Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Meet different process needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding tool and method for electromagnetic plastic friction stir welding

InactiveCN103028838AReduce distortionImprove plasticityNon-electric welding apparatusEngineeringFriction stir welding

The invention discloses a welding tool and method for electromagnetic plastic friction stir welding, which relates to the welding tool and method for friction stir welding and solves the problems of residual stress, hole defect and poorer welding performance in an existing friction stir welding head. The welding tool is characterized in that 2-8 bar magnets are respectively arranged in 2-8 bar magnet grooves, and gaps are arranged between a connecting body and a clamping hole. The method comprises the following steps of 1, packaging insulation paper on the connecting body, arranging the connecting body in the clamping hole, arranging a strong magnet in a strong magnet groove, and arranging the bar magnets in the bar magnet grooves; 2, respectively adhering one conducting plate at the end surface positions at two ends of an abutting part of a to-be-welded workpiece, and respectively connecting an anode and a cathode of an additional power supply to the conducting plates which are arranged at the two ends; 3, enabling the current size to meet the requirement that the density of the current passing the workpiece to be larger than a critical value (106A / m<2>) of electroplasticity, and controlling the resistance thermal power of the workpiece to be under 100W; and 4, carrying out the electromagnetic plastic friction stir welding. The welding tool and the method, disclosed by the invention, are used for the friction stir welding of aluminum alloy, magnesium alloy, copper alloy and dissimilar materials.

Owner:HARBIN INST OF TECH

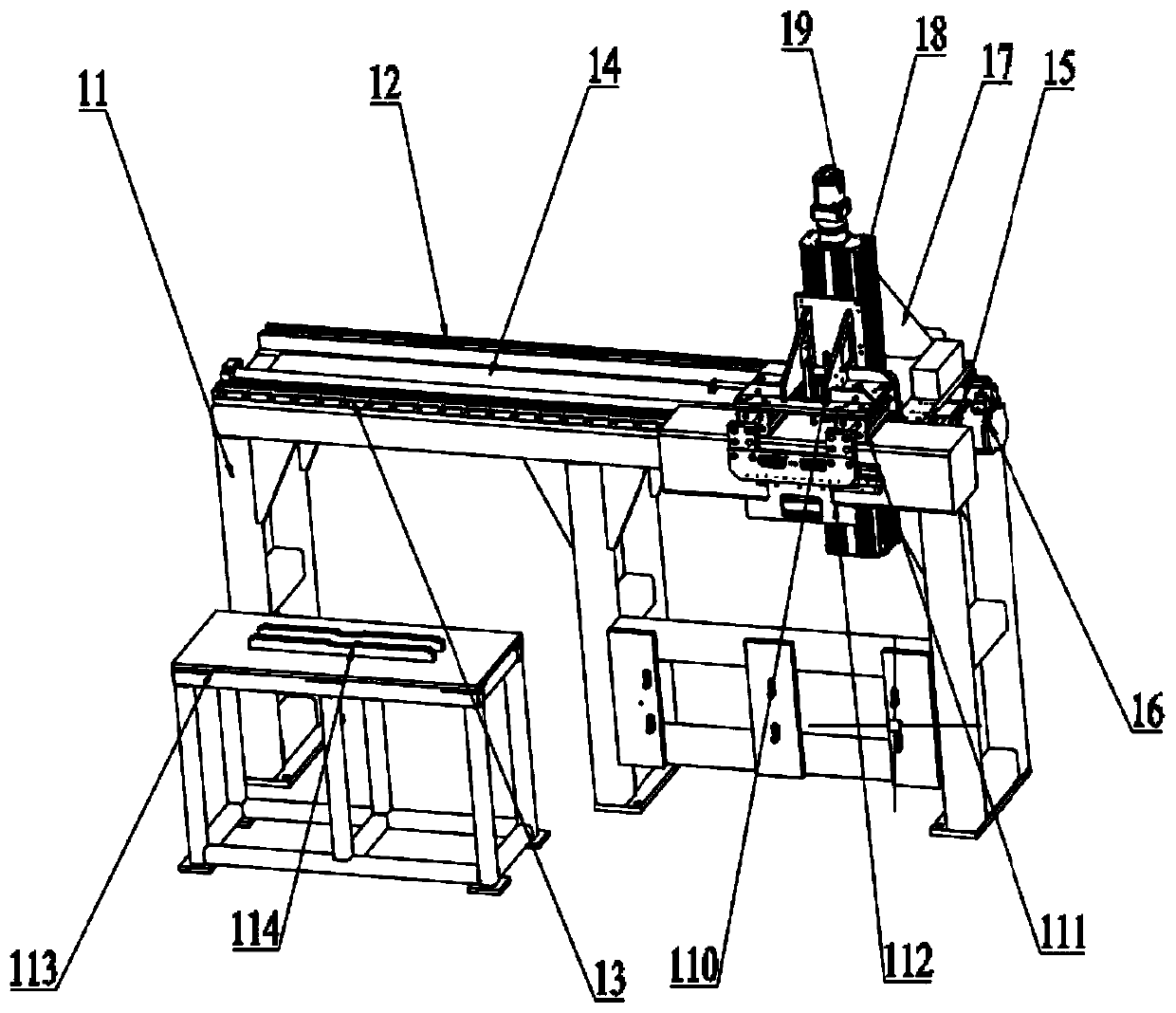

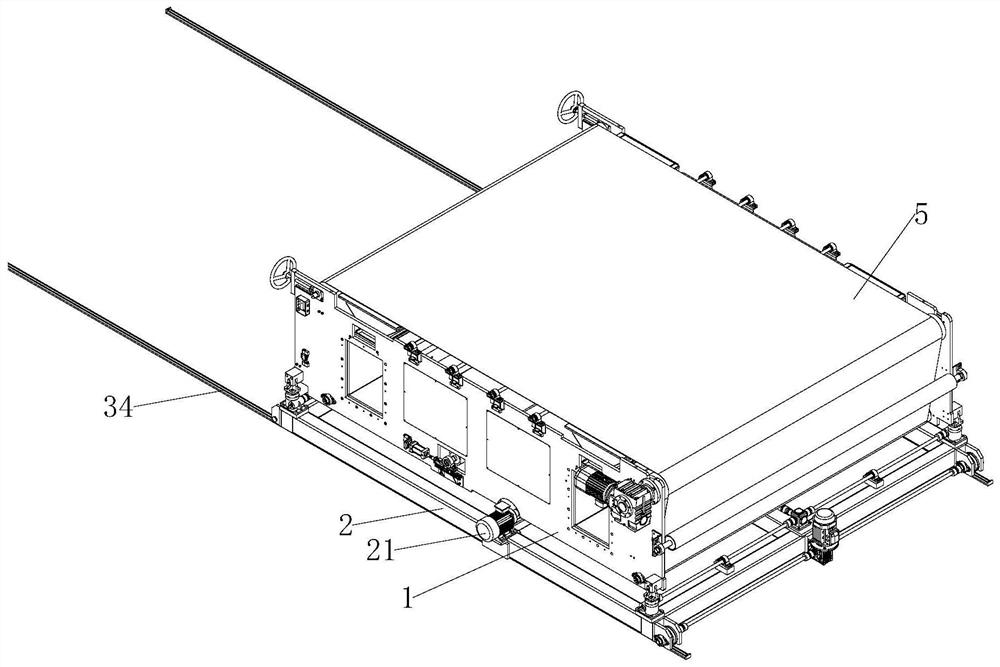

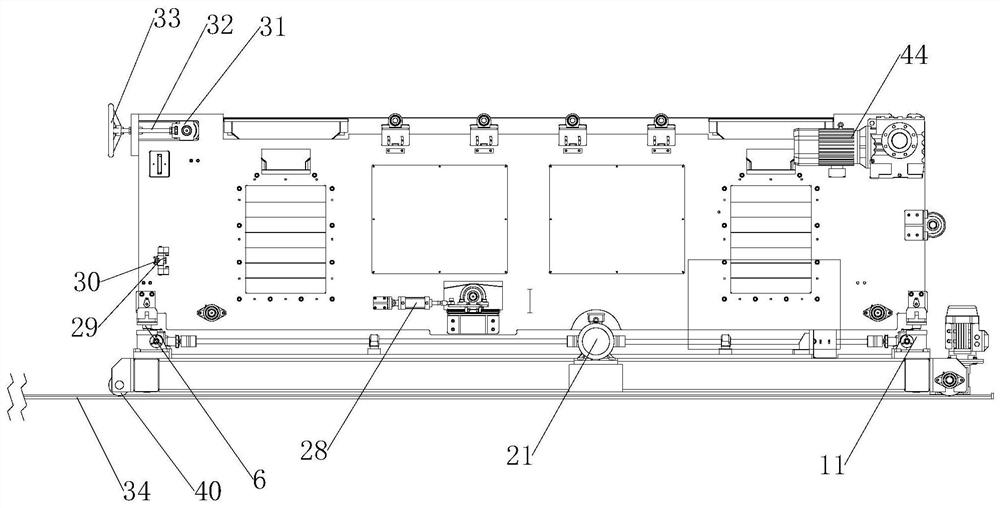

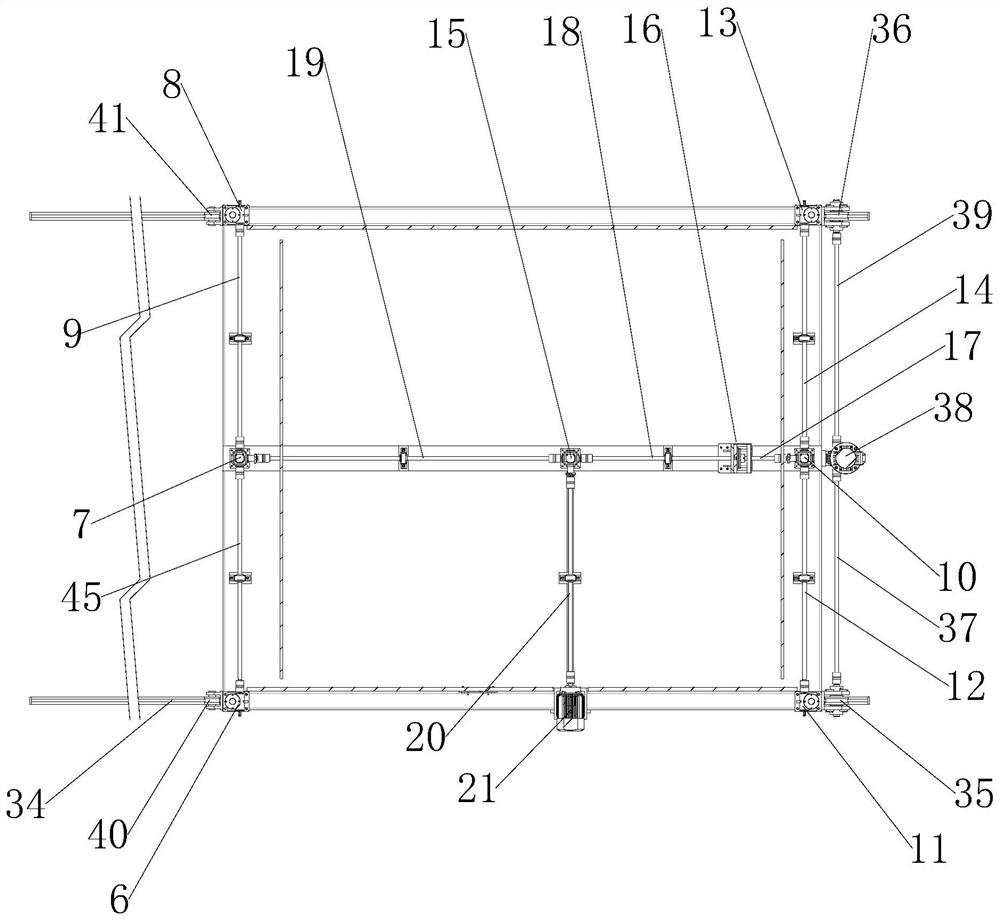

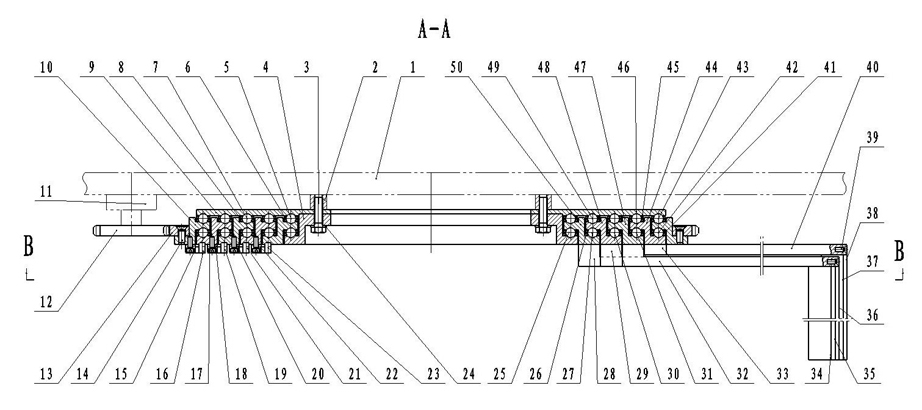

Full-automatic silicon single-crystal rod rolling and grinding integrated equipment

ActiveCN106475878AReduce time between processesImprove processing efficiencyGrinding carriagesGrinding drivesManipulatorEcological environment

The invention relates to silicon single-crystal rod machining equipment and aims to provide full-automatic silicon single-crystal rod rolling and grinding integrated equipment which comprises a long-strip-shaped large bottom frame. Two parallel main guide rails are arranged on the surface of the large bottom frame in the length direction. A grinding work table assembly is movably installed on the two main guide rails, and a main driving motor drives a connecting mechanism so that the grinding work table assembly can move along the main guide rails. Four platforms used for bearing are arranged on the two sides of the large bottom frame and used for bearing a coarse grinding power head assembly, a fine grinding power head assembly, a feeding mechanical hand assembly and a centering mechanical hand assembly correspondingly. A crystal orientation detecting device and a radius detecting unit are further arranged on the large bottom frame. The machining range of the crystal rod rolling and grinding equipment is widened greatly, the machining ability of the crystal rod rolling and grinding equipment is improved greatly, and a silicon bar can be centered automatically; the machining efficiency is improved, and cost of manpower and logistics is saved; long and stable high-precision operation of the equipment can be ensured; and the production noise is remarkably reduced, no organic matter emission is generated, less waste is generated, and the ecological environment is protected.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

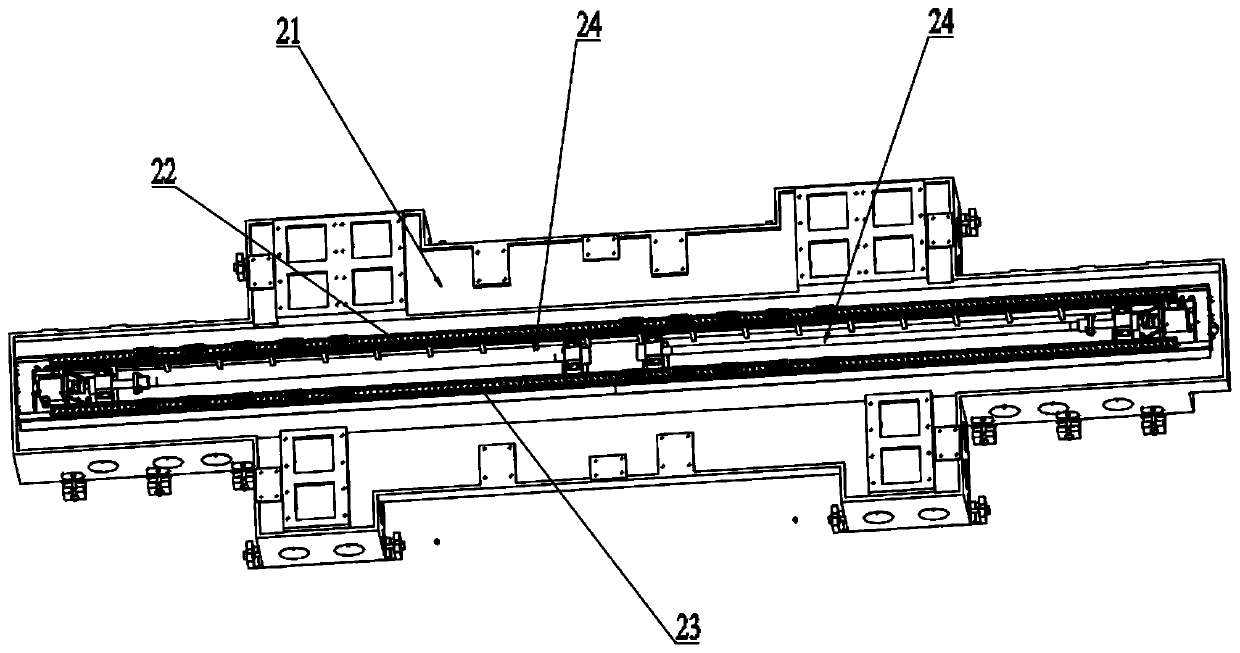

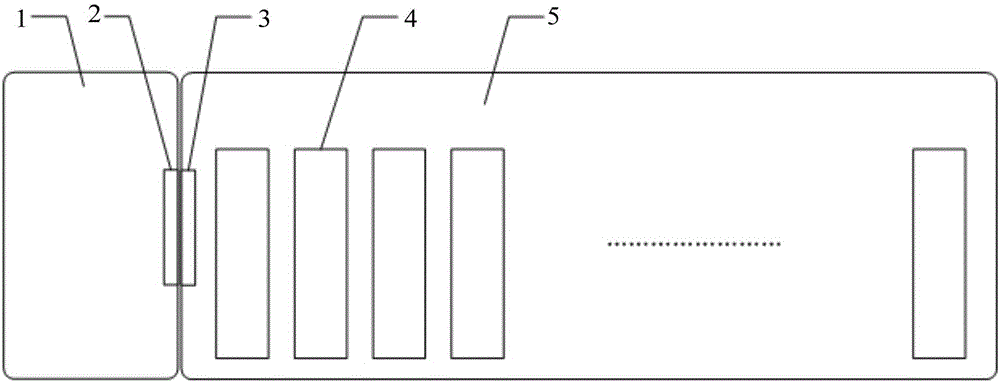

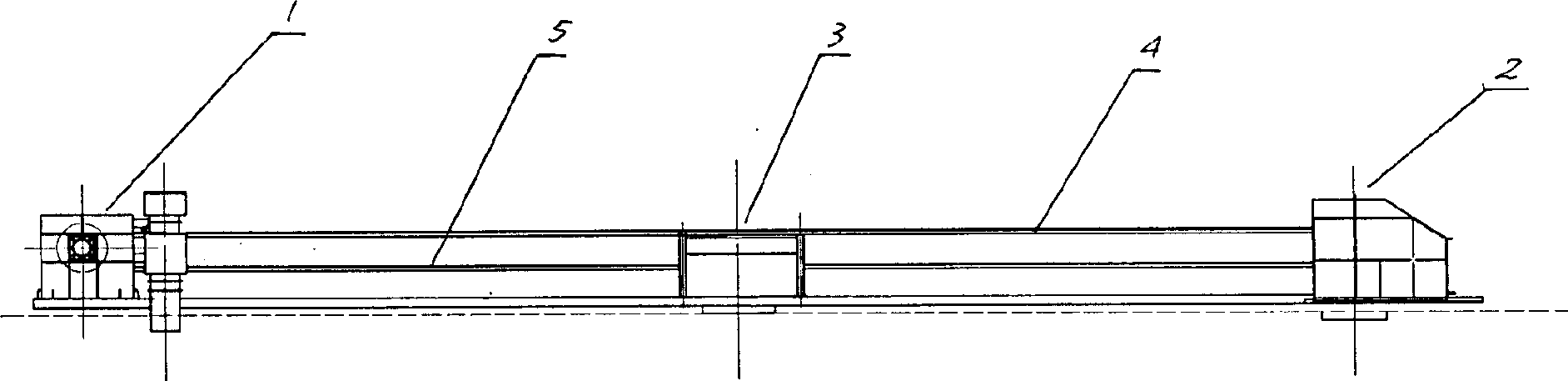

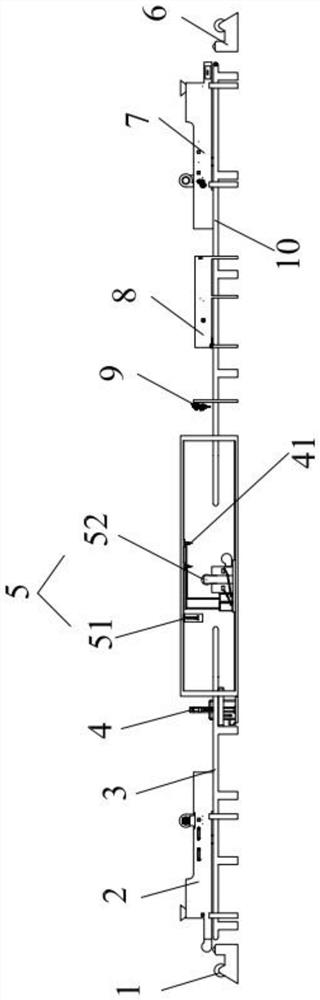

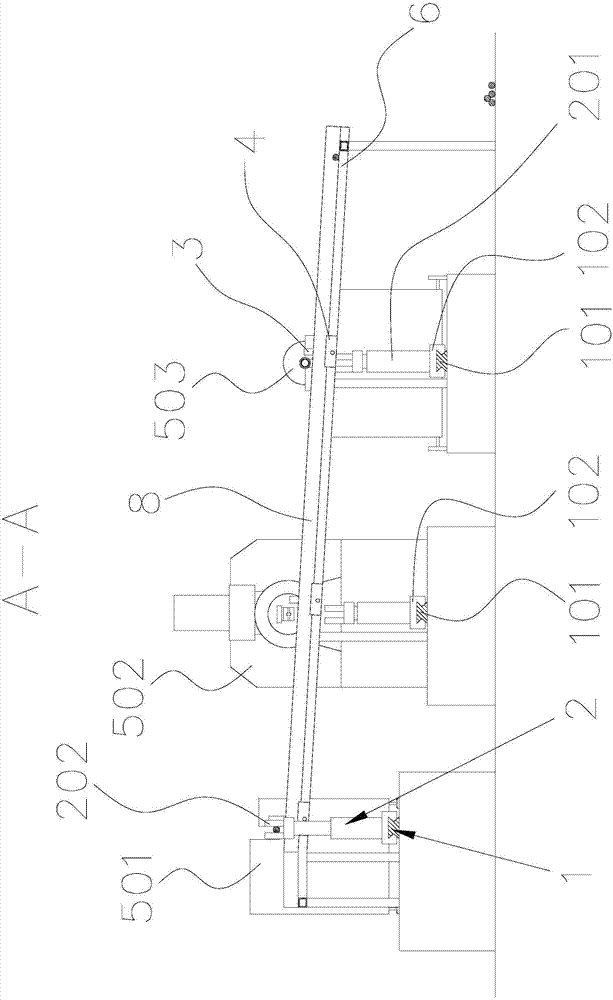

Automatic reinforcing steel bar thread machining production line

ActiveCN105690100AOccupy less laborSmall footprintOther manufacturing equipments/toolsProduction lineEngineering

