Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "No sticking problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

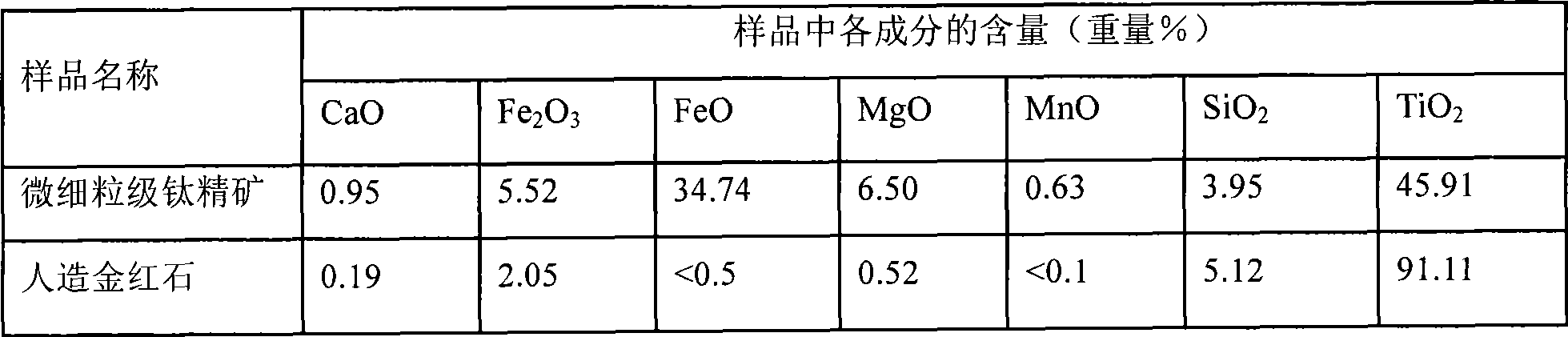

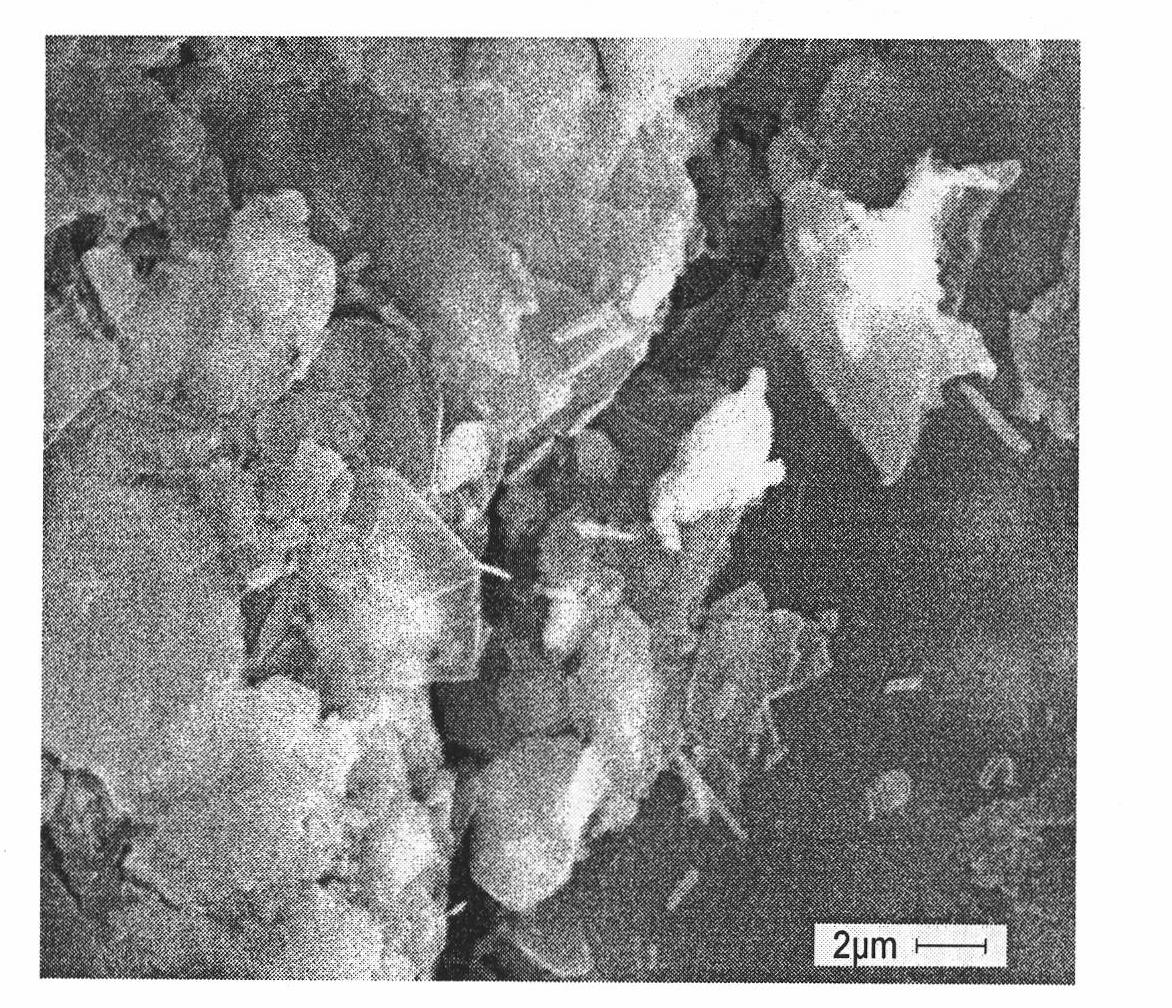

Preparation of synthetic rutile

The invention provides a method for preparing artificial rutile. The method comprises the following steps: titanium concentrate is subjected to oxidizing roasting and reducing roasting for removing impurities in oxidizing roasting products; and the products of which the impurities are removed are calcined, wherein the oxidizing roasting is performed in the presence of oxidizing gas, the reducing roasting is performed in the presence of reducing gas, and the oxidizing roasting and the reducing roasting are performed in a fluidized bed reactor. By adoption of the method, the high-grade artificial rutile can be prepared by adopting coarse fraction titanium concentrate as a raw material and can also be prepared by adopting micron-sized fraction titanium concentrate as the raw material.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

