Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve equipment capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

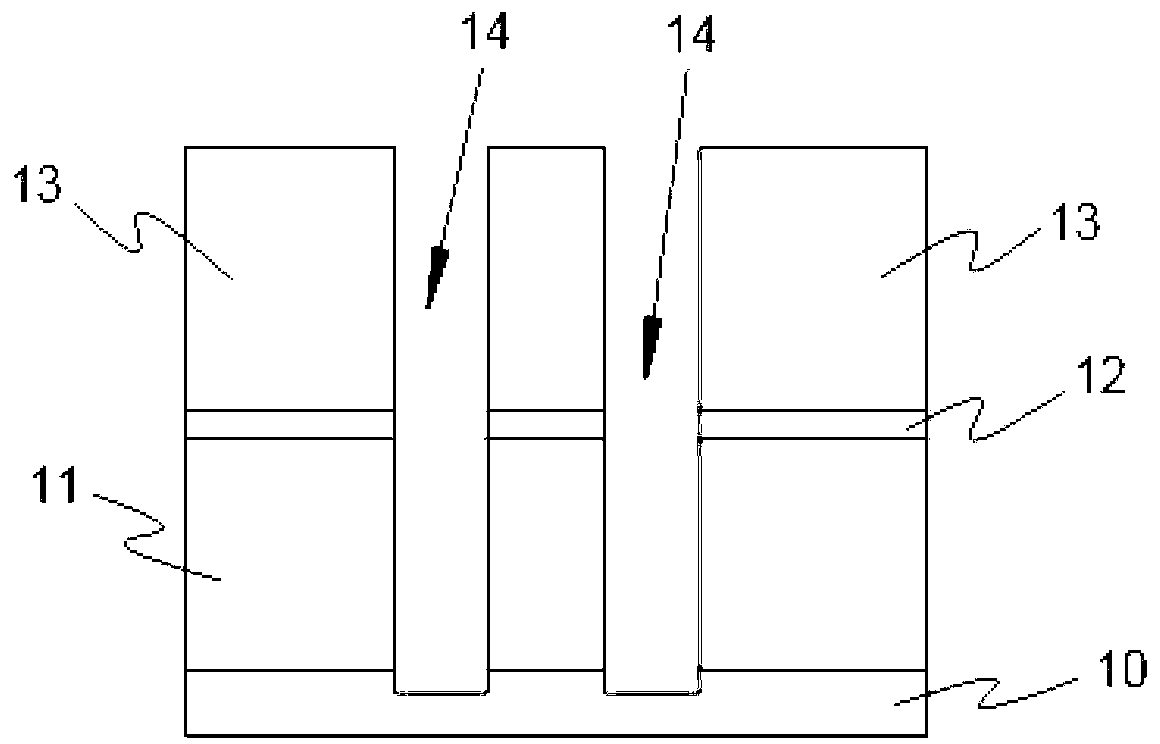

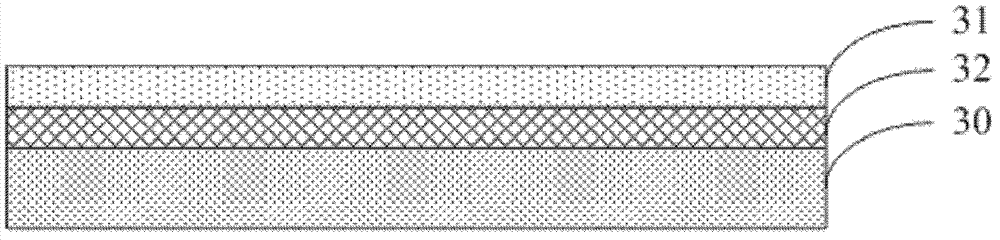

Method for manufacturing X-ray sensor

ActiveCN102629613AReduce in quantityLow costSolid-state devicesRadiation controlled devicesInsulation layerOhmic contact

The invention discloses a method for manufacturing an X-ray sensor. The method comprises: preparing at least two gate scanning lines on a substrate; successively depositing a gate insulation layer, an active layer film, an ohmic contact layer film, a first conducting layer film, and a photovoltaic conversion layer film on the substrate and the gate scanning line and preparing at least two data lines intersected with the gate scanning lines, a photoelectric sensing device and a switching device; preparing a first passiviation layer covering the photoelectric sensing device and the switching device and preparing a via hole on the first passiviation layer, wherein the via hole is located at a selected position in a photoelectric sensing device region; preparing bias lines at a positions corresponding to positions of the data lines and the switching device on the first passiviation layer, wherein the bias lines are electrically connected with the photoelectric sensing device through the via hole; and preparing a second passiviation layer covering the bias lines and the first passiviation layer. According to the method provided by the invention, product cost is reduced and a yield rate and equipment capacity are improved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

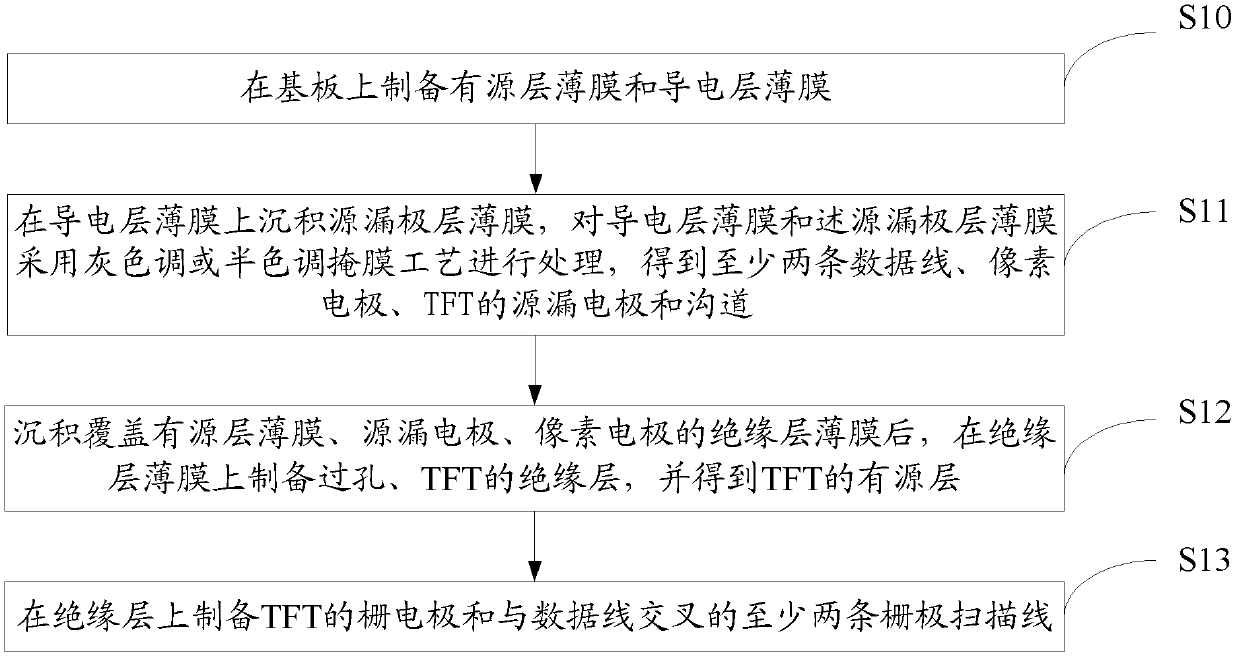

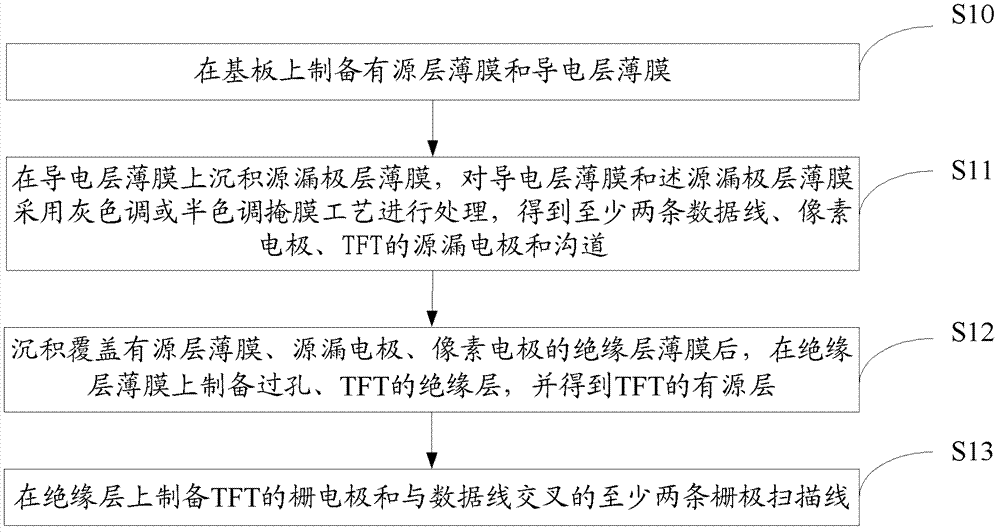

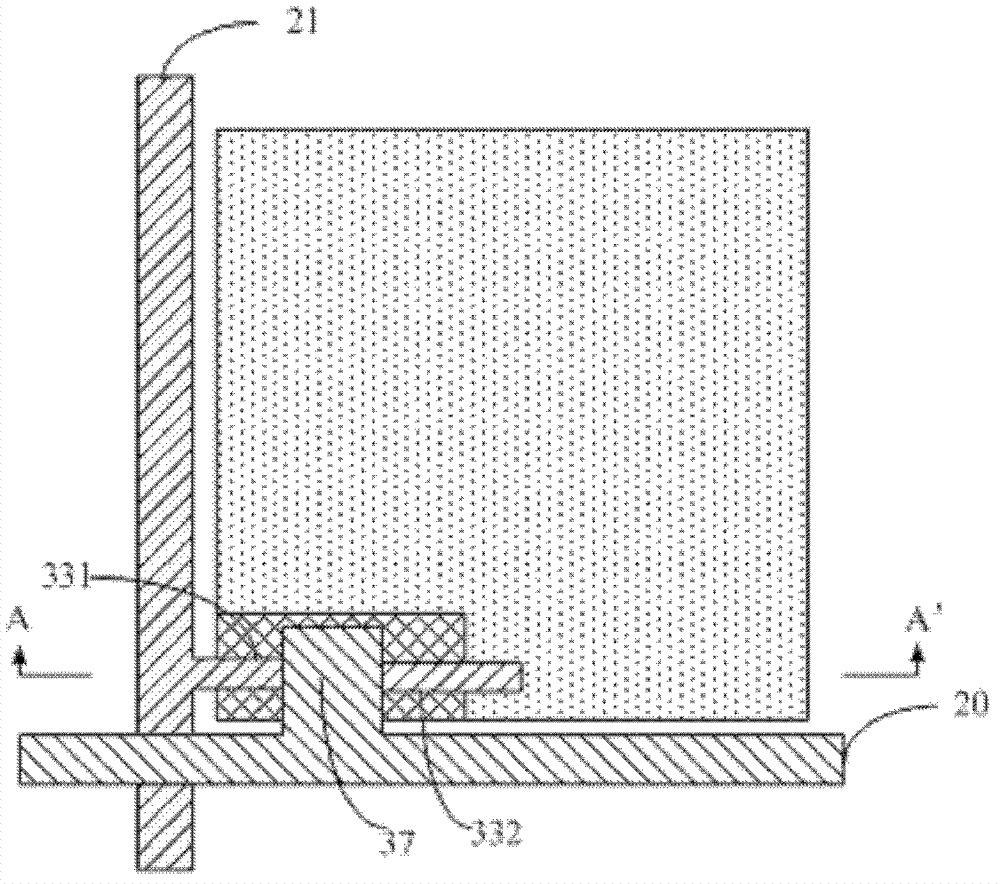

Thin film transistor array substrate and manufacturing method thereof

ActiveCN102629590ALow costReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringActive layer

The invention discloses a thin film transistor array substrate and a manufacturing method thereof. The manufacturing method comprises the following steps: preparing an active layer film and a conducting layer film on the substrate; depositing a source drain layer film on the conducting layer film, using a gray tone or halftone mask process to process the conducting layer film and the source drain layer film so as to obtain at least two data lines, a pixel electrode, a source drain electrode of the TFT (thin film transistor) and a channel; making a source electrode of one column of the TFT on the array substrate connect with one data line; after depositing an insulating layer film which covers the active layer film, the source drain electrode, the data lines and the pixel electrode, preparing via and an insulating layer of the TFT on the insulating layer film and obtaining the active layer of the TFT; preparing a gate electrode of the TFT and at least two grid scanning lines which are intersected with the data lines, and making the gate electrode of one row of the TFT on the array substrate connect with one grid scanning line. By using the method of the invention, product cost can be reduced, and a yield and an equipment capacity can be increased.

Owner:BOE TECH GRP CO LTD

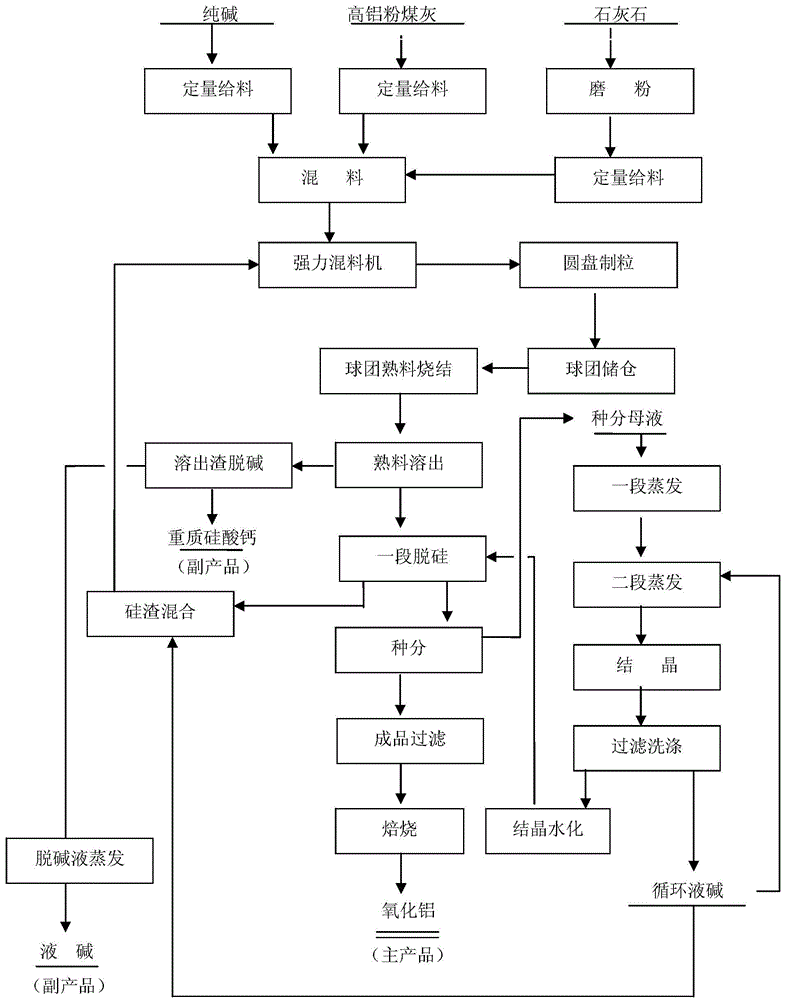

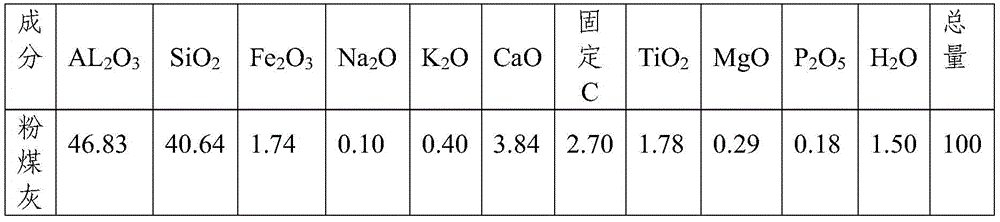

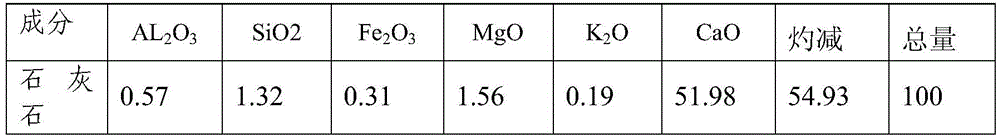

Method for producing aluminum oxide with high-alumina fly ash

ActiveCN105565350AImprove equipment capacityReduce energy consumptionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionAluminium oxide