The invention belongs to the field of building material processing machinery, and in particular relates to an automatic reinforcing steel bar thread machining production line which comprises a conveying mechanism and a plurality of moving mechanisms, wherein the moving directions of the moving mechanisms are perpendicular to the conveying direction of the conveying mechanism; a plurality of lifting clamping devices are arranged on the moving parts of the moving mechanisms; clamping openings of the lifting clamping devices face reinforcing steel bars on the conveying mechanism; machining equipment is arranged at two ends of the moving mechanisms; a limiting block is rotationally connected with one side of a reinforcing steel bar machined by each machining equipment on the conveying mechanism; rotation limiting positions of the limiting blocks are all above the conveying surface of the conveying mechanism; the other rotation limiting positions are below the conveying surface of the conveying mechanism. The automatic reinforcing steel bar thread machining production line has the beneficial effects that the reinforcing steel bars do not need to be moved and loaded and unloaded manually, so that the labor can be saved, and the machining efficiency can be improved; the occupied area is small; the reinforcing steel bars can roll under the action of gravity of self, so that the energy can be saved and the emission can be reduced; the automation degree is high, and the labor intensity is low; a baffle can be aligned with the reinforcing steel bars, a gradually shrunk channel has a guide function, and good thread machining quality can be achieved.

Owner:无锡天盈建筑科技有限公司

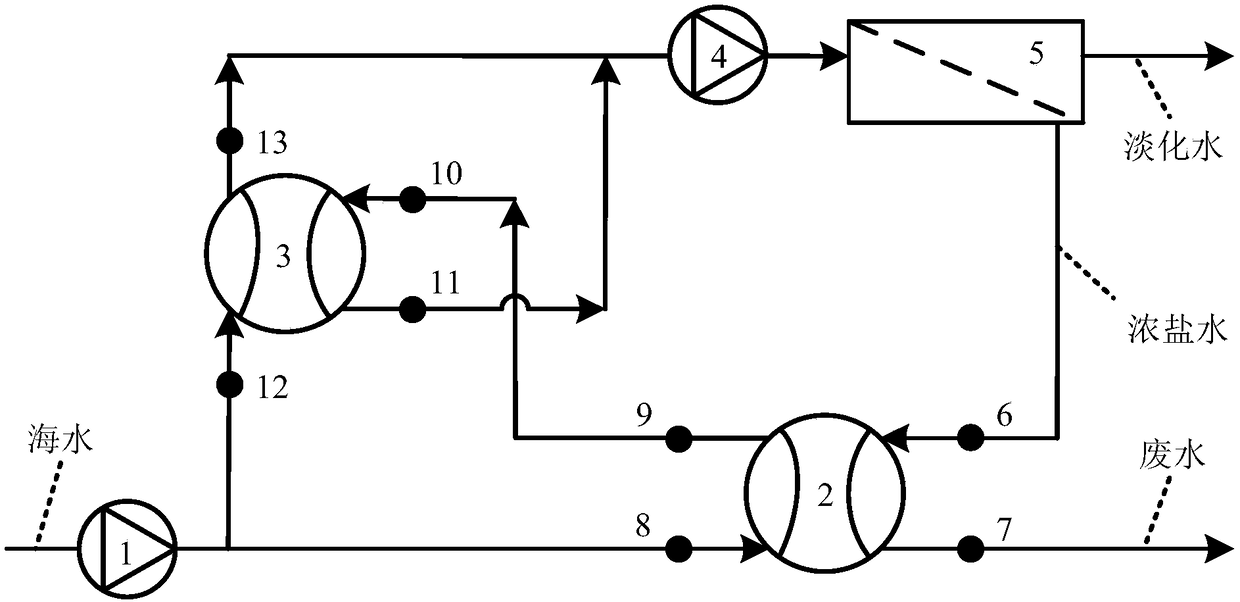

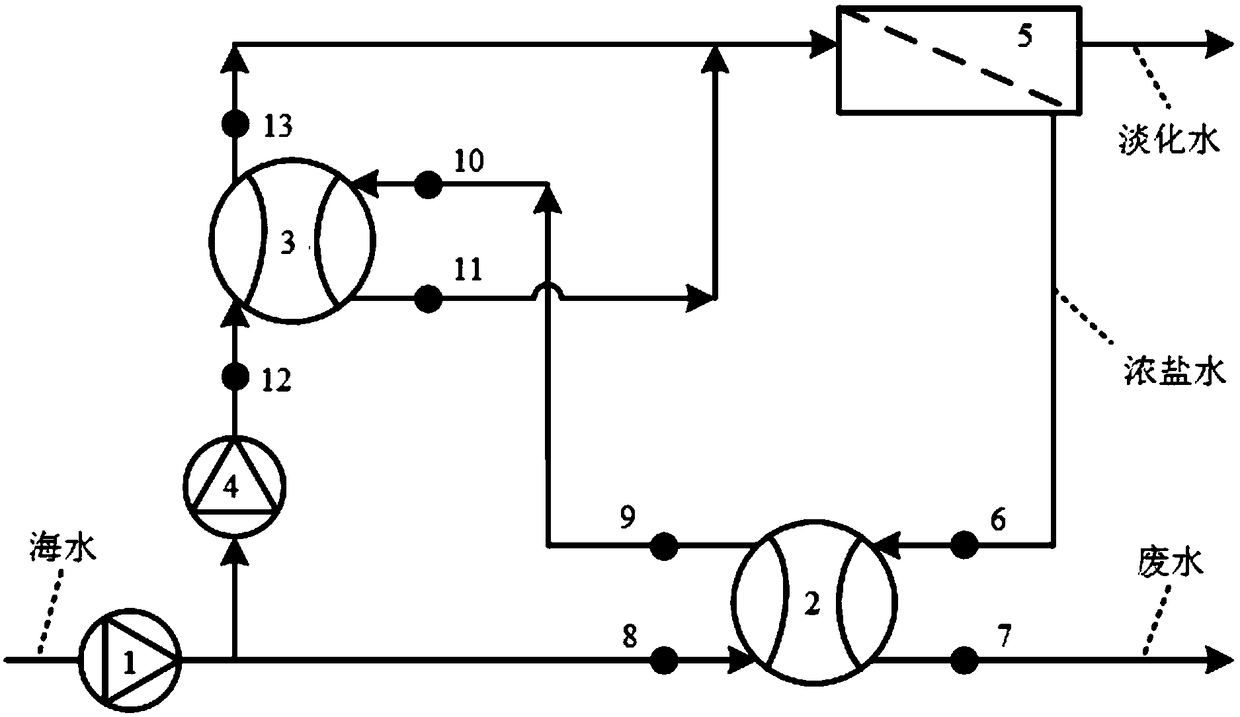

Reverse osmosis seawater desalination system with two-stage residual pressure recovery and seawater desalination treatment method based on same

ActiveCN109305720ACompact structureEasy to useGeneral water supply conservationSeawater treatmentSaline waterProcess engineering

The invention discloses a reverse osmosis seawater desalination system with two-stage residual pressure recovery, and a seawater desalination treatment method based on the same. The reverse osmosis seawater desalination system comprises a seawater supply pump, a high-pressure pump, two sets of pressure energy exchangers and a membrane component; seawater is boosted by the seawater supply pump to be inputted into the system; high-pressure strong brine transfers pressure energy to a stream of low-pressure seawater in a pressure energy exchanger A, and the seawater transfers the pressure energy to another stream of low-pressure seawater in a pressure energy exchanger B after being boosted. The invention provides the novel reverse osmosis seawater desalination system with two-stage residual pressure recovery, and has the advantages that the pressure energy of the high-pressure strong brine is subjected to two-stage residual pressure recovery through two sets of pressure energy recovery devices, the use of a boost pump is reduced, the water recovery rate of the reverse osmosis seawater desalination system can be flexibly regulated, and the system is compact in structure, flexible to operate, efficient and energy saving.

Owner:江苏世丰企业管理咨询有限公司

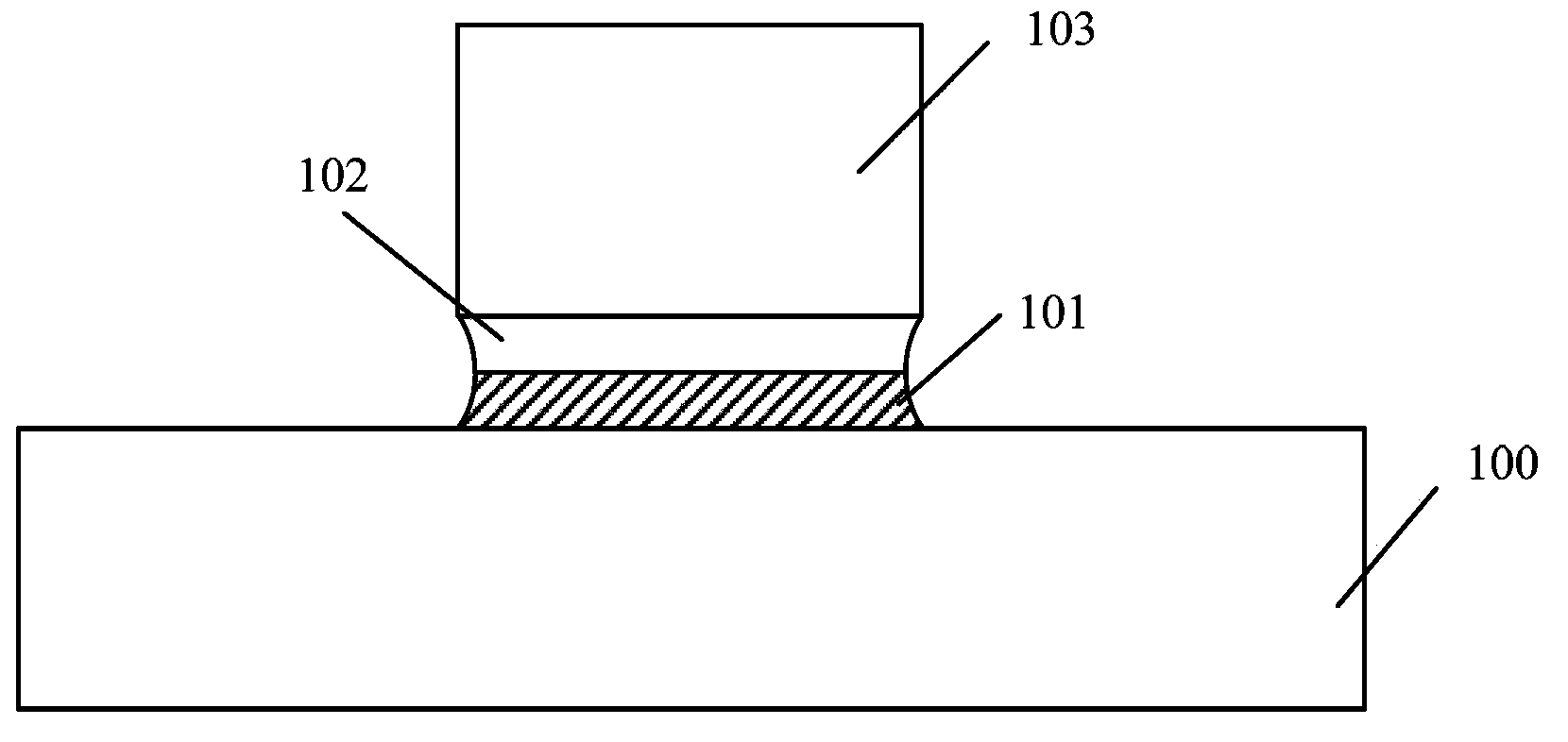

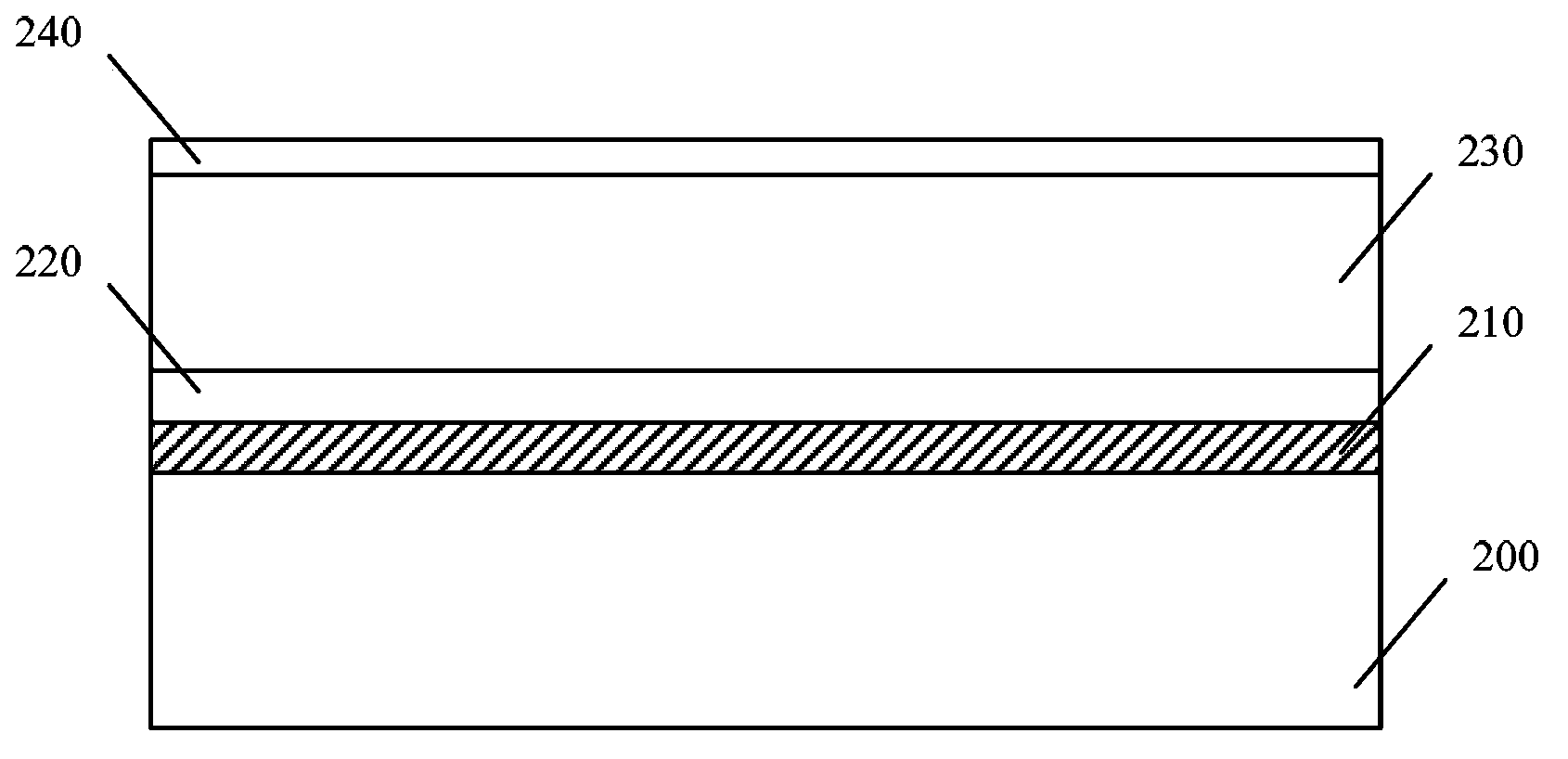

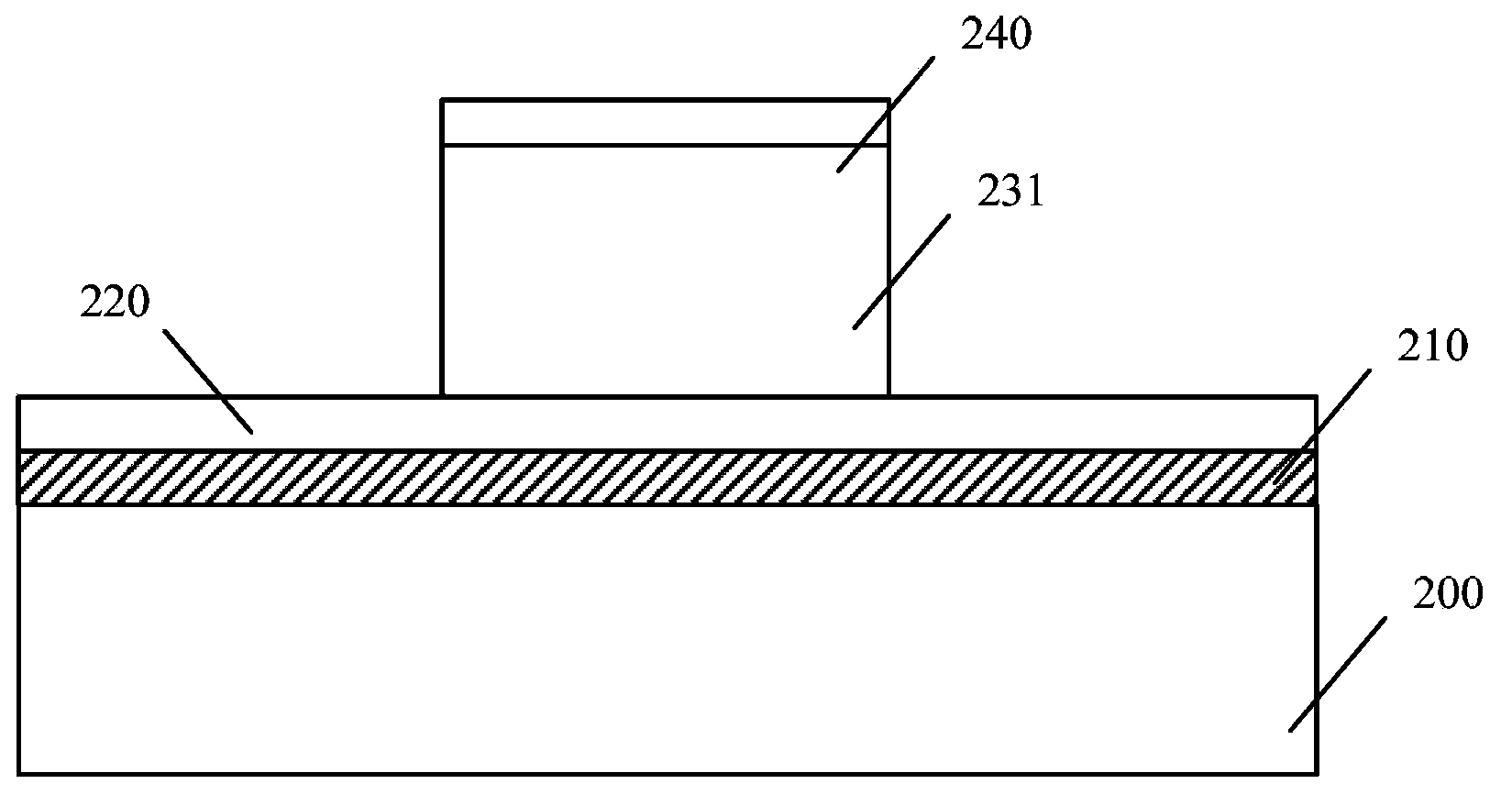

Method for forming gate electrode

A method for forming a gate electrode includes the following steps: a semiconductor substrate is provided, the surface of the semiconductor substrate has a gate medium material layer, a protection material layer is arranged on the gate medium material layer, and a pseudo gate material layer is arranged on the protection material layer; the pseudo gate material layer is etched, and a pseudo gate is formed on the protection material layer; a first side wall is epitaxially formed on a side wall surface of the pseudo gate; the protection material layer is etched using the pseudo gate and the first side wall as a mask, so as to form a protective layer, and the width of the protective layer is larger than that of the pseudo gate; a second side wall is epitaxially formed on a side wall surface of the first side wall; and the gate medium material layer is etched using the pseudo gate and the second side wall as a mask, so as to form a gate medium layer, and the width of the gate medium layer is larger than that of the protective layer. In the gate electrode formed in the invention, the gate medium layer, the protective layer and the pseudo gate are in a stepped structure, and the gate electrode has good performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Nanometer/micron gold film and preparing method thereof