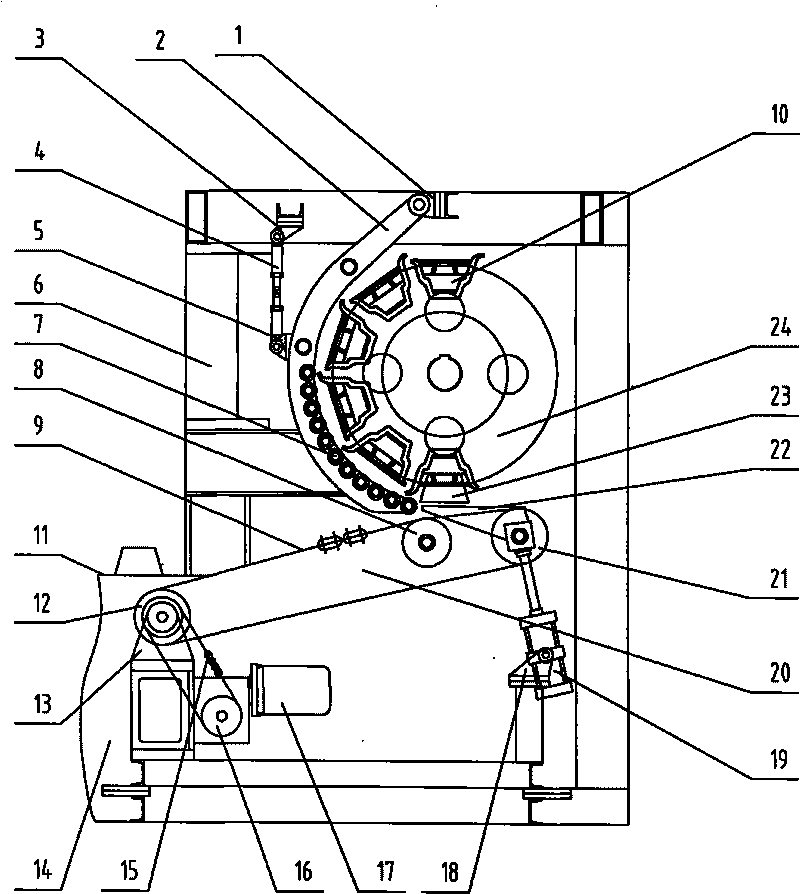

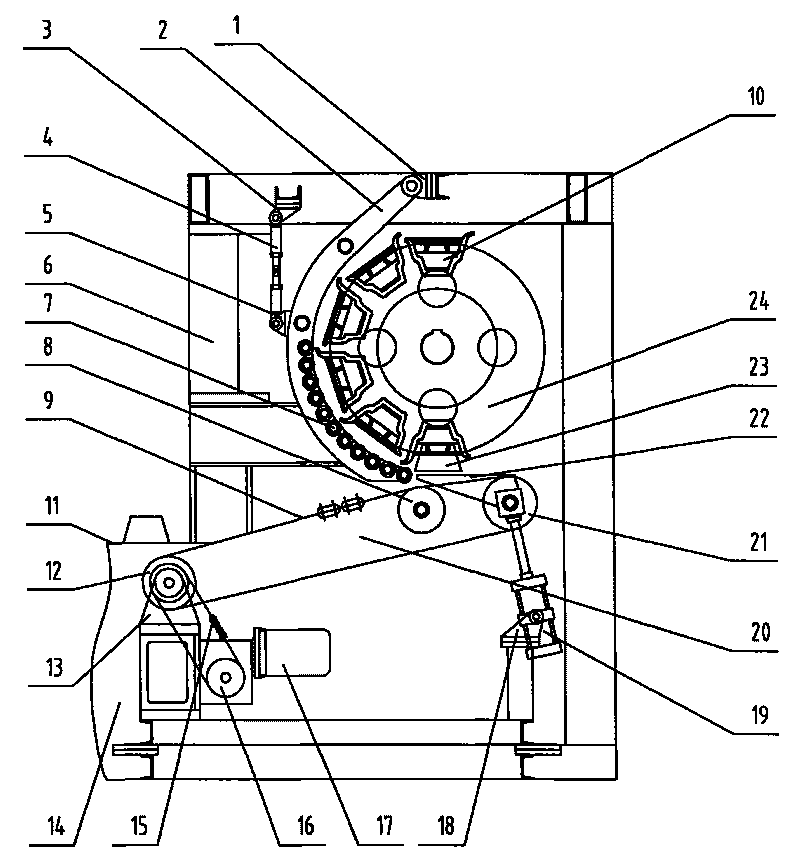

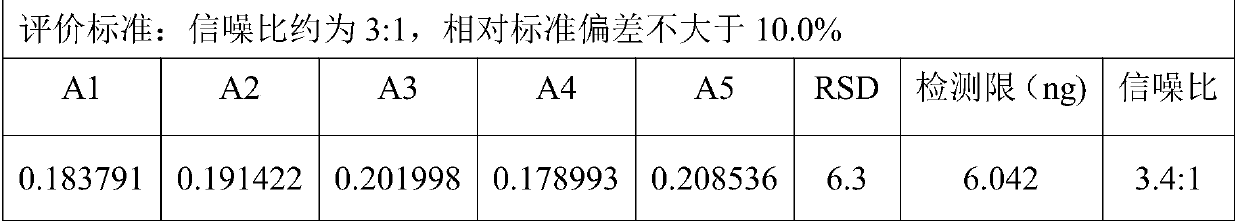

Ingot receiving device for non-ferrous metal continuous casting machine

The invention relates to an ingot receiving device for a non-ferrous metal continuous casting machine. A stand 6 is provided with a motor 17; a power output shaft of the motor 17 is connected with a drive sprocket 16; the drive sprocket 16 is connected with a double-sprocket 12 of a conveying chain component 20 through a chain 15; the double-sprocket 12 is arranged on the stand 6 through a first hinge seat 13; a cylinder 19 is arranged on the stand 6 through a second hinge seat 18; the end part of a piston rod of the cylinder 19 is connected with the conveying chain component 20; one end of the conveying chain component 20 and a casting film component of the casting machine are arranged correspondingly; and the other end of the conveying chain component 20 is arranged and a conveying chain 11 of a cooling conveyer 14 are arranged correspondingly. The ingot receiving device uses the cylinder as a power source, realizes automatic ingot receiving, fully controls the pace of the ingot receiving, avoids the ingot clamping and effectively improves the safety and reliability of the ingot receiving. The ingot receiving device is ultimately favorable for realizing automatization of the casting machine set and improving the production efficiency of the continuous casting machine set.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

