3D glass polishing equipment

A technology of glass and equipment, applied in the field of glass processing, can solve the problems of low equipment space utilization, inconsistent polishing effect, long polishing time, etc., and achieve the effect of saving labor and labor costs, cleaning the surrounding environment of equipment, and quick and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

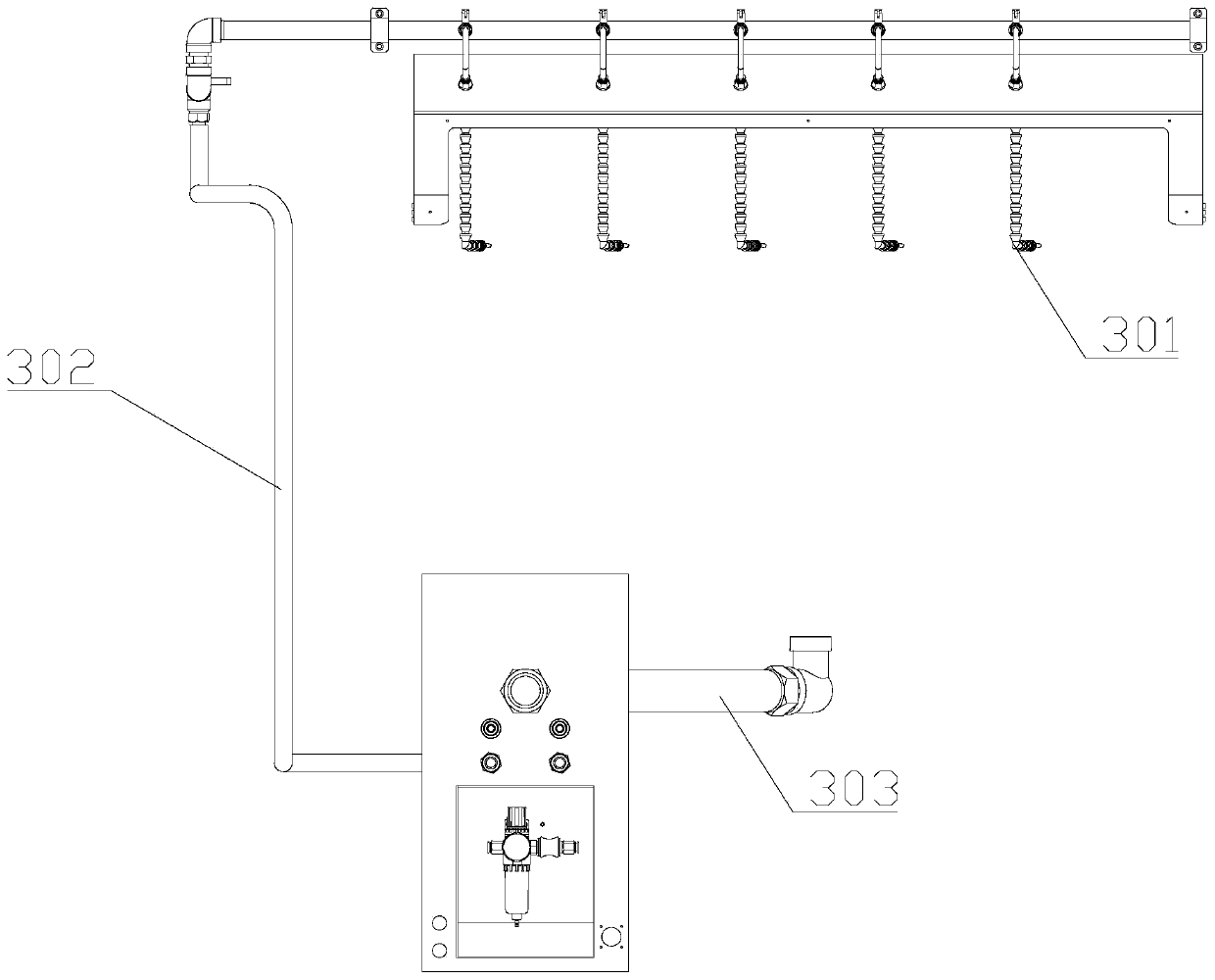

[0034] This embodiment provides a kind of 3D glass polishing equipment, the structure of described 3D glass polishing equipment is as follows figure 1 As shown, it includes a mounting frame body 1 on which an X-Y moving mechanism 2, a polishing liquid injection mechanism 3, a polishing wheel mechanism 4, a jig mechanism 5, a lifting mechanism 6 and an automatic loading and unloading mechanism 7 are installed. The X-Y moving mechanism 2 is connected with the polishing wheel mechanism 4 for driving the polishing wheel mechanism 4 to move along the X-Y direction, while the X-Y moving mechanism 2 is connected with the polishing liquid injection mechanism 3 for driving the polishing wheel mechanism 4 to move along the X-Y direction. The polishing liquid injection mechanism 3 moves along the X-Y direction, and the lifting mechanism 6 is connected with the jig mechanism 5 for driving the jig mechanism 5 to move up and down in the vertical direction.

[0035]The working process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com