ActiveCN104192789AHigh mechanical strengthEasy to stretchSemi-permeable membranesVolume/mass flow by thermal effectsGold filmMechanical property

The invention discloses a nanometer / micron gold film and a preparing method thereof. The nanometer / micron gold film comprises a matrix and a nanometer / micron gold layer. The nanometer / micron gold layer is formed by metal nanoparticles in a deposition mode. Amidogens are arranged on the surface of the matrix. The metal nanoparticles and the amidogens on the surface of the matrix form strong interaction. The preparing method comprises the steps that (1) the surface of the matrix is subjected to oxygen plasma treatment or ultraviolet irradiation; (2) the surface-activated matrix is soaked into an NH2(CH2)3Si(OC2H5)3 solution; and (3) a mixed solution of chloroauric acid and bicarbonate of a strong base and a glucose solution are evenly mixed and are arranged on the surface-amination matrix in a coating mode, and the nanometer / micron gold film is obtained through light-avoiding reaction. According to the nanometer / micron gold film, the types of matrixes are multiple, different mechanical property requirements can be met, combining is firm, breaking is not easy, according to the method, reaction is mild, and cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

Ultralight building material and its producing method

The invention relates to an ultra-light building material which consists of driers, extravasation materials, foaming agents and water and is characterized in that the driers consist of cement which is 10 to 15 percent of the total weight of the driers and semi-hydrated gypsum which is 85 to 90 percent of the total weight of the driers; the extravasation materials consist of an efficient water reducing agent which is 1 to 3 thousandth of the total weight of the driers, a retarder for plaster which is 2 to 4 thousandth of the total weight of the driers, polyvinyl propyl ethernamine which is 0.5 to 1.0 thousandth of the total weight of the driers and anti-cracking fiber which is 1.0 to 1.5 thousandth of the total weight of the driers; the foaming agents is 5 to 6 percent of the total weight of the driers; the weight ratio of the driers to water is 1:0.6 to 1:0.65. The invention also discloses a manufacturing method of the material. The building material is characterized by good mixture workability, easy foam adding and stabilizing and high foaming efficiency.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

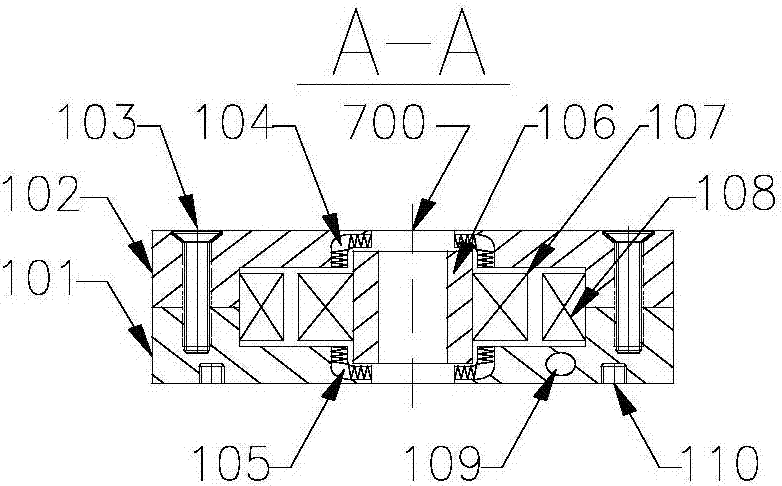

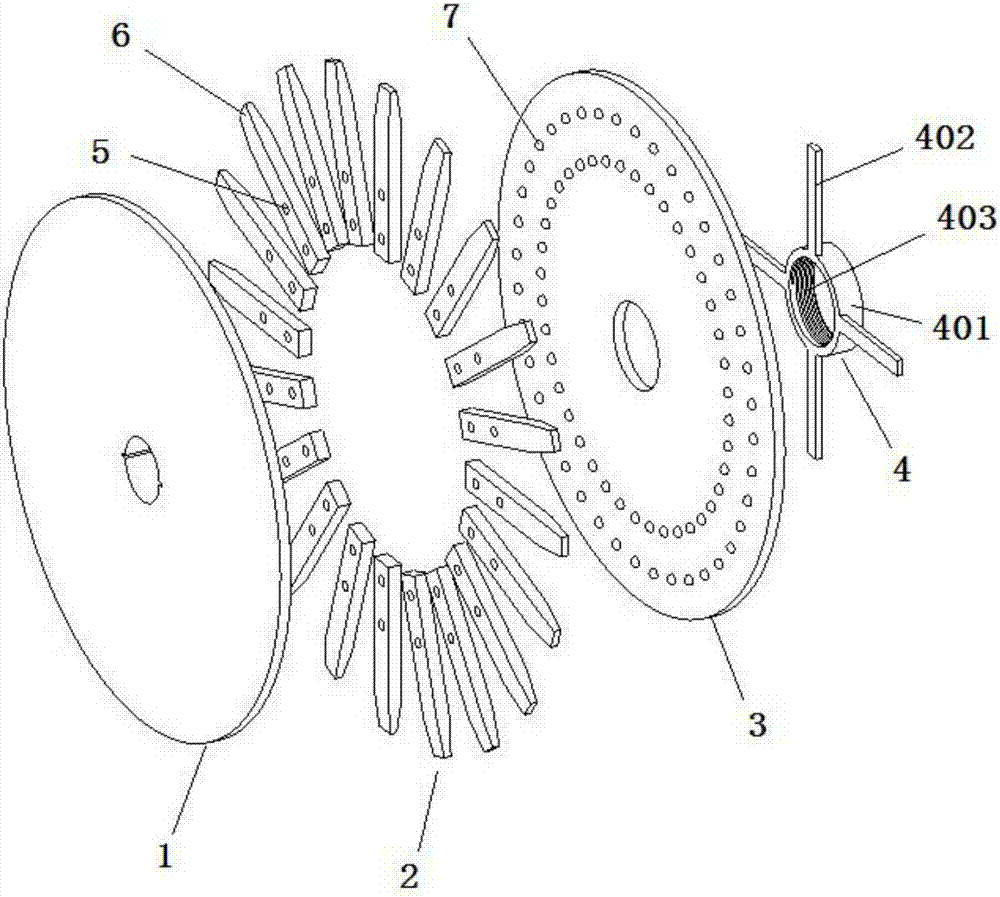

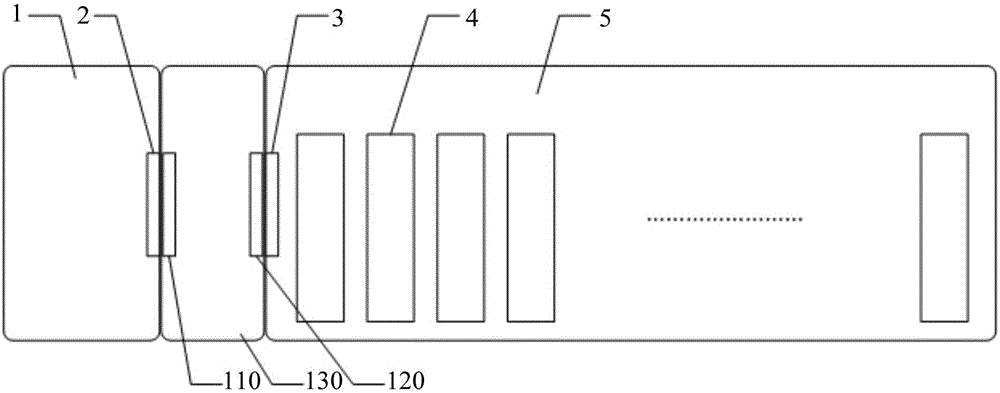

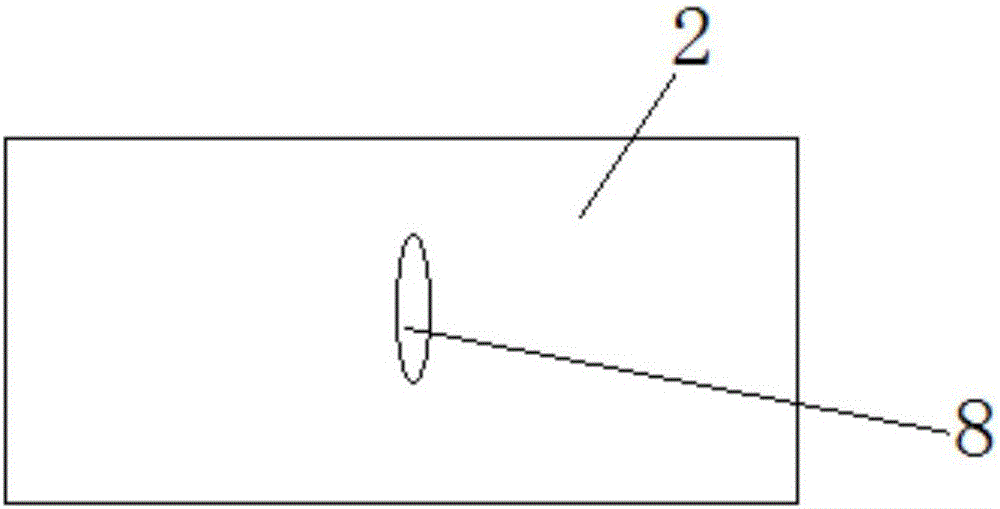

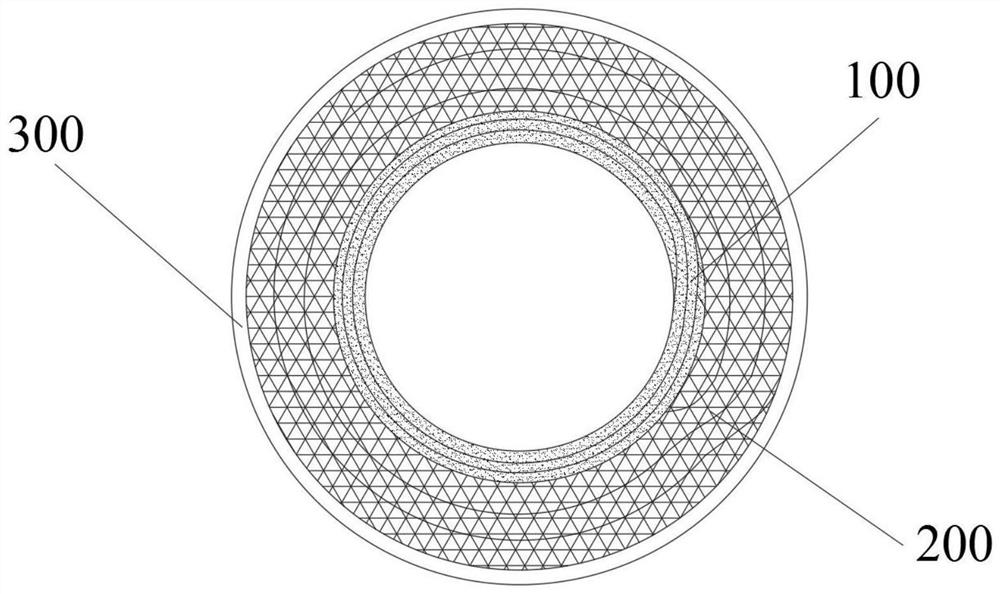

Magnetic false-twisting apparatus dedicated for spandex fibers

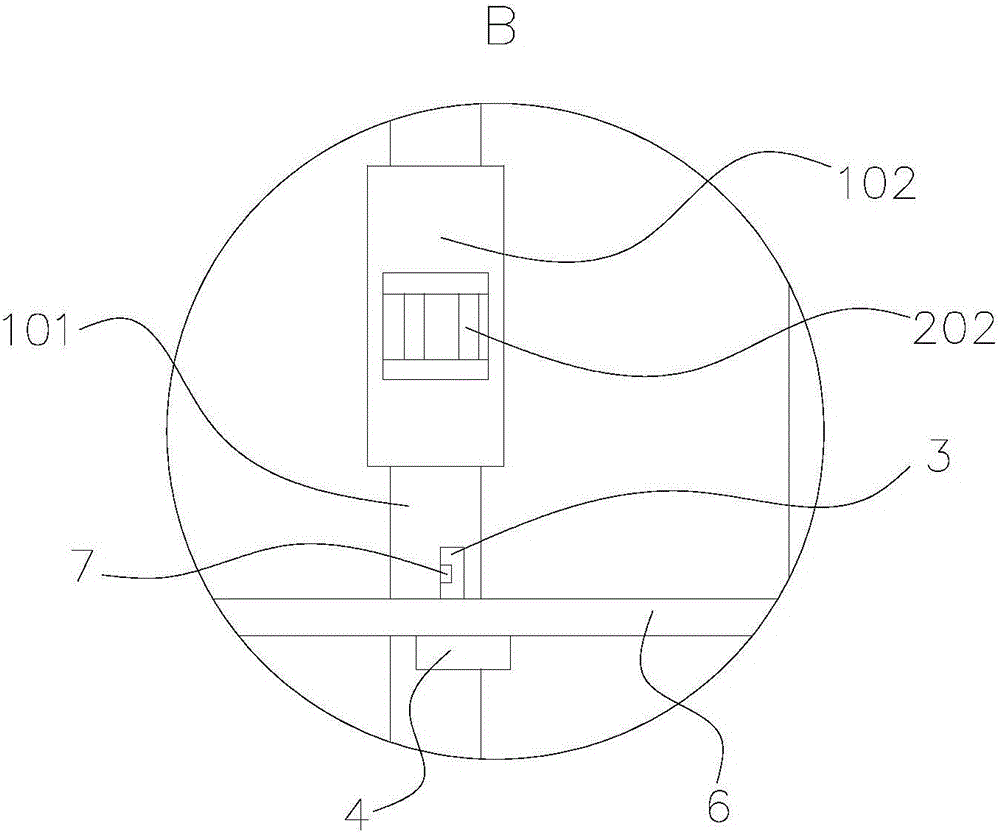

ActiveCN107956009ANovel structureMeet different process needsTextile/flexible product manufactureContinuous wound-up machinesFiberStructural engineering