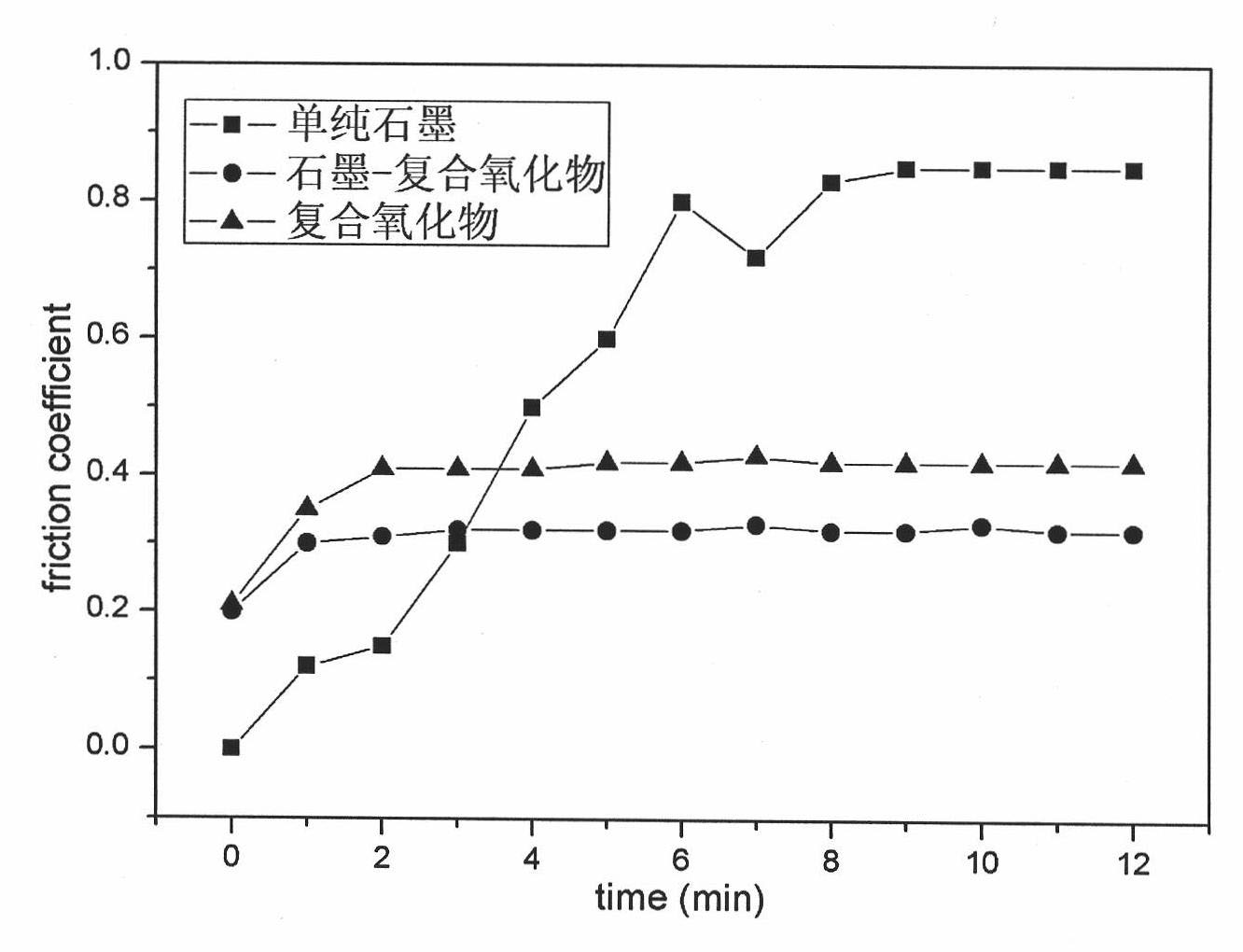

Graphite-oxide composite solid lubricant for hot-rolled seamless steel pipe and preparation method thereof

InactiveCN102093927AImprove carrying capacityGood friction and wear performanceLubricant compositionHigh loadSteel tube

The invention discloses a graphite-oxide composite solid lubricant for a hot-rolled seamless steel pipe and a preparation method thereof. The composite solid lubricant is mainly prepared by taking graphite, boric acid, serpentine, potassium titanate crystal whiskers and mica as main raw material and soluble silicate as adhesive agent by sufficiently stirring and mixing. The composite solid lubricant provided by the invention has high load-carrying capability, good frictional wear reduction performance and long wearing life, and overcomes the following frequently occurring problems of single-graphite solid lubricant: the vibration and noise are large, and the core rod is easy to adhere. During the application process, no noise is detected, the vibration of a rolling mill is small, the steel pipes and the core rods do not adhere, and the rod wrap accident is avoided. In addition, by using the composite solid lubricant, the steel pipe has smooth surface and is suitable for industrial production.

Owner:无锡润鹏复合新材料有限公司

Method for forming graphic pattern

InactiveCN101221889ANo sticking problemsPhotomechanical apparatusSemiconductor/solid-state device manufacturingResist

The invention discloses a method for forming pattern which comprises the following steps of: providing a base board which comprises a for-etching layer; forming a first resist layer on the base board; patterning the top part of the first resist layer; forming a second resist layer on the patterned first resist layer; removing part of the second resist layer; etching the second resist layer, the first resist layer and the for-etching layer. The method of the invention can form a fine pattern, the thickness of the resist layer not being too small. Therefore, the adhesion problem between the resist layer and the base board can not occur and the resist layer can not have the problem of being unable to protect the lower layer structure because of the intolerance of etching.

Owner:UNITED MICROELECTRONICS CORP

Wall base cloth and manufacturing method thereof

InactiveCN105625663AAvoid stickingAvoid the problem of self-performance degradationCovering/liningsSynthetic resin layered productsPlasticizerEngineering

The invention relates to wall base cloth and a manufacturing method thereof. The wall base cloth comprises a supporting base material and an outer water dispersibility polyurethane base layer, wherein the supporting base material comprises a polymer material layer containing one or more kinds of plasticizers, and the polymer material layer is arranged on the main surface of the supporting base material; and the outer water dispersibility polyurethane base layer is formed on the polymer material layer, so that the free surface of the wall base cloth is formed. The free surface of the wall base cloth basically does not contain the plasticizers.

Owner:GUANGDONG HUARUN PAINT CO LTD

Method and device for determining road occupation information

PendingCN114764853AStrong generalization abilityClear edgesImage enhancementImage analysisRegion of interestEdge enhancement

The invention discloses a road occupation information determination method and device, belongs to the field of computer vision, and can be used for auxiliary driving and automatic driving. The method comprises the steps that a first image is acquired, a first region of interest (ROI) is determined according to the first image, and the first ROI comprises at least one construction area marker; obtaining a first binary image of the ROI; performing edge enhancement processing on the at least one construction area marker in the first binary image to obtain a second binary image; obtaining a junction point set of the at least one construction area marker and the road surface according to the second binary image; and determining road occupation information of the at least one construction area marker according to the junction point set of the at least one construction area marker and the road surface, and sending the road occupation information. According to the method, the accuracy of determining the road occupation information of the construction area markers is improved, so that the decision-making accuracy of the vehicle in auxiliary driving and automatic driving is improved.

