Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Prevent back alkalinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of flexible powdery putty for external wall

InactiveCN101381533AImprove flexibilityHigh bonding strengthFilling pastesAntifoam agentMaterials science

The invention provides a method for preparing external-wall flexible powdered putty, which relates to the technical field of building materials. The method comprises the following steps of well mixing cement, dispersible latex powder, inorganic filler and water retaining agent and then adding in and well mixing antifoaming agent and hydrophobic agent. The flexible putty mainly comprises the following materials in weight percentage: 25 to 40 percent of common cement, 2 to 12 percent of dispersible latex powder, 48 to 72 percent of inorganic filler, 0.1 to 0.6 percent of antifoaming agent, 0.03 to 0.15 percent of water retaining agent and 0.05 to 0.3 percent of hydrophobic agent. The putty disclosed by the invention has the advantages of quick drying, easy polishing, construction convenience and the like, has the characteristics of good anti-cracking property, strong water resistance, high flexibility, good bonding strength, heat preservation, alkali return avoidance and other performance, is stable in performance, simple in production process, safe, friendly to environment and free from toxicity. In addition, as the putty is powdered, the putty is convenient to package and transport and simple to use, and can be suitable for manual batch scraping.

Owner:JIANGNAN UNIV

Concrete sealing curing agent

The invention provides a concrete sealing curing agent. The concrete sealing curing agent is prepared from a component A and a component B, which are packaged independently, wherein the component A is prepared from the following components in percentage by weight: 20 weight percent to 25 weight percent of sodium silicate, 5 weight percent to 15 weight percent of poly-lithium silicate, 5 weight percent to 15 weight percent of silica sol, 3 weight percent to 7 weight percent of a photocatalyst, 0.5 weight percent to 1 weight percent of a penetrating agent, 0.5 weight percent to 1 weight percent of a surfactant, 0.4 weight percent to 0.6 weight percent of a surface modifier, 0.4 weight percent to 0.6 weight percent of a de-foaming agent and the balance of de-ionized water; the component B is prepared from the following components in percentage by weight: 0.2 weight percent to 0.6 weight percent of graphene, 25 weight percent to 45 weight percent of organic silicon modified water-based epoxy resin, 5 weight percent to 15 weight percent of silica sol, 0.1 weight percent to 2 weight percent of a catalyst, 0.1 weight percent to 3 weight percent of a stabilizer and the balance of de-ionized water. The concrete sealing curing agent provided by the invention has the advantages of reasonable design, high rigidity, high permeability, good wearing resistance and good waterproof performance, and also has a protection effect on concrete.

Owner:湖北省路桥集团有限公司

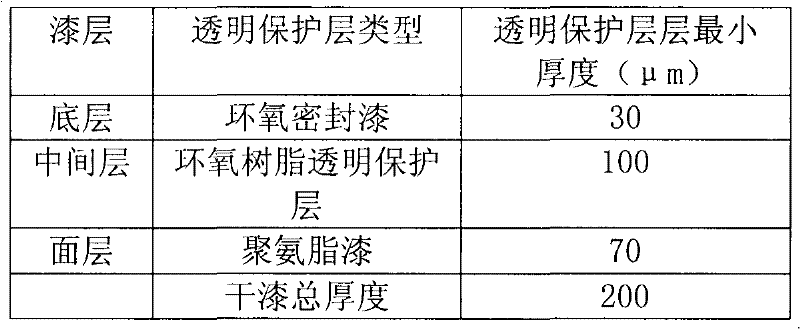

Construction method for as-cast finish concrete transparent protective layer

ActiveCN102352677APrevent back alkalinityReduce alkalinityCovering/liningsProtection layerWater content

The invention relates to a construction method for building concrete, in particular to a construction method for an as-cast finish concrete transparent protective layer, and belongs to the technical field of building construction. The method comprises the following steps of: performing surface treatment on concrete and coating a concrete transparent protective layer. By standard construction measures, the concrete transparent protective layer is coated, namely a base layer is cured for more than 28 days, so that the alkalinity is reduced, the pH value is less than 10, the water content is less than 6 percent, a regulation material is repaired in a felt coating mode uniformly, the transparent protective layer is made of pure organosilicon, drinking water is used for blending, the roller coating interval is 2 hours, a permeable seal primer is coated to prevent the re-alkali of the base material and improve the adhesion of a coated film, and the transparent protective layer has elasticity and extensibility to meet the requirement of concrete shrinkage or expansion.

Owner:江苏诚意工程技术研究院有限公司

Inorganic antibacterial coating and preparation method thereof

ActiveCN109517414AImprove water resistanceImprove adsorption capacityAntifouling/underwater paintsAlkali metal silicate coatingsDispersityWhiskers

The invention relates to inorganic antibacterial coating and a preparation method thereof and belongs to the technical field of building coating. The inorganic antibacterial coating provided by the invention is mainly prepared from the following components in parts by weight: 20 to 50 parts of a silicon-containing inorganic binding agent, 5 to 10 parts of inorganic oxide electret crystal whiskers,5 to 20 parts of silver ion loading type diatomite, 10 to 30 parts of inorganic pigment and filler, 0.1 to 1 part of a stabilizer, 0.5 to 3.5 parts of an auxiliary agent and 12 to 24 parts of water.According to the inorganic antibacterial coating provided by the invention, the stability and dispersity of the coating are ensured, and the antibacterial performance and water resistance of the coating are improved.

Owner:ZHENGZHOU ABILITY ENERGY SAVING TECH CO LTD

Gap filler

The invention discloses a gap filler which comprises the following components in parts by weight: 40-70 parts of quartz sand, 20-30 parts of sulfoaluminate cement, 3-10 parts of antioxidant, 1-3 parts of adhesive, 1-2 parts of cellulose ether, 1-3 parts of mold preventive, 5-10 parts of inorganic aluminum salt waterproofing agent, 1-3 parts of organosilicon leveling agent and 0.5-1 part of lignin fiber. The gap filler disclosed by the invention has the advantages of favorable water resistance, favorable re-alkali resistance, mold resistance and oxidation resistance, is easy and safe for construction, and thus, is a favorable gap filler for spreading and attaching ceramic tiles.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Environment-friendly decoration cement

The invention discloses environment-friendly decoration cement and belongs to the technical field of building materials. The environment-friendly decoration cement is prepared from the following raw materials in parts by weight: 45-60 parts of Portland cement, 0-4 parts of an expanding agent, 4-10 parts of metakaolin, 2-6 parts of silicon powder, 1-3 parts of crystal whiskers, 5-10 parts of redispersible emulsion powder, 1-2 parts of a water reducer, 0.3-1.0 part of a defoaming agent, 0.1-0.15 part of cellulose ether, 5-10 parts of ground calcium carbonate and 10-15 parts of an environment-friendly material. The environment-friendly decoration cement disclosed by the invention has no problems such as alkali efflorescence and cracking and has good peaceability, corrosion resistance and environment-friendly performance.

