Ingot receiving device for non-ferrous metal continuous casting machine

A technology for non-ferrous metals and casting machines, which is applied in the field of ingot-connecting devices for non-ferrous metals continuous casting machines. It can solve problems such as complex mechanism design, high technical difficulty, and damage to ingot casting machines, so as to improve safety and reliability, and improve safety. Performance and productivity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

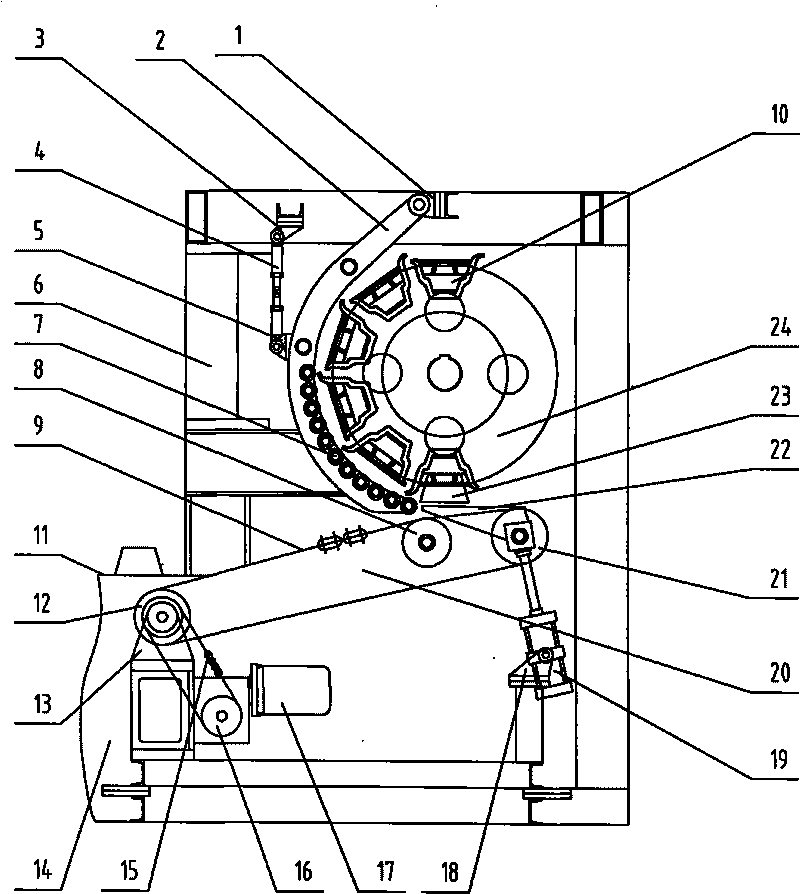

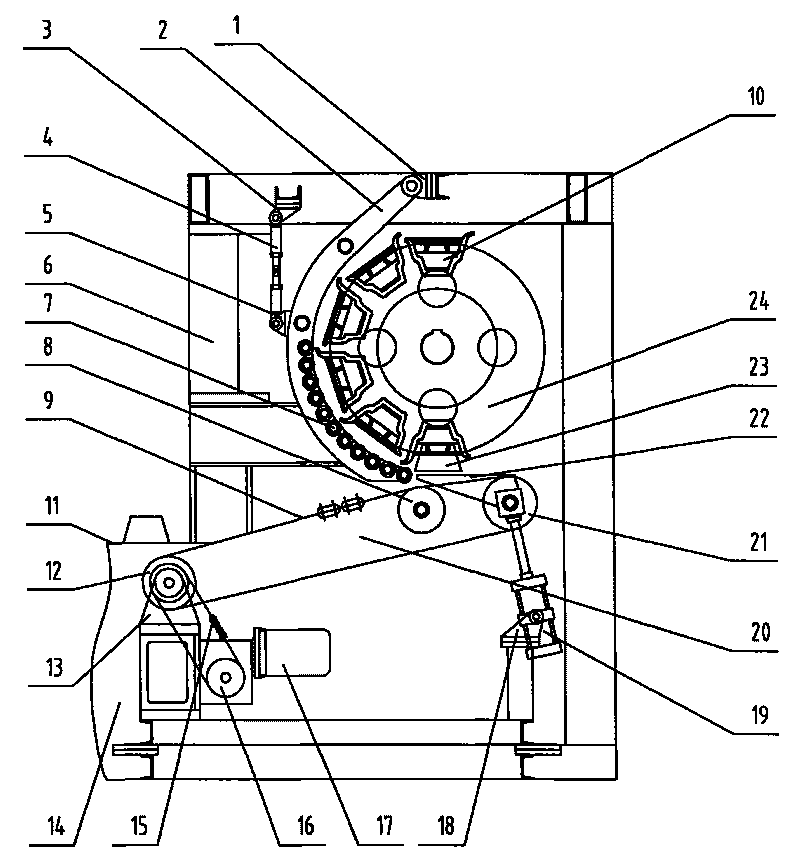

[0007] Such as figure 1 As shown, the described ingot connecting device for non-ferrous metal continuous casting machine includes a frame 6, which is characterized in that it also includes: the frame 6 is provided with a motor 17, and the power output shaft of the motor 17 is connected to the Drive sprocket 16 links to each other, and drive sprocket 16 links to each other with the duplex sprocket 12 of conveyor chain assembly 20 by chain 15, and duplex sprocket 12 is installed on the frame 6 by the first hinge seat 13; Cylinder 19 is passed the second hinge The seat 18 is installed on the frame 6, the piston rod end of the cylinder 19 is connected with the conveying chain assembly 20, and one end of the conveying chain assembly 20 is arranged correspondingly to the cast film assembly of the casting machine; the other end of the conveying chain assembly 20 is connected to the cooling conveyor 14 Chain 11 corresponding setting. The end of the piston rod of the cylinder 19 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com