Stain-resistant scrubbing-resistant colorful ceramic tile joint mixture as well as preparation method and application of mixture

A technology of colored tiles and caulking agent, which is applied in the field of tile caulking agent, can solve the problems of easy leaving traces, difficult cleaning, inconvenient construction, etc., and achieve the effect of avoiding the problem of alkali return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

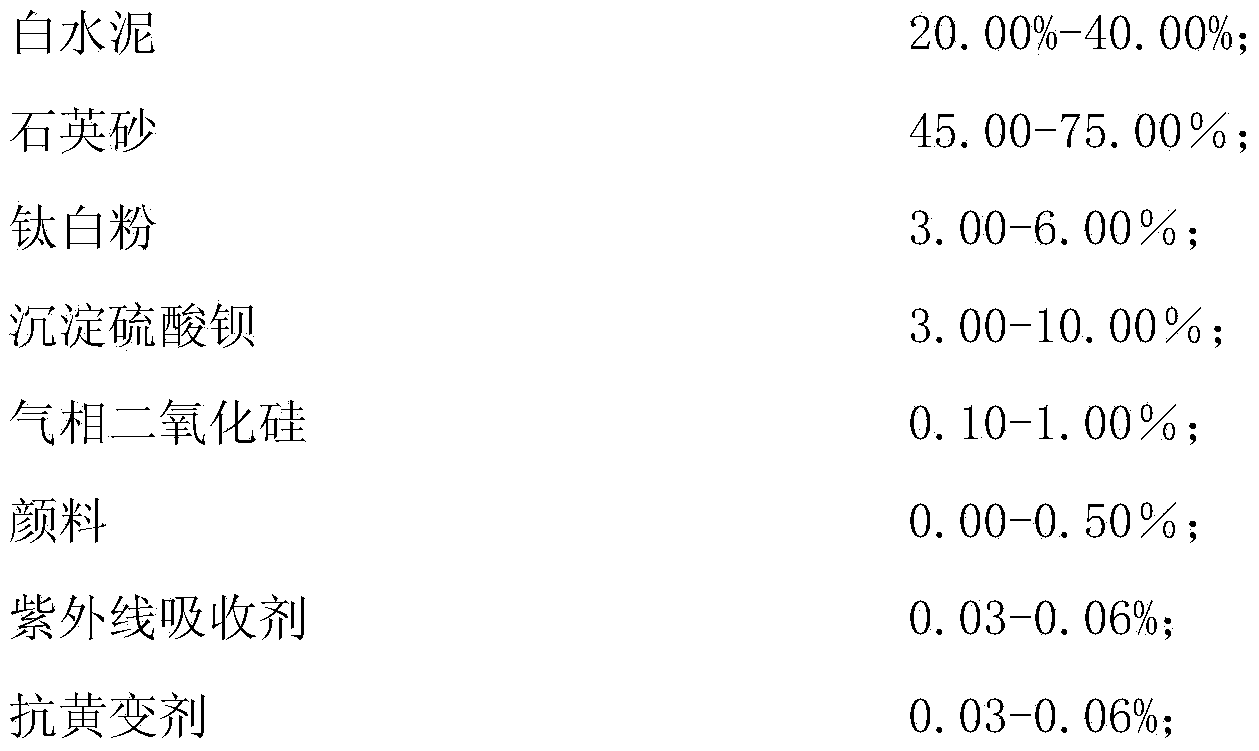

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 (unit Kg, the same below):

[0039] Epoxy resin 130.0

[0040] Epoxy resin curing agent 100.0

[0041] 52.5 Ordinary white Portland cement 140.0;

[0042] Quartz sand 505.0;

[0043] Titanium dioxide 22.0;

[0044] Precipitated barium sulfate 21.8;

[0045] Fumed silica 7.0;

[0046] Pigment 3.5;

[0047] UV absorber 0.42;

[0048] Anti-yellowing agent 0.28.

Embodiment 2

[0050] Epoxy resin 150.0

[0051] Epoxy resin curing agent 100.0

[0052] 52.5 Ordinary white Portland cement 140.0;

[0053] Quartz sand 505.0;

[0054] Titanium dioxide 22.0;

[0055] Precipitated barium sulfate 21.8;

[0056] Fumed silica 7.0;

[0057] Pigment 3.5;

[0058] UV absorber 0.42;

[0059] Anti-yellowing agent 0.28.

Embodiment 3

[0061] Epoxy resin 170.0

[0062] Epoxy resin curing agent 100.0

[0063] 52.5 Ordinary white Portland cement 140.0;

[0064] Quartz sand 505.0;

[0065] Titanium dioxide 22.0;

[0066] Precipitated barium sulfate 21.8;

[0067] Fumed silica 7.0;

[0068] Pigment 3.5;

[0069] UV absorber 0.42;

[0070] Anti-yellowing agent 0.28.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com