Owner:JIAHUA SPECIAL CEMENT

Decorative cement

The invention discloses decorative cement and belongs to the technical field of building materials. The decorative cement comprises, by weight, 45 to 60 parts of Portland cement, 0 to 4 parts of an expander, 4 to 10 parts of metakaolin, 2 to 6 parts of silicon powder, 1 to 3 parts of whiskers, 5 to 10 parts of redispersible latex powder, 1 to 2 parts of a water reducing agent, 0.3 to 1.0 part of adefoaming agent, 0.1 to 0.15 parts of cellulose ether and 15 to 20 parts of ground calcium carbonate. The decorative cement prevents alkali crystallization and cracking and has good workability and corrosion resistance.

Owner:JIAHUA SPECIAL CEMENT

Gap filler

The invention discloses a gap filler which comprises the following components in parts by weight: 40-70 parts of quartz sand, 8-12 parts of calcium carbonate, 20-30 parts of sulfoaluminate cement, 3-10 parts of antioxidant, 1-3 parts of adhesive, 0.2-0.6 part of cellulose ether, 1-3 parts of mold preventive and 5-10 parts of inorganic aluminum salt waterproofing agent. The quartz sand used as the main body component of the gap filler lowers the cost of the gap filler; the mold preventive is mainly used for preventing mold due to water absorption; the addition of the inorganic aluminum salt waterproofing agent can perform the waterproofing function after the gap filler is cured; and the sulfoaluminate cement can prevent the re-alkali phenomenon after use for some time, accelerate the hydration of cement and enhance the strength. The gap filler is easy and safe for construction, and thus, is a favorable gap filler for spreading and attaching ceramic tiles.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

A construction method for greening slope protection in saline-alkali land planted with Zhuge vegetable

ActiveCN108323380BReduce reversion phenomenonAvoid clogged voidsBiocideMagnesium fertilisersVegetationOrychophragmus

The invention discloses a construction method of planting orychophragmus violaceus in a saline-alkali land greening protection slope, and relates to the technical field of greening protection slopes.The method comprises the following steps: (1) cleaning of a slope surface; (2) soil amelioration; (3) preparation of greening concrete; (4) pouring; (5) pretreatment of a sowing slope surface; (6) sowing of the orychophragmus violaceus; and (7) maintenance. The method provided by the invention reduces an efflorescence phenomenon in the saline-alkali land poured greening protection slope, and solves the problems that vegetation of the saline-alkali land protection slope is single and has a low survival rate.

Owner:科利尔环保科技有限责任公司

Gap filler

The invention discloses a gap filler which comprises the following components in parts by weight: 40-60 parts of quartz sand, 20-30 parts of white cement, 3-10 parts of antioxidant, 1-3 parts of adhesive, 1-3 parts of mold preventive, 5-20 parts of white lime, 8-12 parts of calcium carbonate, 1-2 parts of sodium silicate and 1-3 parts of pigment. The gap filler disclosed by the invention has the advantages of high adhesive force, favorable water resistance, high strength and low cost, is convenient for construction, and can be used for filling gaps among ceramic tiles, mosaics and other building materials.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

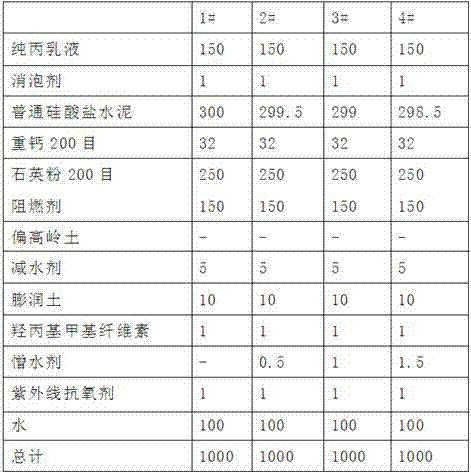

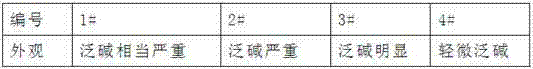

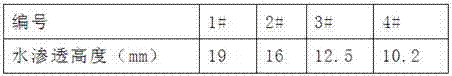

Composite soft material and manufacturing method thereof

ActiveCN103204657AImprove flame retardant performanceImprove waterproof and anti-seepage performancePolymer scienceUltraviolet lights

The invention relates to the field of material application and in particular relates to a composite soft material and a manufacturing method thereof. The composite soft material is prepared from polymer latex, an ultraviolet light absorber, a defoaming agent, a water reducing agent, water, ordinary portland cement, inert filler, quartz powder, a water retaining agent, a water repellent agent, fire retardant high-activity mineral filler and modified bentonite according to a certain weight ratio. The preparation method is simple, raw materials are easily obtained, the obtained soft material has a favorable fire retardance effect and high waterproof and impervious performances, alkali reversion can be thoroughly eliminated, and a heat insulation material at the inner layer is well prevented from being damaged. The composite soft material is a veneer material which is especially suitable for polyurethane foams for external wall external insulation.

Owner:山东伟远节能科技有限公司

Admixture special for color concrete and application method and using method of admixture

The invention provides an admixture special for color concrete and an application method and using method of the admixture. The special admixture comprises a water reducing disperse component and a modified durable component, wherein the water reducing disperse component comprises the following components in parts by mass: 8-20 parts of modified lignosulfonate, 15-35 parts of polymethylene sodium naphthalene sulfonate, 1-5 parts of sodium dodecyl sulfate and 50-70 parts of water; the modified durable component comprises the following components in parts by mass: 5-16 parts of styrene-maleimide, 15-28 parts of organic silane coupling agent, 8-20 parts of stearate, 40-60 parts of redispersible polymer powder and 3-7 parts of inhibitor. According to the special admixture provided in the invention, alkali returning of the color concrete can be inhibited, and the workability, glossiness and durability of the concrete are improved.