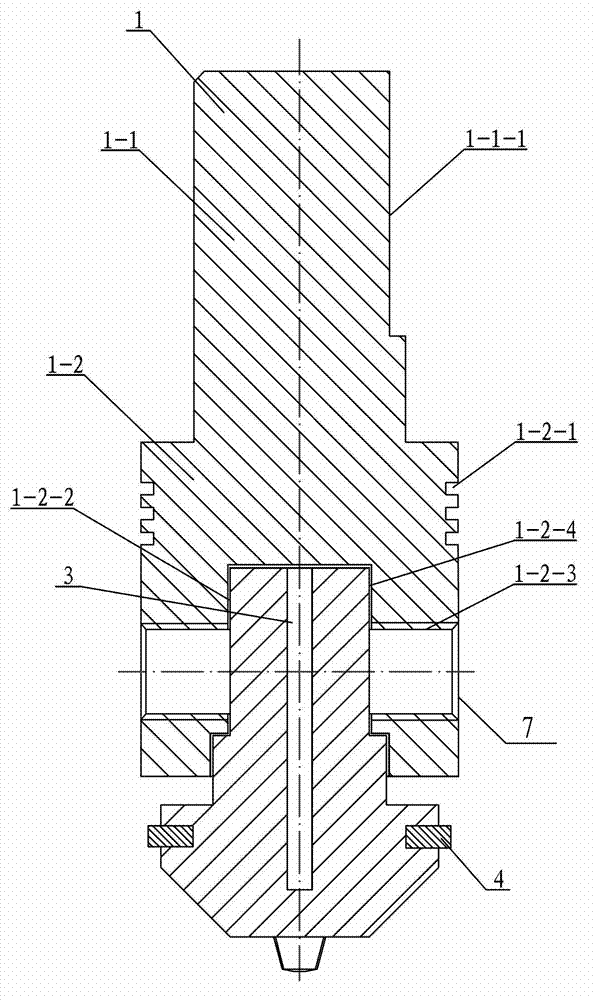

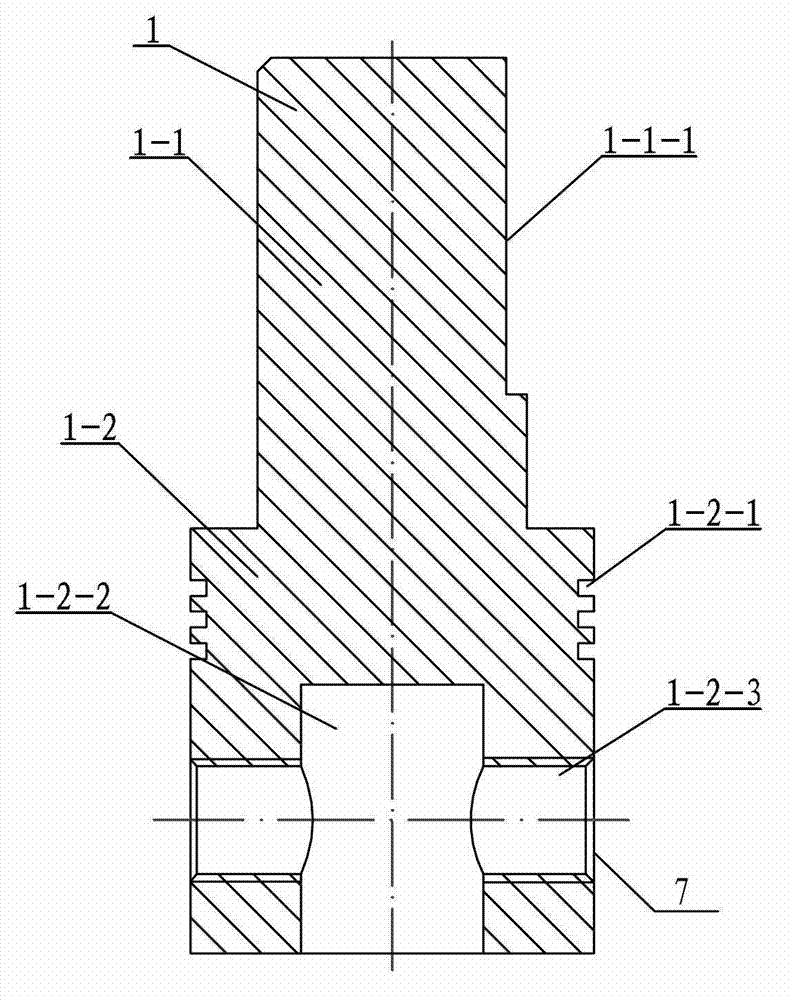

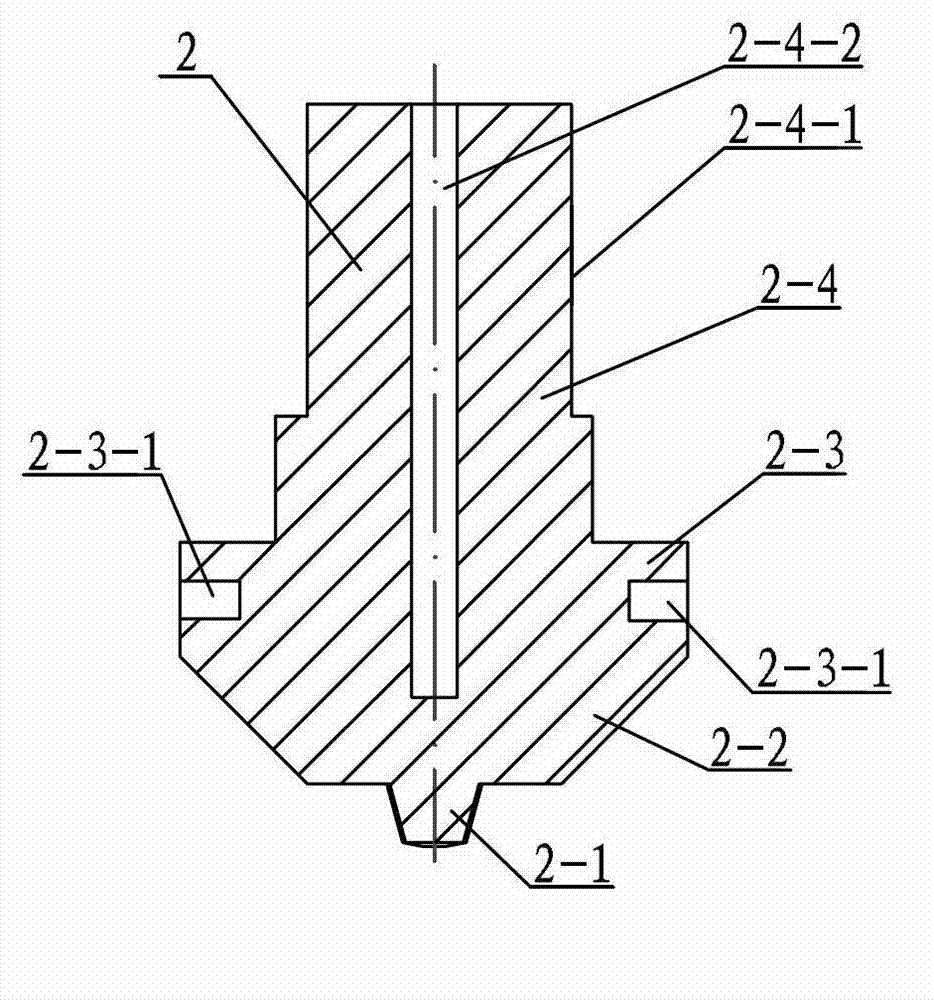

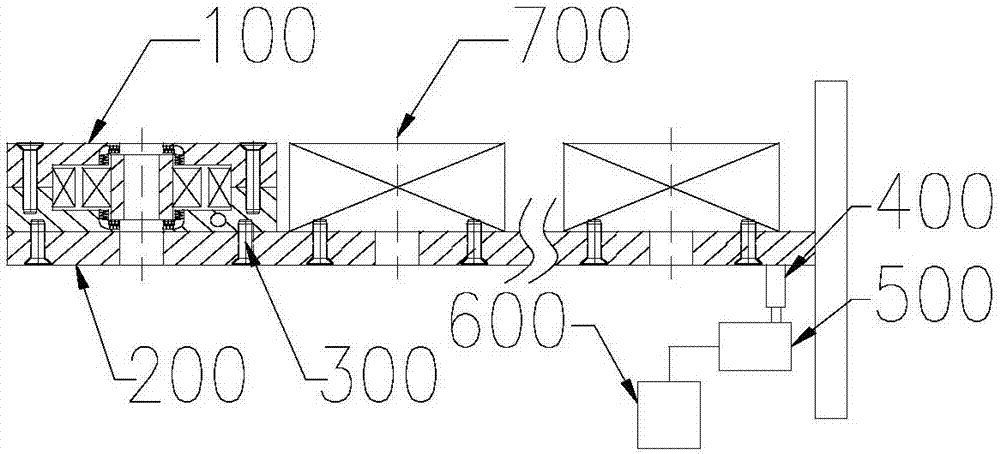

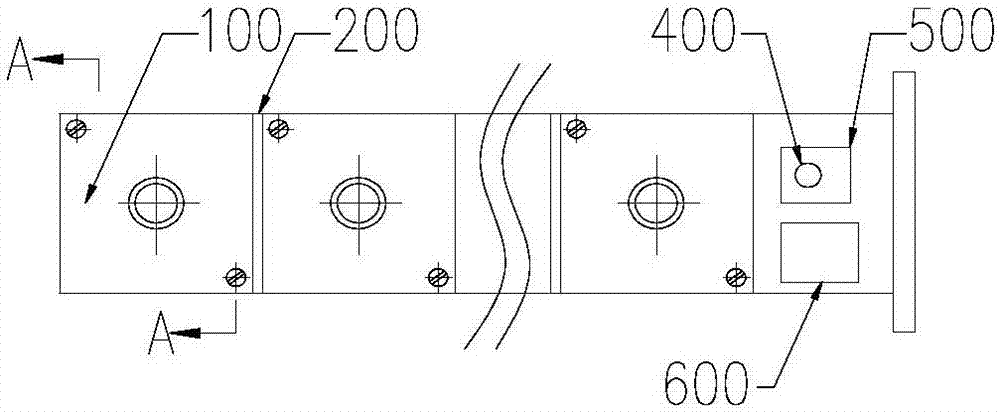

The present invention provides a magnetic false-twisting apparatus dedicated for spandex fibers. The apparatus comprises false-twisting units (100), false-twisting rods (200), connecting bolts (300),a cable (400), a commutating pole (500), a rheostat (600) and spandex fibers (700), wherein the multi-group false-twisting units (100) are horizontally fixed on the false-twisting rods (200) along thefalse-twisting rods (200) via the connecting bolts (300), the multi-group false-twisting units (100) are connected with the commutating pole (500) via the cable (400), and rotation speed of false-twisting ballooning in the false-twisting units is adjusted via the rheostat (600). The false-twisting unit moving parts are contactless and wear-free, and have good uniformity, and the defects that foran existing false twister, operation cost is high, uniformity is poor, noise is large and labor intensity is high are overcome.

Owner:ZHEJIANG HUAFENG SPANDEX

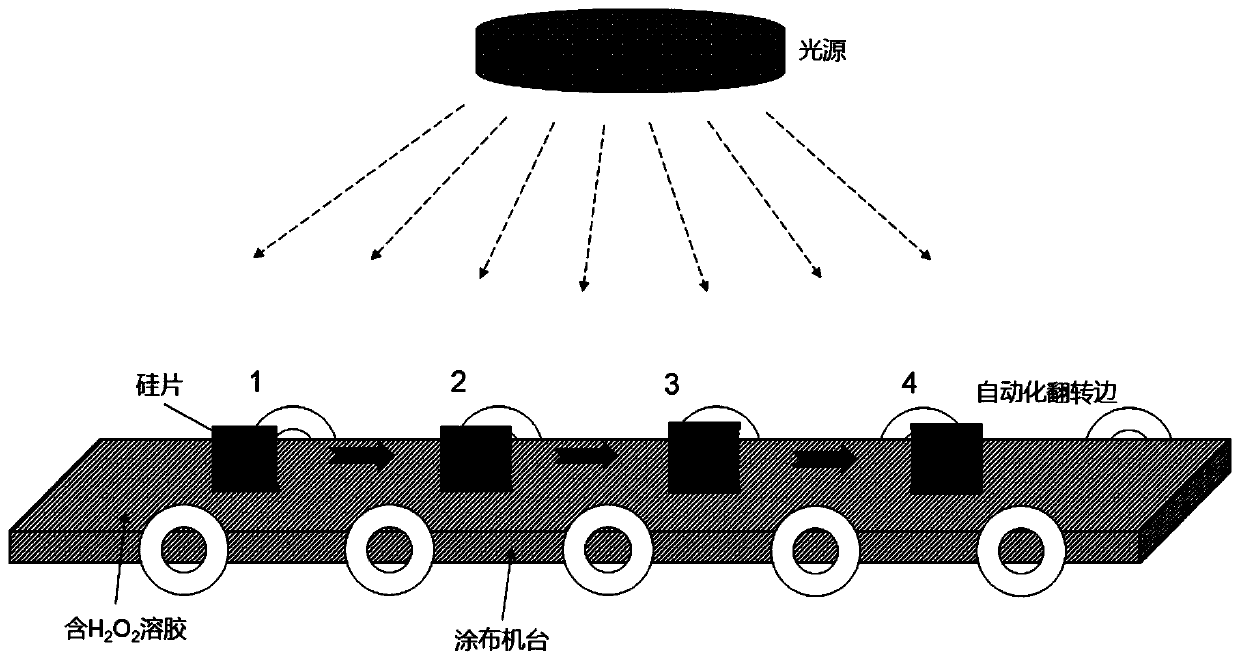

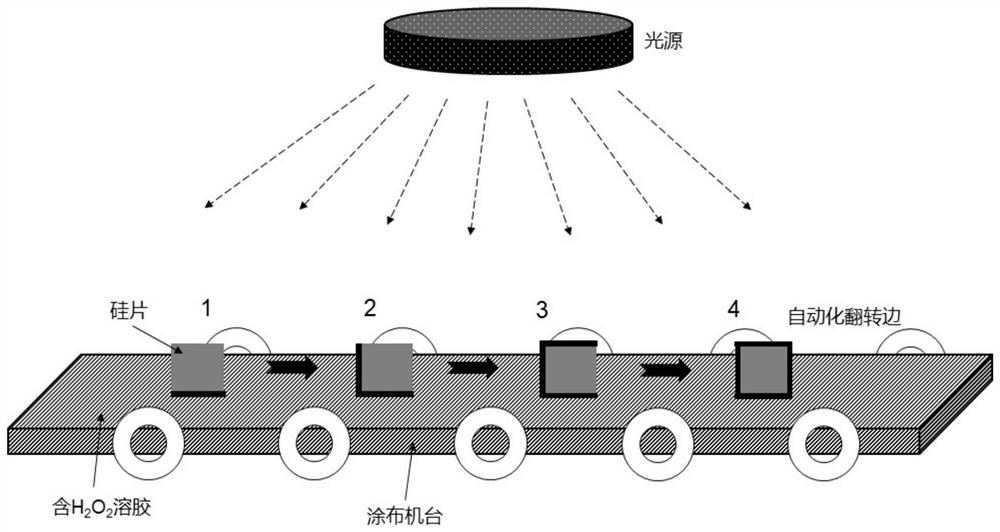

Battery edge passivation method

ActiveCN111509091AFully effective passivationAvoid passivationFinal product manufacturePhotovoltaic energy generationUltraviolet lightsCatalytic oxidation

The invention discloses a cell edge passivation method which comprises the following steps of printing slurry to an edge to be passivated in a crystalline silicon cell in a coating manner, and irradiating the edge with ultraviolet light to form a layer of silicon oxide passivation film on the edge under an illumination catalytic oxidation condition, wherein the slurry contains hydrogen peroxide and SiO2 powder; and after silicon oxide passivation films are formed on all edges needing passivation on the crystalline silicon cell, carrying out annealing treatment on the crystalline silicon cell subjected to illumination catalytic oxidation. Furthermore, the invention also discloses the application of the method. According to the invention, the edge passivation of the crystalline silicon solarcell is realized by using a photocatalytic oxidation technology, so that electrical recombination and electric leakage at the edge of the cell are reduced, and the photoelectric conversion efficiencyof the cell is improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

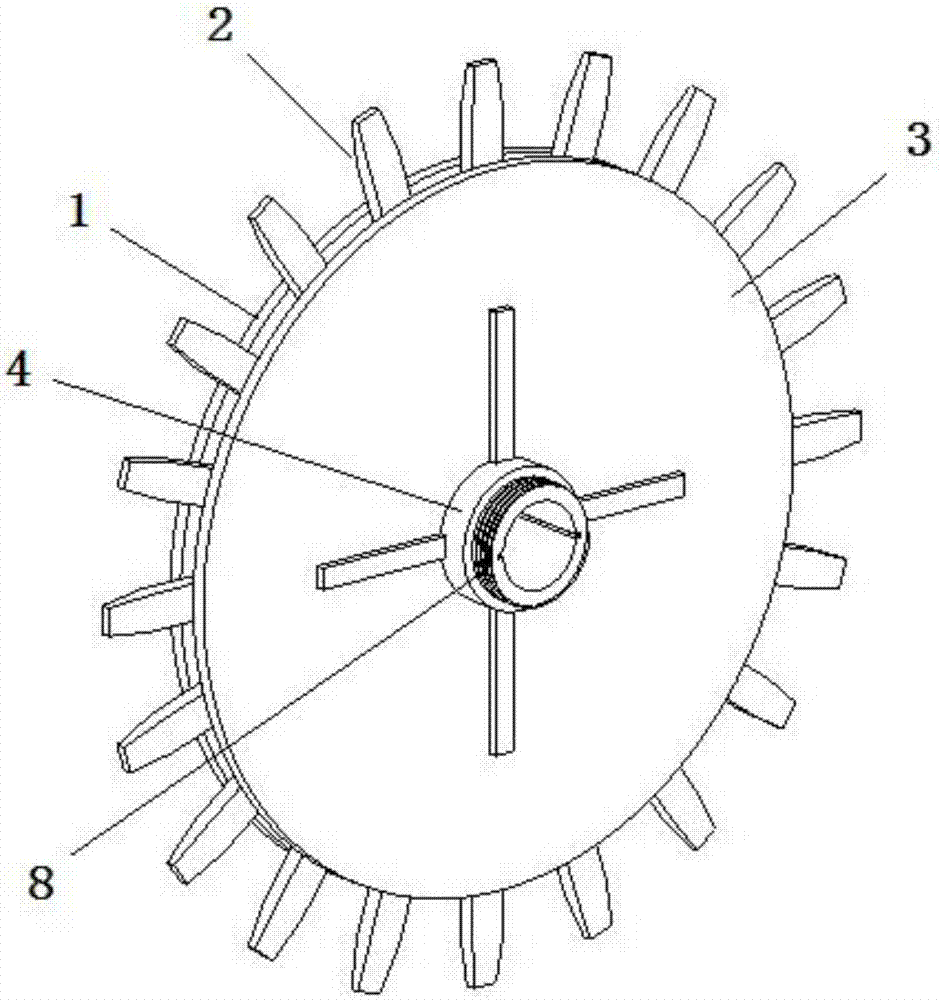

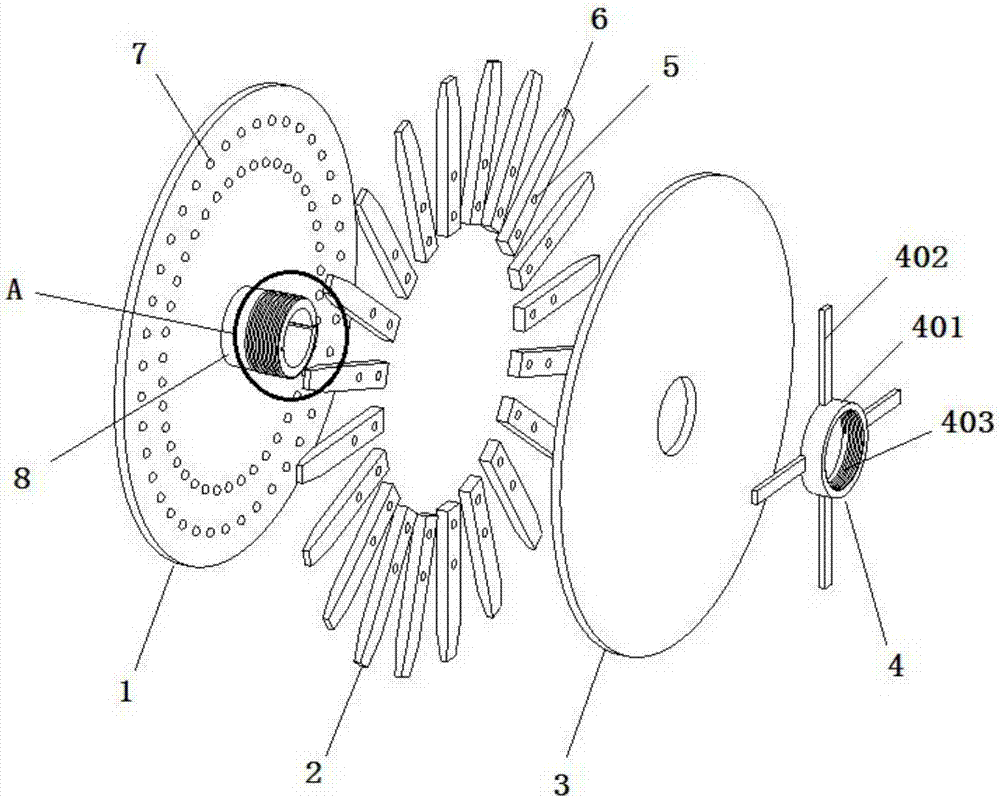

Trimming blade used for tire production

InactiveCN107053268AAdjustable spacingMeet different process needsMetal working apparatusCircular discEngineering

The invention discloses a trimming blade used for tire production. The trimming blade comprises a circular disc I, toothed racks, a circular disc II and a locking piece, wherein a positioning groove is formed in each of the two side surfaces of each of the toothed racks; the toothed racks are annularly distributed between the circular disc I and the circular disc II; a plurality of circles of positioning bulges are arranged on the inner side of each of the circular disc I and the circular disc II; a blade edge part is arranged at the end part of each of the toothed racks; a support tube is arranged at the middle of the circular disc I; a penetration hole is formed in the middle of the circular disc II; the locking piece comprises a rotating sleeve and pressing plates; a thread part is arranged on the outer side of the support tube; a key groove is formed in the inner side of the support tube; a thread groove is formed in the inner side of the rotating sleeve. According to the trimming blade used for tire production, the trimming blade is a combined blade, the positioning grooves in the two sides are clamped with the positioning bulges, the toothed racks can be tightly clamped by the circular disc I and the circular disc II under the effect of the locking piece, so that on one hand, the space among the toothed racks can be adjusted to meet different process requirements, and on the other hand when the toothed racks are damaged, the cost problem brought by integral replacement is avoided due to that only damaged toothed racks need to be replaced.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

