Preparation of synthetic rutile

An artificial rutile, oxidation roasting technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of ineffective removal, low grade of artificial rutile, unsuitable for titanium tetrachloride, etc., and achieve easy control and reduce energy consumption , to avoid the effect of local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0008] The invention provides a method for preparing artificial rutile. The method comprises: oxidative roasting and reduction roasting of titanium concentrate, removal of impurities in the product of reduction roasting, and calcining of the product after removal of impurities. The reduction roasting is carried out under a reducing gas; wherein, the oxidation roasting and reduction roasting are carried out in a fluidized bed reactor.

[0009] The titanium concentrate recovered from the tailings after extracting iron concentrate from the vanadium-titanium magnetite (raw ore) in the Panxi area mainly contains iron metatitanate (FeO·TiO 2 ) crystals, and solid solutions of oxide impurities such as magnesium, manganese, aluminum, vanadium, and silicon. There are generally two methods for recovering titanium concentrate from the above tailings, namely gravity separation and gravity separation plus flotation. The TiO in the titanium concentrate obtained by gravity separation from th...

Embodiment 1

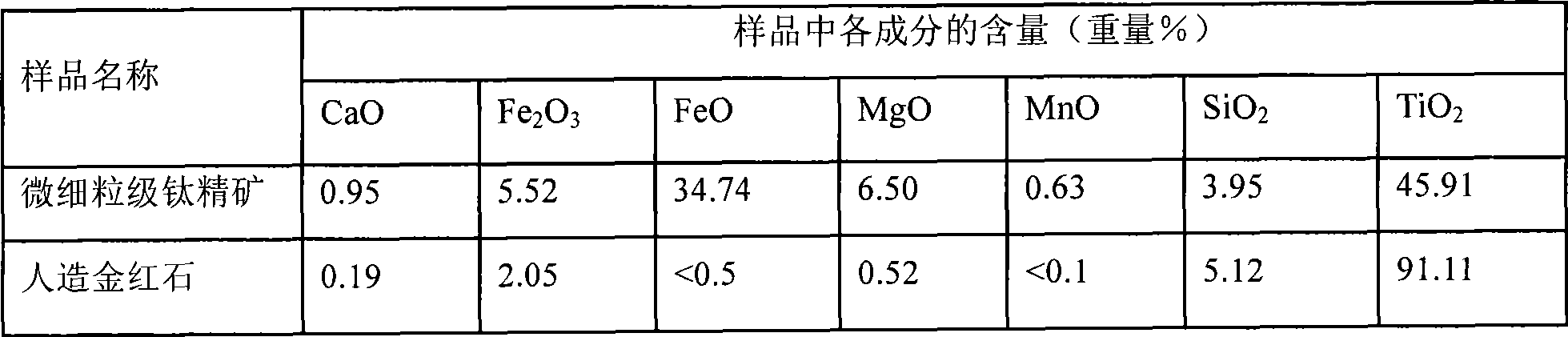

[0031] a. Oxidation roasting: get 20 kilograms of fine-grained titanium concentrates (purchased from Panzhihua Iron and Steel Group's fine-grained titanium concentrates (20# ore), see Table 1 for chemical composition analysis, and see Table 2 for particle size analysis), first at 650 After preheating in the preheater at ℃, it enters the fluidized oxidation furnace (that is, the fluidized bed reactor during oxidation, including the separation section, the settling section and the reaction section interconnected from top to bottom) for oxidation and roasting. Among them, the titanium concentrate enters the reaction section from the feed pipe at the bottom of the fluidized bed reactor, the air enters the reaction section from the reaction gas inlet at the bottom of the fluidized oxidation furnace, and the oxidized roasted product enters the reaction section from the fluidized oxidation furnace. The discharge pipe of the settling section of the furnace is output, and the oxidizing ...

Embodiment 2

[0043] Prepare artificial rutile according to the method described in embodiment 1, the difference is,

[0044] a, in oxidation roasting, the flow velocity of regulating air is 1 cubic meter / hour, the feeding speed of titanium concentrate is 20 kilograms / hour, makes the ratio of the flow velocity of titanium concentrate and the flow velocity of air be 20 kilograms / cubic meter, air The linear velocity in the fluidized oxidation furnace is 0.65 m / s, the temperature of oxidation roasting is 850 DEG C, the pressure of oxidation roasting is 20 kPa, and the oxidation roasting time is 90 minutes;

[0045] In the reduction roasting, the flow rate of the coke oven gas is adjusted to be 1 cubic meter per hour, and the feed rate of the product of the oxidation roasting is 20 kg per hour, so that the ratio of the flow rate of the product of the oxidation roasting to the flow rate of the coke oven gas is 20 kg / hour cubic meter, the linear velocity of coke oven gas in the fluidized reductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com