The invention provides a method for producing aluminum oxide with high-alumina fly ash. The method includes the following steps that 1, fly ash, sodium carbonate and alkali liquor are added into limestone for burdening, pellets are made with a disc-type pelletizing machine, the finished pellets are baked, dried, preheated, sintered and cooled to be sintered into sintered pellets, the sintered pellets are subjected to dry milling with a vertical mill, water or slag washing water is added for digestion, water or washing water is mixed with slag for dealkalization, digestion liquor is desiliconized, aluminum hydroxide crystal seeds are added for seed decomposition, Al(OH)3 is obtained after decomposition, and aluminum oxide is obtained after roasting; seed decomposition mother liquor is evaporated and desalted in two steps. By means of the method, efficient and comprehensive utilization of fly ash is achieved; calcium silicate byproducts of different specifications can be produced by controlling a burdening formula, sintering conditions and dealkalization conditions, the volume weight can be controlled to be 300-800 kg / m<3>, the calcium silicate byproducts are suitable for building material and soil conditioning respectively, the light weight property of the calcium silicate byproducts can be guaranteed, and the reduction of transport cost can also be guaranteed.

Owner:开曼铝业(三门峡)有限公司

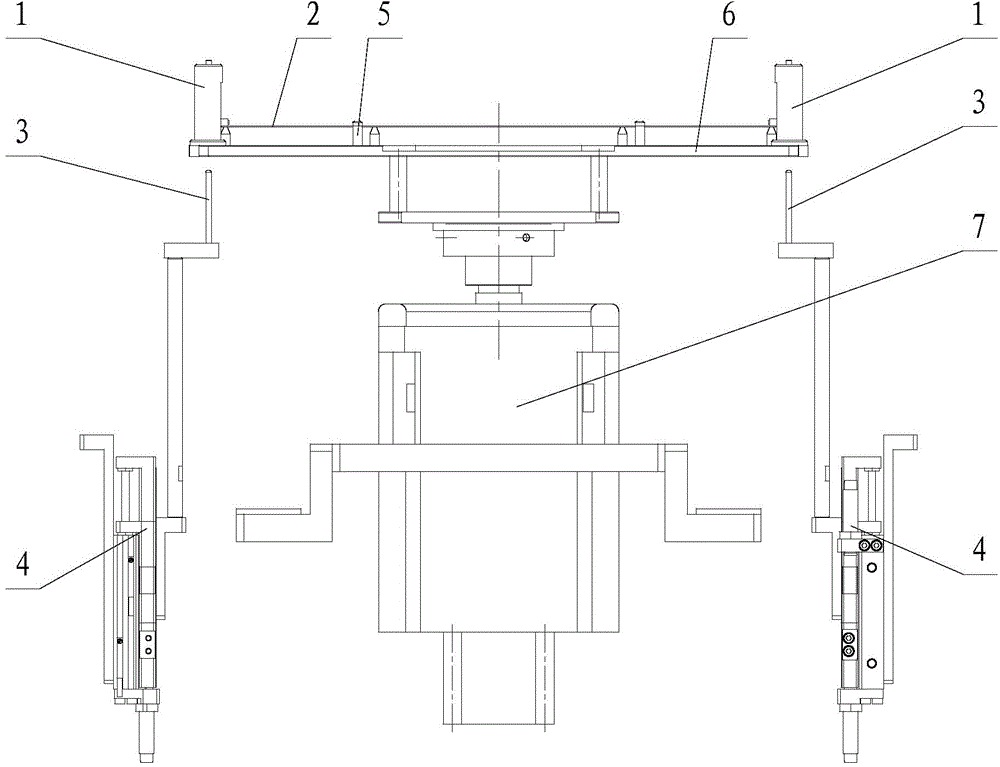

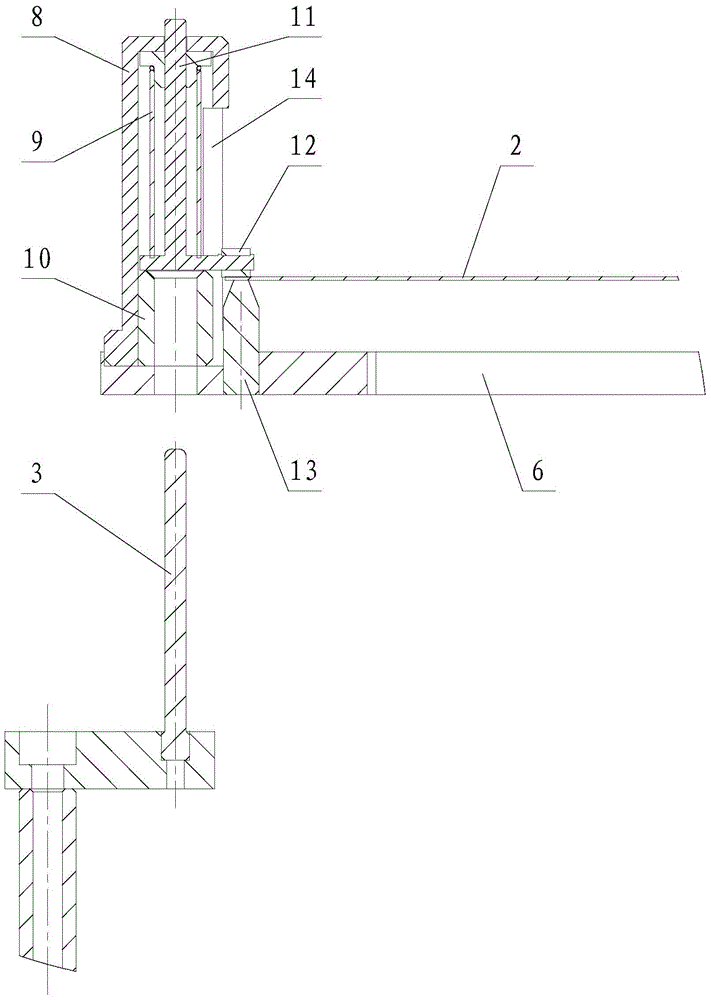

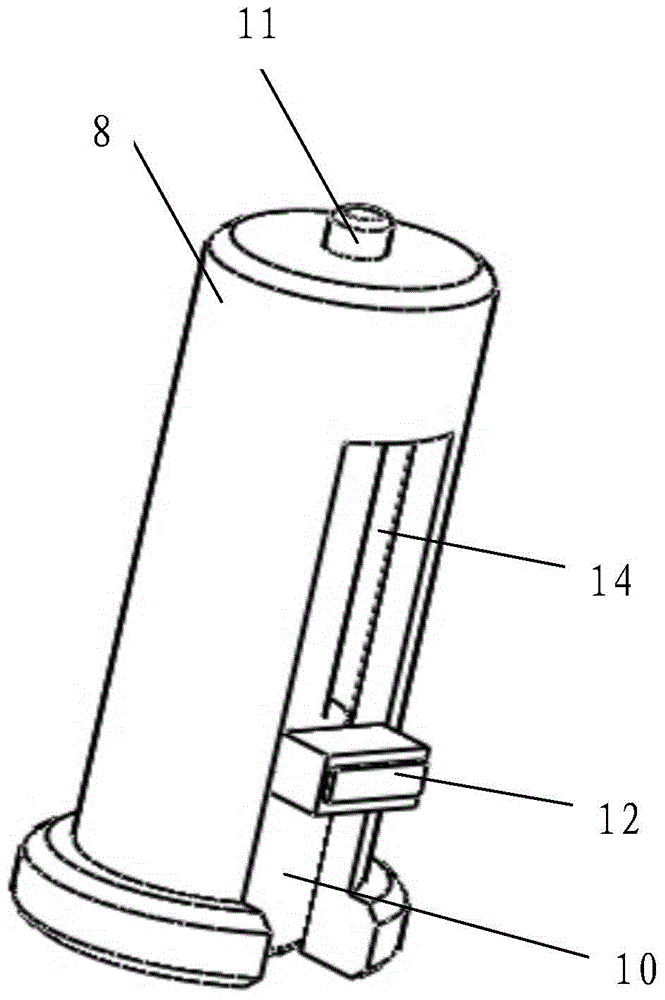

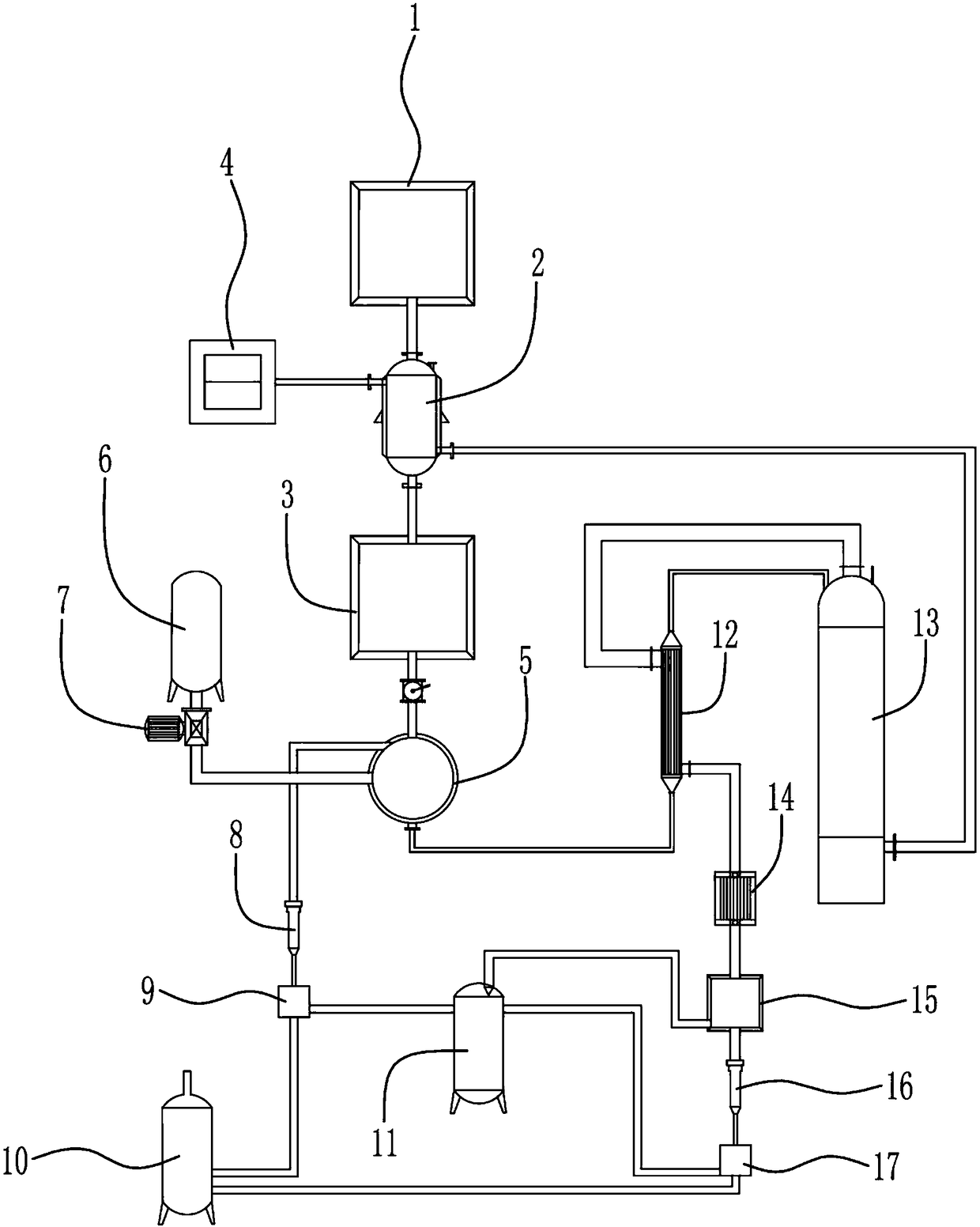

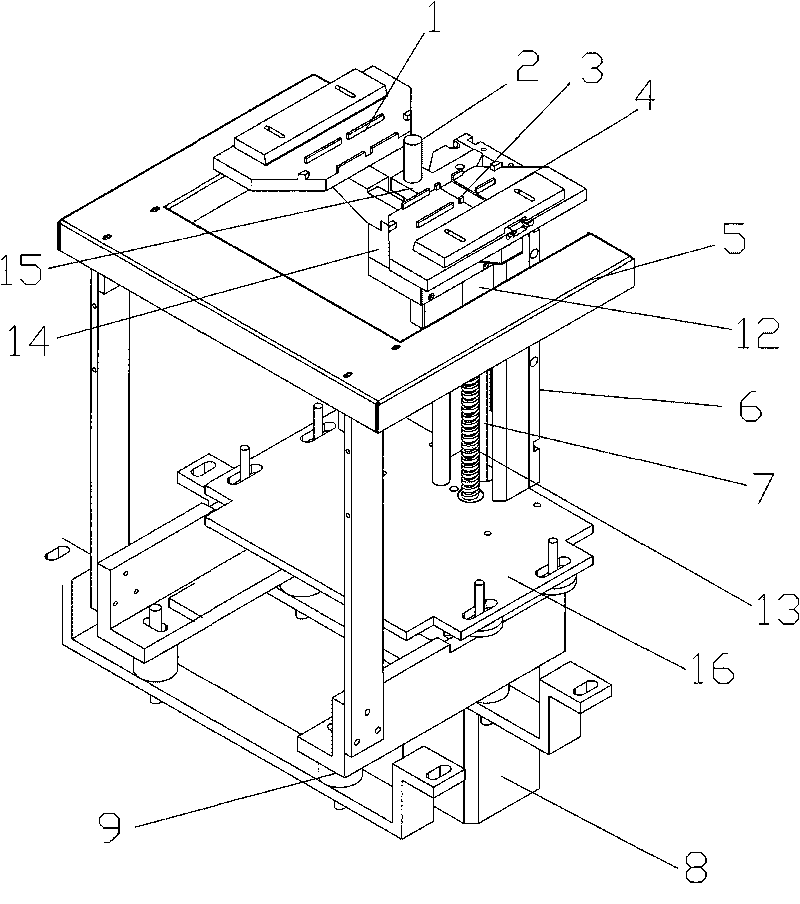

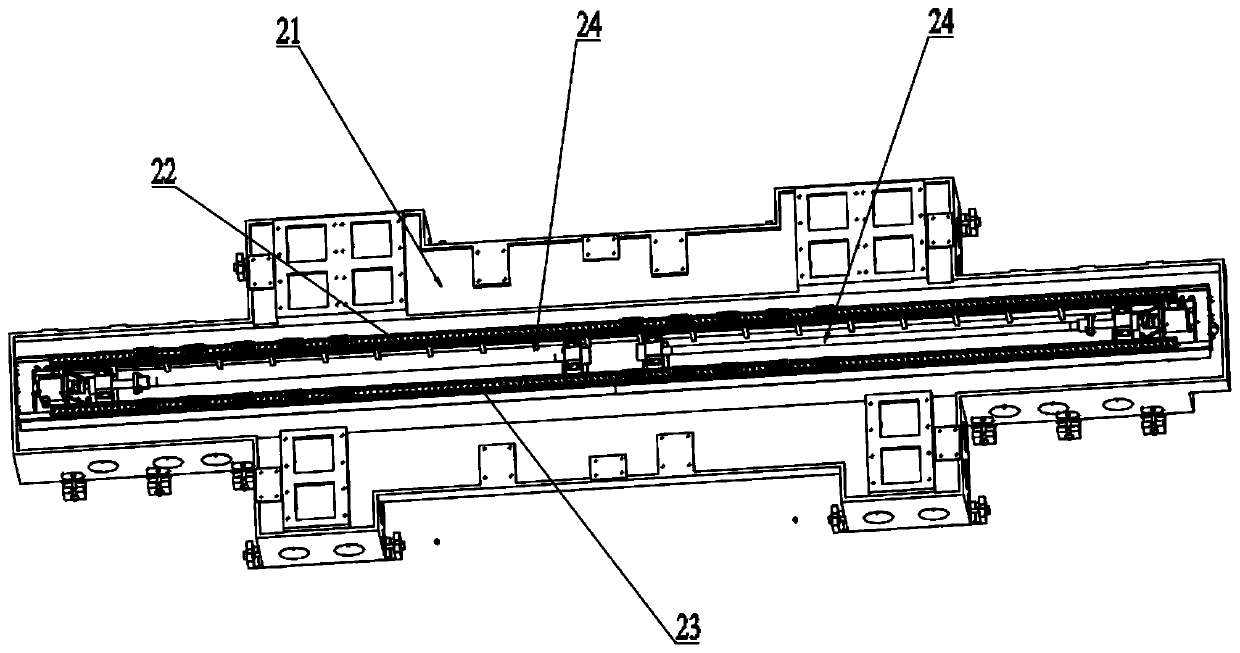

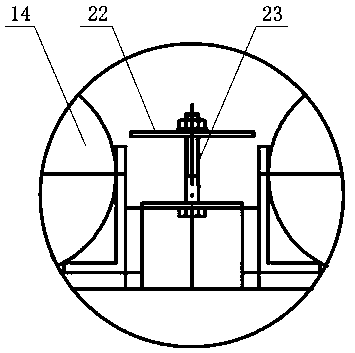

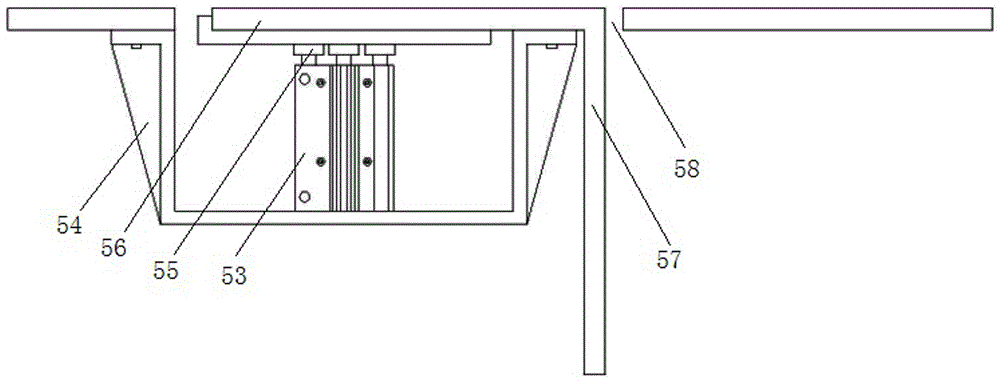

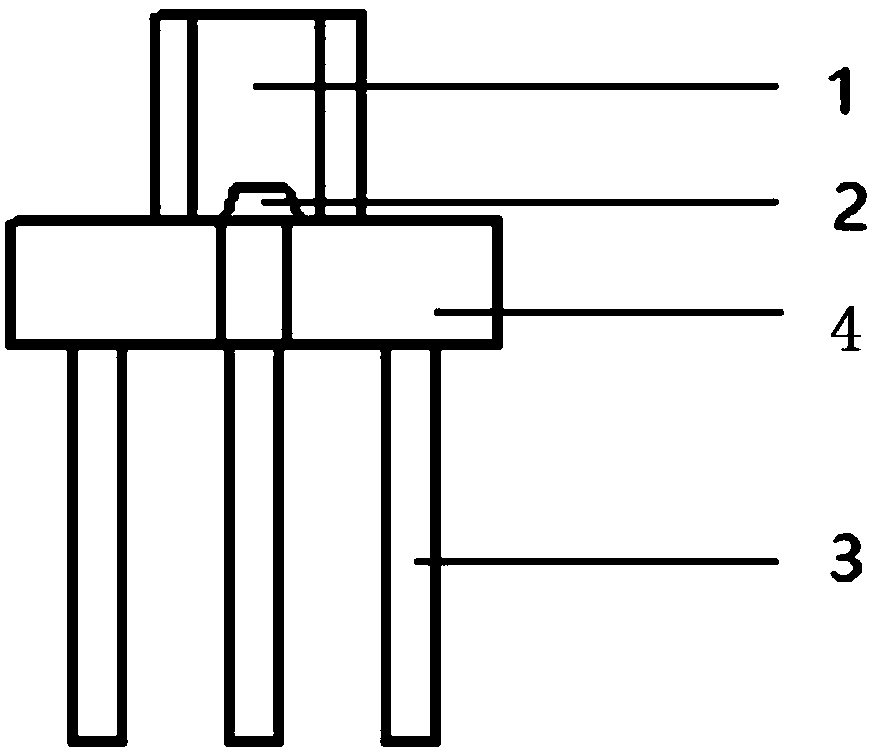

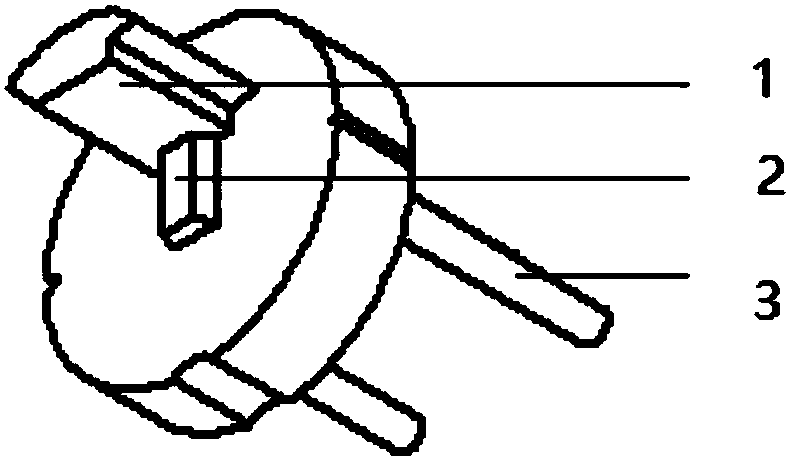

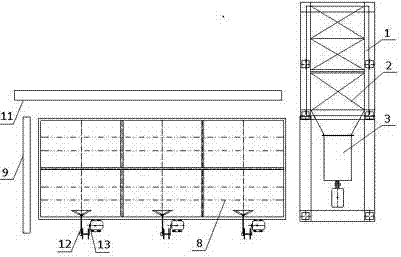