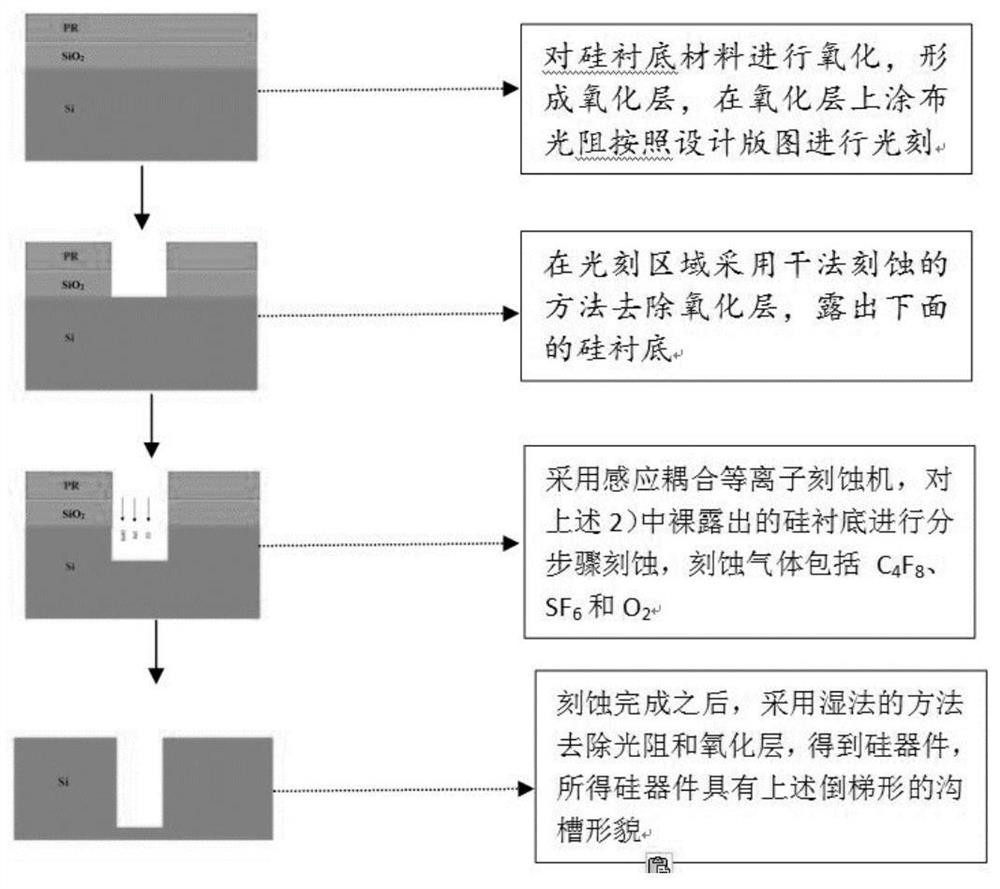

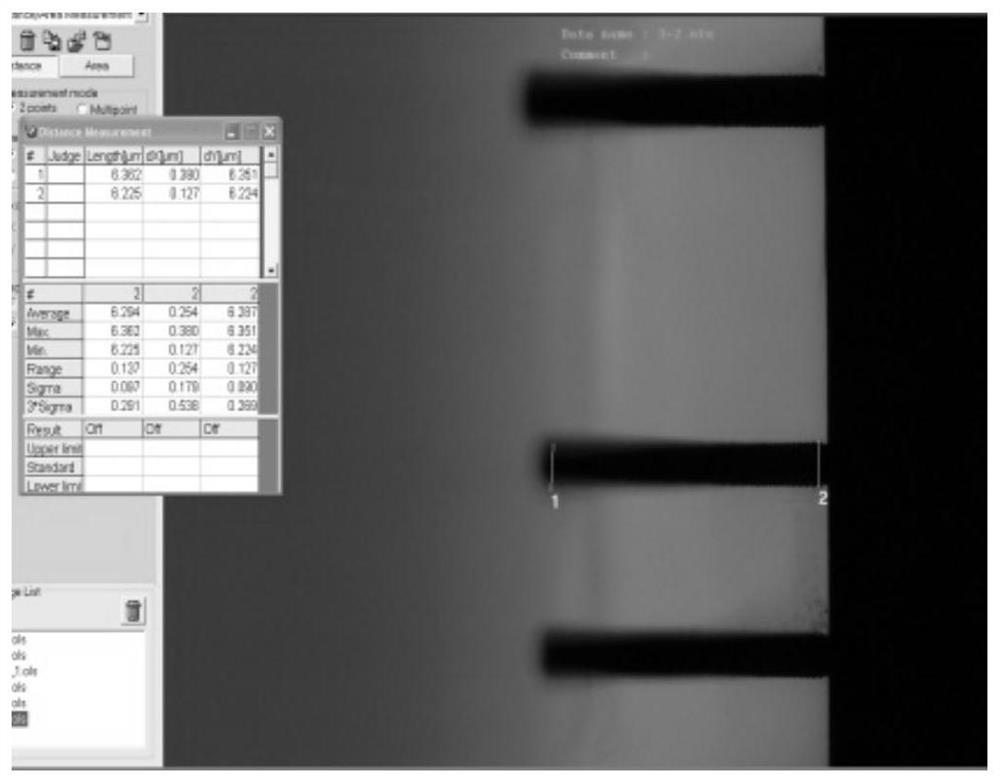

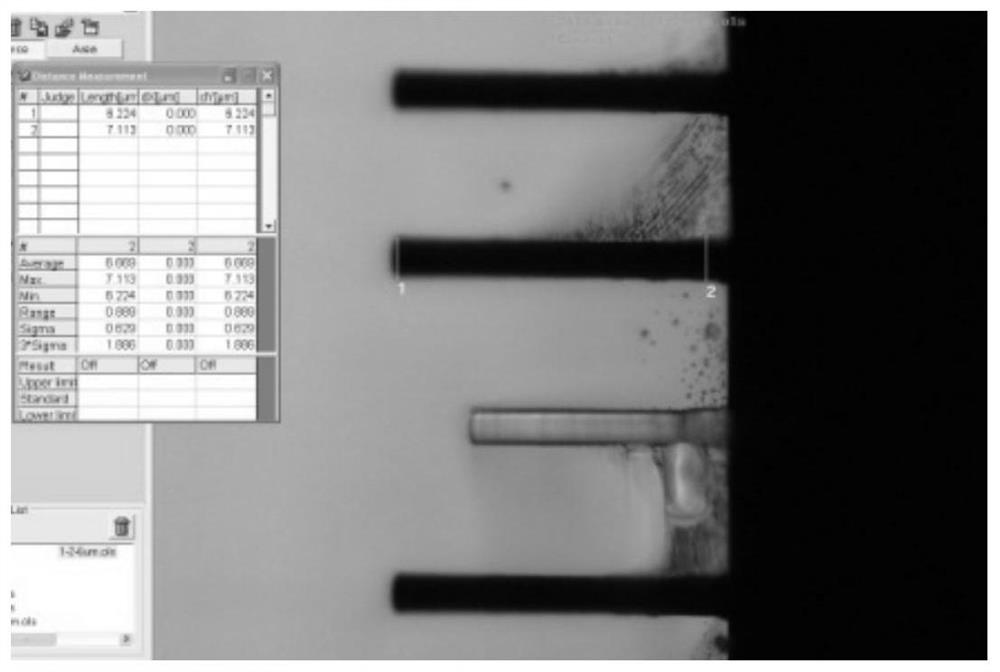

Inverted trapezoidal groove etching process method

PendingCN112164650AMeet different process needsEasy to understandSemiconductor/solid-state device manufacturingEtchingPhysical chemistry

The invention discloses an inverted trapezoidal groove etching process method, and belongs to the field of microelectronic manufacturing processes. The invention relates to an inverted trapezoidal groove etching process method, which comprises the following steps: 1) oxidizing a silicon substrate material to form an oxide layer, coating a photoresist on the oxide layer, and photoetching accordingto a design layout; 2) removing the oxide layer in the photoetching region by adopting an RIE etching method until the silicon substrate is exposed; (3) etching the silicon substrate step by step by adopting an inductively coupled plasma etching machine, alternately etching by adopting C4F8 and SF6, and obtaining a silicon groove with a preset depth after etching is completed; etching the silicongroove by adopting SF6 and O2 etching methods, and obtaining an inverted trapezoidal silicon groove after etching is completed; and 4) after the etching is finished, removing the photoresist and the oxide layer by adopting a wet method to obtain the silicon device. According to the process method disclosed by the invention, the inverted trapezoidal grooves with different silicon groove depths canbe obtained, and different process requirements are met.