Owner:HUAIAN TESTING CENT FOR CONSTR ENG

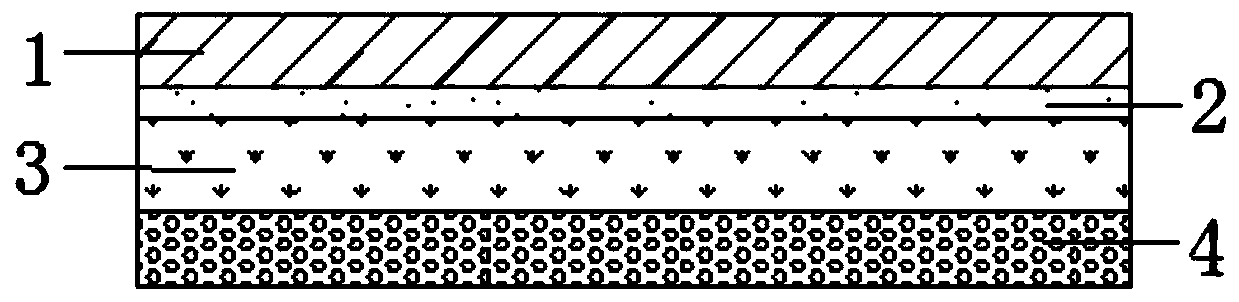

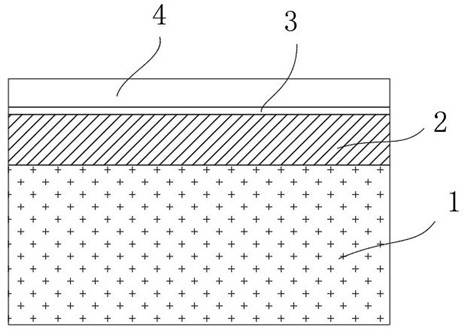

Stone-like paint heat preservation plate

PendingCN110700426AImprove fire resistanceAvoid spreadingClimate change adaptationLaminationCalcium silicateRough surface

The invention relates to the technical field of heat preservation plates, and particularly relates to a stone-like paint heat preservation plate. The stone-like paint heat preservation plate comprisesa heat preservation layer, a bonding layer, a panel layer and a facing layer which are sequentially stacked, wherein a plurality of grooves are formed in the surface, making contact with the bondinglayer, of the heat preservation layer; the panel layer is made of a calcium silicate plate; the upper surface and the lower surface of the panel layer are rough surfaces; the facing layer comprises aprimer layer, a finish paint layer and a mask paint layer; the primer layer is polished once before the finish paint layer is sprayed, and the mask paint layer is polished once before the mask paint layer is sprayed; the rock wool heat preservation layer is adopted in the stone-like paint heat preservation plate and can bear the high temperature of 1000 DEG C or above, in a fire disaster, rock wool can effectively prevent fire spreading, and a fireproof barrier is formed; meanwhile, the stone-like paint heat preservation plate further has the beneficial effects of achieving heat preservation and heat insulation, absorbing sound, reducing noise, being hydrophobic, stable in size, not being damaged by worms or corroded and the like; and therefore, the rock wool heat preservation layer is adopted in the stone-like paint heat preservation plate, the heat preservation and fire resistance of the stone-like paint heat preservation plate are effectively improved, and the use safety of the stone-like paint heat preservation plate is obviously improved.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

Radiation-proof decoration cement

The invention discloses a radiation-proof decoration cement, and belongs to the technical field of building materials. The decoration cement comprises, by weight, 40-50 parts of radiation-proof cement, 0-4 parts of an expanding agent, 4-10 parts of metakaolin, 2-6 parts of silicon powder, 1-3 parts of whiskers, 5-10 parts of redispersible latex powder, 1-2 parts of a water reducer, 0.3-1.0 part ofan antifoaming agent, 0.1-0.15 part of cellulose ether and 25-30 parts of barite powder. The radiation-proof cement is one of barium cement, strontium cement and boron-containing cement. The radiation-proof decoration cement has the advantages of no alkali efflorescence or cracking problems, good workability, good corrosion resistance and very strong radiation resistance.