Owner:HUAWEI TECH CO LTD

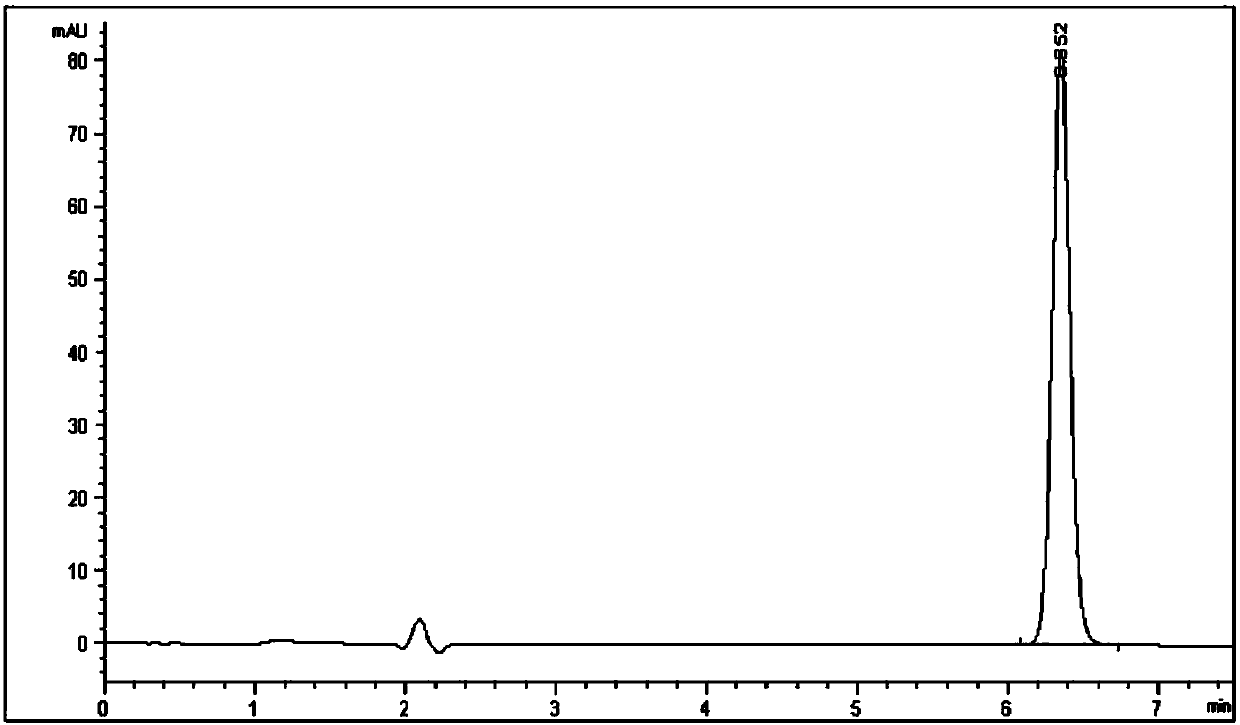

Determination method of main drug content in omeprazole solid preparation

The invention provides a determination method of a main drug content in an omeprazole solid preparation. A mixed solvent of sodium heptanesulfonate and acetonitrile is used as a mobile phase, methyl alcohol is used as a diluent, and high performance liquid chromatography (HPLC) is adopted for detecting. The determination method provided by the invention is subjected to methodology validation, andthe determination method of the main drug content in the omeprazole solid preparation provided by the invention has a great advantage on sample detection compared with a determination method of an existing detection technology on the content in the omeprazole solid preparation, so that the retention time of omeprazole can be stable, the separation degree is favorable, and the number of theoreticalplates can reach to 10000 or more; the solubleness of the omeprazole by methyl alcohol is favorable, and the problem of caking is solved; meanwhile, the error of manual operation is reduced, and thedetection accuracy is improved.

Owner:SHANGHAI SINE WANXIANG PHARMA +1

Carrageenan and preparation method thereof

The invention discloses carrageenan and a preparation method thereof. The carrageenan is prepared by carrying out alkali treatment on seaweed, washing, boiling glue, filtering, salting out precipitate, carrying out filter pressing, drying and crushing; in the steps of cleaning, carrying out alkali treatment, washing and boiling glue of the seaweed, the prevention step of avoiding the seaweed being wound on a stirring shaft and going bad is also performed. The prevention step refers to using an overload regulation mechanism to determine the amount of the seaweed on the stirring shaft; when too much seaweed is accumulated, a cutting mechanism is automatically started for cleaning the seaweed on the screw type stirring shaft, so that the seaweed is prevented from going bad, and the high quality of the carrageenan is guaranteed.

Owner:FUJIAN LVLI BIOTECH

Double-layer bletilla striata dressing

ActiveCN108904866ASolve solubilitySolve adhesionPharmaceutical delivery mechanismAbsorbent padsWound healingBletilla striata

The invention relates to double-layer bletilla striata dressing, and belongs to the technical field of biological medicines. The double-layer bletilla striata dressing is composed of a surface layer and a dressing layer, wherein the surface layer is composed of a hemostatic material poorly soluble or insoluble in water, the dressing layer is composed of a bletilla striata porous material having good biocompatibility and being easily soluble in water, for the structural design of interpenetrating network connection between the surface layer and the dressing layer, the integrated forming methodis adopted for realizing physical embedding, and a freeze-drying method is adopted for obtaining a lower dressing layer. The design has the advantages that structure is reasonable, the combination isfirm, the realization is easy, due to the poorly soluble surface layer, the problems that the dressing is difficult to take for use, easily has adhesion, has difficulty in applying, and is large in waste, are solved, due to the porous structure of the easily soluble dressing layer, the dressing rapidly dissolves for forming a protection film, thus the hemostasis efficacy is realized, and the optimal environment for wound healing is created. The dressing is integrally composed of the degradable and absorbable material, and is suitable for being applied to the fields of functional dressing and tissue engineering.

Owner:WUHAN TEXTILE UNIV

a soy milk machine

ActiveCN107495836BNo sticking problemsThere will be no burnt phenomenonBeverage vesselsBiotechnologyEngineering

The invention relates to a small kitchen electrical appliance and especially relates to a soybean milk machine. The machine comprises a machine head and a cup body, wherein the machine head comprises a machine head upper cover and a metal lower cover. The machine is characterized in that an anti-overflowing electrode rod is not disposed on the machine head; a water level identification line is disposed on the cup body; a first coating area coated by an insulated non-sticky coating and a first hollow area which is not coated by the insulated non-sticky layer are disposed on the outer wall of the metal lower cover; the first hollow area is located above the water level identification line; an anti-overflowing detection pole is formed by the first hollow area; an electric conduction pole is disposed on the cup body; the electric conduction pole is located under the water level identification line; and when soybean milk ascends, the electric conduction pole can communicate with the anti-overflowing detection pole, so anti-overflowing signals can be detected. Through application of the technical scheme, no anti-overflowing electrode rod is disposed on the soybean milk machine head, so the whole machine can be cleaned more easily; the anti-overflowing signals can be detected reliably and stably by the soybean milk machine; and plus, in comparison with the prior art, soybean milk adhesion does not take place to the soybean milk machine provided by the invention.

Owner:JOYOUNG CO LTD

A double-layer bletilla striata dressing

ActiveCN108904866BSolve solubilitySolve adhesionPharmaceutical delivery mechanismAbsorbent padsBletilla striataFreeze-drying

The invention relates to a double-layer bletilla striata dressing, which belongs to the technical field of biomedicine. The double-layer bletilla striata dressing of the present invention is made up of surface layer and dressing layer, and surface layer is made of insoluble or water-insoluble hemostatic material, and dressing layer is made of Bletilla striata porous material with good biocompatibility, easily soluble in water, between surface layer and dressing layer The structural design of the interpenetrating network connection adopts the physical mosaic of the integral molding method, and the lower dressing layer is obtained by the freeze-drying method. The design structure of the present invention is reasonable, the combination is firm, and it is easy to realize. The problem of large waste, the porous structure of the soluble dressing layer ensures that the dressing quickly dissolves to form a protective film to achieve hemostatic effect and create an optimal environment for wound healing. The whole dressing is composed of degradable absorbing material, which is suitable for application in the field of functional dressing and tissue engineering.

