A kind of battery edge passivation method

An edge and battery technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of reducing the performance of small cells, increasing the loss of electrical performance, and damage to the edges of small cells, so as to improve photoelectric conversion efficiency, improve power generation performance, The effect of no pollution in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

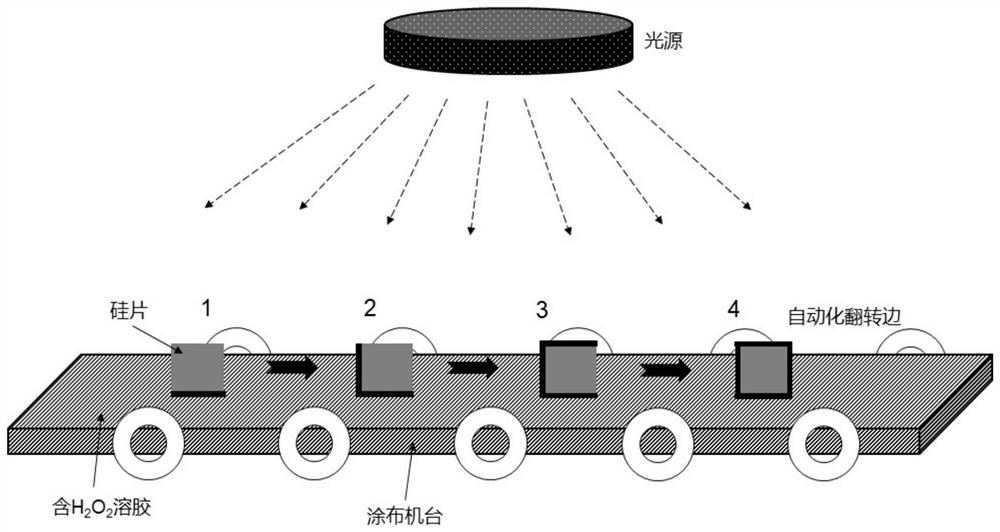

[0036] Embodiment 1 discloses a battery edge passivation method, which is used in the production process of the battery. This step can be considered to be arranged after the silicon substrate emitter junction is fabricated, and before the anti-reflection film and passivation film are prepared on the front and back, without affecting The other steps of battery fabrication are carried out. Specifically include the following steps:

[0037] A1: Preparation of oxidant (also photocatalyst), that is, slurry containing hydrogen peroxide, the main components are hydrogen peroxide, SiO 2 Powder and other ingredients. The details are as follows: first configure the 30 wt% H 2 o 2 solution 100 ml, and then continuously add SiO to the solution 2 15 g of powder (the particle size of the powder is 0.2 microns), until the gel is formed, and finally add 2 g of resin (binder) and stir evenly to form a slurry.

[0038] A2: After making the phosphorus emitter junction (or boron emitter junc...

Embodiment 2

[0043] Embodiment 2 discloses a battery edge passivation method for passivating the battery edge after cutting, which specifically includes the following steps:

[0044] B1: Preparation of oxidant (also photocatalyst), that is, slurry containing hydrogen peroxide, the main components are hydrogen peroxide, SiO 2 Powder and other ingredients. The details are as follows: first configure the 30 wt% H 2 o 2 solution 100 ml, and then continuously add SiO to the solution 2 15 g of powder (the particle size of the powder is 0.2 microns), until the gel is formed, and finally add 2 g of resin (binder) and stir evenly to form a slurry.

[0045] B2: Select a 156 mm*156 mm n-type monocrystalline silicon cell, and cut the cell by laser to form a half piece (also called a half piece). Of course, it can also be cut pieces such as one-third piece, one-quarter piece, ..., one-Nth piece.

[0046] B3: Place the above-mentioned cut battery half piece on the coating tape, the cutting edge is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com