Owner:JIAHUA SPECIAL CEMENT

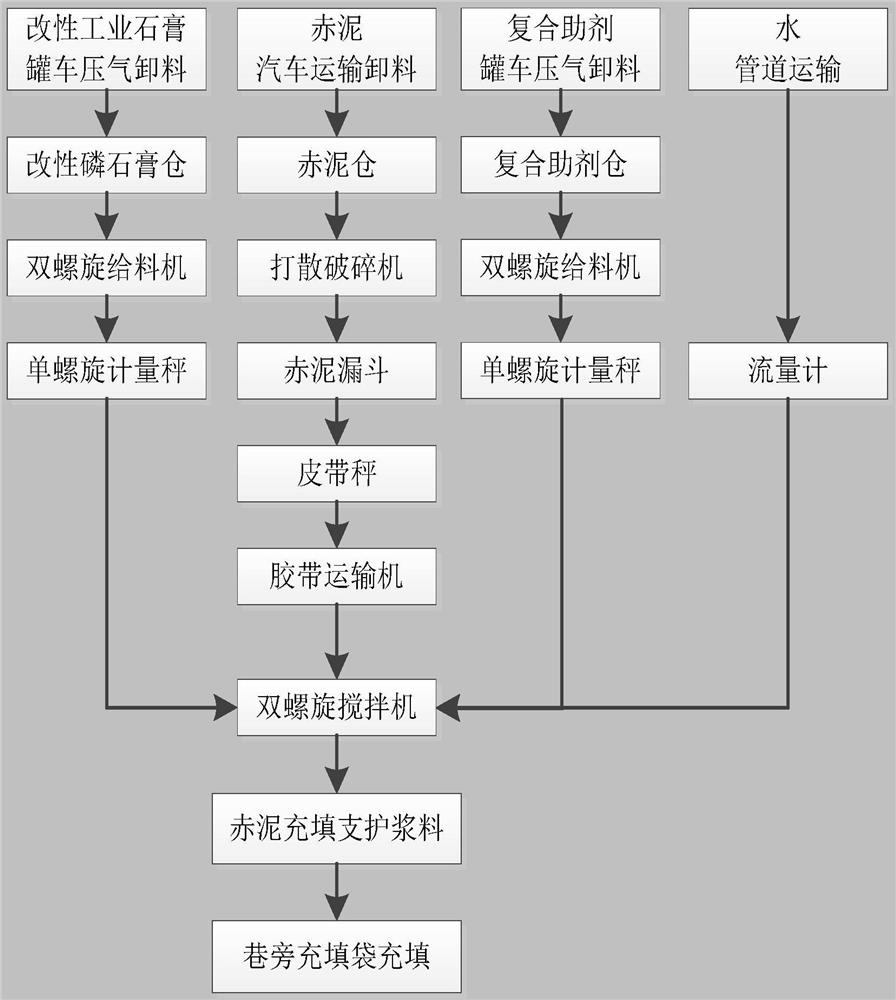

Gob-side entry retaining roadside filling support material using modified industrial gypsum to solidify red mud and preparation method of gob-side entry retaining roadside filling support material

InactiveCN113526941AImprove stabilityGuaranteed stabilitySolid waste managementMaterial fill-upMining engineeringRed mud

The invention discloses a gob-side entry retaining roadside filling support material using modified industrial gypsum to solidify red mud, which is prepared from the following raw materials in parts by weight: 70-85 parts of red mud, 13-30 parts of modified industrial gypsum and 2-10 parts of compound additive. The manufacturing method of the gob-side entry retaining roadside filling support material comprises the following steps: scattering and crushing red mud to below 3mm for later use; premixing the compound additive, the modified industrial gypsum and the scattered and crushed red mud to obtain a solid mixture; mixing and stirring water and the solid mixture strongly, and obtaining a filling paste slurry; and conveying the filling paste slurry to a filling bag for filling and curing to obtain the roadside filling support material. The prepared roadside filling support slurry is good in stability, good in fluidity and high in strength after being cured. According to the filling material, the defects that the filling construction difficulty of concrete is high, the filling cost of high water is high and the strength is low are overcome, the roadside filling and supporting cost of gob-side entry retaining mining of a mine is reduced, and harmless, large-scale and resource utilization of the two solid wastes of the red mud and the industrial gypsum is realized.

Owner:GUIZHOU INST OF TECH

Fireproof partition laminate

ActiveCN105239744AImprove toughnessHigh hardnessCovering/liningsFire proofingNonwoven fabricSilicon dioxide

The invention discloses a fireproof partition laminate, comprising a face layer and a bottom layer made of fiberglass fabric or nonwoven fabric. Space between the face layer and the bottom layer is filled with an inorganic mixture, wherein the inorganic mixture comprises: sawdust, gypsum powder, perlite, magnesium oxide, magnesium chloride, glutinous rice flour, uric acid resin, oxalic acid, lime, copper sulfate, asbestos, gaseous silicon dioxide, and aluminum oxide. The invention aims to overcome the defects of the prior art and provides the fireproof partition laminate effective in reducing wood utilization and retarding flame.

Owner:顾军雄 +5

Water-based alkali resistant paint

InactiveCN105295680APrevent back alkalinityExcellent film performancePolyurea/polyurethane coatingsPolyester coatingsWater basedBrick

The invention provides a water-based alkali resistant paint, which comprises the following raw materials by weight: 40-60 parts of an organosilicon modified pure acrylic emulsion, 50-70 parts of water-based unsaturated polyester acrylate resin, 40-60 parts of waterborne polyurethane resin, 10-15 parts of triethylenetetramine, 11-14 parts of a film-forming assistant, 9-15 parts of a defoaming agent, 7-9 parts of a curing agent, 20-28 parts of an alkali-resistant emulsion, 10-13 parts of hydroxyethyl cellulose, 8-10 parts of a formaldehyde absorbent, 12-16 parts of titanium dioxide, 12-16 parts of talc powder, 18-25 parts of a pure acrylic emulsion, 2-4 parts of a preservative, and 30-40 parts of water. The water-based alkali resistant paint provided by the invention can adsorb formaldehyde and purify air, does not cause harm to human health, and is suitable for internal and external brick walls and the like. The paint contains alkali-resistant component, at the end of construction, the paint film has good effect, and efflorescence and floating are unlikely to appear, thus effectively preventing wall alkali efflorescence. Also, the water-based alkali resistant paint has strong adhesion and low VOC.

Owner:TIANJIN MEISHIBANG PAINT CHEM IND

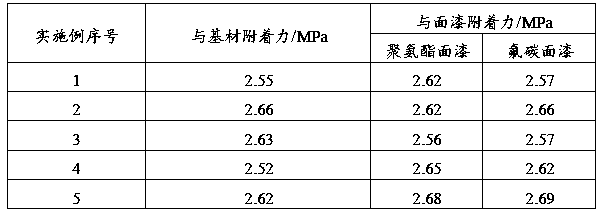

Epoxy seal paint and preparation method thereof

InactiveCN105505200ASimple ingredientsEasy to producePolyamide coatingsEpoxy resin coatingsEpoxySeepage force

The invention discloses epoxy seal paint which comprises a main material and a curing agent. The main material is prepared from, by weight, 15-25 parts of epoxy resin, 50-60 parts of xylene and 20-30 parts of n-butyl alcohol; the curing agent is prepared from, by weight, 45-60 parts of polyamide resin, 30-40 parts of xylene and 10-20 parts of n-butyl alcohol. When the epoxy seal paint is used, the main paint and the curing agent are uniformly mixed to be used according to the weight ratio of 5:1. The invention further discloses a preparation method of the epoxy seal paint. The epoxy seal paint is simple in component, convenient and fast to produce, convenient to construct, high in seepage force and capable of preventing concrete members from alkali efflorescence, good caking properties with a concrete base surface and polyurethanes class or fluorocarbon class finishing coat are achieved, and adhesive force is larger than 2.5 MPa.