Owner:XIAN MICROELECTRONICS TECH INST

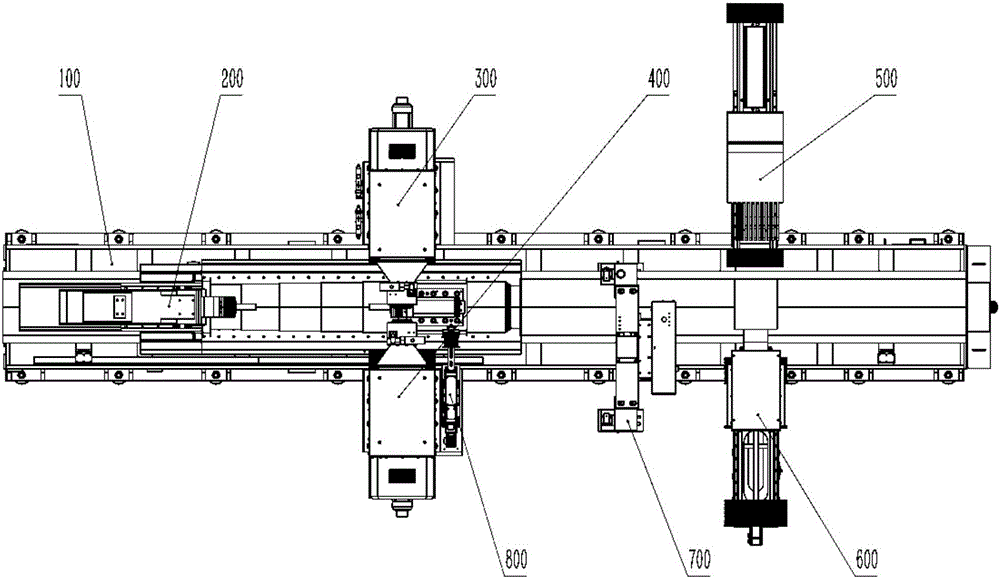

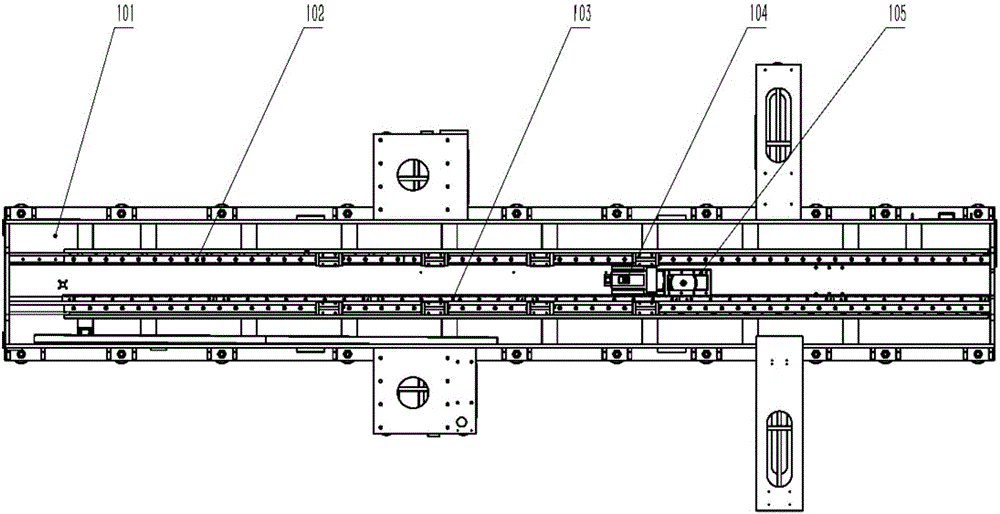

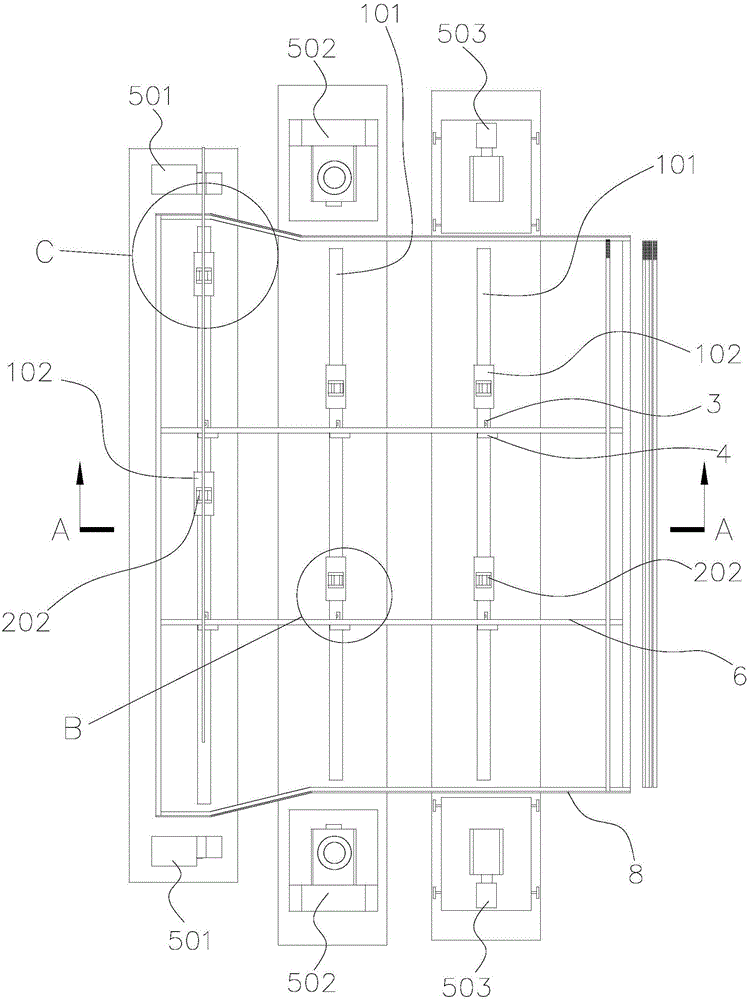

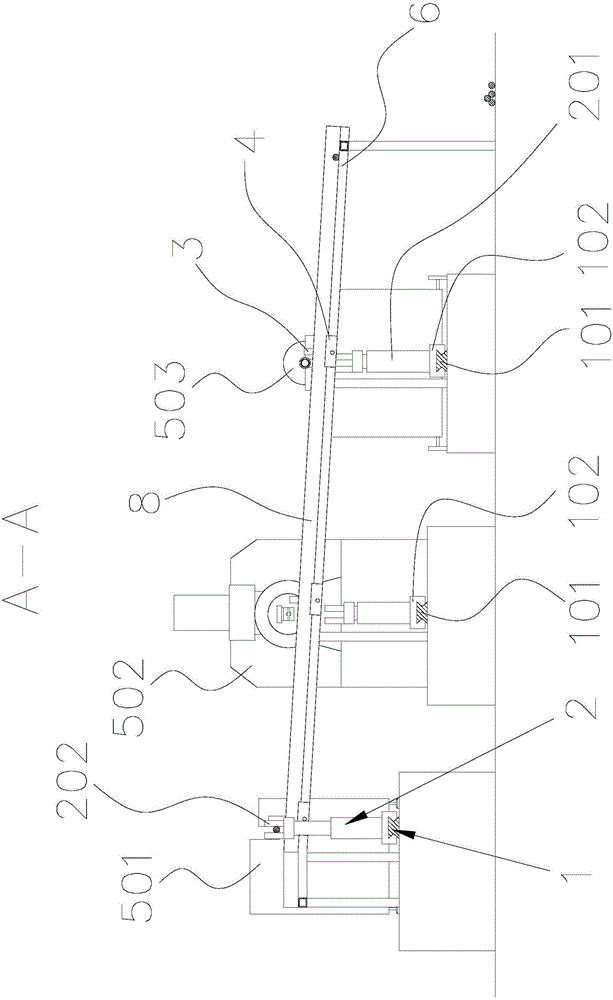

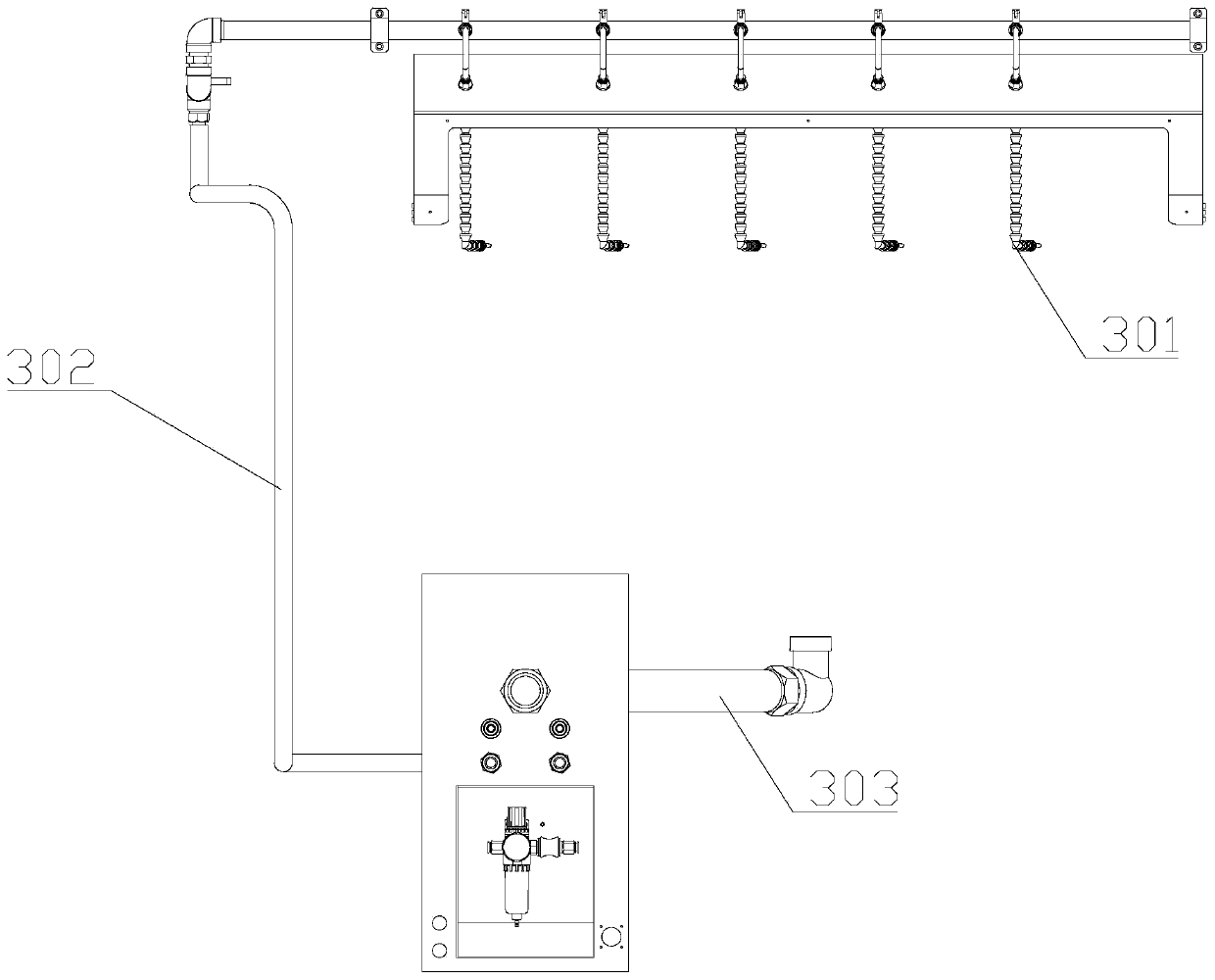

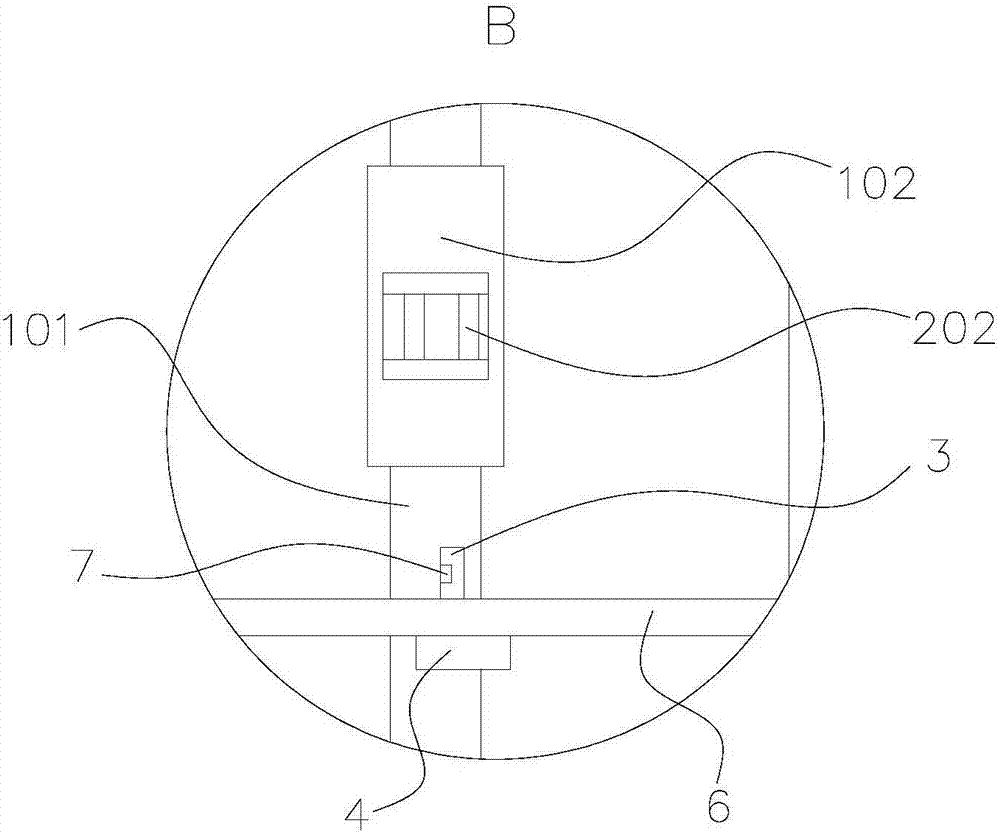

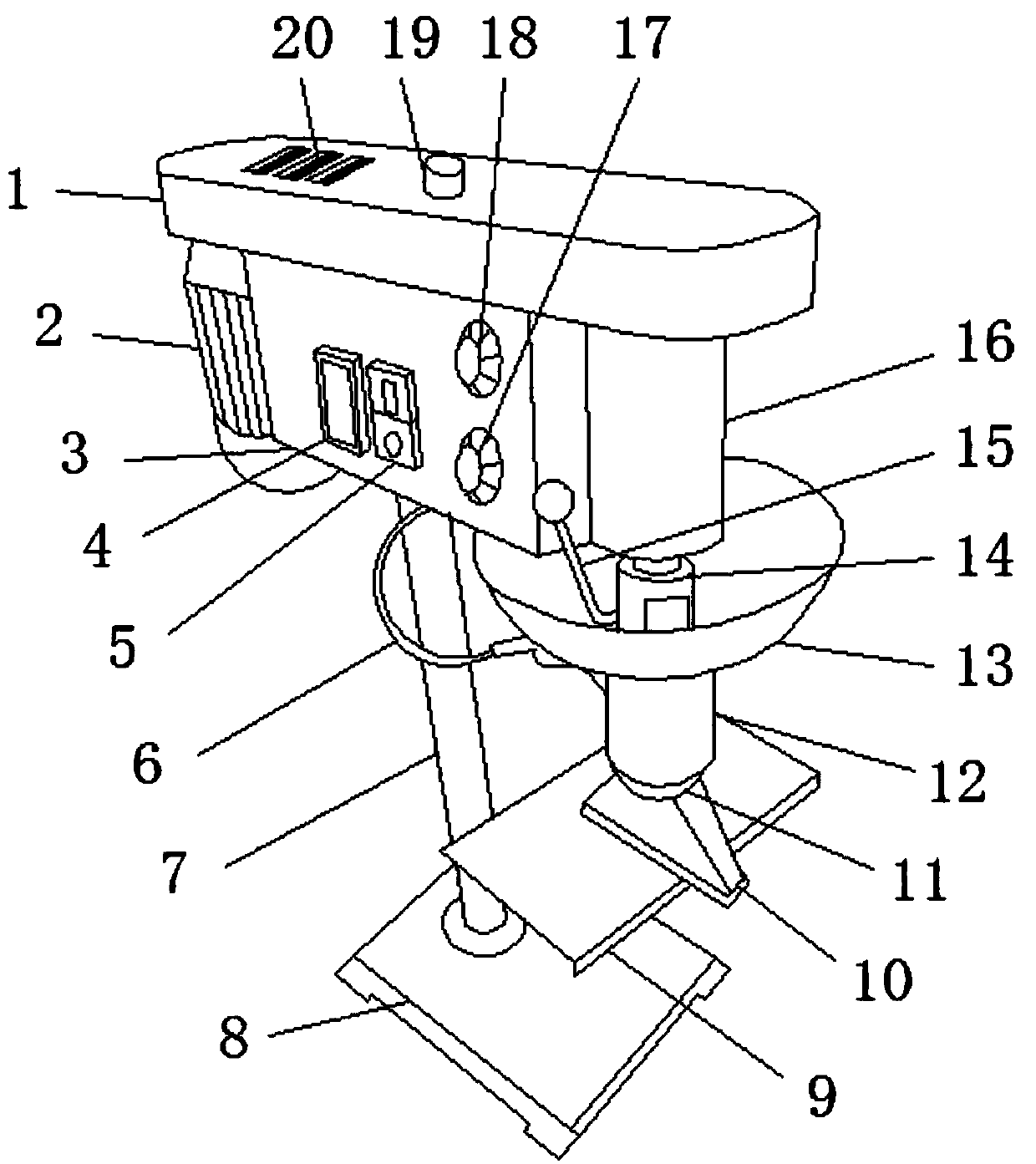

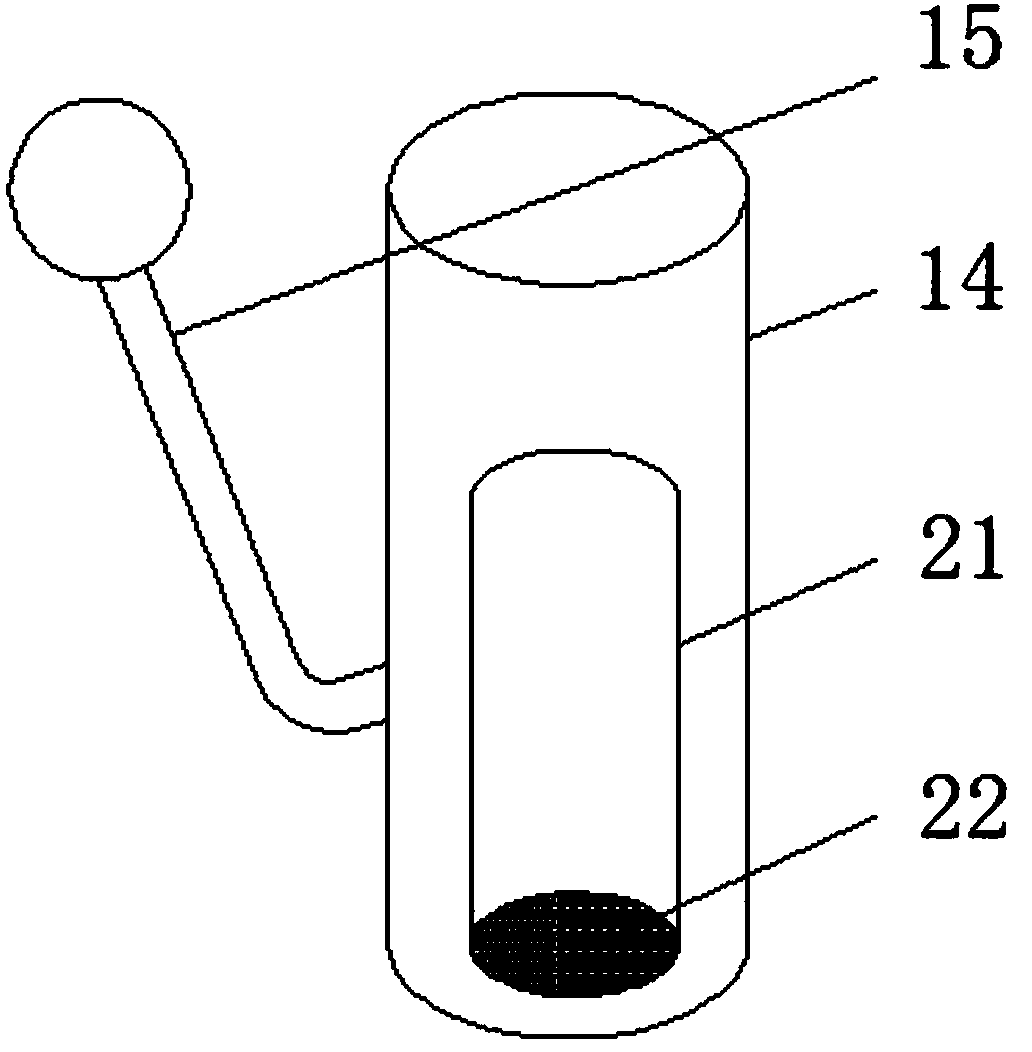

3D glass polishing equipment

ActiveCN111546211AReduce labor costsSolve the problem of not being able to polish the concave surface of the glassPolishing machinesGrinding drivesPolishingIndustrial engineering

The invention belongs to the technical field of glass processing and discloses 3D glass polishing equipment. The 3D glass polishing equipment comprises a mounting frame. An X-Y moving mechanism, a polishing agent injection mechanism, a polishing wheel mechanism, a jig mechanism, a lifting mechanism and an automatic feed and discharge mechanism are mounted on the mounting frame. The X-Y moving mechanism drives the polishing wheel mechanism to move in the X-Y directions. The lifting mechanism drives the jig mechanism to ascend and descend. The 3D glass polishing equipment is high in automation degree, achieves the full-automatic feeding and discharging and automatic polishing effects, reduces labor force for manually carrying materials and the labor cost, is easy and convenient to operate and reduces the breakage risk. An operator can operate multiple sets of equipment simultaneously. Moreover, the jig mechanism cooperates with the lifting mechanism and can assist in polishing the planeand the arc surface of a workpiece. The problem that traditional polishing equipment cannot polishing the concave surface of glass is solved. The 3D glass polishing equipment is compact in structure,strict in protection and capable of effectively saving the space of a site. The ambient environment of the equipment is more clean. A jig and a polishing wheel are quick and convenient to replace. Themaintenance cost is lowered. Online production of a whole line is facilitated.

Owner:湖南安冠智能科技有限公司 +1

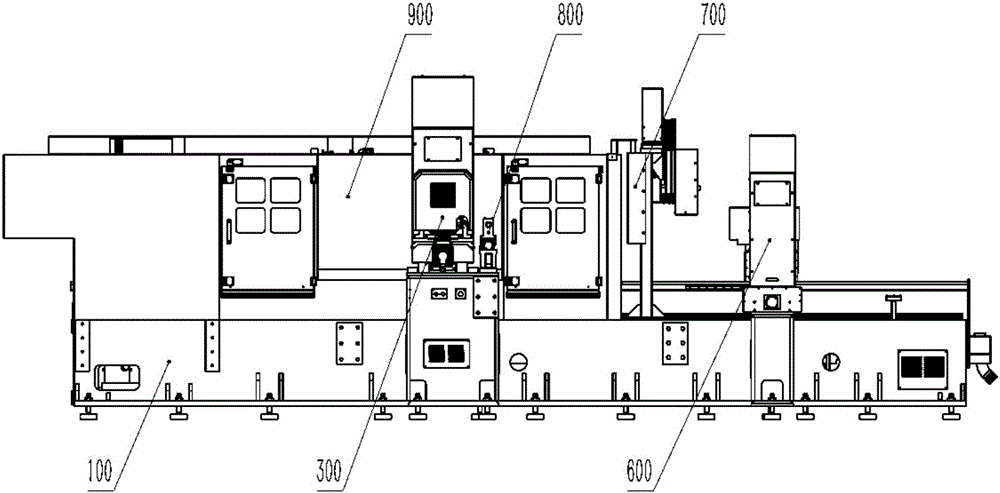

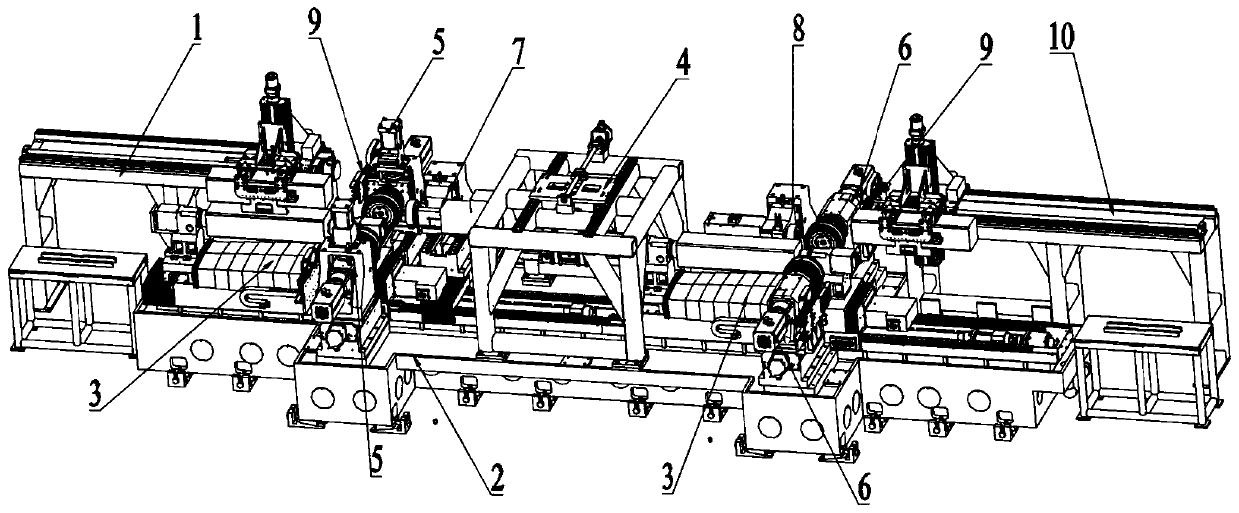

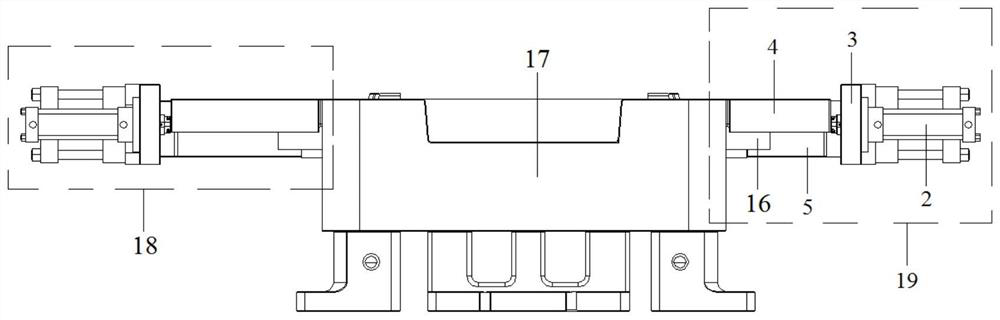

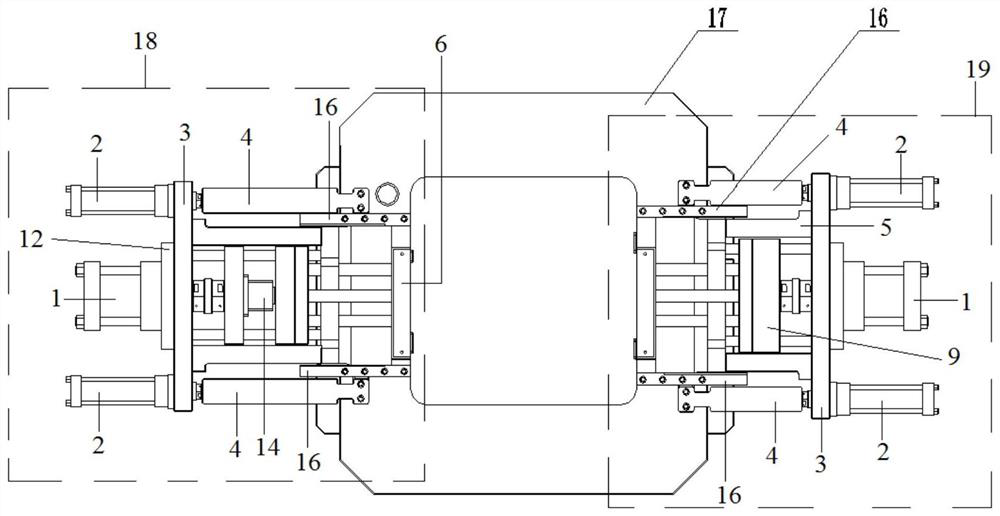

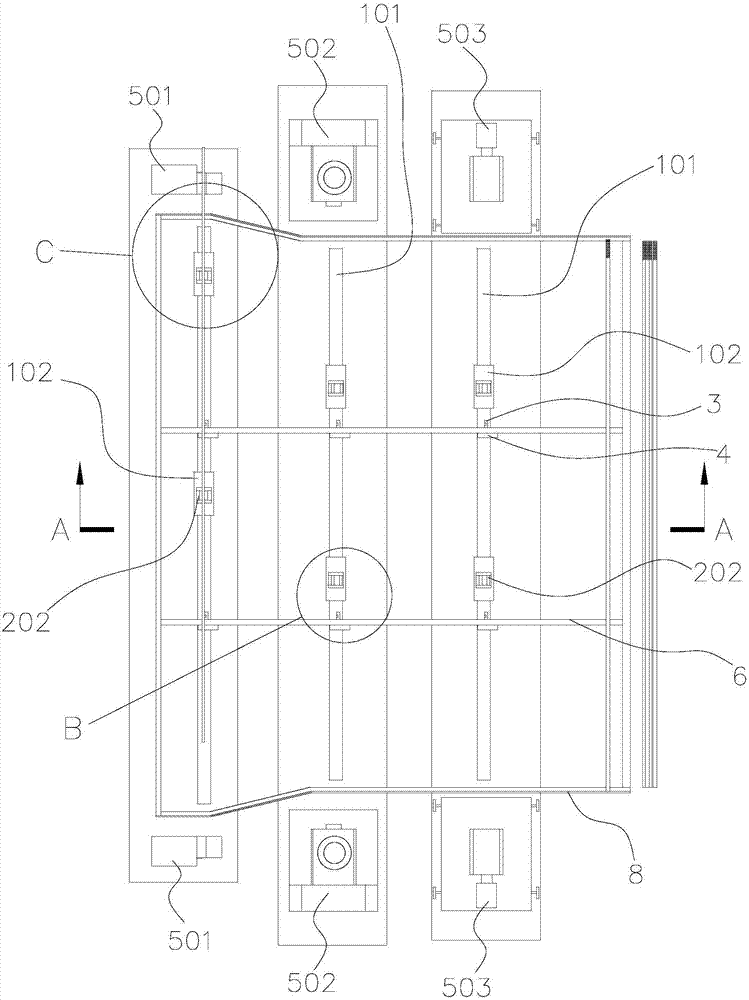

Efficient grinding and chamfering all-in-one machine

PendingCN110653704AReduce idle timeImprove equipment capacityGrinding carriagesGrinding machinesGrindingProcess engineering

The invention provides an efficient grinding and chamfering all-in-one machine. The machine comprises a base assembly, workbench assemblies, a transfer manipulator, coarse grinding assemblies, refining assemblies, a coarse barreling assembly, a fine barreling assembly, a feeding mechanism and a discharging mechanism, wherein the base assembly comprises a base and a guide rail arranged on the base,the two workbench assemblies are arranged, the two workbench assemblies are slidably arranged at the two ends of the base correspondingly, the transfer manipulator is arranged in the middle of the base, the two coarse grinding assemblies and the two refining assemblies are arranged, and are each oppositely arranged on the two sides of the base, the coarse barreling assembly is arranged on one side of the base and located between the coarse grinding assemblies and the transfer manipulator, the fine barreling assembly is arranged on one side of the base and located between the refining assemblies and the transfer manipulator, and the feeding mechanism and the discharging mechanism are the same in structure and are arranged at the two ends of the base correspondingly. The machine can conductintegrated polishing on arcs, corners and surfaces of polysiliconsingle of different specifications, a coarse grinding procedure and a refining procedure do not interfere with each other, the idle time of the machine is shortened, the machine capacity is high, and the machining period is short.

Owner:QINGDAO GAOCE TECH CO LTD

Interlocking device of modular bus type electromagnetic valve group

ActiveCN106439197ARealize the interlock functionMeet different process needsOperating means/releasing devices for valvesPreventing unauthorised/accidental actuationSolenoid valveEngineering

The invention discloses an interlocking device of a modular bus type electromagnetic valve group. The modular bus type electromagnetic valve group comprises a bus coupler, an electromagnetic valve seat and a plurality of electromagnetic valves integrated on the electromagnetic valve seat. The interlocking device comprises an input interface, an output interface and a controller, wherein the input interface is connected with the bus coupler, and is used for receiving an electromagnetic valve control instruction transmitted by the bus coupler; the output interface is connected with the plurality of electromagnetic valves through the electromagnetic valve seat; and the controller is used for determining a target electromagnetic valve from the plurality of electromagnetic valves according to the electromagnetic valve control instruction, and interlocking the target electromagnetic valve. According to the interlocking device, an individual target electromagnetic valve can be interlocked according to the practical requirement, the interlock function of an assigned electromagnetic valve is achieved, and different technological requirements can be met. The invention further discloses the modular bus type electromagnetic valve group.