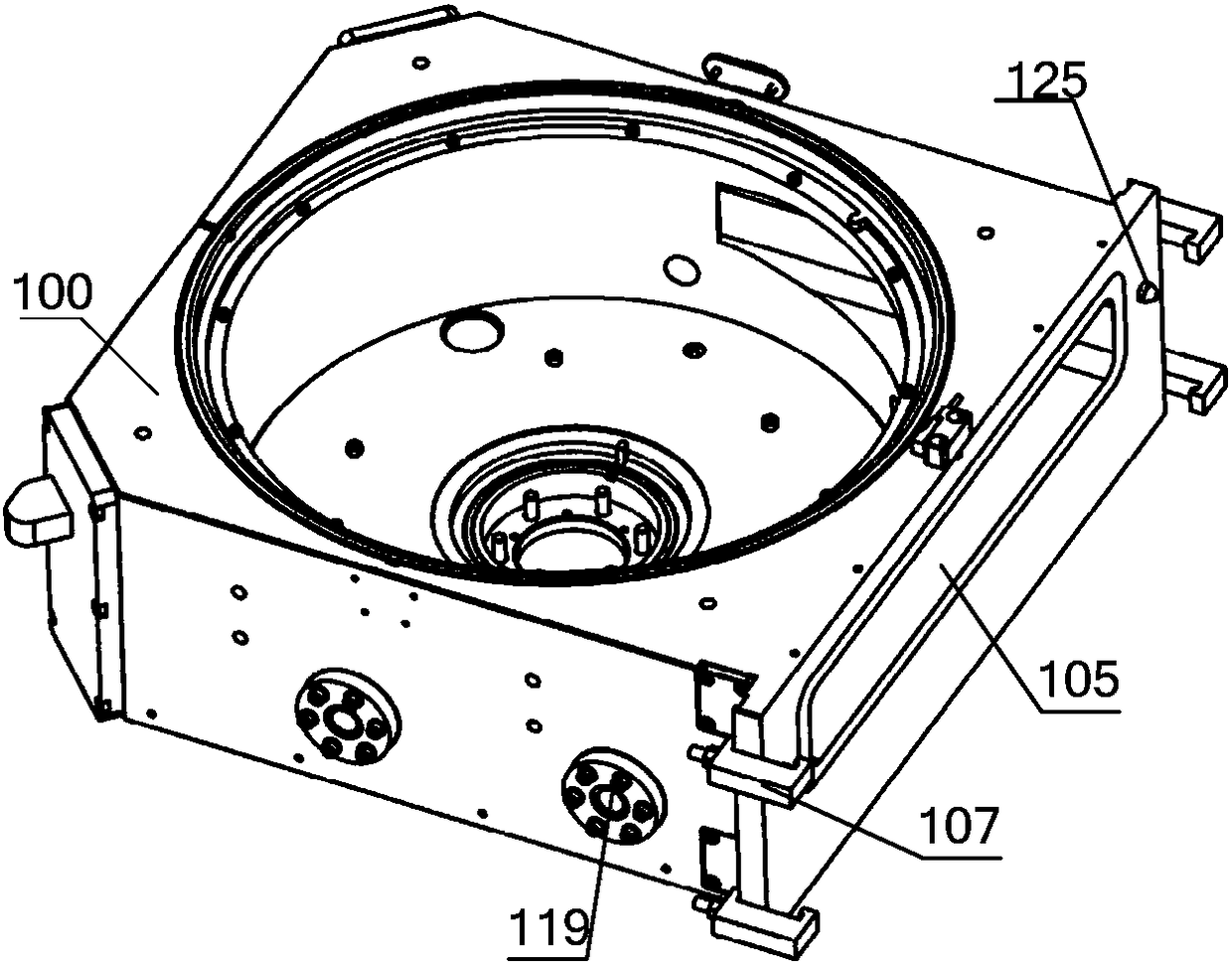

Automatic cleaning wafer edge clamping mechanism

ActiveCN104979264AEasy to install and debugImprove equipment capacitySemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention belongs to the field of semiconductor wafer cleaning, and specifically relates to an automatic cleaning wafer edge clamping mechanism. The automatic cleaning wafer edge clamping mechanism comprises clampers, thimbles and elevating cylinders, wherein the multiple clampers are uniformly distributed along the edge of a wafer carrying table in a centrifuge unit, the casing of the centrifuge unit is externally provided with the elevating cylinders in the same quantity as the clampers, and the output end of each elevating cylinder is provided with one thimble; the clampers comprise spring sleeves, springs, limiting sleeves and spring guide rods, the limiting sleeves are installed at the edge of the wafer carrying table, the spring sleeves cover the limiting sleeves, the spring guide rods are disposed inside the spring sleeves and are supported through the limiting sleeves, the springs are sleeved on the spring guide rods, and the two ends of each spring respectively abut against the spring sleeves and the spring guide rods; and the elevating cylinders drive the thimbles to elevate so as to drive the spring guide rods to elevate, and the edge of a wafer placed on the wafer carrying table is clamped by the spring guide rods. According to the invention, the edge of the wafer can be automatically clamped and loosened, and the requirement for clamping the edge of the wafer in a semiconductor cleaning technology is met.

Owner:SHENYANG KINGSEMI CO LTD

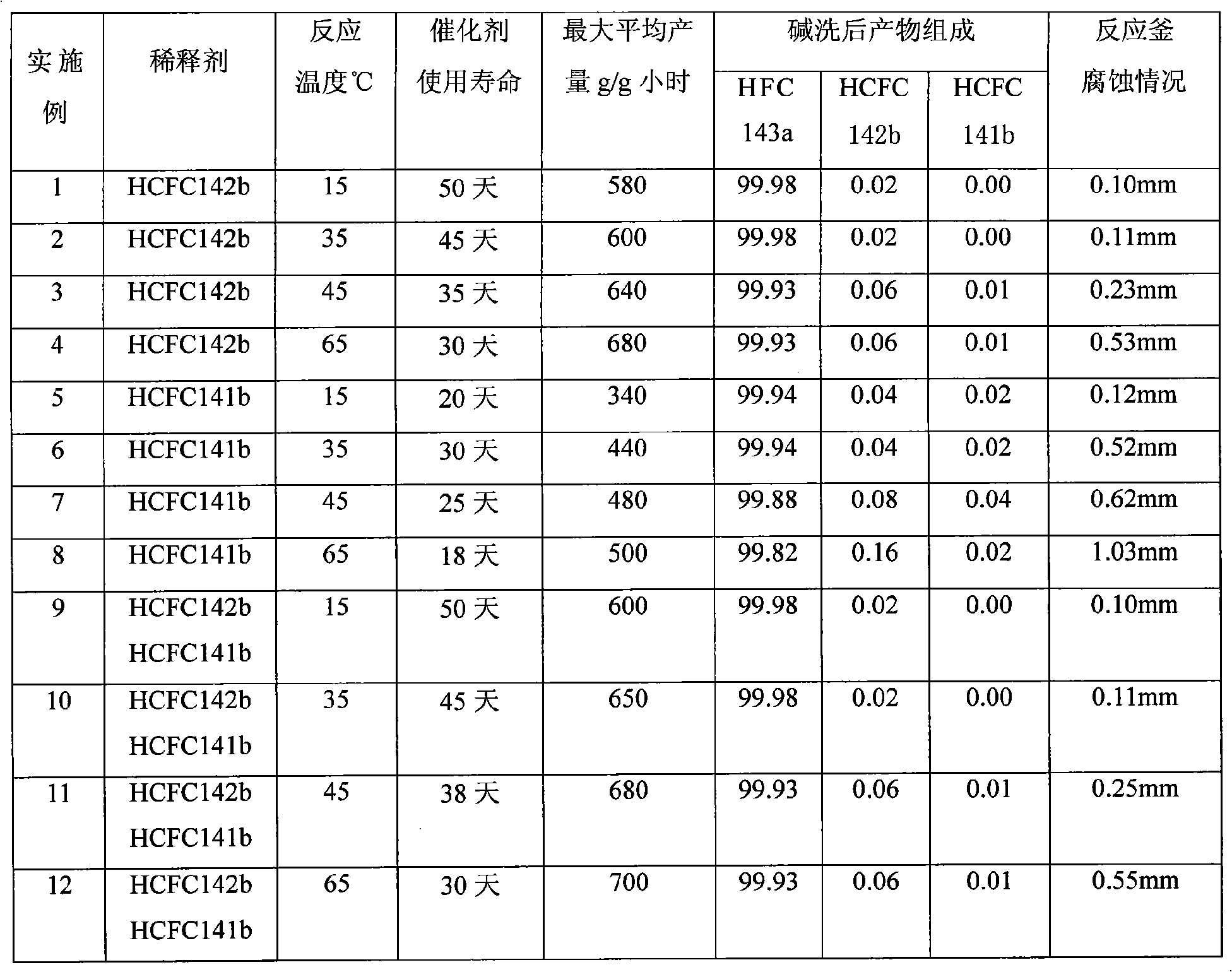

Preparation of 1,1,1-trifluoroethane

InactiveCN101348413AExtended service lifeReduce manufacturing costPreparation by halogen replacementHydrofluoric acidReaction temperature