Owner:安徽万诚达新型材料有限公司

Yellow River Delta saline-alkaline land winter wheat water-saving yield-increasing sowing method

PendingCN110036842AIncrease water storagePostponeCereal cultivationSoil-working methodsSowingRiver delta

The invention relates to the technical field of crop planting, in particular to a Yellow River Delta saline-alkaline land winter wheat water-saving yield-increasing sowing method. The method includessteps: treating previous-crop straw, performing primary rotary tillage once, deeply loosening, watering, performing secondary rotary tillage for 2-3 times, compacting before sowing, performing full-width sowing, and compacting at proper time after sowing. Linked technical steps are adopted for operation and supplement each other, promote each other and are scientific in design, the defects in existing winter wheat planting in Yellow River Delta regions are fully eliminated, and yield increase of winter wheat in the regions is realized on the basis of water saving.

Owner:宋元瑞

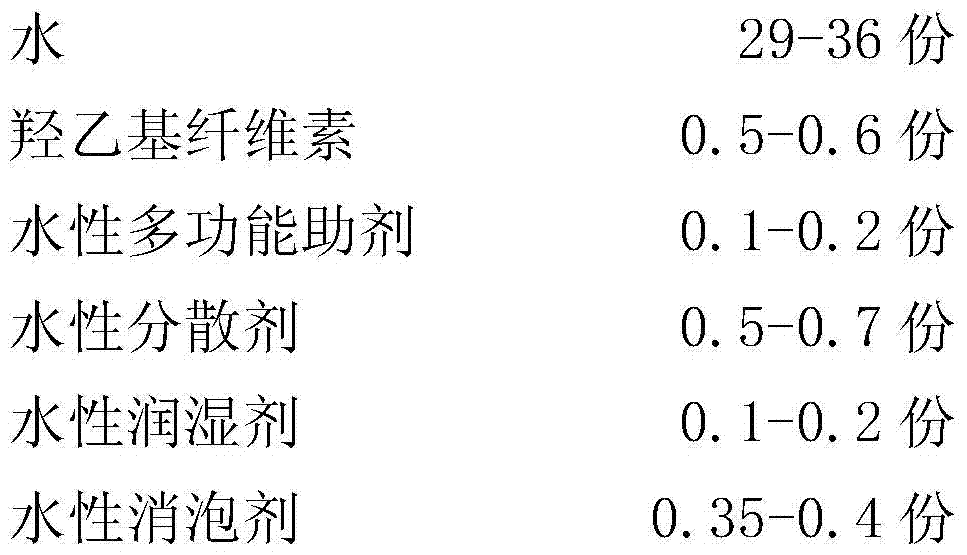

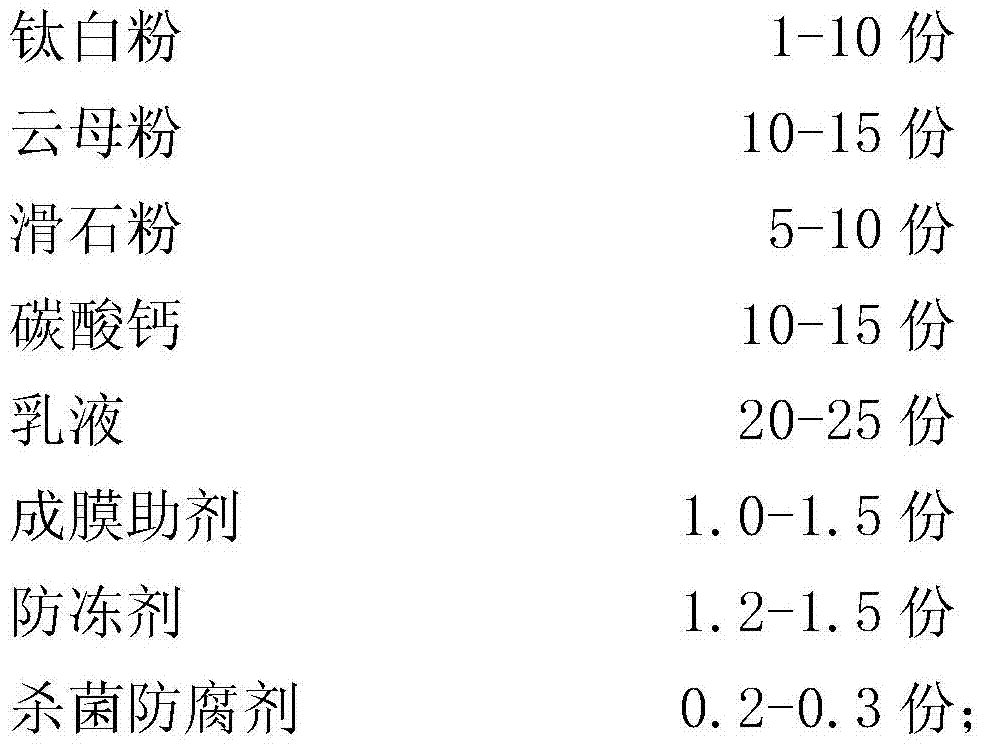

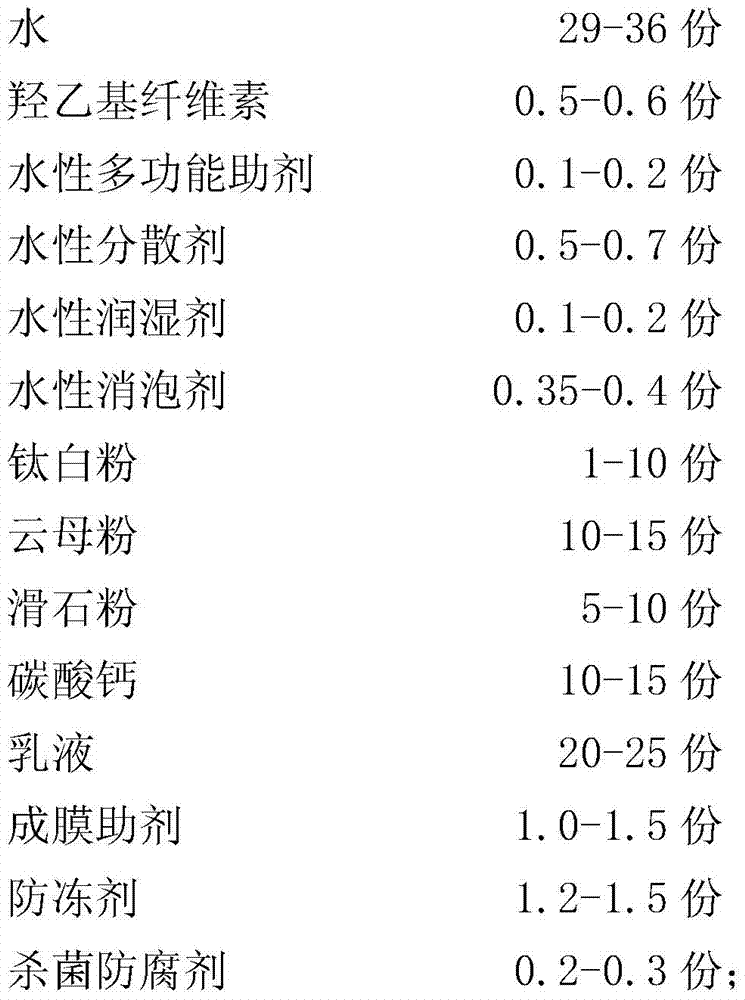

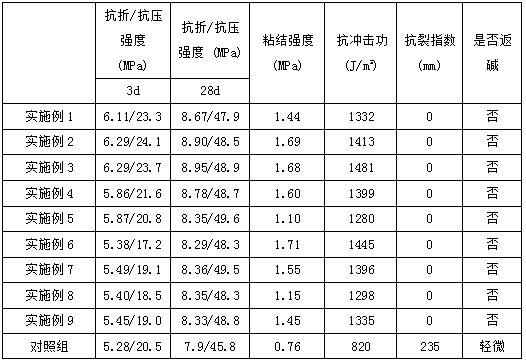

Alkali-resistant primer and preparation method thereof

ActiveCN104592815BFree from saline erosionPrevent precipitationAntifouling/underwater paintsConjugated diene hydrocarbon coatingsWater basedEmulsion

The invention relates to an alkali-resistant primer and a preparation method thereof. The alkali-resistant primer is prepared from the following components in parts by weight: water, hydroxyethyl cellulose, water-based multifunctional assistant, water-based dispersing agent, water-based wetting agent, water-based defoaming agent, titanium white, mica powder, talcum powder, calcium carbonate, emulsion, film forming assistant, antifreezing agent and sterilizing preservative. The emulsion is a butadiene-styrene copolymer emulsion. The alkali-resistant primer has alkali-resistant and sealing functions, and can effectively prevent the wall from alkali efflorescence.

Owner:SKSHU PAINT

No-tillage rotation method for Avena sativa and forage sorghum in coastal mud flat

InactiveCN109392630AHigh organic contentImprove eco-efficiencyCereal cultivationAgriculture gas emission reductionLand improvementPromotion effect

The invention discloses a no-tillage rotation method for Avena sativa and forage sorghum in a coastal mud flat. The method comprises the following steps: (1) selecting a planting area, (2) managing soil in spring, (3) planting Avena sativa, (4) planting forage sorghum, (5) performing growth and harvest of forage sorghum and (6) performing change into a next crop. According to the no-tillage rotation method, crop rotation farming agriculture and physical, chemical and biological control measures of saline-alkali land are combined organically, a saline-alkali land improvement mode with ecological, economic and social benefits is obtained, and a positively promotion effect is generated on transformation of saline-alkali land in the coastal mud flat and sustainable development of agriculture.