Owner:WUHAN TEXTILE UNIV

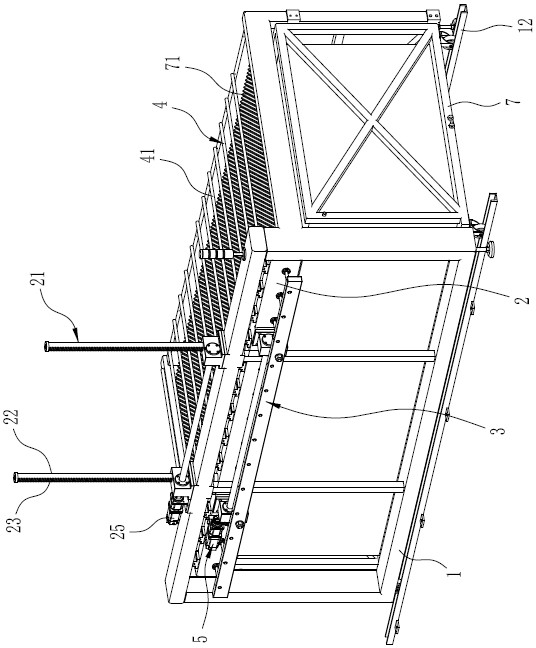

Water curtain block corrugated paper stacking system

InactiveCN114476801AAvoid driftingNo sticking problemsPile receiversStructural engineeringIndustrial engineering

The invention discloses a water curtain block corrugated paper stacking system which comprises a machine base, a stacking position used for stopping a stacking carrier is arranged on the machine base, a lifting base is installed on the machine base and located on one side of the stacking position, and a lifting control device is arranged between the lifting base and the machine base. A bracket capable of extending to the position above the stacking position is transversely installed on the lifting base in a penetrating and sliding mode, the bracket is used for bearing input corrugated paper, and a paper floating preventing device is arranged on the lifting base. The machine base is provided with a stacking channel facilitating descending of the bracket into the stacking position, the lifting base is provided with a pulling-away control device capable of transversely pulling the bracket away from the position above the stacking position, and a paper positioning device is fixedly arranged on the lifting base in the pulling-away direction of the bracket. According to the automatic stacking device, waved corrugated paper with the single face coated with glue can be automatically stacked, stacking is neat, and automatic production of water curtain blocks in a matched mode is facilitated.

Owner:青州市祥力轻工设备有限公司

A needle-free electrospinning device for porous materials

ActiveCN104988586BNo sticking problemsNo cloggingFilament/thread formingPorous mediumElectrospinning

The invention relates to a porous material syringe needle-free static spinning apparatus characterized in that a spinning buffering cylinder of a spinning system is cylindrical; the upper and lower ends of the spinning buffering cylinder are conical; a liquid outlet is formed in the lower end of the spinning buffering cylinder; the diameter of the hole is 3 to 20mm; a porous medium sleeve is arranged on the lower end of the spinning buffering cylinder; the spinning buffering cylinder is connected with a power device via a copper core clamp; an outward extraction electrode of a copper core of the copper core clamp is connected with a power supplying system; an aperture formed in the top end of the spinning buffering cylinder is connected with a liquid discharging end of a liquid supplying device via a liquid supplying pipeline; a liquid charging end of the liquid supplying device is connected with a liquid storage case; and a receiving plate faces right under the liquid outlet formed in the lower end of the spinning buffering cylinder. Special spinning assemblies are employed, so spinning quality can be greatly improved and spinning evenness can be guaranteed; and the porous material syringe needle-free static spinning apparatus is characterized by simple technology, easy industrial application and wide application range.

Owner:CHINA FIRST AUTOMOBILE

Glassware coated with non-sticky coating layer, and preparation technology thereof

ActiveCN110330233AComply with health requirementsImprove bindingEpoxy resin coatingsSurface layerSpray coating

The invention discloses a glassware coated with a non-sticky coating layer. The glassware coated with a non-sticky coating layer comprises a glass base body; the glass base body possesses an internalsurface; the internal surface is coated with the non-sticky coating layer; the non-sticky coating layer and the internal surface of the glass base body are connected through a binding layer; the non-sticky coating layer comprises a bottom layer and a surface layer; and preferably, the glass base body is prepared from high borosilicate glass. The invention also discloses preparation technology of the glassware. The preparation technology comprises steps of glassware internal surface pre-treatment, binding layer spraying coating, bottom layer spraying coating, surface layer spraying coating, andsintering, so that a finished product is obtained at last. According to the preparation technology, glass surface sand-blast treatment is avoided, and coating of the binding layer is adopted, the entire effect is improved, the non-sticky coating layer possesses excellent combination force with the glass base body, the glassware surface is not sticky, is convenient to clean, possesses corrosion resistance and high temperature resistance, and is long in service life.

Owner:NINGBO RE COOK IMP & EXP CO LTD

Filtering check valve and side block with same

PendingCN114413038AEffort-saving removal of threadsNo sticking problemsCheck valvesValve housingsIsocyanatePolyurea

The invention relates to a filtering check valve and a side block with the filtering check valve. The filtering check valve is used on a spray gun for spraying rapid solidification materials such as polyurethane foam and polyurea. The invention aims to solve the problem that the side block is difficult to disassemble and easy to damage. In order to achieve the purpose, a side sealing box and a filtering check valve in the side block are each provided with an O-shaped ring which is matched with a side block shell in a sealing mode, the installation positions of the O-shaped rings are closer to fluid than threads, and therefore the fluid cannot make contact with the threads at the fixing positions of the side sealing box, the filtering check valve and the side block shell. Therefore, the problem of thread adhesion caused by crystallization and solidification of components such as resin or isocyanate at the thread is solved, so that the thread is very labor-saving to disassemble, and the thread is not damaged.

Owner:JINAN ABURE MASCH EQUIP CO LTD

Depth-adjustable outer plate punch forming device for computer production

InactiveCN113305224AFor automatic positioningReduce damage rateShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a depth-adjustable outer plate punch forming device for computer production, and relates to the technical field of computer part production equipment. In order to solve the problem that the damage rate is increased due to the fact that an outer plate is fixed, the device specifically comprises a machine body, and an automatic containing structure is arranged on the outer wall of the top of the machine body; and combined grooves are formed in the inner walls of the opposite sides of the machine body and comprise inclined grooves or horizontal grooves, a plurality of elastic rubber columns are arranged on the inner walls of the bottoms of the inclined grooves, a buffering air bag is fixedly connected to the inner wall of one side of each horizontal groove, and a plurality of buffers are fixedly connected to the inner wall of one side of each buffering air bag. During punching, a plate is shaped in a punching die, the plate on the peripheral edge of the punching die extends outwards while being punched, and the two buffering air bags, a front buffering assembly and a rear extrusion assembly are extruded in the reverse direction, so that impact force during shaping is relieved, the purpose of reducing the damage rate of the plate is achieved, the qualification rate of plate stamping forming is effectively increased, and plate loss is reduced.