The invention relates to a preparation method for trifluoroethane, in particular to a method for preparing 1, 1, 1-trifluoroethane (HFC143a) through catalytic fluorination of HCFC141b (i.e. 1, 1, 1-HCFC141b) and anhydrous hydrofluoric acid in the presence of a liquid phase catalyst. The method comprises HCFC141b, anhydrous hydrofluoric acid, the liquid phase catalyst and a diluent agent, and is characterized in that the diluent agent is a mixed solution of one or two of HCFC141b and HCFC142b; the liquid phase catalyst preferably adopts a SbCl5 catalyst, and the molar ratio of HF to HCFC141b during reaction is preferably controlled between 2.0 and 2.3; reaction temperature is preferably controlled between 10 and 75 DEG C; and reaction pressure is preferably controlled between 0.6 and 2.0MPa. The preparation method not only has high productivity, equipment productivity, utilization rate of equipment and labor work efficiency, but also can greatly prolong the service life of the catalyst and greatly reduce production cost.

Owner:ZHEJIANG XINGTENG CHEM

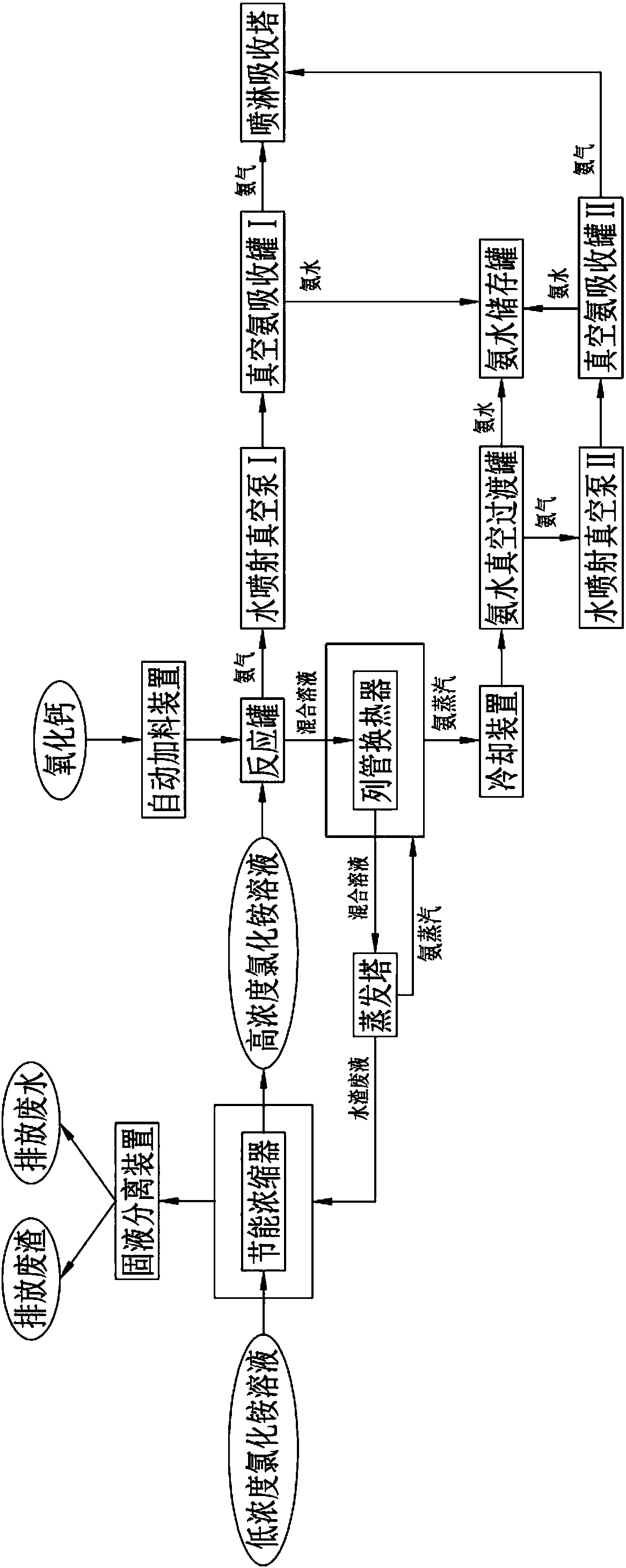

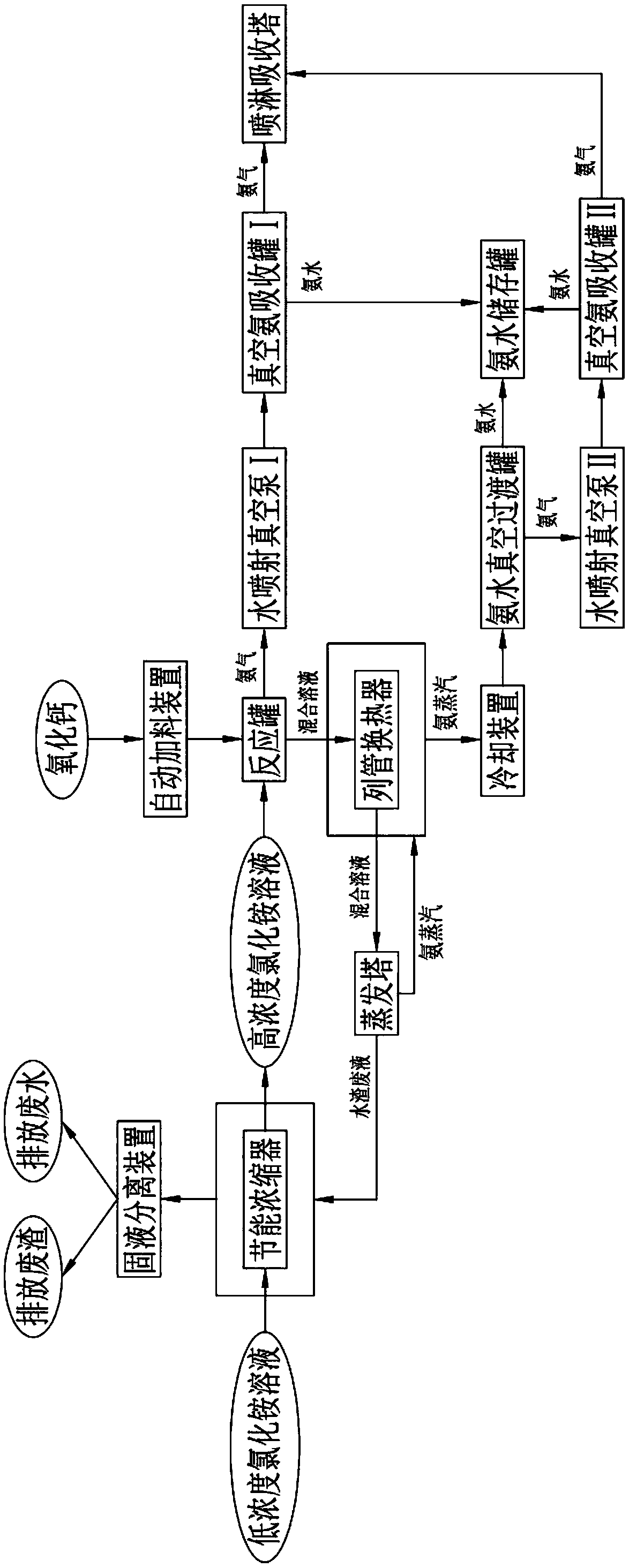

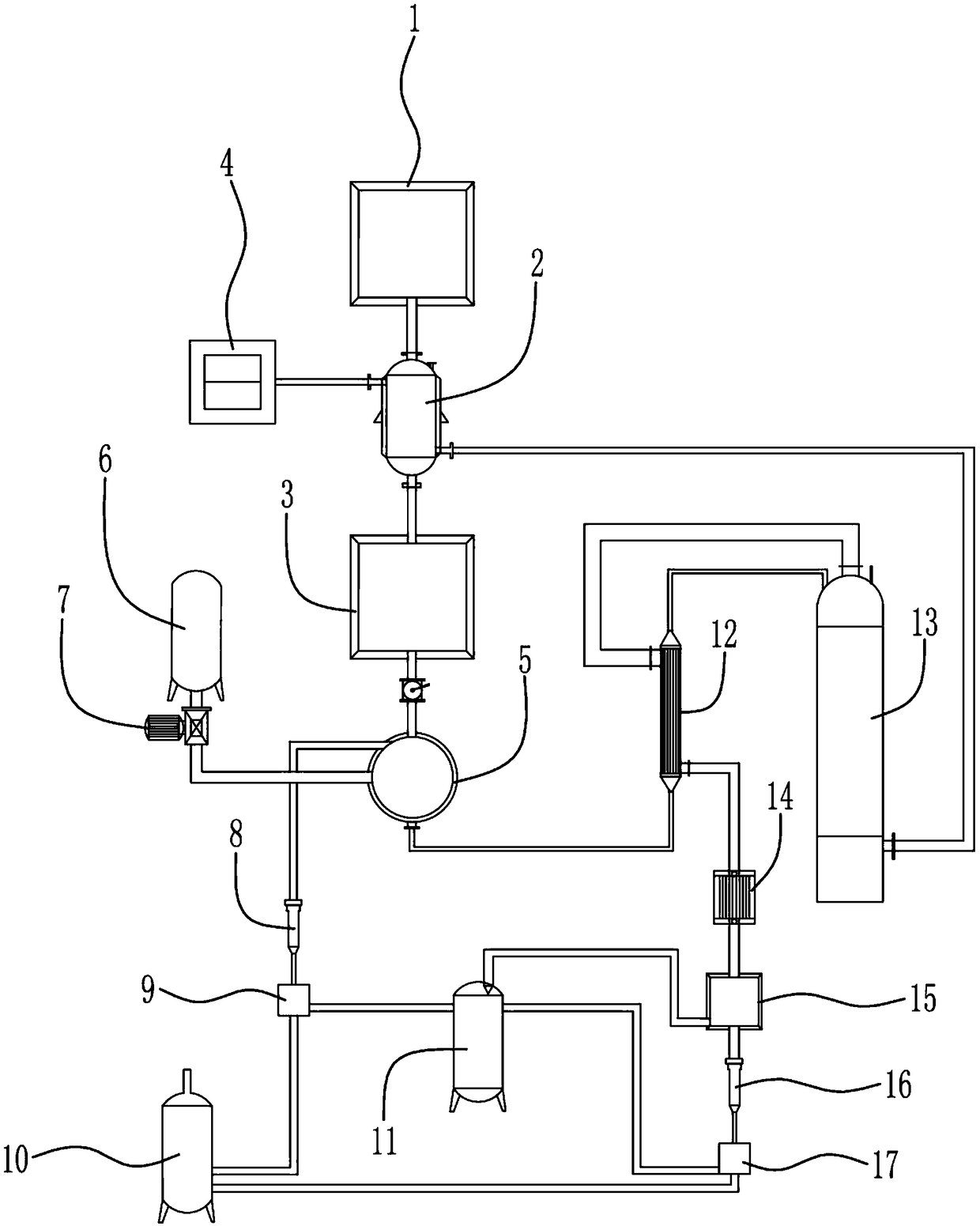

System for recovering ammonia from rare earth separation waste liquor

PendingCN108467049AEfficient and thorough dischargeReduce pollutionChemical industryAmmonia preparation/separationRare earthAmmonia

The invention discloses a system for recovering ammonia from rare earth separation waste liquor. The system comprises a solution tank I, an energy-saving concentrator, a solution tank II and other parts, wherein a solution outlet of the solution tank I is connected to a material concentration inlet of the energy-saving concentrator through a pipeline, a material concentration outlet of the energy-saving concentrator is connected to a solution inlet of the solution tank II through the pipeline, and a solution outlet of the solution tank II is connected to a material inlet of a reaction tank through the pipeline. Ammonia is recovered by the system, ammonia recovery rate can be 99.5% or higher, concentration of finally obtained ammonia water reaches 8.0-10.0 mol / L, and recovery is efficient and thorough; meanwhile, according to the method, ammonia nitrogen content of finally discharged wastewater after being treated with the method is smaller than or equal to 5.0 ppm which is far lower than 15.0 ppm specified in national first level discharge standard, and low discharge and low pollution are realized; besides, for operation with the method, only 0.8-1.0 ton of steam is consumed for each ton of the ammonia water, steam needed for the operation is saved greatly, and energy is saved.