Owner:YANGZHOU UNIV

Cement sealing curing agent and preparation method thereof

The invention discloses a cement sealing curing agent and a preparation method thereof. The curing agent is prepared by mixing component A and component B at a ratio of 6:1, and the raw material formula of component A includes sodium polysilicate, polysilicic acid Lithium, hydroxyethyl cellulose, zeolite, metakaolin, sodium dihydrogen phosphate, wetting agent, penetrant, defoamer, surface modifier, stabilizer, deionized water, the raw material formula of component B includes aliphatic Urethane Acrylate, Trimethylolpropane Triacrylate, Nano Graphene Oxide, Nano Iron, Aluminum Hydroxide, Aluminum Sulfate, Sodium Hydroxide, Deionized Water. The permeability of the present invention is stronger, which greatly improves the strength and wear resistance of the surface layer of the concrete structure, and prolongs the service life of the ground. Component A of the curing agent can be used alone, but under the action of component B, it will be greatly To shorten the curing time and increase its strength to a certain extent, component B plays a synergistic effect on component A.

Owner:力特克新材料(广东)有限公司

a decorative cement

Owner:JIAHUA SPECIAL CEMENT

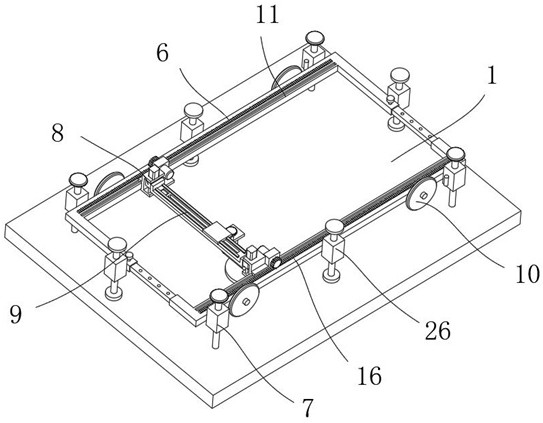

Anti-efflorescence floor and intelligent auxiliary construction method thereof

ActiveCN113668808APrevent back alkalinityImprove the level ofSolid waste managementFlooringPunchingArchitectural engineering

The invention provides an anti-efflorescence floor. The anti-efflorescence floor comprises a concrete surface layer, wherein a cement layer is fixed on the upper surface of the concrete surface layer, the thickness of the cement layer is 5cm, the surface of the cement layer is coated with glue, ceramic tiles are pasted on the surface of the glue, and the thickness of the glue is 15mm. Before the floor tiles are laid, mortar leveling and hardening are carried out on the floor, then the floor tiles are pasted through the glue, so that no gap exists between the floor tiles and the hardened layer, and water seepage and efflorescence are avoided. The invention further provides an intelligent auxiliary construction method of the anti-efflorescence floor. The intelligent auxiliary construction method is completed by adopting a paving device in a matched mode. The auxiliary laying construction method comprises the following steps that S1, paying-off and point fixing are carried out, paying-off is carried out on the concrete surface layer, and a plurality of positioning grooves which are arranged in an array mode are punched in the surface of the concrete surface layer through a punching machine. According to the anti-efflorescence floor and the intelligent auxiliary construction method thereof, people can conveniently level the cement mortar layer on the surface of the concrete surface layer in a large area, so that the overall levelness of the indoor is improved, and the attractiveness is improved.