Owner:京山亿捷电脑有限公司

Full-width manufacturing method of diamond picture

PendingCN112744016AReduce gapImprove the picture effectSievingDecorative surface effectsMetallurgyMaterials science

The invention discloses a full-width manufacturing method of a diamond picture, and aims to provide the full-width manufacturing method of the diamond picture, and the full-width manufacturing method not only can greatly reduce gaps among diamonds on the diamond picture and enable the diamonds on the diamond picture to be densely arranged according to requirements so as to improve the picture effect of the diamond picture, but also can solve the problem of sticking of the diamonds during manufacturing of the diamond picture. The method comprises the following steps that A, diamond screening through a diamond screening machine, wherein diamond screening through the diamond screening machine comprise single-row template diamond screening and double-row template diamond screening; and B, pasting single-row diamonds and double-row diamonds, and pasting the single-row diamonds and the double-row diamonds in sequence, wherein a plurality of rows of diamonds formed on an adhesive layer of drawing paper in the step of pasting the single-row diamonds and a plurality of rows of diamonds formed on an adhesive layer of drawing paper in the step of pasting the double-row diamonds are sequentially and alternately arranged and distributed.

Owner:夏芳

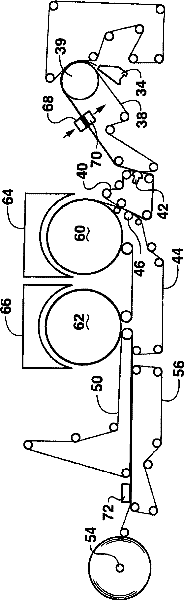

Chained ingot receiving mechanism used for continuous casting production line of aluminum ingot

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

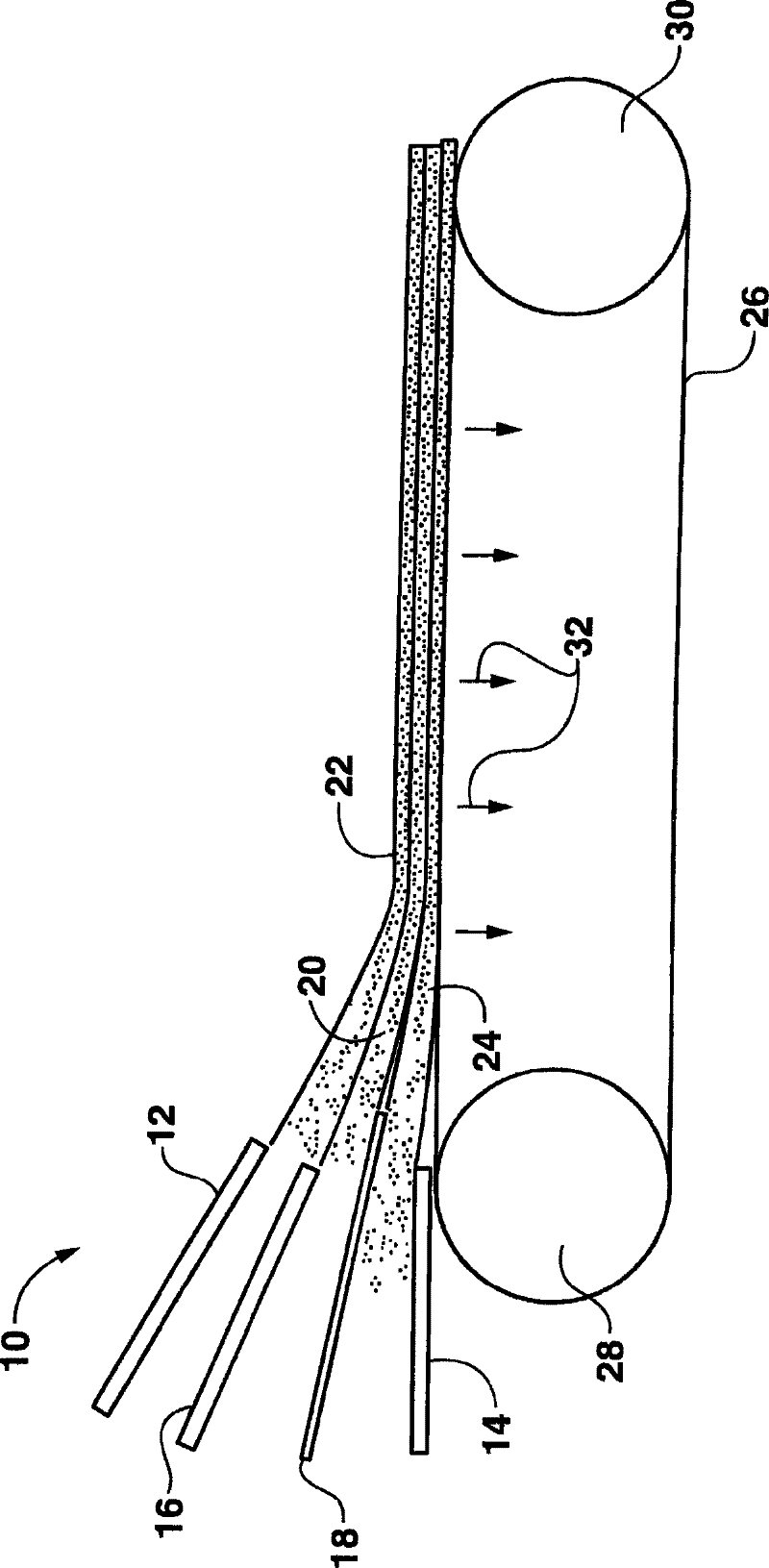

Process for producing tissue products

InactiveCN101553619BDoes not increase hardnessWill not affect the performance of absorbing liquidReinforcing agents additionPaper/cardboardPolymer scienceAdhesive

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an alpha-olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The alpha-olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web as the web is being formed. Alternatively, the additive composition may be topically applied to the web in a post processing operation. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive duringa creping operation.