Owner:全南县新资源稀土有限责任公司

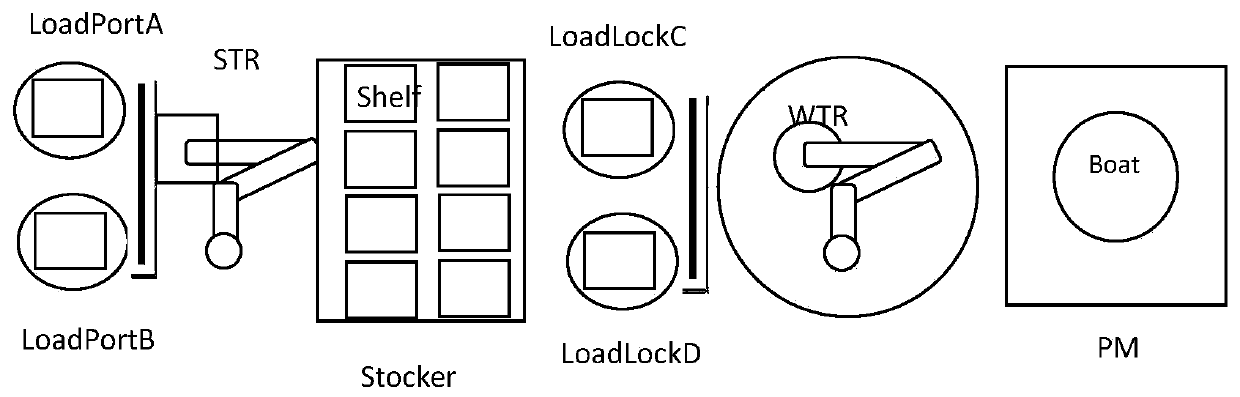

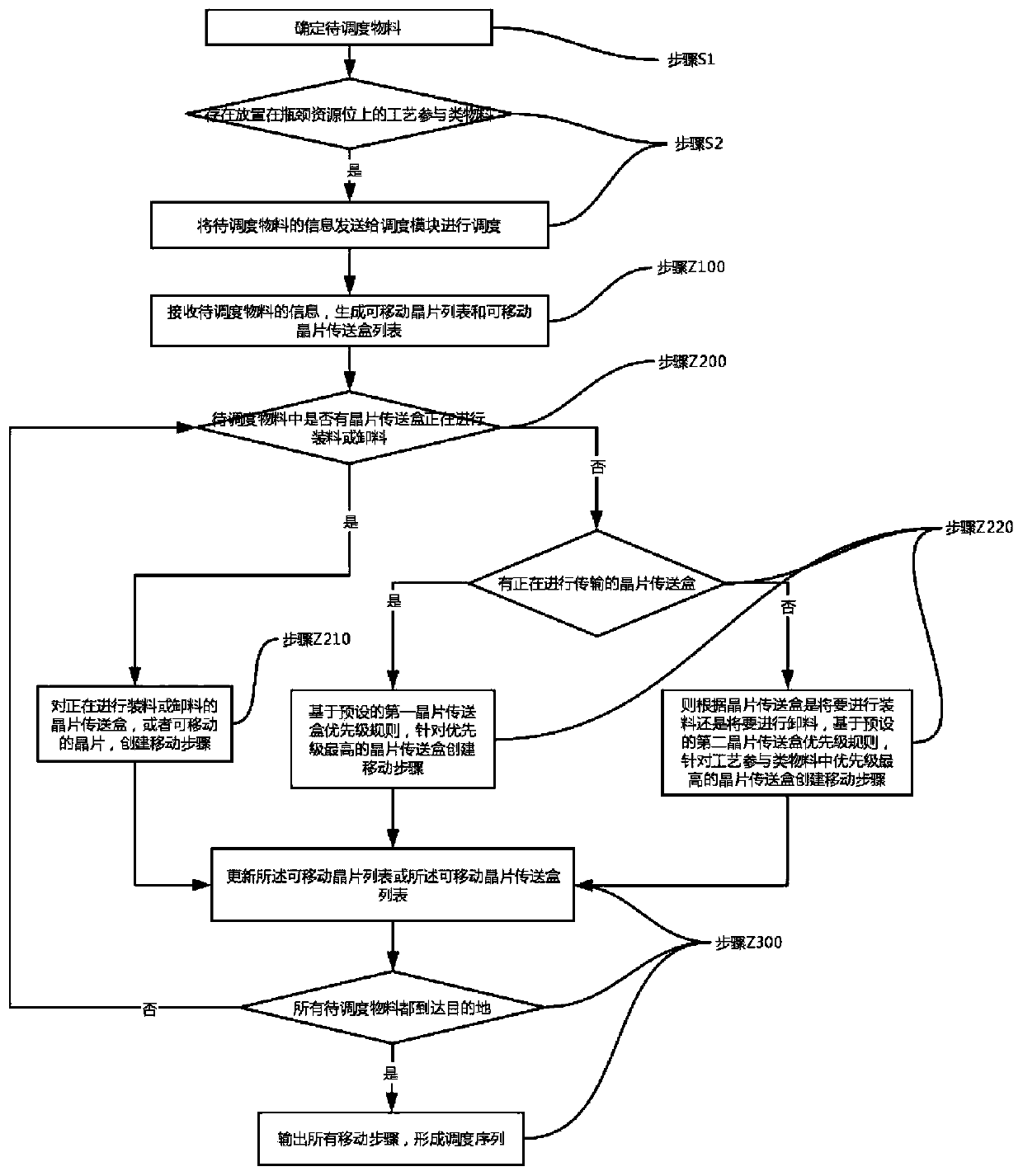

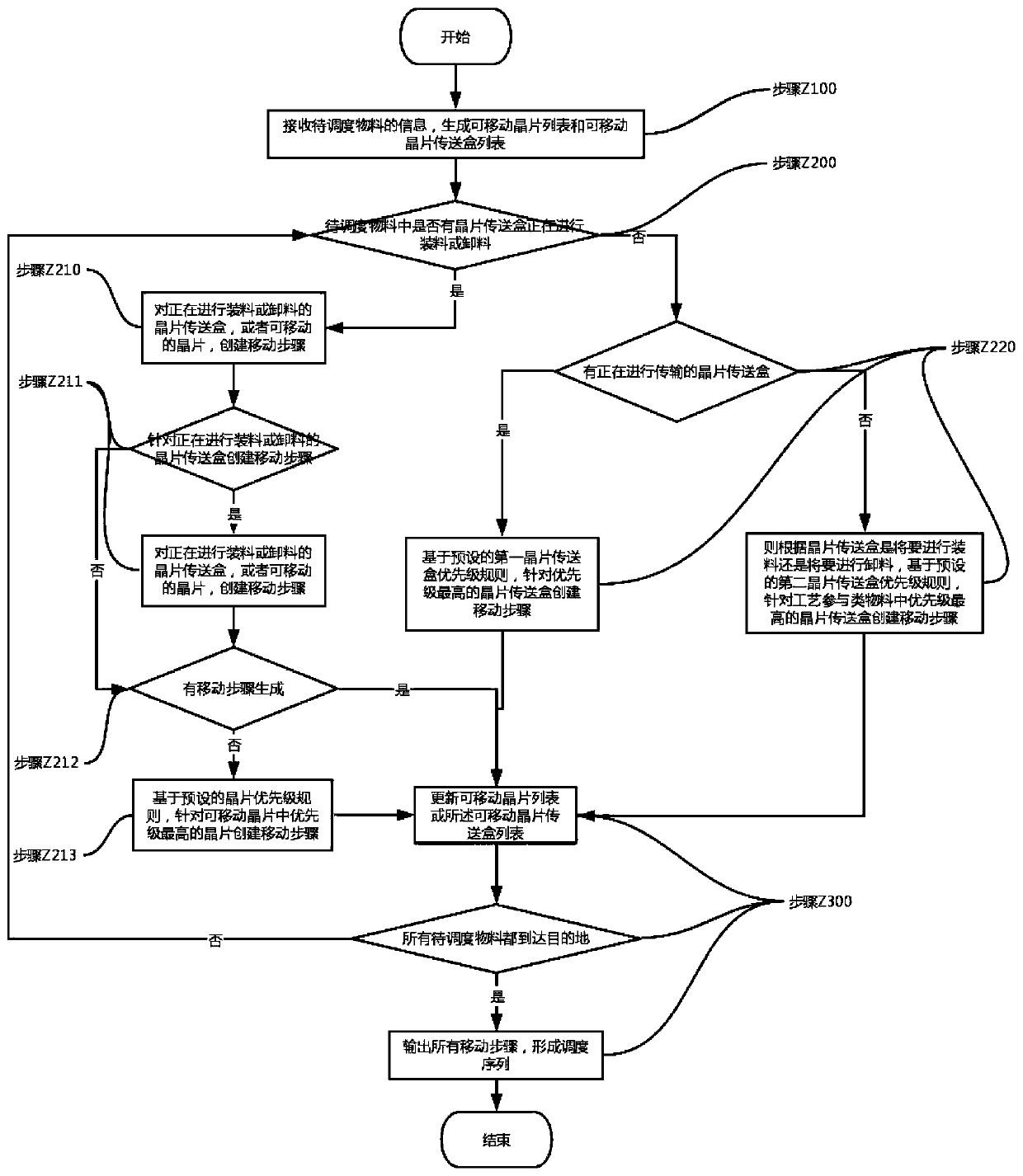

Material classification scheduling method for preventing scheduling deadlock

ActiveCN111446186AImprove reliability and equipment productivityImprove experienceSemiconductor/solid-state device manufacturingConveyor partsReal-time computingMaterial classification

The invention relates to a material classification scheduling method for preventing scheduling deadlock. The method comprises the steps of determining a to-be-scheduled material; and if the to-be-scheduled material has the process participation material placed on a bottleneck resource position, sending the information of the to-be-scheduled material to a scheduling module for scheduling, and outputting a scheduling sequence. The scheduling module is used for scheduling, and the process of outputting the scheduling sequence comprises the steps of if a wafer transfer box which is being transferred exists in a material to be scheduled, creating a moving step for the wafer transfer box with the highest priority based on a preset first wafer transfer box priority rule. According to the invention, the technical problem of scheduling calculation deadlock caused by competition for bottleneck resources when the semiconductor equipment with a stocker schedules a plurality of transmission operations and process operations at the same time is solved; the reliability of machine software operation and the equipment productivity are improved; and the experience degree of customers is further improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

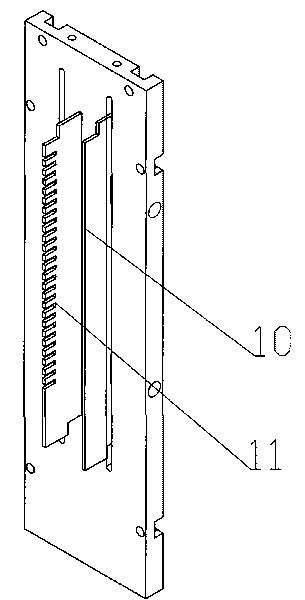

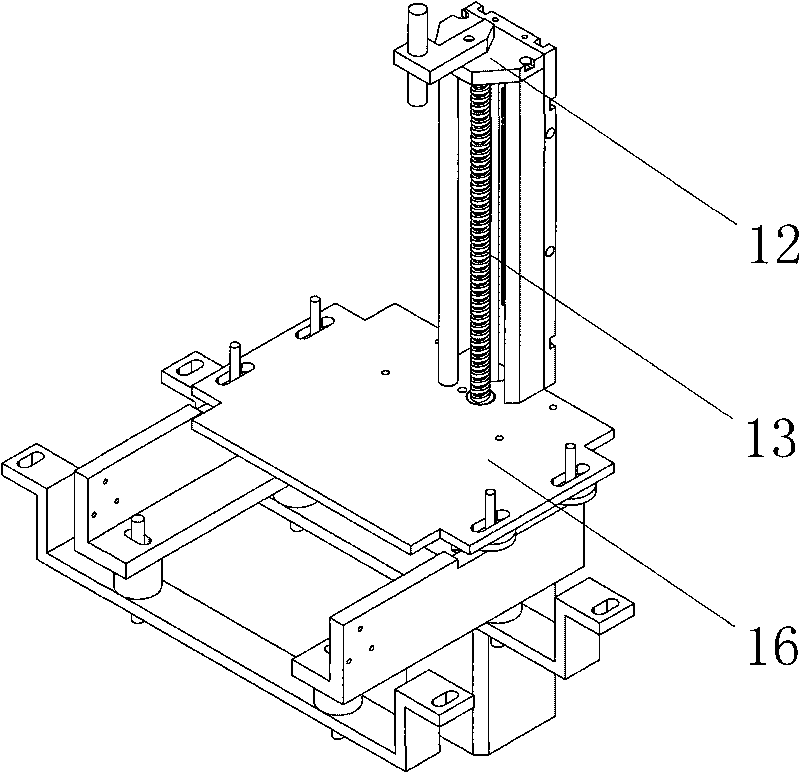

Wafer detection device

ActiveCN101728292AReduce scan timeImprove equipment capacitySemiconductor/solid-state device testing/measurementEngineeringMachining process

The invention relates to the technology of scanning and recording semiconductor wafers in the process of processing the wafers, in particular to a wafer detection device. The wafer detection device records numbers and positions of the wafers to be processed in a wafer box and solves the problems of long time for scanning the wafer box, influence on equipment capacity and the like in the prior art. The device is provided with wafer holding platforms, a proximity switch, a pressure switch, a bracket, a coded disk device and a screw driving device, wherein the wafer holding platforms are a wafer holding platform I and a wafer holding platform II oppositely arranged on a base; the bottom of the base is provided with the screw driving device which consists of a ball screw and a matched nut; the base is connected with the nut of the screw driving device; and a screw base on the top of the ball screw is provided with the proximity switch which is positioned between the wafer holding platform I and the wafer holding platform II. The wafer detection mode can reduce detection time and improve productivity.

Owner:SHENYANG KINGSEMI CO LTD

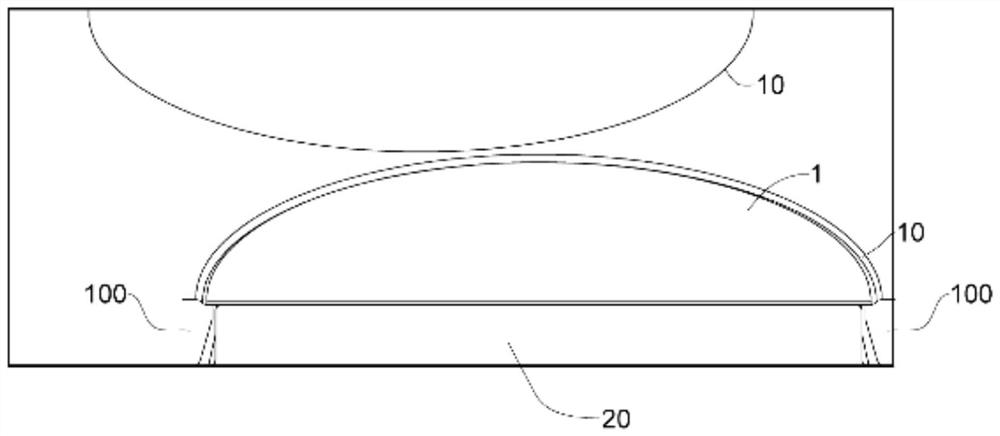

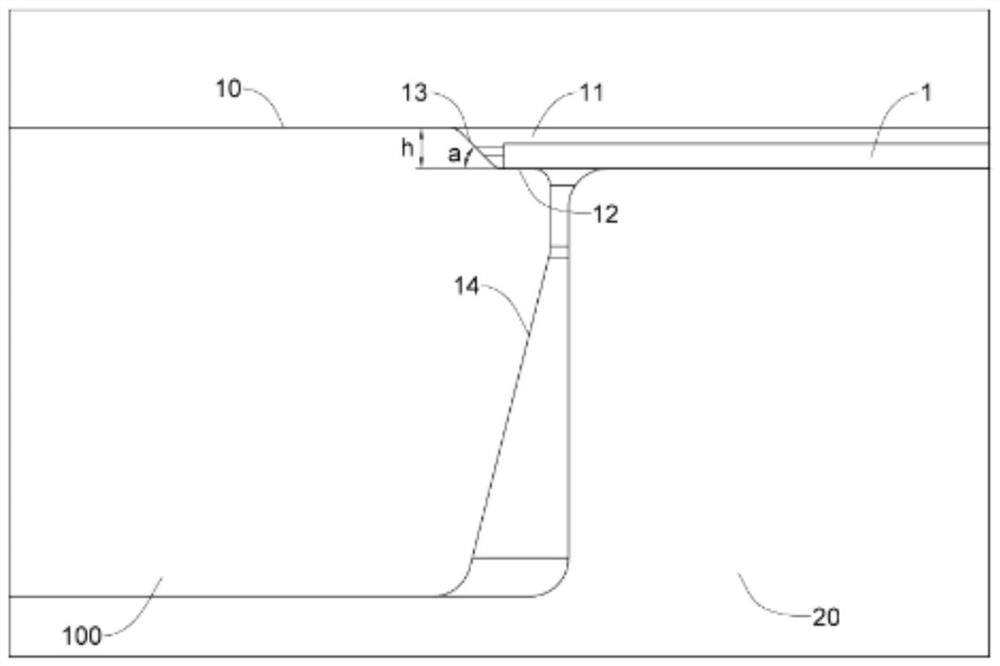

Tray device capable of adjusting thickness of wafer edge film

PendingCN112786522AAdjustable thicknessQuick pick and placeSemiconductor/solid-state device manufacturingWaferMechanical engineering

The invention relates to a tray device capable of adjusting the thickness of a wafer edge film. The tray device comprises a plurality of wafer bearing tables, each wafer bearing table is provided with an opening, and the edge of the opening is provided with an abutting part and a first inclined part extending upwards from the abutting part to the surface of the wafer bearing table. The thickness of the edge film of the wafer is adjusted by changing the inclination angle and height of the first inclined part.

