CO conversion reaction furnace

A technology of transformation reaction and furnace body, applied in the direction of inorganic chemistry, non-metallic elements, chemical instruments and methods, etc., to achieve the effect of avoiding side reactions of methanation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

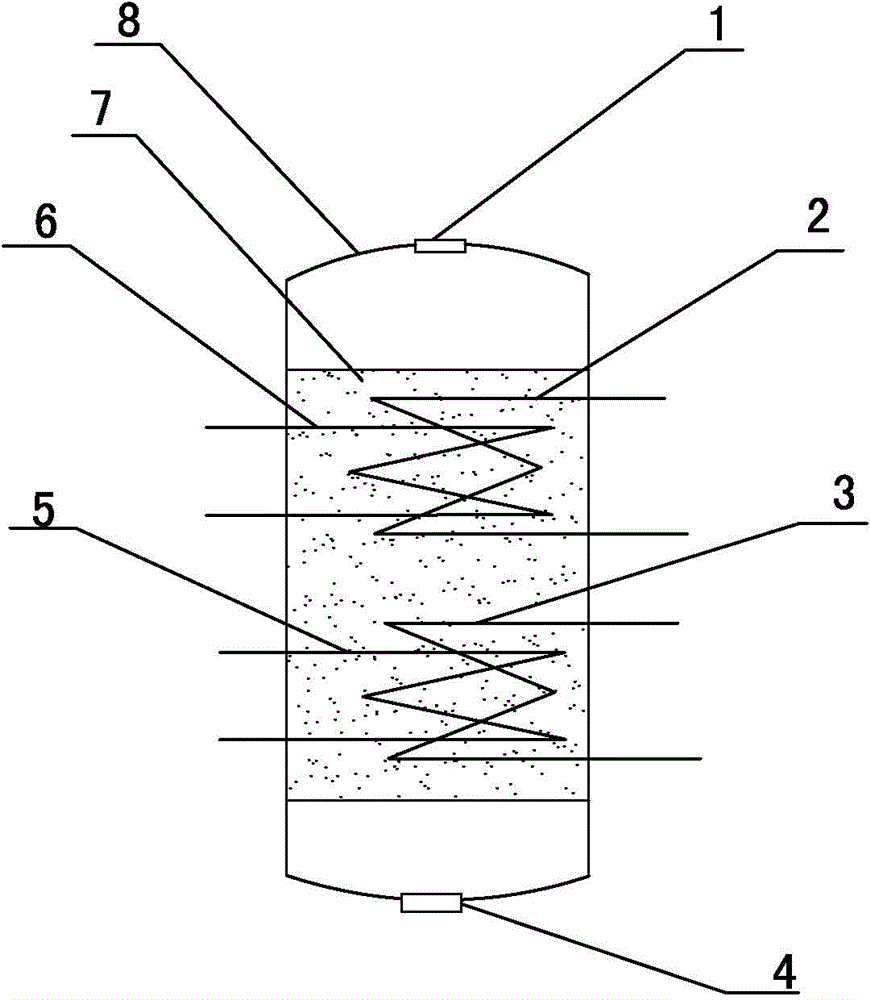

[0019] Such as figure 1 As shown, including the body of furnace 8, the top of the body of furnace 8 is provided with a feed inlet 1, the bottom of the body of furnace 8 is provided with a discharge port 4, the inside of the body of furnace 8 is provided with a catalyst bed 7, and the distance from the top of the body of furnace 8 is 100% of that of the body of furnace. The first heat exchange device is set at 16% of the height of the furnace body 8. The first heat exchange device is composed of the first large heat exchange coil 2 and the first small heat exchange coil 6. Set up the second heat exchange device at 20%, the second heat exchange device is composed of the second large heat exchange coil 3 and the second small heat exchange coil 4, the first large heat exchange coil 2 and the second large heat exchange coil The pipe 3 diameter is 75% of the furnace body diameter, and the diameter of the first small heat exchange coil 6 and the second small heat exchange coil 5 is 5...

Embodiment 2

[0021] Such as figure 1 As shown, including the body of furnace 8, the top of the body of furnace 8 is provided with a feed inlet 1, the bottom of the body of furnace 8 is provided with a discharge port 4, the inside of the body of furnace 8 is provided with a catalyst bed 7, and the distance from the top of the body of furnace 8 is 100% of that of the body of furnace. The first heat exchange device is set at 22% of the height of the furnace body. The first heat exchange device is composed of the first large heat exchange coil 2 and the first small heat exchange coil 6. The distance from the bottom of the furnace body 8 accounts for 20% of the height of the furnace body The second heat exchange device is set at 25%, the second heat exchange device is composed of the second large heat exchange coil 3 and the second small heat exchange coil 4, the first large heat exchange coil 2 and the second large heat exchange coil The pipe 3 diameter is 65% of the furnace body diameter, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com