Owner:KIMBERLY-CLARK WORLDWIDE INC

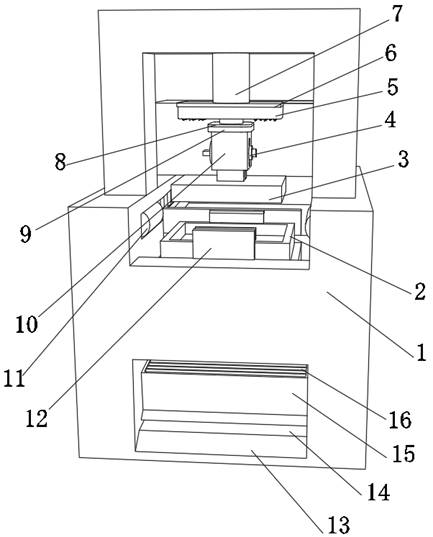

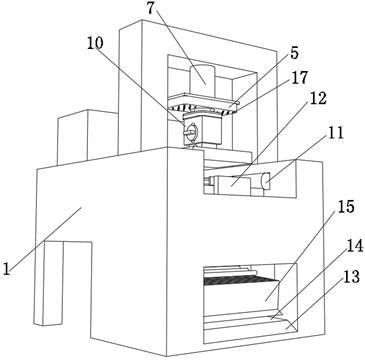

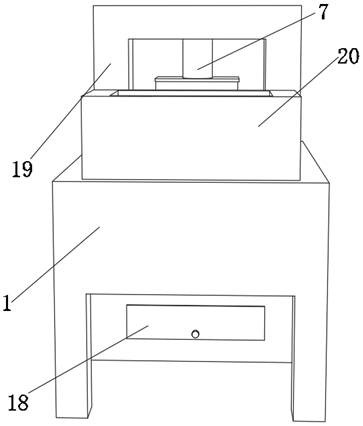

Ingot receiving device for non-ferrous metal continuous casting machine

The invention relates to an ingot receiving device for a non-ferrous metal continuous casting machine. A stand 6 is provided with a motor 17; a power output shaft of the motor 17 is connected with a drive sprocket 16; the drive sprocket 16 is connected with a double-sprocket 12 of a conveying chain component 20 through a chain 15; the double-sprocket 12 is arranged on the stand 6 through a first hinge seat 13; a cylinder 19 is arranged on the stand 6 through a second hinge seat 18; the end part of a piston rod of the cylinder 19 is connected with the conveying chain component 20; one end of the conveying chain component 20 and a casting film component of the casting machine are arranged correspondingly; and the other end of the conveying chain component 20 is arranged and a conveying chain 11 of a cooling conveyer 14 are arranged correspondingly. The ingot receiving device uses the cylinder as a power source, realizes automatic ingot receiving, fully controls the pace of the ingot receiving, avoids the ingot clamping and effectively improves the safety and reliability of the ingot receiving. The ingot receiving device is ultimately favorable for realizing automatization of the casting machine set and improving the production efficiency of the continuous casting machine set.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Capacitive pressure sensor with high linearity and manufacturing method thereof

ActiveCN105606269AHigh sensitivityHigh feasibilityForce measurementFluid pressure measurement using capacitance variationCapacitive pressure sensorElastic component

The invention discloses a capacitive pressure sensor with high linearity. The pressure sensor comprises a silicon substrate layer, a silicon dioxide layer and a polysilicon layer which are successively arranged from bottom to top. The silicon substrate layer is provided with a first cavity and four lower electrodes. The silicon dioxide layer is provided with a polysilicon supporting layer and a second cavity. The second cavity is connected to the first cavity. The polysilicon layer comprises a movable sensitive film layer, four upper electrodes and a polysilicon anchor area. One end of each upper electrode is connected to one end surface of the movable sensitive film layer through a connecting rod. The other end of each upper electrode is connected to the polysilicon anchor area through an elastic component. The lower electrodes are located below the connecting rod. End surfaces of the upper electrodes, which are close to the movable sensitive film layer, and end surfaces of the lower electrodes, which are far away from the first cavity, are in a same surface. The pressure sensor converts a longitudinal displacement change into a transverse area change so that the high linearity is possessed. Simultaneously, upper and lower pole plates of the pressure sensor are non-contacted so that device reliability is increased.

Owner:SOUTHEAST UNIV

Aqueous polyamide dispersion and preparation method thereof

The invention provides an aqueous polyamide dispersion. The aqueous polyamide dispersion comprises the following components in parts by weight: 25-35 parts of polyamide micropowder, 2-6 parts of an emulsifier, 1-3 parts of an emulsifying dispersing agent, 1-3 parts of a wetting agent and 60-65 parts of water. The invention also provides a preparation method of the aqueous polyamide dispersion. Themethod comprises the following steps of: 1, adding 25-35 parts of the polyamide micropowder to 60-65 parts by weight of the water; 2, adding 2-6 parts by weight of the emulsifier to an aqueous polyamide micropowder solution prepared in the step 1; 3, adding 1-3 parts of the emulsifying dispersing agent to a solution prepared in the step 2; and 4, adding 1-3 parts of the wetting agent to a solution prepared in the step 3. The aqueous polyamide dispersion provided by the invention has the beneficial effects that the smoothness and the wearing easiness of a PVC (Poly Vinyl Chloride) labor protection glove are improved and the compatibility with other substances in a powder-based water slurry product is good.

Owner:青岛奥开工业材料有限公司

A capacitive pressure sensor with high linearity and its preparation method

ActiveCN105606269BHigh sensitivityHigh feasibilityForce measurementFluid pressure measurement using capacitance variationCapacitive pressure sensorSilicon oxide

The invention discloses a capacitive pressure sensor with high linearity. The pressure sensor comprises a silicon substrate layer, a silicon dioxide layer and a polysilicon layer arranged sequentially from bottom to top; the silicon substrate layer is provided with a first cavity and four a lower electrode; a polysilicon support layer and a second cavity are provided in the silicon dioxide layer, and the second cavity communicates with the first cavity; the polysilicon layer includes a movable sensitive film layer, four upper electrodes, and a polysilicon anchor region, each One end of each upper electrode is connected to one end of the movable sensitive film layer through a connecting rod, the other end of each upper electrode is connected to the polysilicon anchor area through an elastic member, the lower electrode is located below the connecting rod, and the upper electrode is close to the movable sensitive film layer. The end face of the thin film layer and the end face of the lower electrode away from the first cavity are in the same plane. The pressure sensor converts the longitudinal displacement change into the transverse area change, has high linearity, and at the same time, the upper and lower plates of the pressure sensor are non-contact, which improves the reliability of the device.

Owner:SOUTHEAST UNIV

Stirring device for chemical industry

PendingCN114768616ATo achieve the purpose of coolingAchieve cooling speedRotary stirring mixersTransportation and packagingChemical industryEngineering

The invention relates to a related device for chemical engineering, in particular to a stirring device for chemical engineering, which comprises a cylinder body, a cooling mechanism, a power mechanism and a stirring mechanism, the cooling mechanism is slidably installed in a groove arranged on the cylinder body, the cylinder body is in threaded connection with the cooling mechanism, the power mechanism is fixedly installed on the cylinder body, and the stirring mechanism is fixedly installed on the cylinder body. The stirring mechanism is mounted in a groove formed in the power mechanism in a sliding manner, and the stirring mechanism is meshed with the power mechanism; according to the device, vortexes of different sizes can be formed for stirring, various stirring requirements are met, newly-added powdery materials can be rapidly fed into the middle position of liquid, material mixing is accelerated, the dust phenomenon of a material adding opening is avoided, the liquid near the inner wall of the cylinder body can be kept to flow all the time, the uniform mixing speed is increased, and the stirring efficiency is improved. And meanwhile, the device can perform cooling treatment.

Owner:北京中科金源环保科技有限公司

Slitting method of double-sided acrylic coated film

The invention provides a slitting method of a two-sided crylic acid coating film. The slitting method comprises the following steps of: correctly loading a two-sided crylic acid coating film to be slit on an unreeling shaft and then inflating air and well fixing, stringing the film to a reeling shaft by a guide roll, and setting specific unreeling tension, reeling tension, weight of a pressure roll at the reeling part and drawing-up speed according to the roll film width of the double-sided crylic acid coating film; and starting up, pressing an acceleration button to reach a set drawing-up speed, beginning to reduce speed till the film on the unreeling shaft to run by about 100m remaining, pressing a stop button after the film runs out, and labeling the roll film. The end surface of the roll film of the slit coating film is flat and even (the width difference is + / -0.2mm), and no adhesion problem is caused after the two-sided crylic acid coating film is placed for 6 months.