Owner:PIOTECH CO LTD

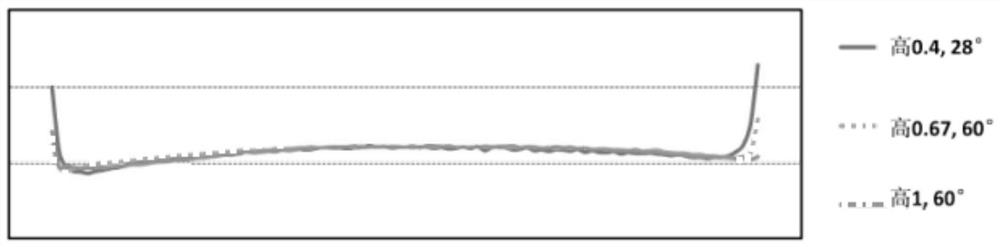

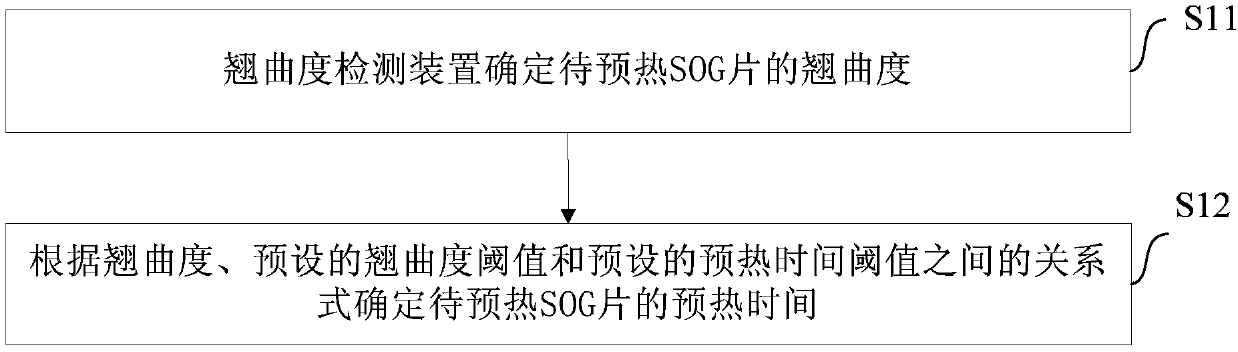

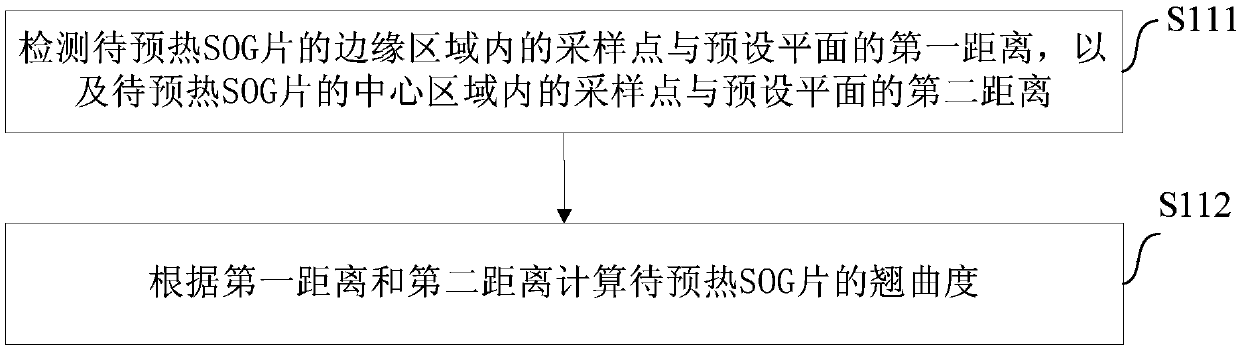

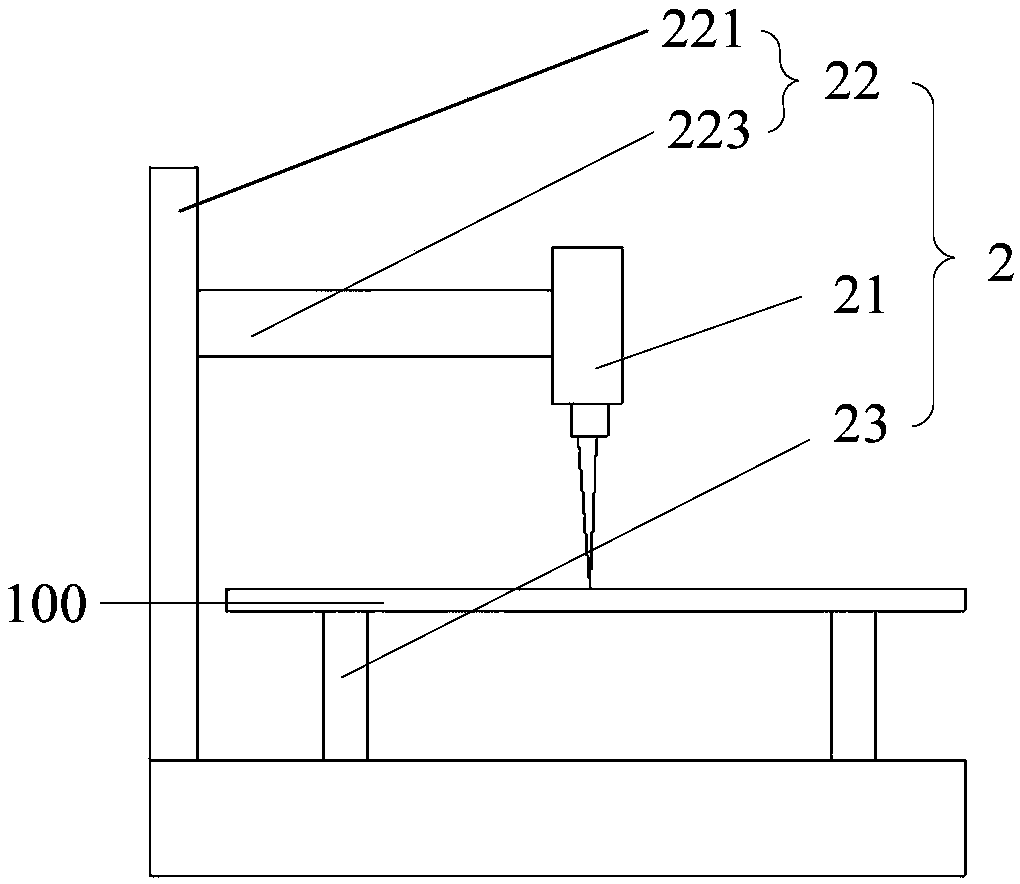

SOG chip pretreatment method, SOG chip transmission method and system and warpage detection device

InactiveCN110416110AFlexible pretreatment processImprove work efficiencySemiconductor/solid-state device manufacturingConveyor partsPretreatment methodTransmission system

The invention provides an SOG chip pretreatment method, an SOG chip transmission method, a warpage detection device and an SOG chip transmission system. The preheating time of to-be-preheated SOG chips is determined through determining the warpage of the to-be-preheated SOG chips according to a relation among the warpage, a preset warpage threshold and a preset preheating time threshold. Accordingto the SOG chip pretreatment method, the preheating time of each SOG chip is calculated through calculating the warpage of each SOG chip before pretreatment of each SOG chip, different SOG chips aredifferent in warpage and also are different in corresponding preheating time, and unified preheating time is not set for a plurality of SOG chips, so that the pretreatment process is more flexible andmore specific, and the work efficiency of the system and the equipment productivity can be improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

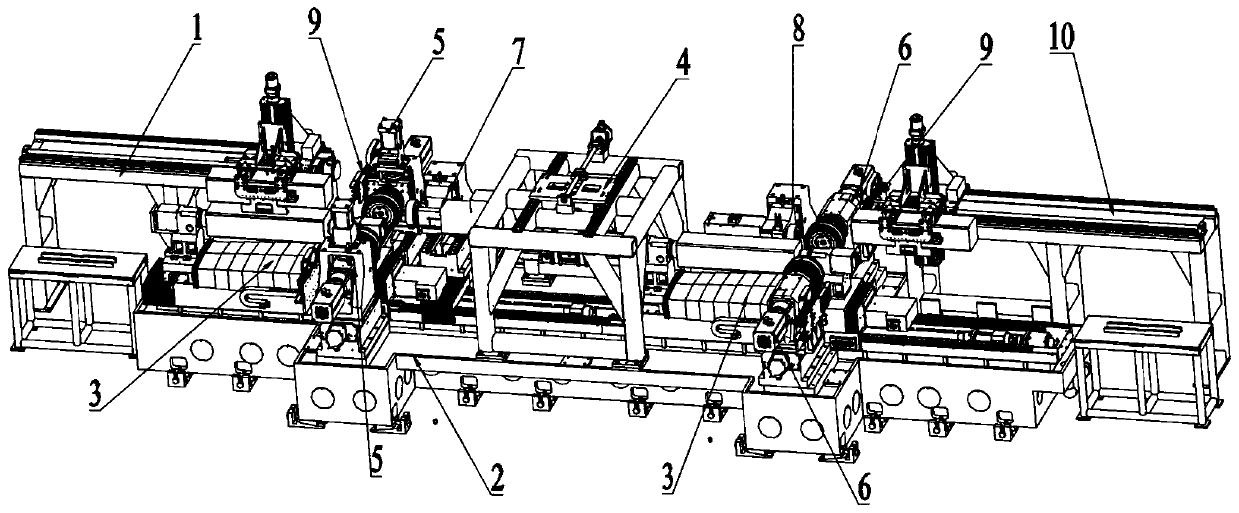

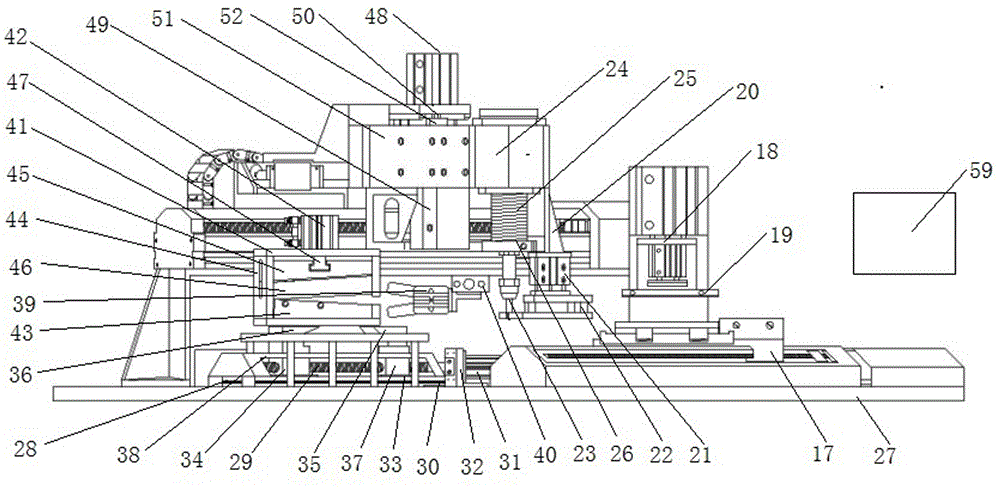

Efficient grinding and chamfering all-in-one machine

PendingCN110653704AReduce idle timeImprove equipment capacityGrinding carriagesGrinding machinesGrindingProcess engineering

The invention provides an efficient grinding and chamfering all-in-one machine. The machine comprises a base assembly, workbench assemblies, a transfer manipulator, coarse grinding assemblies, refining assemblies, a coarse barreling assembly, a fine barreling assembly, a feeding mechanism and a discharging mechanism, wherein the base assembly comprises a base and a guide rail arranged on the base,the two workbench assemblies are arranged, the two workbench assemblies are slidably arranged at the two ends of the base correspondingly, the transfer manipulator is arranged in the middle of the base, the two coarse grinding assemblies and the two refining assemblies are arranged, and are each oppositely arranged on the two sides of the base, the coarse barreling assembly is arranged on one side of the base and located between the coarse grinding assemblies and the transfer manipulator, the fine barreling assembly is arranged on one side of the base and located between the refining assemblies and the transfer manipulator, and the feeding mechanism and the discharging mechanism are the same in structure and are arranged at the two ends of the base correspondingly. The machine can conductintegrated polishing on arcs, corners and surfaces of polysiliconsingle of different specifications, a coarse grinding procedure and a refining procedure do not interfere with each other, the idle time of the machine is shortened, the machine capacity is high, and the machining period is short.

