Shielding baffle plate mechanism used for vertical multi-target vacuum coating machine

A technology of vacuum coating machine and baffle mechanism, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., to achieve the effects of reducing manufacturing cost, flexible operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

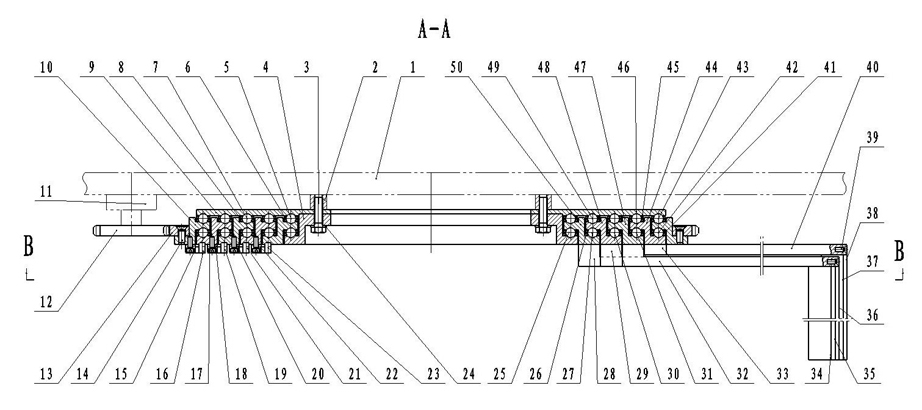

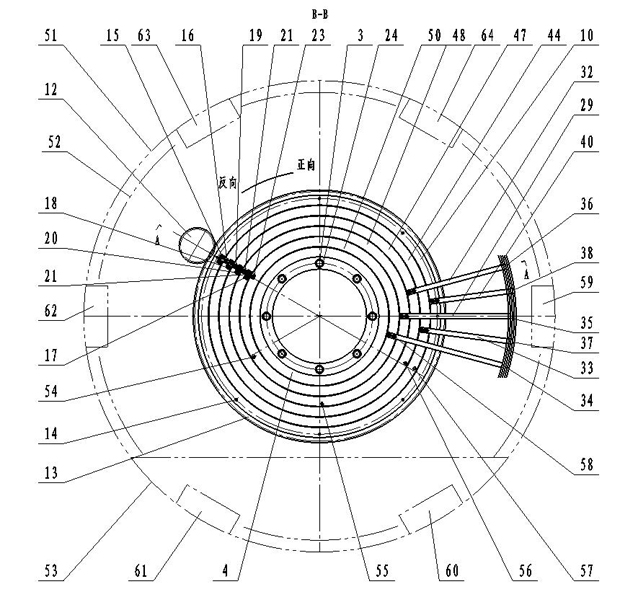

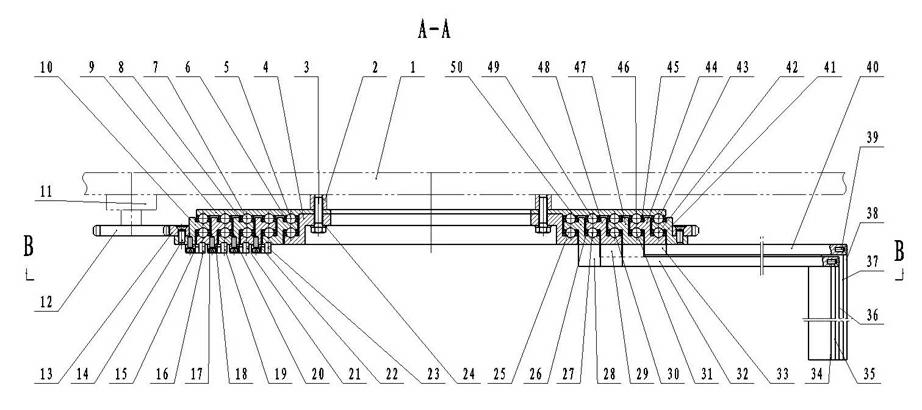

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

[0033] The composition of this embodiment is as figure 1 with figure 2 As shown: a cylindrical vertical vacuum coating machine, on the circumference of the vacuum chamber side wall 51, 6 coating target sources 59, 60, 61, 62, 63, 64 are evenly distributed; the shielding block of the embodiment of the present invention The design of the plate mechanism adopts 5 shielding baffles 34, 35, 36, 37, 38, at least one coating target position is shielded during work, and at most 5 target positions are shielded at the same time.

[0034] Relying on the inner ring 4, the first-stage ball cage 6 with the first-stage lower ball 25 is placed on the outer ring plate of the inner ring 4; the first-stage seat ring 50 is set outside the inner ring 4, and the first-stage The inner ring plate of the seat ring 50 is pressed on the first-stage lower ball 25; on the inner ring plate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com