Owner:HWATSING TECH +1

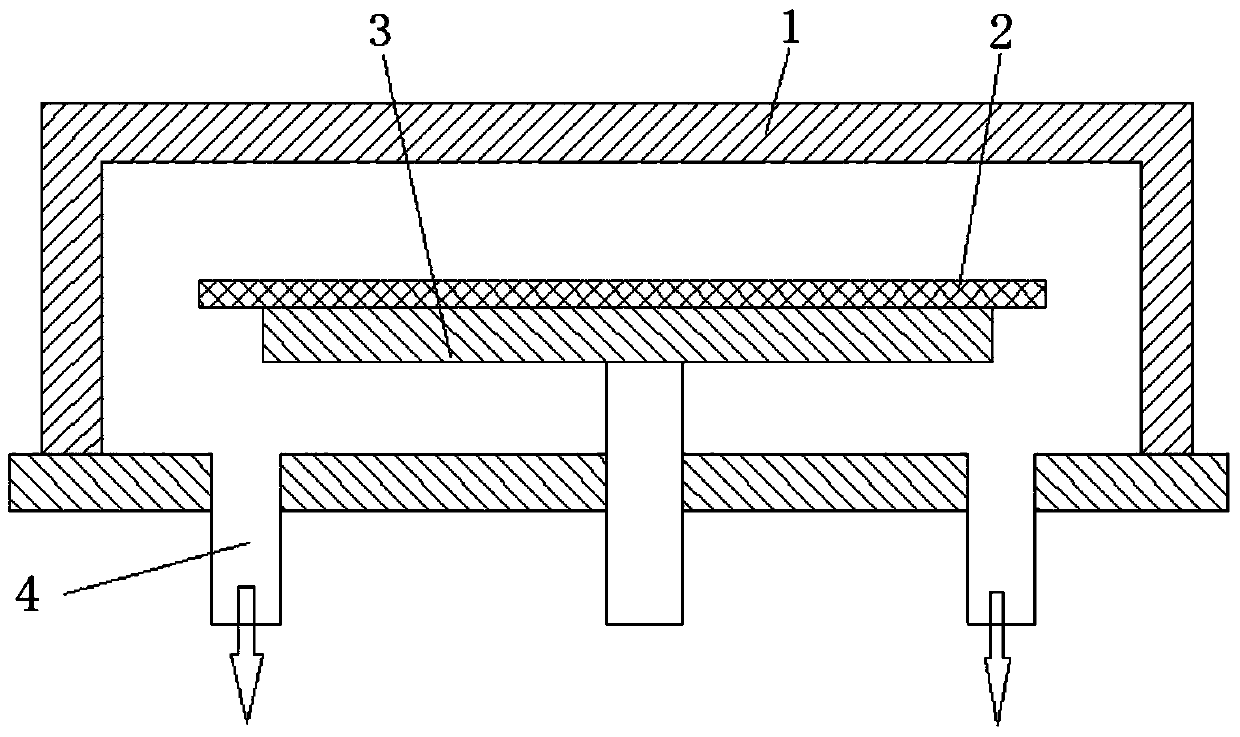

Pressure-reduction drying system and method for substrate

ActiveCN106111487AReduce removal timeImprove drying efficiencyPretreated surfacesCoatingsTemperature controlDual action

The invention discloses a pressure-reduction drying system and method for a substrate. The pressure-reduction drying system comprises an airtight drying cavity (1). A drying platform (3) used for bearing the substrate (2) is arranged in the drying cavity (1). Vacuumizing holes (4) communicating with the interior of the drying cavity are further formed in the drying cavity (1). The pressure-reduction drying system is provided with a temperature controller (5). A heating structure (6) used for heating the substrate (2) is arranged on the drying platform (3). The temperature controller (5) is electrically connected with the heating structure (6) and used for controlling the heating temperature of the heating structure (6). According to the pressure-reduction drying system and method for the substrate, the heating structure is arranged on the drying platform for bearing the substrate, the heating temperature of the heating structure is controlled through the temperature controller, and time for removing a solvent of the substrate in the drying cavity is shortened under the dual effects of vacuumizing and heating, the drying efficiency is improved, and the productivity is improved accordingly.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

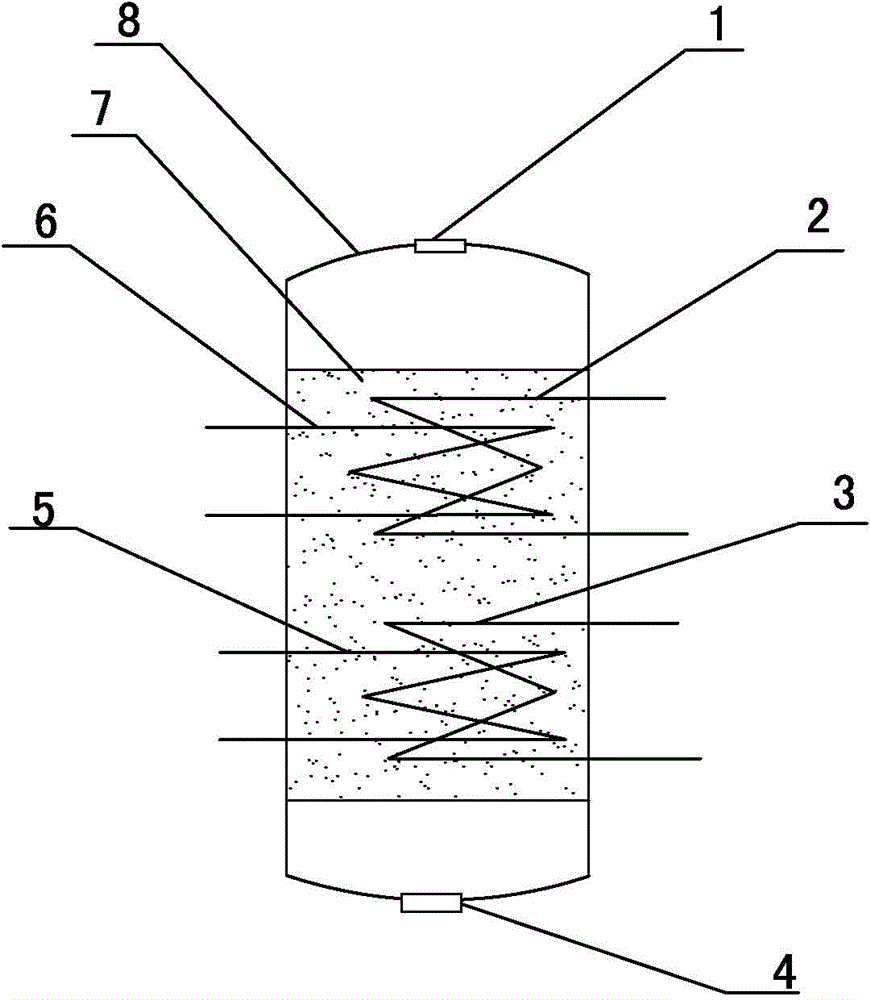

CO conversion reaction furnace

The invention belongs to the technical field of CO sulfur resistant conversion, and specifically relates to a CO conversion reaction furnace. The furnace comprises a furnace body, a catalyst bed is arranged in the furnace body; a first heat exchange device is arranged on a position (A), the distance between the top of the furnace and the position (A) accounts for 16 to 22% of the height of the furnace, the first heat exchange device is composed of a first large heat exchange coil pipe and a first small heat exchange coil pipe; a second heat exchange device is arranged on a position (B), the distance between the bottom of the furnace and the position (B) accounts for 20 to 25% of the height of the furnace, the second heat exchange device is composed of a second large heat exchange coil pipe and a second small heat exchange coil pipe; the diameters of the first large heat exchange coil pipe and the second large heat exchange coil pipe is 75 to 55% of the diameter of the furnace body, and the diameters of the first small heat exchange coil pipe and the second small heat exchange coil pipe is 45 to 55% of the diameter of the catalyst bed. The temperature of the bed is effectively controlled in a range of 320 to 380 DEG C so as to avoid the methanation by-reactions; at the same time the reaction speed is taken into account, a section of conversion can be effectively arranged to meet the requirements on CO content, and the CO conversion reaction furnace is suitable for technology with different water / gas ratios and CO contents.

Owner:CHINA PETROLEUM & CHEM CORP

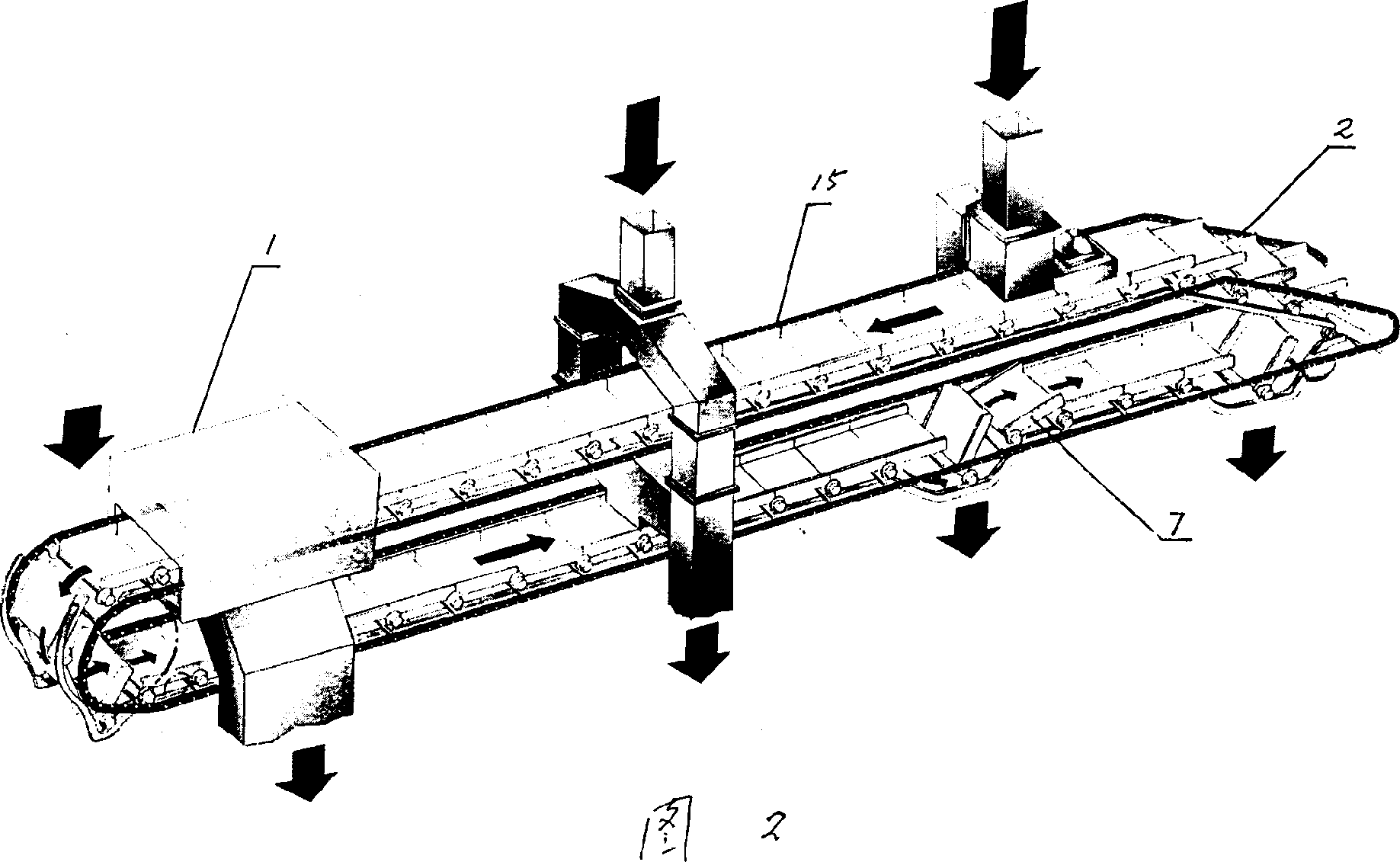

Disk-type conveyer with multiple feeding and discharging points

InactiveCN1397476AMeet different process needsAvoid replacementConveyor partsEngineeringMechanical engineering

A tray conveyer for high-temp cement clinker with multiple loading points and unloading points is composed of head unit for turning the trays upward, tail unit for forced unloading, the middle unit consisting of track and supporting frame, multi-point loading and unloading units, and conveying unit consisting of trays and chains.

Owner:CHENGDU LEEJUN IND

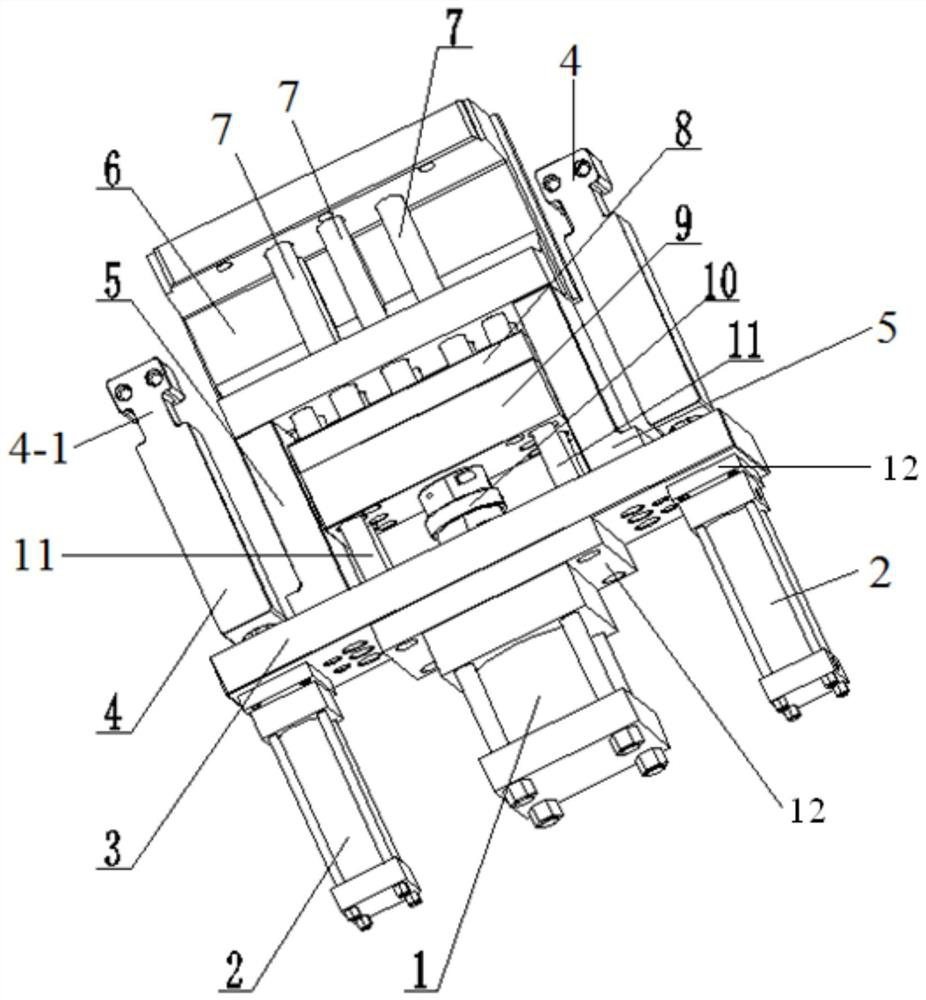

Local loading forced feeding and core pulling device of large aluminum alloy extrusion casting mold

The invention discloses a local loading forced feeding and core pulling device of a large aluminum alloy extrusion casting mold, and relates to a feeding and core pulling device of an aluminum alloy extrusion casting mold. The invention aims to solve the technical problems that the pressure effect of some areas is not obvious or does not have the pressure effect due to pressure gradient existing in the extrusion casting forming process of a large component with non-uniform wall thickness, and shrinkage cavities and shrinkage porosity exist. According to the device, a mold feeding function and a core pulling function are combined, and a first-stage feeding mechanism and a second-stage feeding mechanism are provided; according to the two-stage feeding mechanism, an independent feeding mold oil cylinder is additionally arranged to work together with an original feeding mold oil cylinder, so that double-cylinder series feeding is realized; and the two-stage feeding mechanism is an extension of the first-stage feeding mechanism, the double cylinders can simultaneously progress and can also progress in a staggered manner, so that the process applicability is wide.

Owner:HARBIN INST OF TECH

Web curtain receiver

PendingCN112647192AEasy to operateReduce labor intensityLap forming devicesNon-woven fabricsEngineeringStructural engineering

The invention discloses a web curtain receiver which comprises a web curtain rack, a base, a plurality of transmission rollers, a first driving mechanism, a first lifting mechanism, a second lifting mechanism and a controller, the transmission rollers are rotationally installed on the web curtain rack, web curtains are arranged on the transmission rollers, and the first driving mechanism is in transmission connection with the transmission rollers; a first melting nozzle and a second melting nozzle are arranged above the web curtain at intervals, and air suction mechanisms are arranged at the positions, corresponding to the first melting nozzle and the second melting nozzle, below the web curtain; and the first lifting mechanism is installed at the end, close to the first melting nozzle, of the base, the second lifting mechanism is installed at the end, close to the second melting nozzle, of the bottom of the base, the power output ends of the first lifting mechanism and the second lifting mechanism fix the web curtain rack, and the distances between the first melting nozzle and the net curtain and between the second melting nozzle and the net curtain in the vertical direction are adjustable. The web curtain receiver can quickly and conveniently adjust the height between the web curtain and the melting nozzles, and the labor intensity is reduced.

Owner:BORCH MACHINERY

Automatic food feeding device

InactiveCN108773674AHigh degree of automationConducive to standardized product qualityCharge manipulationConveyor partsEngineeringMechanical engineering

Owner:蔡欣

High-strength bamboo fiber wound composite pipe and preparation method thereof

The invention discloses a high-strength bamboo fiber wound composite pipe and a preparation method thereof. The high-strength bamboo fiber wound composite pipe sequentially comprises a lining layer, a reinforcing layer and an outer protective layer from inside to outside, and belongs to the field of bamboo wound composite pipes. A lining layer sheet is wound around the surface of a mold roller, compacted through a pressure roller and finally cured to obtain the lining layer; a bamboo fiber lining sheet is composed of a thin film layer and a bamboo fiber layer adhered to the thin film layer, and the bamboo fiber layer is formed by adding glue into a bamboo fiber net; a bamboo fiber reinforced sheet is wound on the lining layer, compacted through the pressure roller, and cured to obtain the reinforcing layer; and outer protective layer glue is sprayed on the reinforcing layer and cured to obtain the outer protective layer. The high-strength bamboo fiber wound composite pipe has the beneficial effects that: the lining layer is composed of the thin film layer and the bamboo fiber layer, so that thin films as well as the thin films and the glue can be tightly bonded, and the added bamboo fiber layer can also improve the strength of the lining layer; and lining layer glue is coated with the thin film, and the curing thickness of the lining layer is controlled by controlling the feeding of the glue and fibers, so that the production is more convenient.

Owner:鑫竹海(福建)管道制造有限公司

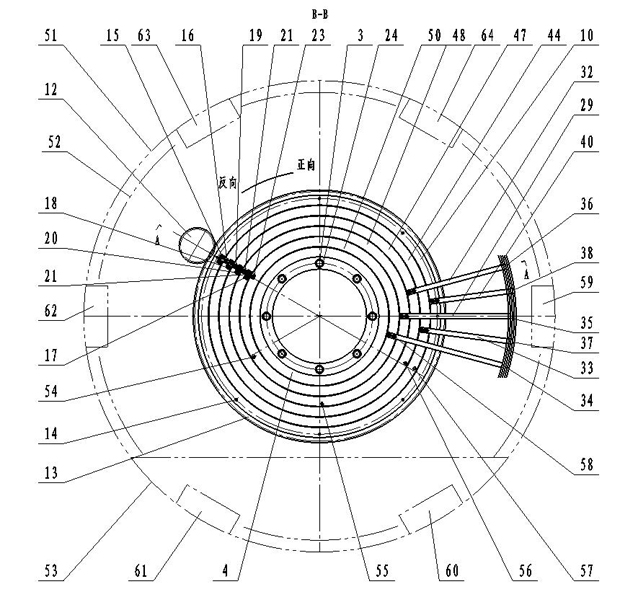

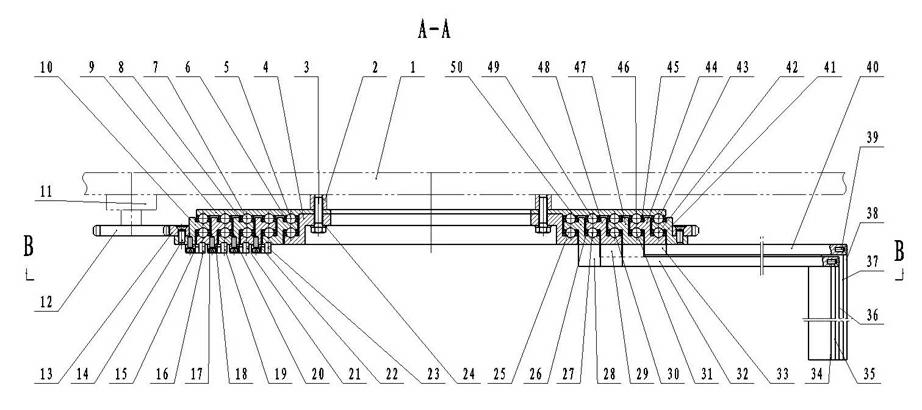

Shielding baffle plate mechanism used for vertical multi-target vacuum coating machine

InactiveCN102080211AFlexible operationEasy to arrangeVacuum evaporation coatingSputtering coatingDrive wheelEngineering

A shielding baffle plate mechanism used for a vertical multi-target vacuum coating machine comprises multistage seat rings, frame rods, baffle plates, a big gear ring and a driving mechanism. The shielding baffle plate mechanism is characterized in that the number of the baffle plates can be flexibly determined according to needs; the seat rings with the same number are sequentially sleeved from inside to outside and supported with each other by balls; the downside of each stage of seat ring is connected to one baffle plate through the frame rods; each stage of frame rods are arranged at different heights and angles so as to avoid interference; locating pins or limiting pins below the adjacent seat rings of inner sides can be poked by the baffle plate below each stage of seat ring and are driven to rotate forwardly and reversely; and the big gear ring is fixed by the outermost seat ring which is engaged with a driving wheel. Through accurately controlling the alternate forward and reverse rotation angles of the unique driving wheel, the baffle plates of each stage can be arranged at specified shielding positions so as to realize the condition that the baffle plates shield various possible position combination modes. The invention provides a key part structure with the advantages of comprehensive shielding function, flexible and reasonable structure and convenient and quick operation for a vacuum coating technology.