Owner:QINGDAO GAOCE TECH CO LTD

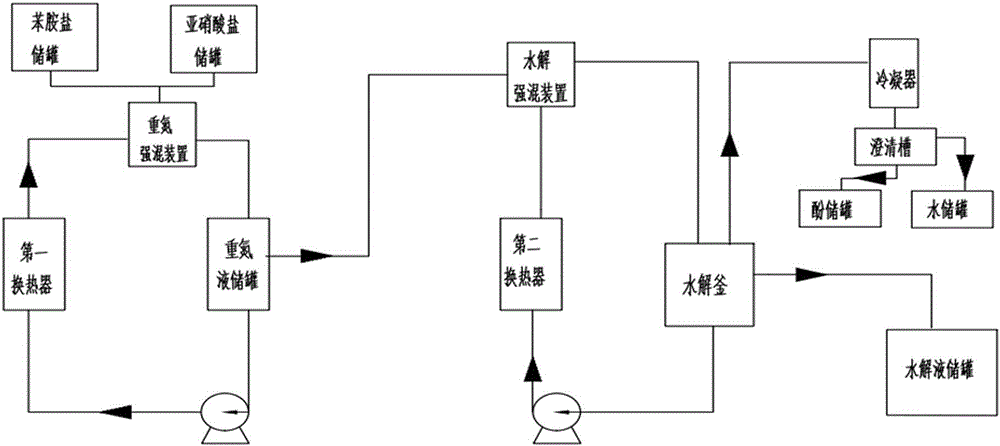

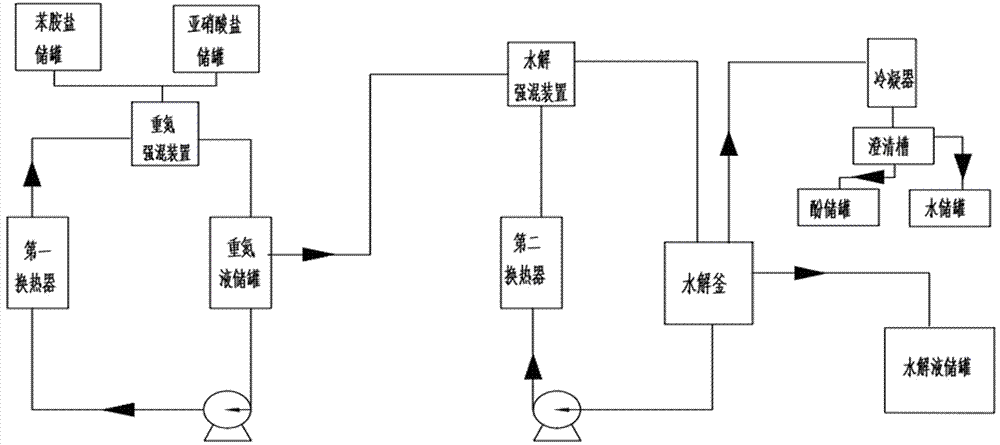

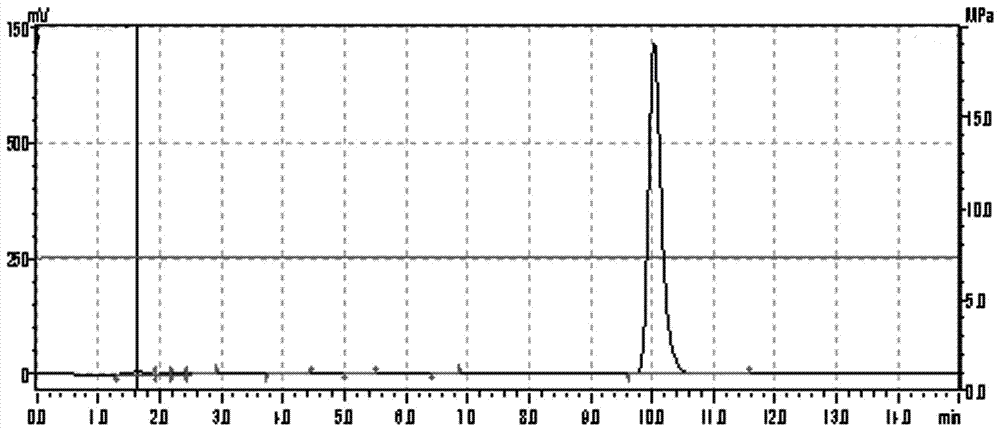

Method and system for continuously producing 2,5-dichlorophenol

ActiveCN105384610AShort reaction timeLess side effectsOrganic chemistryOrganic compound preparationNitrite saltSide reaction

The present invention provides a method and system for continuously producing 2,5-dichlorophenol. The method comprises an aniline salt diazotization process and a diazo solution hydrolysis process. The aniline salt diazotization process comprises the steps of continuously feeding aniline salt and nitrite into a diazo intensive mixing apparatus; performing a diazotization reaction under intensive mixing; feeding a diazo solution generated by the reaction into a diazo solution storing tank; back-mixing a part of the diazo solution in the diazo solution storing tank after cooling and feeding the part of the diazo solution into the diazo intensive mixing apparatus; removing all or a part of heat generated in the diazotization reaction by using the back-mixed cryogenic diazo solution; and directly performing continuous hydrolysis on the other part of the diazo solution. According to the method provided by the present invention, by adopting an intensive mixing process and a back-mixing process, mass and heat transfer during the diazotization reaction and the hydrolysis reaction can be quickly performed; heat can be taken away or given in time; a reaction time is shortened; the side reaction is reduced; the heat utilization rate is improved; the costs are lowered; and a safety factor and the device production capacity are improved.

Owner:SHANDONG WEIFANG RAINBOW CHEM

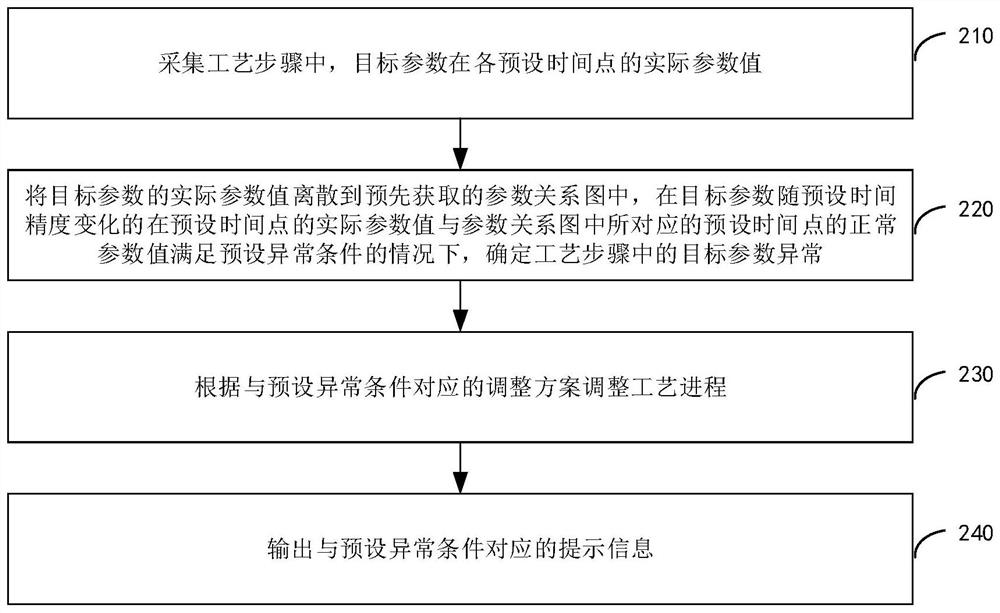

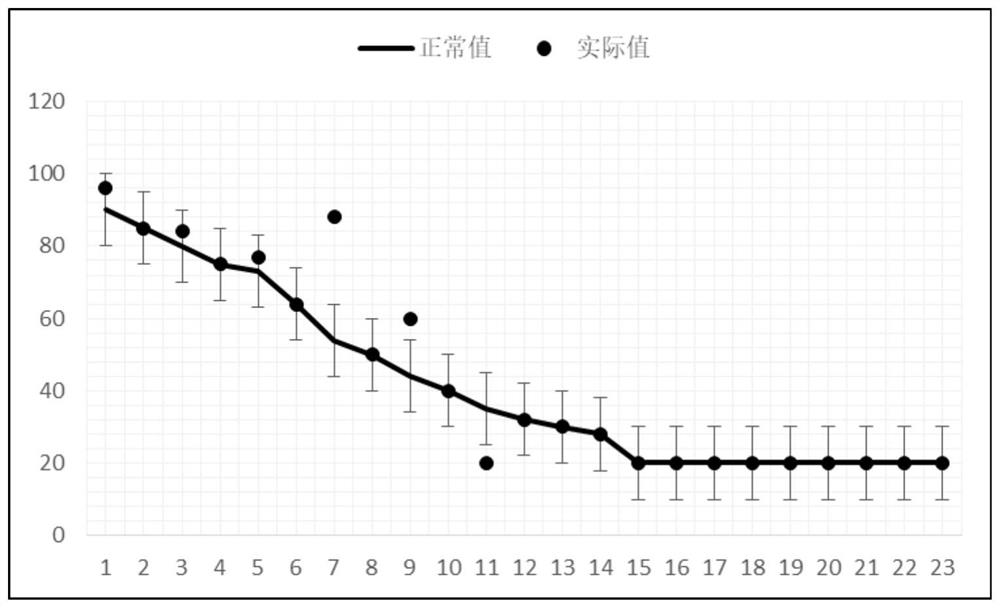

Parameter anomaly detection method and semiconductor process equipment

PendingCN114420586ADetection speedImprove equipment capacitySemiconductor/solid-state device manufacturingAlgorithmSemiconductor

The embodiment of the invention provides a parameter anomaly detection method and semiconductor process equipment, the process of the semiconductor process equipment comprises a plurality of process steps which are carried out in sequence, and the parameter anomaly detection method comprises the following steps: collecting actual parameter values of a target parameter at each preset time point in the process steps; dispersing the actual parameter value of the target parameter into a pre-acquired parameter relation graph, and when the actual parameter value, changing along with the preset time precision, of the target parameter at the preset time point and a normal parameter value, corresponding to the preset time point, in the parameter relation graph meet a preset abnormal condition, determining the target parameter according to the preset abnormal condition. Determining that the target parameter in the process step is abnormal, wherein the parameter relation graph is a relation graph that the normal parameter value of the target parameter in the process step changes along with each preset time point; adjusting the process according to an adjustment scheme corresponding to the preset abnormal condition; and outputting prompt information corresponding to the preset abnormal condition. By adopting the parameter anomaly detection method provided by the invention, the parameter anomaly detection efficiency can be improved.

Owner:西安北方华创微电子装备有限公司 +1

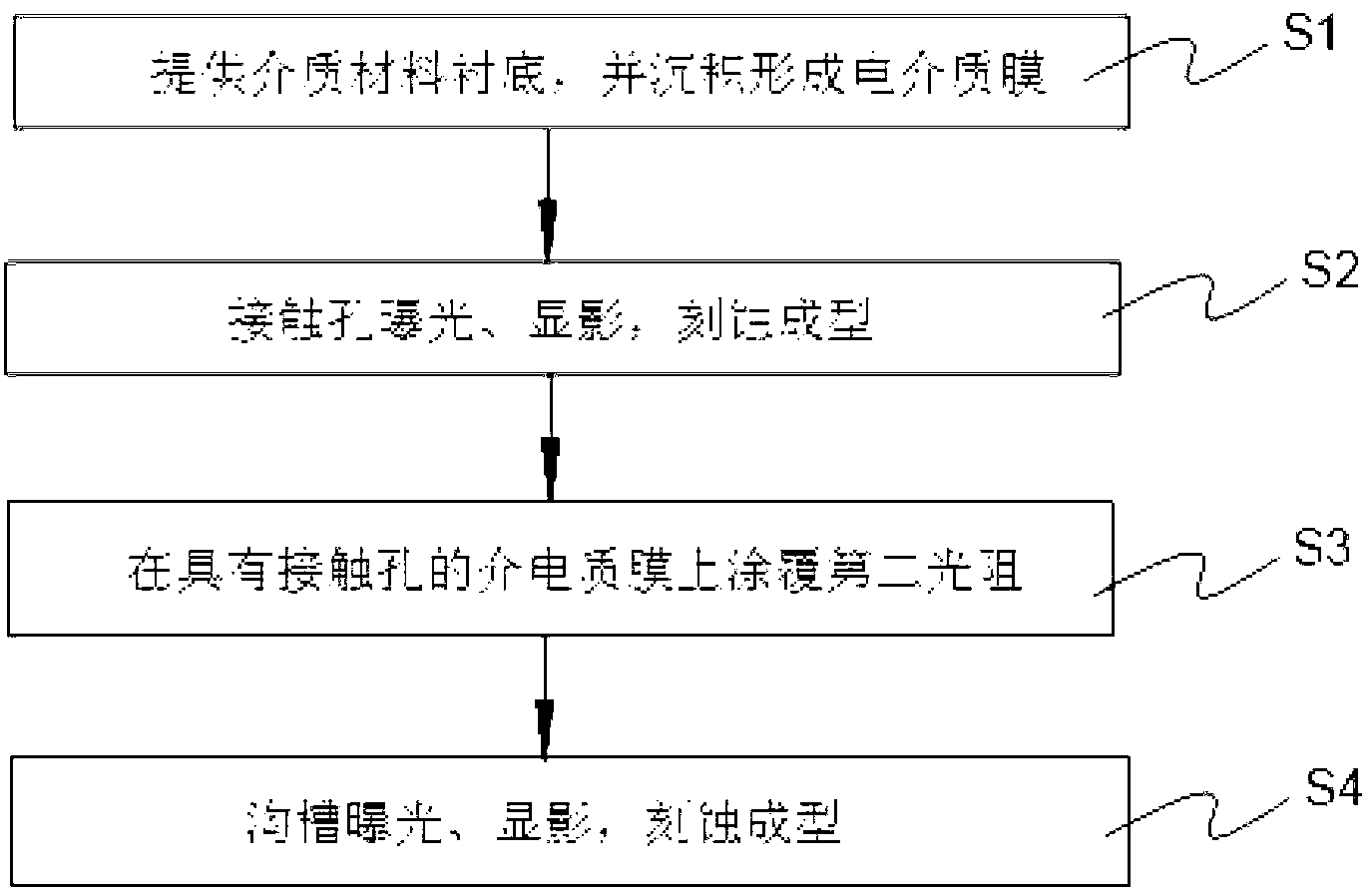

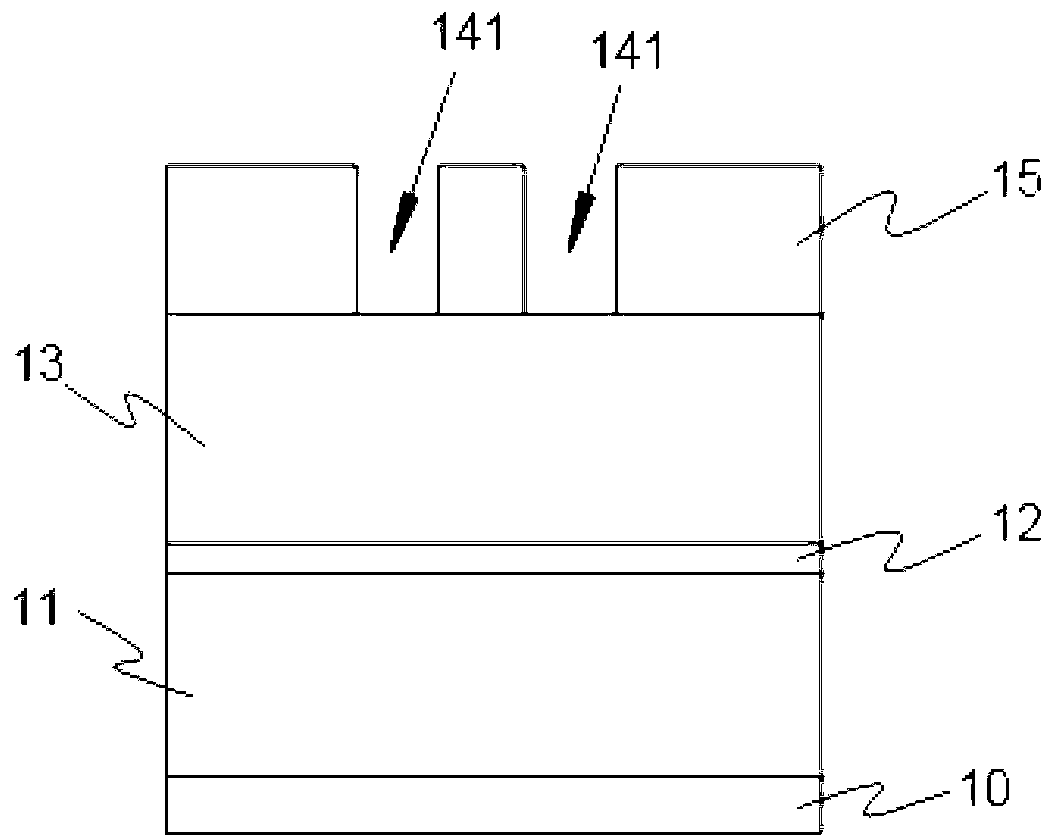

Method for preparing dielectric film on dual damascene structure through etching forming process

InactiveCN102800626AImprove equipment capacityReduce equipment wear and tearSemiconductor/solid-state device manufacturingDielectric substratePhotoresist

