A repairing material for building wall cracks

A repair material and a technology for building walls, which are applied in the field of repair materials for cracks in building walls, can solve problems such as repeated cracks in walls, and achieve the effects of not easy to fall off, high adhesion, and low market price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

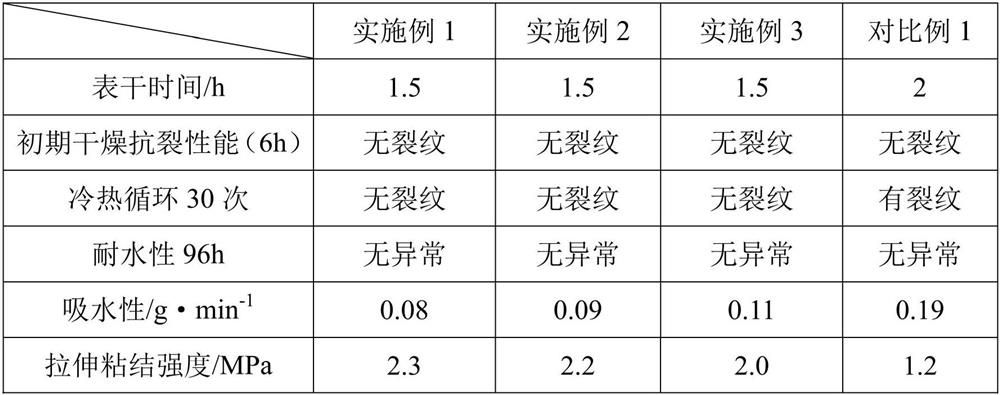

Examples

Embodiment 1

[0019] (1) According to the parts by weight of the components, respectively weigh 0.2 parts of silicon dioxide, 0.3 parts of talcum powder, and 0.3 parts of Na 2 O CaO 6SiO 2 0.2 parts, quartz sand 0.06 parts, cement clinker (cement clinker includes C 3 S / C 2 S / 3CaO.Al 2 o 3 , and C 2 S+C 3 S accounts for 67% of the total cement clinker, CaO and SiO 2 Mass ratio greater than 2) is 4 parts, hydroxypropyl methylcellulose is 3 parts, sodium tripolyphosphate is 15 parts, polypropylene short fiber with a length of 8mm is 3 parts, fly ash is 5 parts, gypsum is 6 parts 1.5 parts of grinding aid, 2 parts of superfine admixture and 18 parts of water.

[0020] (2) Silica, talc, Na 2 O CaO 6SiO 2 , quartz sand, cement clinker, hydroxypropyl methylcellulose, sodium tripolyphosphate, polypropylene short fiber, fly ash, gypsum, grinding aids and superfine admixtures are mixed and then added to the crushing mixer to prepare The particle size of the mixture is 15um.

[0021] (3) Mi...

Embodiment 2

[0024] (1) According to the parts by weight of the components, respectively weigh 0.1 parts of silicon dioxide, 0.4 parts of talcum powder, and 0.4 parts of Na 2 O CaO 6SiO 2 0.1 part, 0.02 part of barium carbonate, 0.02 part of boric acid, cement clinker (cement clinker includes C 3 S / C 2 S / 3CaO.Al 2 o 3 , and C 2 S+C 3 S accounts for 67% of the total cement clinker, CaO and SiO 2 Mass ratio greater than 2) is 8 parts, hydroxypropyl methylcellulose is 1 part, sodium tripolyphosphate is 3 parts, polypropylene short fiber with a length of 13mm is 5 parts, pozzolanic mixed material is 2 parts, gypsum is 11 parts, 0.4 parts of grinding aid, 4 parts of superfine admixture and 10 parts of water.

[0025] (2) Silica, talc, Na 2 O CaO 6SiO 2 , barium carbonate, boric acid, cement clinker (cement clinker includes C 3 S / C 2 S / 3CaO.Al 2 o 3 , and C 2 S+C 3 S accounts for 67% of the total cement clinker, CaO and SiO 2 The mass ratio is greater than 2), hydroxypropyl methy...

Embodiment 3

[0029] (1) According to the parts by weight of the components, respectively weigh 0.3 parts of silicon dioxide, 0.2 parts of talcum powder, and 0.2 parts of Na 2 O CaO 6SiO 2 0.3 parts, barite 0.04 parts, cement clinker (cement clinker includes C 3 S / C 2 S / 3CaO.Al 2 o 3 , and C 2 S+C 3 S accounts for 67% of the total cement clinker, CaO and SiO 2 Mass ratio greater than 2) is 2.5 parts, hydroxypropyl methylcellulose is 4 parts, sodium tripolyphosphate is 25 parts, polypropylene short fiber with a length of 10 mm is 1 part, granulated blast furnace slag is 8 parts, gypsum is 1 part, 3 parts of grinding aid, 0.2 part of superfine admixture and 13 parts of water.

[0030] (2) Silica, talc, Na 2 O CaO 6SiO 2 , barite, cement clinker (cement clinker includes C 3 S / C 2 S / 3CaO.Al 2 o 3 , and C 2 S+C 3 S accounts for 67% of the total cement clinker, CaO and SiO 2 The mass ratio is greater than 2), hydroxypropyl methylcellulose, sodium tripolyphosphate, polypropylene sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com