Owner:HAINAN SHINER IND

Glassware coated with non-stick coating and its preparation process

ActiveCN110330233BImprove bindingSimplify processing stepsEpoxy resin coatingsGlass vesselBorosilicate glass

The invention discloses a glass vessel coated with a non-stick coating, which comprises a glass substrate, the glass substrate has an inner surface, the inner surface is coated with a non-stick coating, and the gap between the non-stick coating and the inner surface of the glass substrate is The transition is connected by an adhesive layer, wherein the non-stick coating includes a bottom layer and a surface layer; preferably, the glass substrate is made of high borosilicate glass. The invention also discloses a preparation process of the glassware coated with the non-stick coating, which includes pretreatment of the inner surface of the glassware, spraying of the adhesive layer, spraying of the bottom layer, spraying of the surface layer, and sintering to finally obtain the product. The glassware of the present invention avoids the sandblasting treatment on the glass surface but adopts the method of spraying a layer of bonding layer, the overall effect is improved, the non-stick coating has good bonding force with the substrate, and the surface of the vessel is non-stick, easy to clean, corrosion-resistant, High temperature resistance, long service life.

Owner:NINGBO RE COOK IMP & EXP CO LTD

Method for treating valuable secondary materials such as electronic waste through oxygen inclined blowing rotary converter

PendingCN114657379AEasy to controlWell formedMaintainance of heating chambersFurnace typesSlagRaw material

The invention discloses a method for treating valuable secondary materials such as electronic waste through an oxygen inclined blowing rotary converter. The method comprises the following steps: (1) material preparation: pretreating valuable secondary materials such as electronic wastes; (2) burdening: burdening the following components in percentage by mass: 62-92% of valuable secondary materials such as electronic wastes, 5-20% of scrap iron or iron shots, 2-10% of quartz stone or silicon powder and 1-8% of limestone; (3) smelting and deslagging: continuously adding materials, smelting under an oxygen-enriched condition, pouring out slag when the quantity of melt in the furnace is close to the position of a furnace mouth, continuously feeding and smelting, and repeating the operation for multiple times until crude copper liquid in the furnace is close to the furnace mouth; (4) blowing: blowing industrial oxygen or oxygen-enriched air into the furnace, blowing for 30-120 minutes, sampling and observing, and finishing blowing after conditions are met; and (5) discharging: pouring out the crude copper liquid through a furnace mouth, casting the crude copper liquid into an ingot shape, and leaving furnace slag in the furnace to enter the next operation furnace period. The method is efficient, energy-saving, environment-friendly, high in recovery rate and high in raw material adaptability.

Owner:LANZHOU HUAYE TECH ENG CO LTD

Anti-adherence protection patch for electronic product package

The invention discloses an anti-adherence protection patch for electronic product package. The patch comprises an HC (Hydrocarbon Compound) layer, an OCA (Optically Clear Adhesive) layer, an optical PET (Polyethylene Glycol Terephthalate) layer, a silica gel layer and a release membrane which are arranged in sequence. The anti-adherence protection patch has high permeability and haze, problems that a conventional protection patch for electronic product package has long-term transportation abrasion, scratching damage caused in use, electrostatic adherence, and the like, can be solved, the problem that a common HC is adhered to a packaging box since a surface is particularly flat can be avoided because of a designed planar microcosmic concave-convex structure, meanwhile, the flexibility of the protection patch can be improved, then the patch can be easily fitted with an electronic product with radians or curved surfaces, and in addition, the silica gel layer is easy in adherence and goodin bubble elimination effect and can be repeatedly used.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

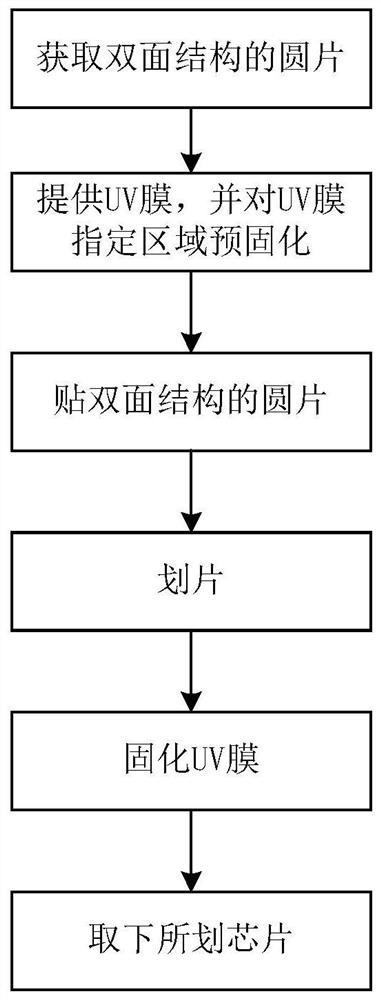

Scribing method of wafer with double-sided structure

PendingCN114093814AReduce viscosityNo sticking problemsSemiconductor/solid-state device manufacturingSemiconductorSemiconductor technology

The invention discloses a scribing method for a wafer with a double-sided structure, and relates to the technical field of semiconductors, and the method comprises the steps: obtaining the wafer with the double-sided structure; providing a UV film, and performing pre-curing treatment on a specified area of the UV film; enabling one side of the wafer to be attached to the UV film, so that the pre-cured designated area completely covers the chip area on the wafer; scribing the wafer attached with the UV film to complete the separation of the chips on the wafer; and carrying out secondary curing treatment on the UV film, and taking down the chip. According to the method for pre-curing the designated area of the UV film, the viscidity in the designated area of the UV film is reduced to the degree that the structural surface of the wafer cannot be damaged, and the viscidity of the UV film outside the designated area is not reduced, so while the structural surface is protected, the effect of fixing the wafer can be achieved, and after final cutting, the problem that the structure of the chip is stuck by the UV film is avoided, and the yield is improved.

Owner:无锡微视传感科技有限公司

Porous material syringe needle-free static spinning apparatus

ActiveCN104988586AImprove spinning efficiencyFinished silk uniformFilament/thread formingPorous mediumPower apparatus

The invention relates to a porous material syringe needle-free static spinning apparatus characterized in that a spinning buffering cylinder of a spinning system is cylindrical; the upper and lower ends of the spinning buffering cylinder are conical; a liquid outlet is formed in the lower end of the spinning buffering cylinder; the diameter of the hole is 3 to 20mm; a porous medium sleeve is arranged on the lower end of the spinning buffering cylinder; the spinning buffering cylinder is connected with a power device via a copper core clamp; an outward extraction electrode of a copper core of the copper core clamp is connected with a power supplying system; an aperture formed in the top end of the spinning buffering cylinder is connected with a liquid discharging end of a liquid supplying device via a liquid supplying pipeline; a liquid charging end of the liquid supplying device is connected with a liquid storage case; and a receiving plate faces right under the liquid outlet formed in the lower end of the spinning buffering cylinder. Special spinning assemblies are employed, so spinning quality can be greatly improved and spinning evenness can be guaranteed; and the porous material syringe needle-free static spinning apparatus is characterized by simple technology, easy industrial application and wide application range.

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com