Automatic stacking mechanical arm for solar glass tubes

A technology of solar glass and manipulators, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

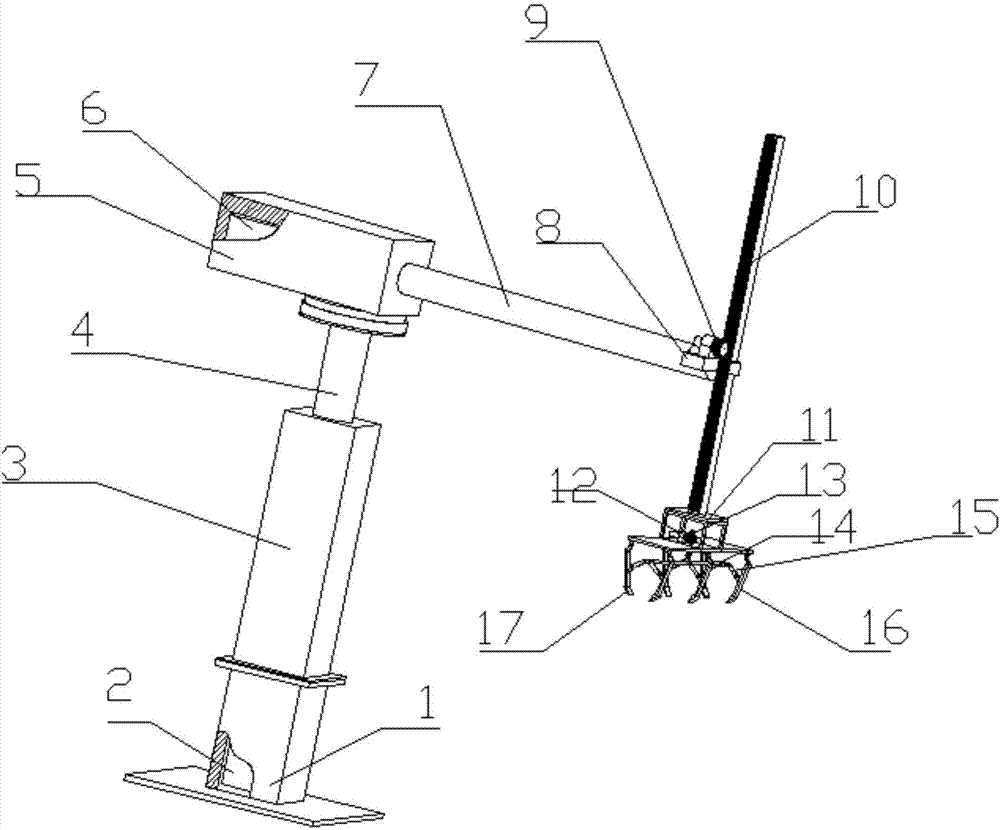

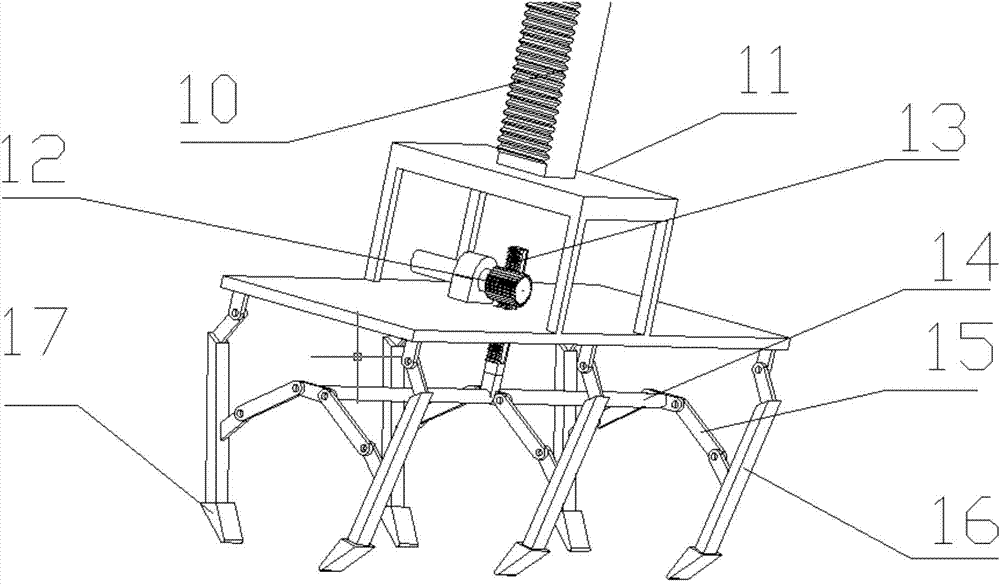

[0009] As shown in the figure, the solar glass tube automatic palletizing manipulator is composed of 1. Base, 2. Hydraulic cylinder Ⅰ, 3. Base cover, 4. Lifting rod, 5. Gear turntable, 6. Hydraulic cylinder Ⅱ, 7. Telescopic Rod, 8, rack seat, 9, lifting gear, 10, lifting rack, 11, claw hand seat, 12, claw gear, 13, claw rack, 14, pull rod, 15, connecting rod, 16, claw, 17 There is a hydraulic cylinder I2 in the base 1, the cylinder of this hydraulic cylinder is connected with the base 1, the piston rod is connected with the lifting rod 4, the bottom of the lifting rod 4 is in the base cover 3, the top of the lifting rod 4 is connected with the The bottom of the gear turntable 5 is connected, and there is a hydraulic cylinder II6 inside the gear turntable 5. The cylinder barrel of this hydraulic cylinder is connected with the gear turntable 5, the piston rod of the hydraulic cylinder is connected with the telescopic rod 7, and the rack seat 8 is fixedly connected with the telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com