Magnetic false-twisting apparatus dedicated for spandex fibers

A technology of spandex fiber and false twisting, which is applied in the field of false twisting in the spandex fiber spinning section, which can solve the problems of high labor intensity, high operating cost, and loud noise, and achieve the effect of high labor intensity, high operating cost and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

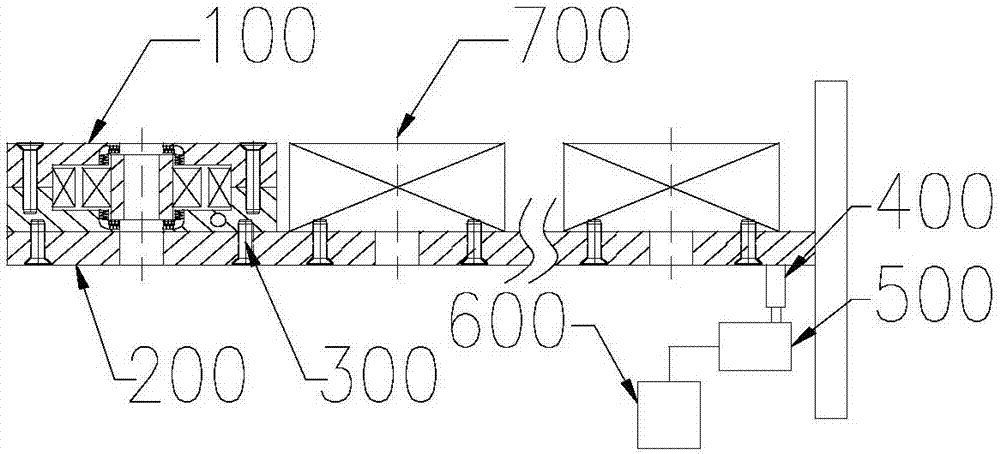

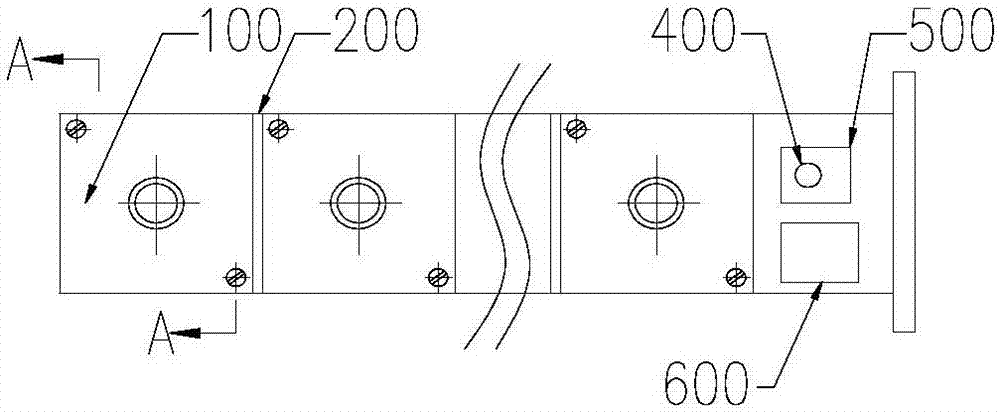

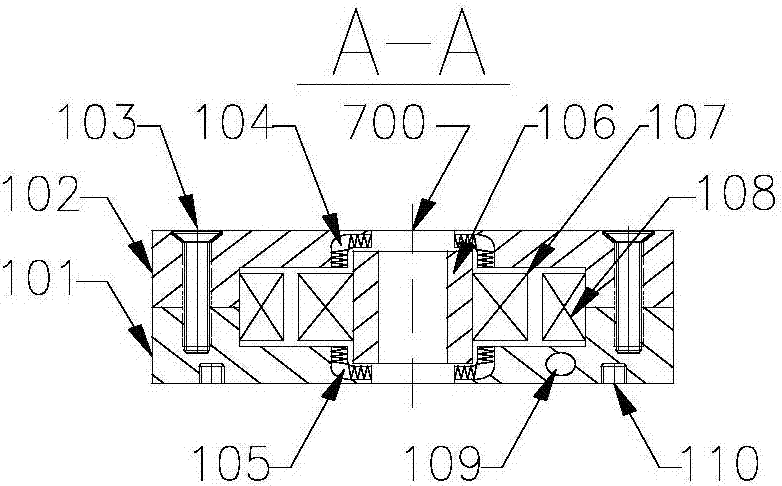

[0036] The invention utilizes the principle of magnetic levitation to realize the non-contact support and positioning of the false twist balloon. Specifically, the horizontal magnets of the upper and lower electromagnetic coils in the false twist unit are energized to generate axial magnetic levitation force to suspend the false twist balloon in the false twist unit, and the shaft is lifted. The vertical magnets of the upper and lower electromagnetic coils in the false twist unit are energized to generate longitudinal magnetic levitation force to keep the gap between the main pole stator and the iron core rotor unchanged;

[0037] At the same time, the present invention also uses the principle of electromagnetic field drive to drive the false twist balloon to rotate at high speed without contact. Specifically, the main magnetic pole stator is energized by the commutation pole to generate a magnetic field to drive the iron core rotor to rotate, and the iron core rotor is fixed ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com