Owner:冠恒建设集团有限公司

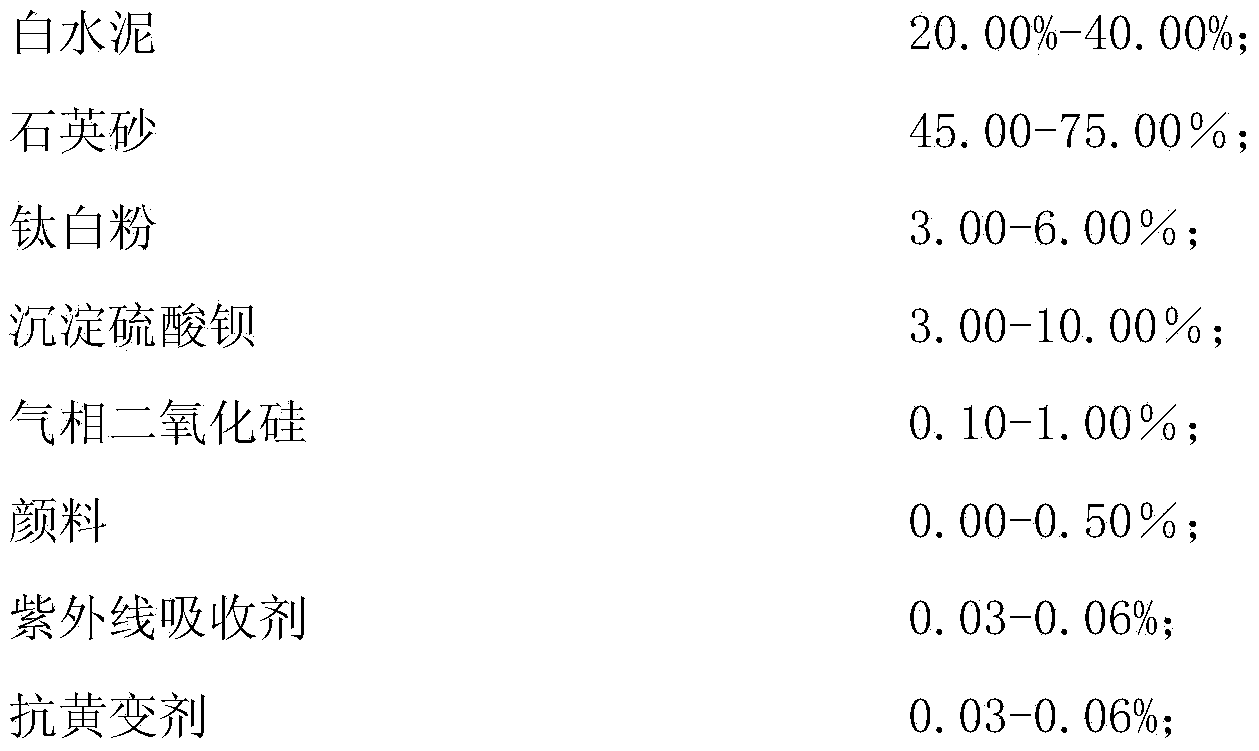

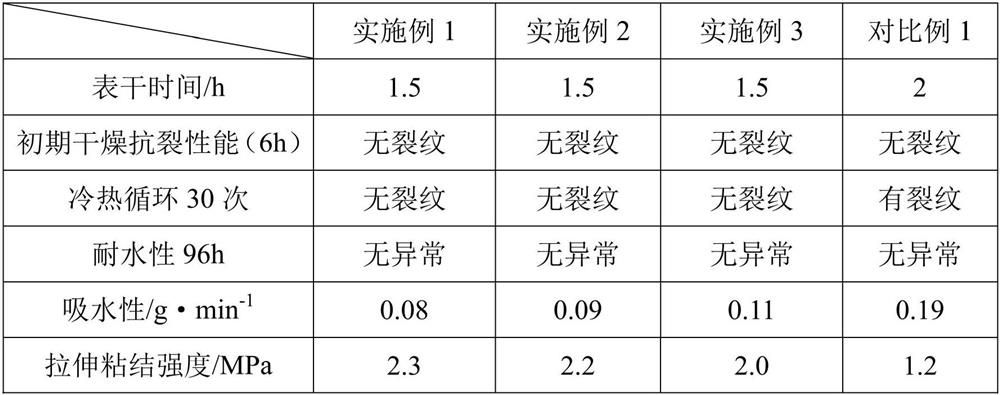

Stain-resistant scrubbing-resistant colorful ceramic tile joint mixture as well as preparation method and application of mixture

The invention discloses a stain-resistant and scrubbing-resistant colorful ceramic tile joint mixture which is prepared from epoxy resin, a curing agent and powder, wherein the powder comprises white cement, quartz sand, titanium dioxide, precipitated barium sulphate, gas phase silica, dye, ultraviolet light absorber and yellowing-resistant agent. According to the ceramic tile joint mixture, not only the problem of alkali return of the common cement-base ceramic tile joint mixture can be thoroughly solved, but also the joint mixture is convenient to construct, the redundant joint mixture can be washed by water, and the joint mixture is cured under room temperature, and is stain-resistant and scrubbing-resistant.

