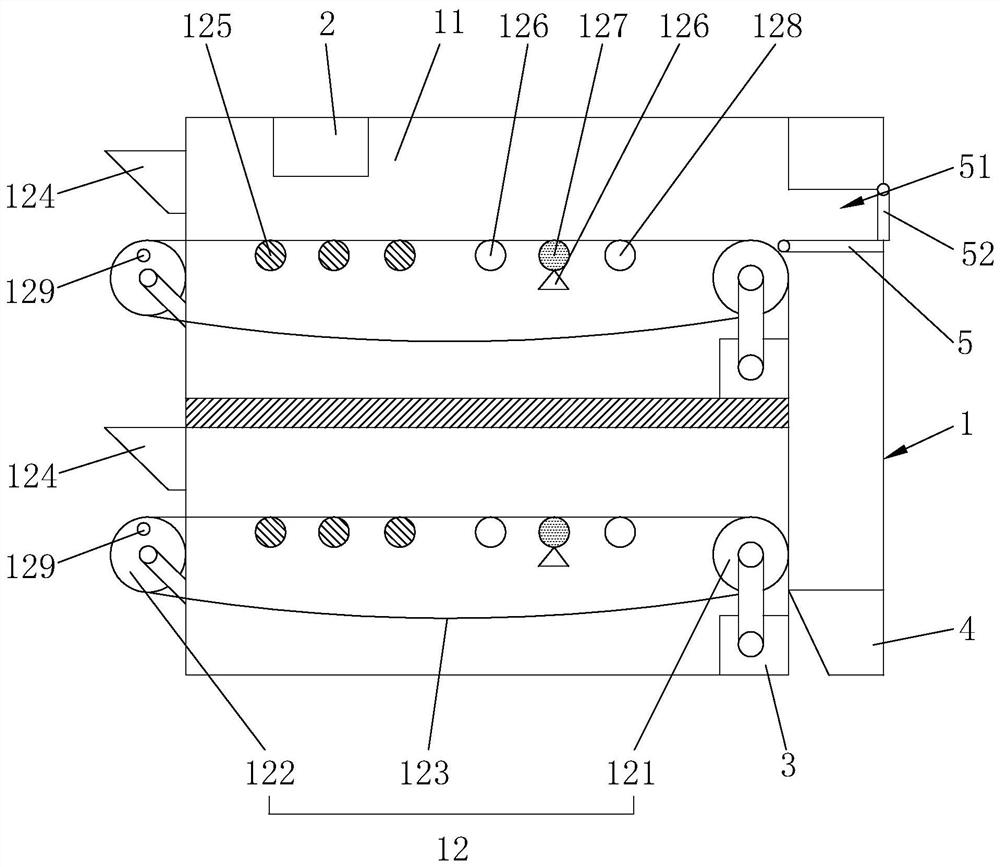

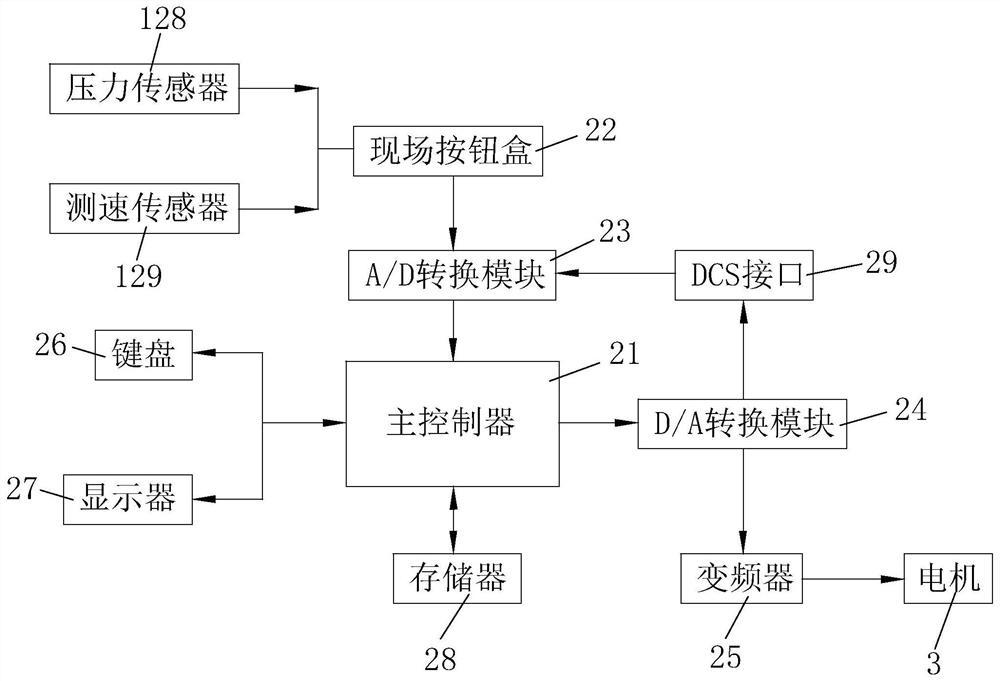

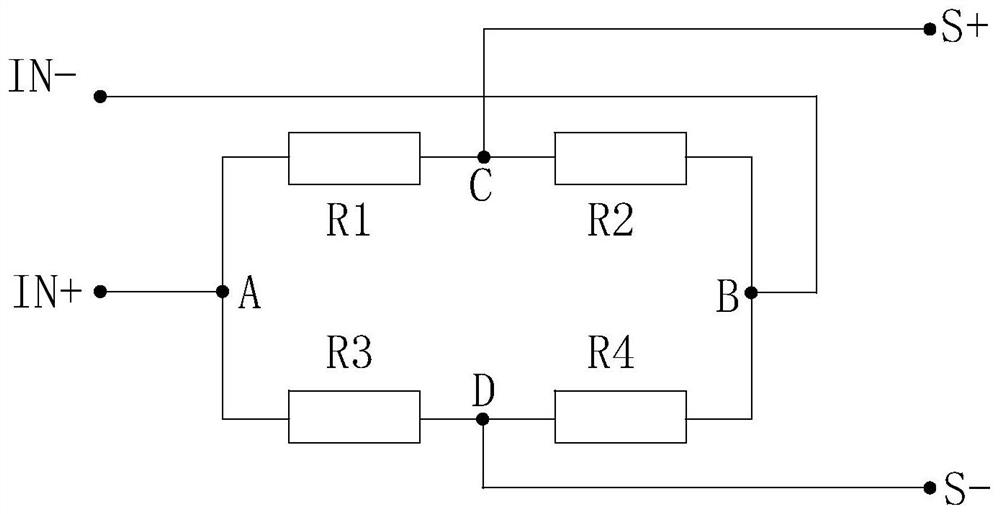

[0024] refer to figure 1 , is an automatic batching control system disclosed in the present invention, including an automatic batching machine 1 and a control module 2 connected to the automatic batching machine 1 . refer to figure 2 , the control module 2 includes a main controller 21, an on-site button box 22, an A / D conversion module 23, a D / A conversion module 24 and a frequency converter 25, and the on-site button box 22 is connected to the automatic batching machine 1 and the A / D conversion module 23, The main controller 21 is connected to the A / D conversion module 23 and the D / A conversion module 24 respectively, and the frequency converter 25 is connected to the D / A conversion module 24 and the motor 3 of the automatic batching machine 1 respectively. After the field button box 22 receives the pressure signal and speed signal from the automatic bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com