Owner:NORTHEASTERN UNIV

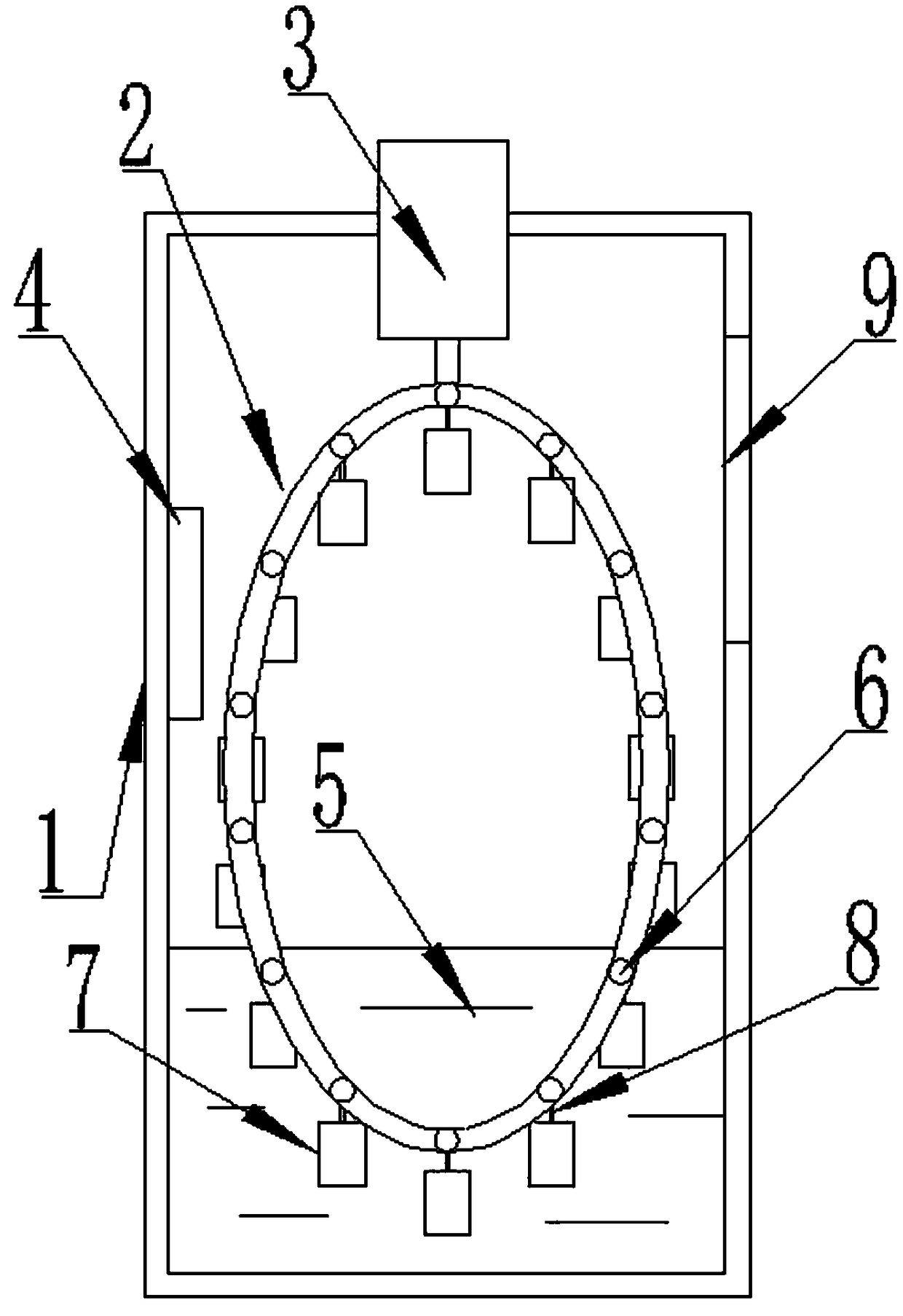

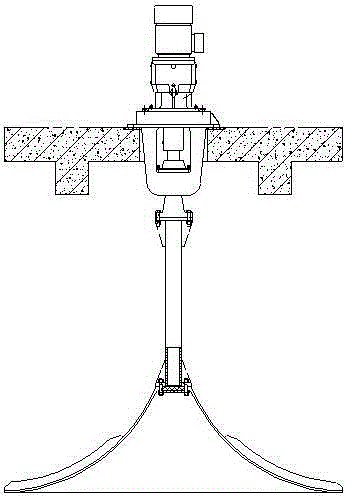

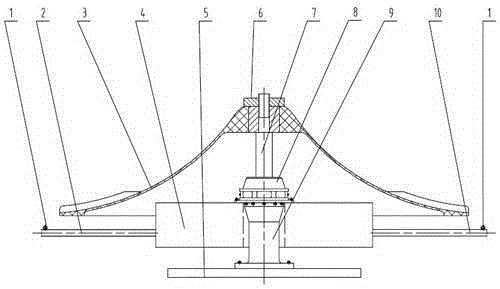

A submersible hyperboloid mixer

The invention discloses a submersible hyperboloid mixer. The submersible hyperboloid mixer comprises a stable ring, an air pipe, a hyperboloid impeller, a buoy, a pedestal, an impeller nut, an output shaft, a gear reducer, a submersible motor and a water pipe, wherein a power output shaft of the submersible motor is connected with an input shaft of the gear reducer; the hyperboloid impeller is assembled on an output shaft of the gear reducer and fixed by the impeller nut; the submersible motor and the gear reducer are fixed on the buoy; a water pipe and an air pipe are connected on the buoy; the pedestal is connected with the submersible motor. The submersible hyperboloid mixer can stir at different depths in the wastewater treatment process through adjusting the proportion of air and water in the buoy on the submersible hyperboloid mixer, and can be successfully installed without stopping the sewage treatment process so as to ensure the normal operation of the sewage treatment process and shorten the reconstruction time; thus, the submersible hyperboloid mixer is reliable and convenient to install.

Owner:LANSHEN GRP CORP LTD +1

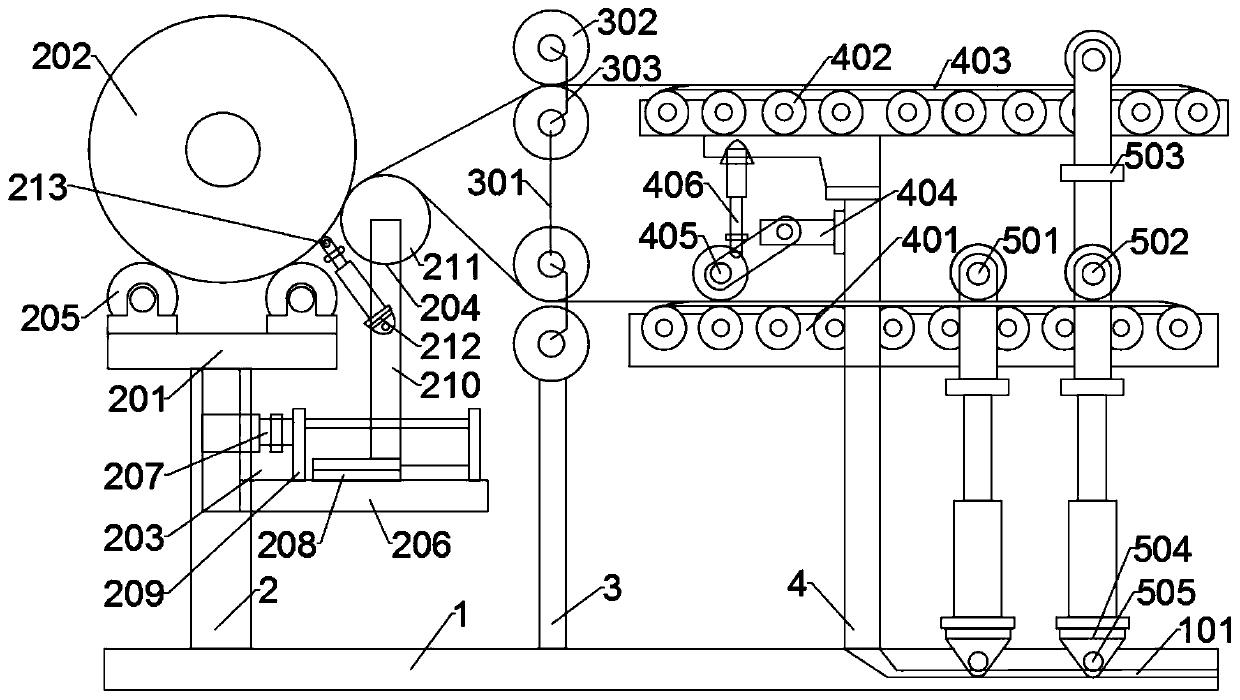

A double-circle diaphragm automatic film feeding equipment

ActiveCN109051071BTo achieve the film feeding effectMeet different process needsWrapping material feeding apparatusCantileverMechanical engineering

The invention discloses a double-circle diaphragm automatic film feeding device, which comprises a flat base, a first vertical support rod, a second vertical support rod, and a third vertical supportrod. The first vertical support rod, the second vertical support rod, and the third vertical support rod are mounted with a film placing device, a slack adjusting device, and a film feeding device. The film placing device comprises a carrier plate mounted on the top of the first vertical support rod by a hinge. The top of the first vertical support rod is mounted with a film placing roller by a fixing rod, and a film splitting shaft is mounted on the side of the first vertical support rod by an extension platform. The film feeding device comprises two sets of horizontal substrate arranged in parallel on the third vertical support rod. A convey belt is sleeved at the horizontal substrates by rollers. A glue coating roller is mounted on the side of the third vertical support rod top by a horizontal cantilever. The double-circle diaphragm automatic film feeding device can integrate the film feeding, splitting, and conveying, and can adjust the pressing effect of the diaphragm fitly whilethe films are independently fed, so that the different process requirements can be satisfied.

Owner:四川省绵阳市鸿永盛模塑有限公司

A substrate decompression drying system and drying method thereof

ActiveCN106111487BReduce removal timeImprove drying efficiencyPretreated surfacesCoatingsDual effectEngineering

The invention discloses a pressure-reduction drying system and method for a substrate. The pressure-reduction drying system comprises an airtight drying cavity (1). A drying platform (3) used for bearing the substrate (2) is arranged in the drying cavity (1). Vacuumizing holes (4) communicating with the interior of the drying cavity are further formed in the drying cavity (1). The pressure-reduction drying system is provided with a temperature controller (5). A heating structure (6) used for heating the substrate (2) is arranged on the drying platform (3). The temperature controller (5) is electrically connected with the heating structure (6) and used for controlling the heating temperature of the heating structure (6). According to the pressure-reduction drying system and method for the substrate, the heating structure is arranged on the drying platform for bearing the substrate, the heating temperature of the heating structure is controlled through the temperature controller, and time for removing a solvent of the substrate in the drying cavity is shortened under the dual effects of vacuumizing and heating, the drying efficiency is improved, and the productivity is improved accordingly.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

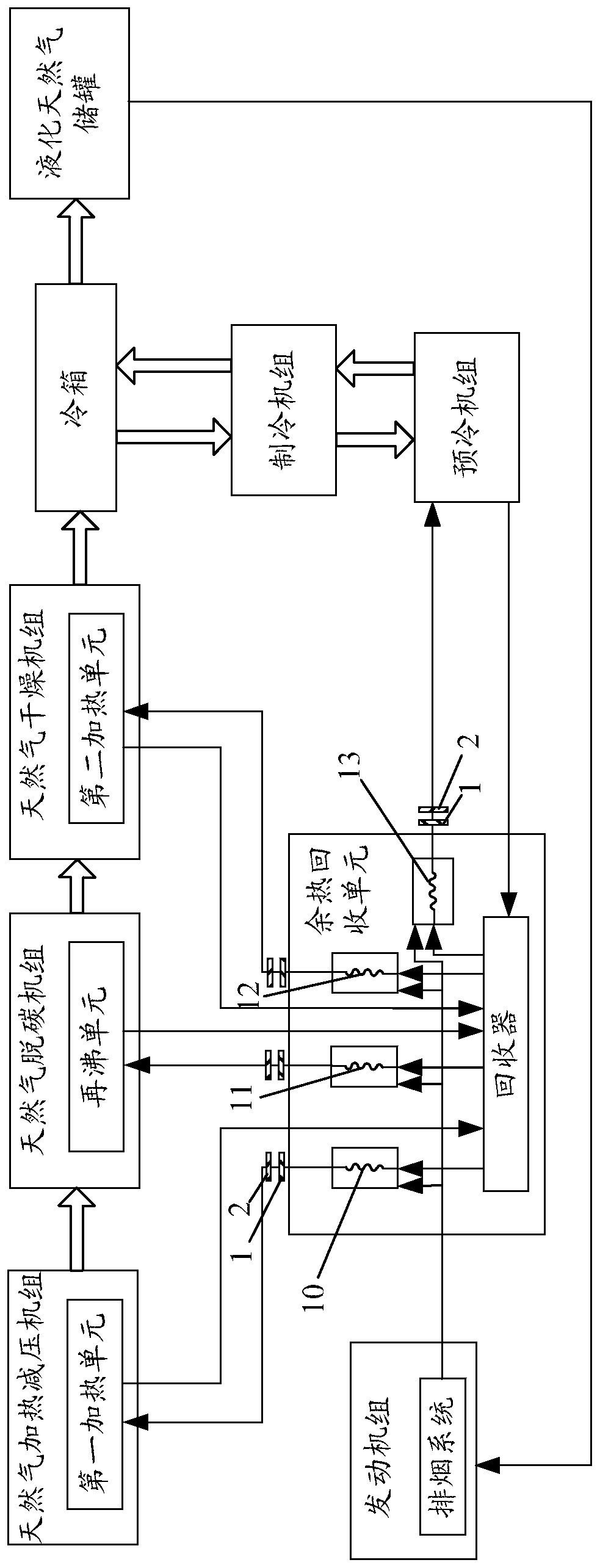

Skid-mounted natural gas liquefaction device and technology

PendingCN110360810AReduce energy consumptionReduce cooling energy consumptionSolidificationLiquefactionProcess engineeringRefrigeration

The invention relates to the technical field of natural gas liquefaction, and discloses a skid-mounted natural gas liquefaction device and technology. A waste heat recycling unit is arranged, an inletend of the waste heat recycling unit is communicated with a smoke discharge port of a smoke discharge system of a power generator unit, heat exchange mediums are utilized for recycling heat of discharged smoke of the smoke discharge system of the power generator unit in a way of heat exchange, the high-temperature heat exchange mediums absorbing the heat of the discharged smoke heat natural gas in the natural gas liquefaction technology in a way of heat exchange, thus the energy consumption for the skid-mounted natural gas liquefaction technology is greatly lowered, and the energy consumptionis greatly reduced. Meanwhile, the temperatures of the heat exchange mediums conveyed to different technologies are different, and thus different technology requirements are met. Besides, part of thehigh-temperature heat exchange mediums obtained after heat exchange with the discharged smoke are conveyed to a precooling unit, so that the refrigeration energy consumption of a refrigeration unit is lowered, and the energy consumption of the whole technology is further lowered.

Owner:山东巨创燃气设备有限公司

A kind of steel thread automatic processing production line

ActiveCN105690100BOccupy less laborSmall footprintOther manufacturing equipments/toolsProduction lineEngineering

The invention belongs to the field of building material processing machinery, and in particular relates to an automatic reinforcing steel bar thread machining production line which comprises a conveying mechanism and a plurality of moving mechanisms, wherein the moving directions of the moving mechanisms are perpendicular to the conveying direction of the conveying mechanism; a plurality of lifting clamping devices are arranged on the moving parts of the moving mechanisms; clamping openings of the lifting clamping devices face reinforcing steel bars on the conveying mechanism; machining equipment is arranged at two ends of the moving mechanisms; a limiting block is rotationally connected with one side of a reinforcing steel bar machined by each machining equipment on the conveying mechanism; rotation limiting positions of the limiting blocks are all above the conveying surface of the conveying mechanism; the other rotation limiting positions are below the conveying surface of the conveying mechanism. The automatic reinforcing steel bar thread machining production line has the beneficial effects that the reinforcing steel bars do not need to be moved and loaded and unloaded manually, so that the labor can be saved, and the machining efficiency can be improved; the occupied area is small; the reinforcing steel bars can roll under the action of gravity of self, so that the energy can be saved and the emission can be reduced; the automation degree is high, and the labor intensity is low; a baffle can be aligned with the reinforcing steel bars, a gradually shrunk channel has a guide function, and good thread machining quality can be achieved.

Owner:无锡天盈建筑科技有限公司

A kind of nano/micro gold film and preparation method thereof

ActiveCN104192789BHigh mechanical strengthEasy to stretchSemi-permeable membranesFixed microstructural devicesGold filmMechanical property

The invention discloses a nanometer / micron gold film and a preparing method thereof. The nanometer / micron gold film comprises a matrix and a nanometer / micron gold layer. The nanometer / micron gold layer is formed by metal nanoparticles in a deposition mode. Amidogens are arranged on the surface of the matrix. The metal nanoparticles and the amidogens on the surface of the matrix form strong interaction. The preparing method comprises the steps that (1) the surface of the matrix is subjected to oxygen plasma treatment or ultraviolet irradiation; (2) the surface-activated matrix is soaked into an NH2(CH2)3Si(OC2H5)3 solution; and (3) a mixed solution of chloroauric acid and bicarbonate of a strong base and a glucose solution are evenly mixed and are arranged on the surface-amination matrix in a coating mode, and the nanometer / micron gold film is obtained through light-avoiding reaction. According to the nanometer / micron gold film, the types of matrixes are multiple, different mechanical property requirements can be met, combining is firm, breaking is not easy, according to the method, reaction is mild, and cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

Automatic three-dimensional Liangpi machine

The invention discloses an automatic three-dimensional Liangpi machine. The machine comprises an upper shell, a control box, a support rod, a feeding funnel and an unloading device, an air outlet pipeis arranged on the surface of the upper shell, a motor is arranged below the upper shell, the control box is arranged on the right side of the motor, a steam control screen is arranged on the surfaceof the control box, a power switch is arranged on the right side of the steam control screen, a steam adjusting knob is arranged on the surface of the control box, a rotating speed adjusting knob isarranged below the steam adjusting knob, a speed changer is arranged on the right side of the control box, a former is arranged on the lower side of the feeding funnel, the control box is connected tothe former through a steam pipe, the unloading device is arranged in the feeding funnel, and unloading pipe is arranged in the unloading device, and an adjusting handle is arranged on the surface ofthe unloading device. According to the invention, a discharge nozzle can be replaced according to actual requirements through a fastening device arranged below the former so as to meet different process requirements, and to improve the functionality of equipment.

Owner:李洁

A kind of battery edge passivation method

ActiveCN111509091BFully effective passivationAvoid passivationFinal product manufacturePhotovoltaic energy generationUltraviolet lightsSilicon oxide

The invention discloses a battery edge passivation method. The slurry is printed on the edge of the crystalline silicon battery to be passivated by coating, and the edge is irradiated with ultraviolet light, so that under the condition of photocatalytic oxidation, A silicon oxide passivation film is formed on the side; the slurry contains hydrogen peroxide and SiO 2 powder; after the silicon oxide passivation film is formed on all sides that need to be passivated on the crystalline silicon battery, annealing treatment is performed on the crystalline silicon battery that has completed photocatalytic oxidation. Further, the present invention also discloses the application of the above method. The invention utilizes the photocatalytic oxidation technology to passivate the edge of the crystalline silicon solar cell, thereby reducing electrical recombination and leakage at the edge of the cell, and improving the photoelectric conversion efficiency of the cell.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com