Owner:东方雨虹民用建材有限责任公司

Construction method of planting orychophragmus violaceus in saline-alkali land greening protection slope

ActiveCN108323380AReduce reversion phenomenonAvoid clogged voidsBiocideMagnesium fertilisersVegetationOrychophragmus

The invention discloses a construction method of planting orychophragmus violaceus in a saline-alkali land greening protection slope, and relates to the technical field of greening protection slopes.The method comprises the following steps: (1) cleaning of a slope surface; (2) soil amelioration; (3) preparation of greening concrete; (4) pouring; (5) pretreatment of a sowing slope surface; (6) sowing of the orychophragmus violaceus; and (7) maintenance. The method provided by the invention reduces an efflorescence phenomenon in the saline-alkali land poured greening protection slope, and solves the problems that vegetation of the saline-alkali land protection slope is single and has a low survival rate.

Owner:科利尔环保科技有限责任公司

A repairing material for building wall cracks

The invention discloses a repairing material for building wall cracks, which comprises the following raw materials: 0.1-0.3 parts of silicon dioxide, 0.2-0.4 parts of talcum powder, and 0.1-0.3 parts of silicate double salt , 0.04-0.08 parts of inorganic minerals, 2.5-8 parts of cement clinker, 1-4 parts of hydroxypropyl methylcellulose, 3-25 parts of sodium tripolyphosphate, and 1-5 parts of polypropylene short fiber 2-8 parts for mixed materials, 1-11 parts for gypsum, 0.4-3 parts for grinding aids, 0.2-4 parts for superfine admixtures and 5-28 parts for water. The repairing material for building wall cracking of the present invention has a high degree of adhesion, can repair cracks at one time, is not easy to repeatedly appear cracks, is not easy to fall off and produce hollowing, and can prevent the wall from returning to alkali; the use method is simple and time-saving Labor-saving, labor-saving and material-saving; raw materials are easy to buy, and the market price is low.

Owner:天津志清建筑工程有限公司

A special admixture for colored concrete and its application and usage method

The invention provides an admixture special for color concrete and an application method and using method of the admixture. The special admixture comprises a water reducing disperse component and a modified durable component, wherein the water reducing disperse component comprises the following components in parts by mass: 8-20 parts of modified lignosulfonate, 15-35 parts of polymethylene sodium naphthalene sulfonate, 1-5 parts of sodium dodecyl sulfate and 50-70 parts of water; the modified durable component comprises the following components in parts by mass: 5-16 parts of styrene-maleimide, 15-28 parts of organic silane coupling agent, 8-20 parts of stearate, 40-60 parts of redispersible polymer powder and 3-7 parts of inhibitor. According to the special admixture provided in the invention, alkali returning of the color concrete can be inhibited, and the workability, glossiness and durability of the concrete are improved.

Owner:HUAIAN TESTING CENT FOR CONSTR ENG

A kind of anti-radiation decorative cement

The invention discloses a radiation-proof decoration cement, and belongs to the technical field of building materials. The decoration cement comprises, by weight, 40-50 parts of radiation-proof cement, 0-4 parts of an expanding agent, 4-10 parts of metakaolin, 2-6 parts of silicon powder, 1-3 parts of whiskers, 5-10 parts of redispersible latex powder, 1-2 parts of a water reducer, 0.3-1.0 part ofan antifoaming agent, 0.1-0.15 part of cellulose ether and 25-30 parts of barite powder. The radiation-proof cement is one of barium cement, strontium cement and boron-containing cement. The radiation-proof decoration cement has the advantages of no alkali efflorescence or cracking problems, good workability, good corrosion resistance and very strong radiation resistance.

Owner:JIAHUA SPECIAL CEMENT

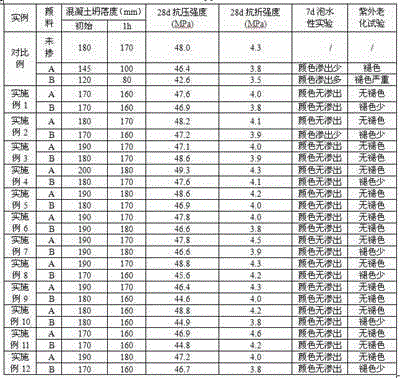

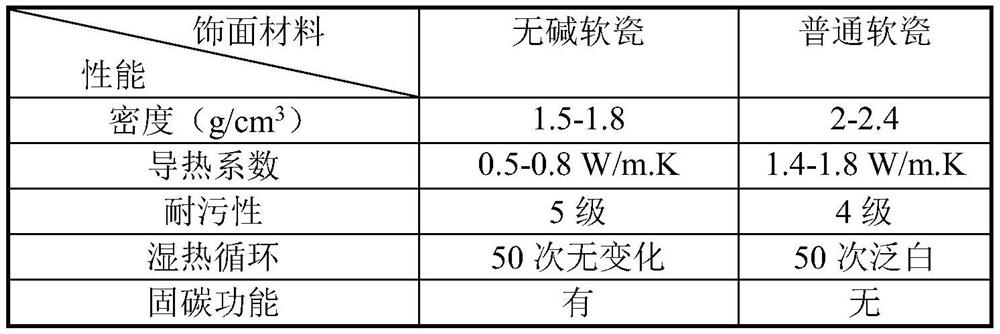

Alkali-free soft porcelain capable of fixing carbon and preparation method of alkali-free soft porcelain

ActiveCN114873952ABreathe freelyPrevent back alkalinityCovering/liningsSolid waste managementAlkali freePhysical chemistry

The invention discloses alkali-free soft porcelain capable of fixing carbon and a preparation method thereof.The alkali-free soft porcelain capable of fixing carbon is composed of a base layer and a surface layer, the thickness of the base layer is 2-6 mm, and the base layer is composed of 40-60 parts of quartz sand, 10-25 parts of calcium powder, 5-15 parts of water-based emulsion, 5-15 parts of water and 1-5 parts of auxiliaries; the thickness of the surface layer is 0.5-1.5 mm, and the surface layer is mainly prepared from 30-60 parts of clay, 10-20 parts of bentonite, 5-10 parts of latex powder, 15-25 parts of water and 10-20 parts of chlorophyll zeolite gel particles; the composition of the soft porcelain material does not contain cement, so that the common alkali efflorescence problem of a building material cannot be caused; through photosynthesis of active chlorophyll in the soft porcelain surface layer, carbon dioxide in the atmosphere is absorbed to a certain extent, oxygen is released, the carbon sequestration function is achieved, a wall capable of breathing is formed on the surface of a building, and the action plan of carbon peak reaching and carbon neutralization is assisted.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com