The invention relates to a method for preparing a dielectric film on a dual damascene structure through the etching forming process, which comprises the following execution steps of: (S1) providing a dielectric substrate, and forming a dielectric film on the dielectric substrate; (S2) deeply coating a first photoresist layer different from the surface of the dielectric substrate on an upper overlying layer of the dielectric film, forming the contact hole pattern through exposure and development, and further preparing the contact hole through the etching forming process; (S3) coating a second photoresist layer on the dielectric film with the contact hole; and (S4) coating a third photoresist layer on the second photoresist layer, forming the groove pattern through exposure and development, and preparing the groove through the etching forming process. With the method for preparing a dielectric film on a dual damascene structure through the etching forming process, not only can the production capacity of equipment be increased and equipment loss is reduced, but also the production process is optimized, the production efficiency is increased, and the production cost is lowered.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

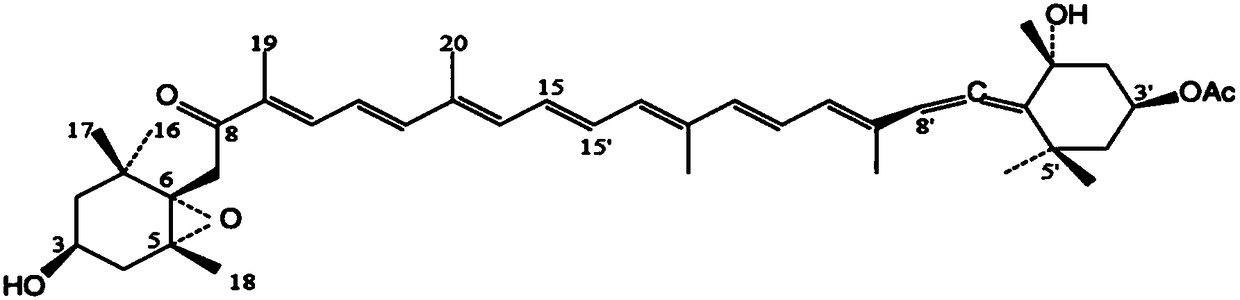

Culture method for improving fucoxanthin accumulation of phaeodactylum tricornutum bohlin

ActiveCN108239665AImprove equipment capacityLess investmentMicroorganism based processesFermentationPhaeodactylum tricornutumFucoxanthin

The invention discloses a culture method for improving fucoxanthin accumulation of phaeodactylum tricornutum bohlin. The culture method comprises the following steps: 1) culturing a dense phaeodactylum tricornutum bohlin solution; 2) preparing a culture solution from well and rock salt bittern and Haematococcus pluvialis Exopolysaccharides; and 3) carrying out heterotrophic culture on the concentrated algae solution and a heterotrophic culture solution in a fermentation tank to accumulate fucoxanthin. The accumulation of the fucoxanthin of the phaeodactylum tricornutum bohlin is improved. Thecontent of the fucoxanthin of the phaeodactylum tricornutum bohlin can be increased greatly, the breeding and processing cost can be reduced to a great extent, the economical benefit is improved and applications of the fucoxanthin are promoted.

Owner:云南爱尔发生物技术股份有限公司

Circuit board multi-position pick-and-place control and conveying system and control and conveying methods

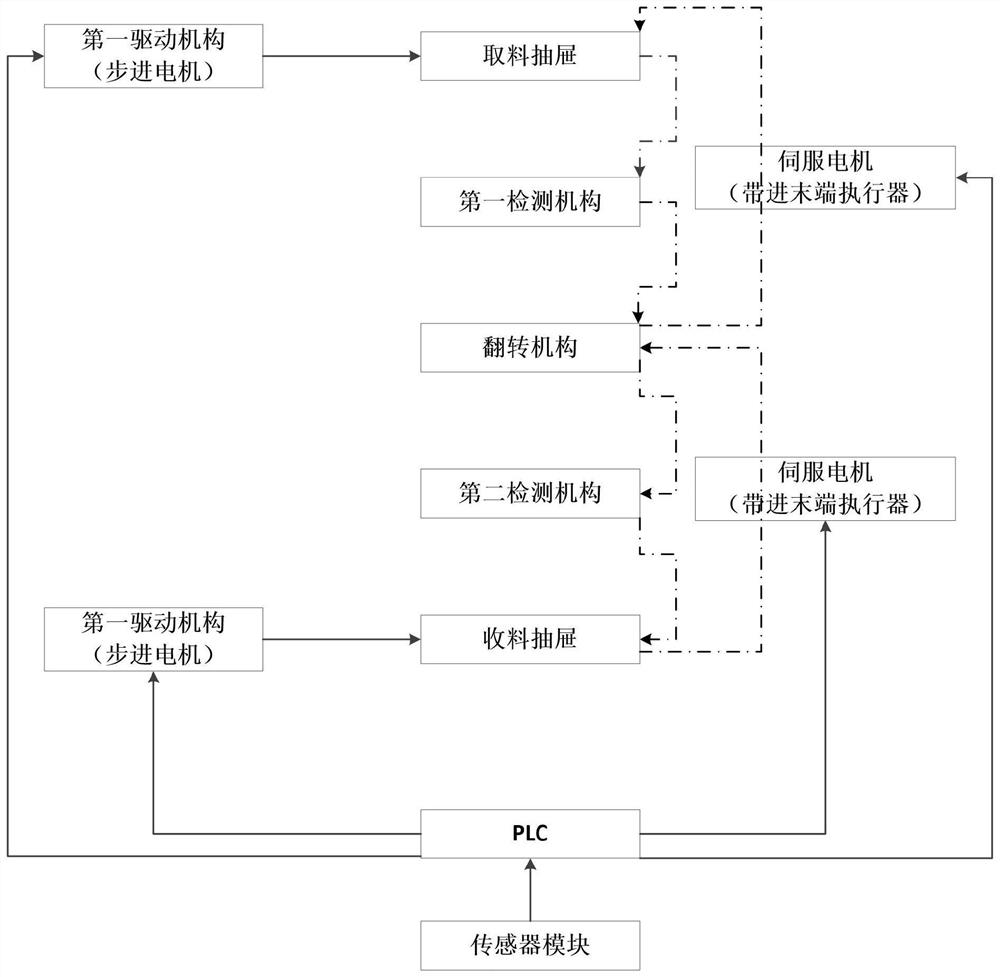

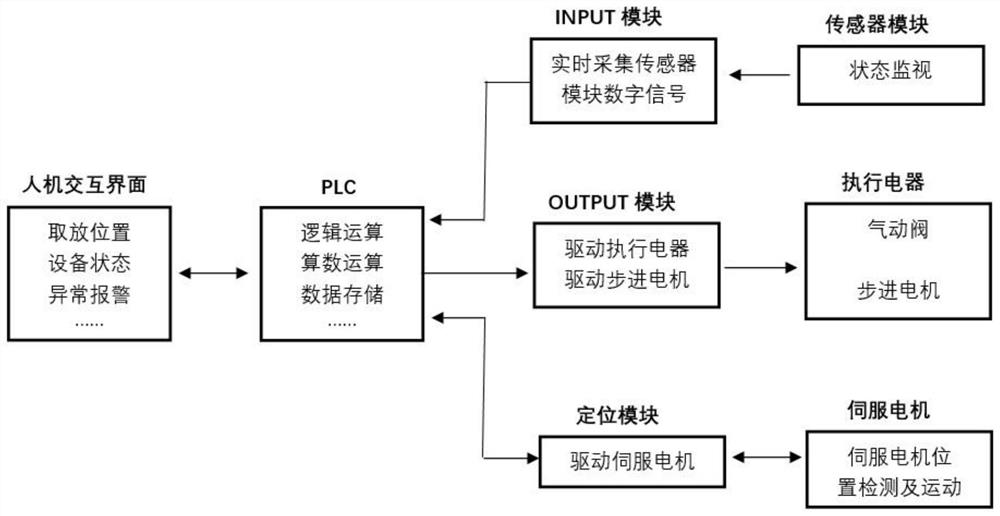

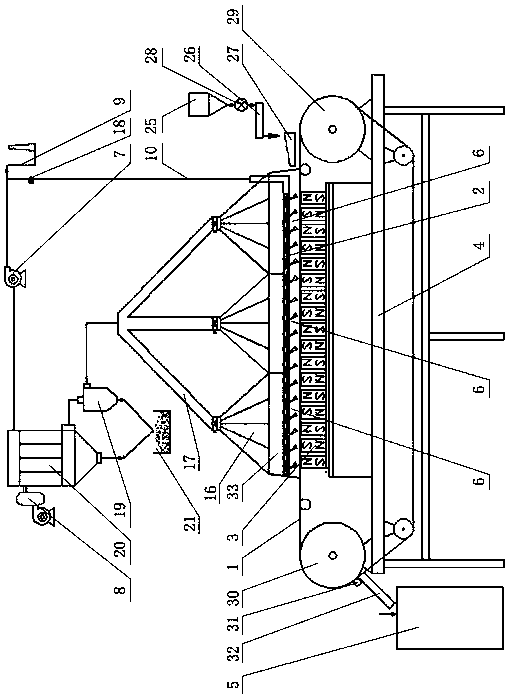

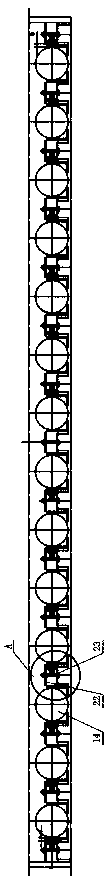

PendingCN112474425AImprove equipment reliabilityImprove equipment capacityControl devices for conveyorsSortingControl systemData management

The invention discloses a circuit board multi-position pick-and-place control and conveying system and control and conveying methods. The control system comprises a first drive mechanism which is usedas an actuator of a drawer in order to achieve the batch feeding and / or receiving of circuit boards, a second driving mechanism which is used as an actuator for a pick-and-place positioning device inorder to drive the pick-and-place positioning device to move to a target positioning position, the pick-and-place positioning device which is provided with an end effector and used for loading or unloading the circuit board, a sensor module which is used for collecting the state of each driving mechanism and / or the end effector, and a controller which is used for receiving an acquisition signal of the sensor module, controlling the first driving mechanism to drive the drawer to feed and / or receive materials, controlling the second driving mechanism to drive the pick-and-place positioning device to move to a plurality of target positioning positions, and controlling the end effector to load or unload the circuit board. The system integrates the functions of control, alarm, safety control,production data management and the like, and has the characteristics of high efficiency, high stability, convenience in operation and the like.

Owner:CIMS SUZHOU CO LTD

Powdery magnetic material segmented dry magnetic separation device and using method thereof

PendingCN110801936AImprove sorting efficiencyHigh sorting accuracyMagnetic separationMagnetic polesAir blower

The invention discloses a powdery magnetic material segmented dry magnetic separation device and a using method thereof, which belong to the technical field of mineral separation engineering, and solve the problems of low iron ore concentrate grade and low metal recovery rate in a magnetic material dry magnetic separation process. Three to five separation areas are arranged above a belt side by side; each separation area is provided with an air blowing mechanism and an air draft mechanism; an air outlet of each air draft mechanism is connected with a tailings collecting device; the magnetic system is composed of a plurality of main magnetic poles; and the magnetic field intensities of the main magnetic poles are evenly distributed in the width direction of the belt and the magnetic field intensities are distributed from high to low in the length direction of the belt from the feeding end to the discharging end. The using method comprises the steps: the blast volume is adjusted to sequentially increase in the belt movement direction; the magnetic induction intensity of the main magnetic pole is adjusted to be sequentially reduced along the belt movement direction; and magnetic separation work is started. By adjusting the magnetic field intensity and the blast volume in each separation area, the separation efficiency, the separation precision and the metal recovery rate of the magnetic materials are improved.

Owner:甘肃酒钢集团西部重工股份有限公司

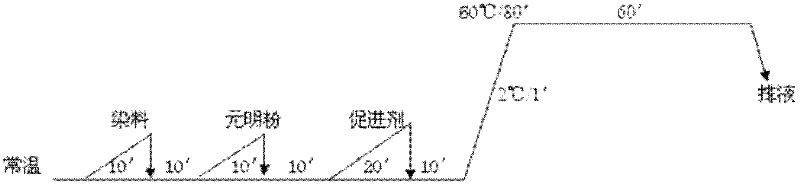

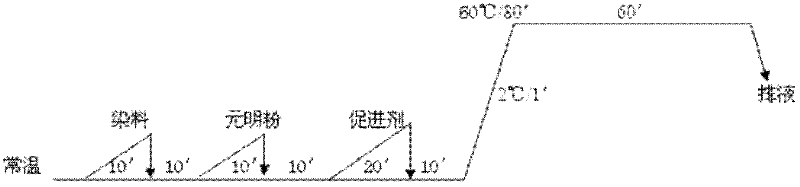

Alkali-free dyeing process for reactive dye

InactiveCN102535193AImprove equipment capacityReduce COD valueDyeing processSodium carbonateReactive dye

The invention relates to the technical field of fabric dyeing, in particular to an alkali-free dyeing process for reactive dye, which comprises the steps of 1 adding dye of dyed fabrics into a dye vat at the normal temperature; 2 performing the step 1 for ten minutes; 3 dissolving anhydrous sodium sulphate Na2So4 in an auxiliary vat and adding the dissolved anhydrous sodium sulphate Na2So4 into the dye vat; 4 performing the step 3 for ten minutes; 5 adding accelerating agents into the dye vat; 6 performing the step 5 for ten minutes; 7 heating the dye vat to sixty DEG C with the speed of two DEG C rising every minute; 8 performing the step 7 for sixty minutes; and 9 after the completion of the dyeing, discharging dye liquor and performing a washing procedure. Compared with the prior art, the alkali-free dyeing process for the reactive dye utilizes the accelerating agents 169 to perform alkali-free dyeing, and the dosage of the accelerating agents 169 only accounts for one eighth of sodium carbonate. Compared with production cost of a traditional process, the dyeing process saves water, electricity and steam by about 20%, improves device production capacity by about 15%, and reduces discharge of wastewater by about 20%. In addition, the value of chemical oxygen demand (COD) in the discharged wastewater is remarkably lowered.

Owner:宁波侨泰兴纺织有限公司

Method for recovering ammonia from rare earth separation waste liquid

ActiveCN108715496AEfficient and thorough dischargeReduce pollutionWater contaminantsChemical industryEvaporationRare earth

The invention discloses a method for recovering ammonia from rare earth separation waste liquid. The method especially includes the steps of mixing and concentrating a low-concentration ammonium chloride solution to be recovered; allowing the low-concentration ammonium chloride solution to be recovered to react with calcium oxide; recovering ammonia from reaction overflow through a water-jet pumpI and a vacuum ammonia absorption tank I; recovering a solution obtained from reaction with a tube heat exchanger, an evaporation tower, an ammonia vacuum transfer tank and the like. The ammonia is recovered with the method, the recovery rate of the ammonia is greater than or equal to 99.5%, the concentration of ammonia water obtained finally reaches 8.0-10.0mol L, and efficient and thorough recovery is achieved; meanwhile, the ammonia nitrogen content in the waste liquid discharged by this method is less than or equal to 5.0ppm, far less than the national first-level discharge standard of 15.0ppm, and low discharge and low pollution are achieved; in addition, with the method, the consumption of steam is only 0.8-1.0tons / ton of ammonia water, the amount of steam needed for the operation isgreatly saved, and energy is saved.

Owner:全南县新资源稀土有限责任公司

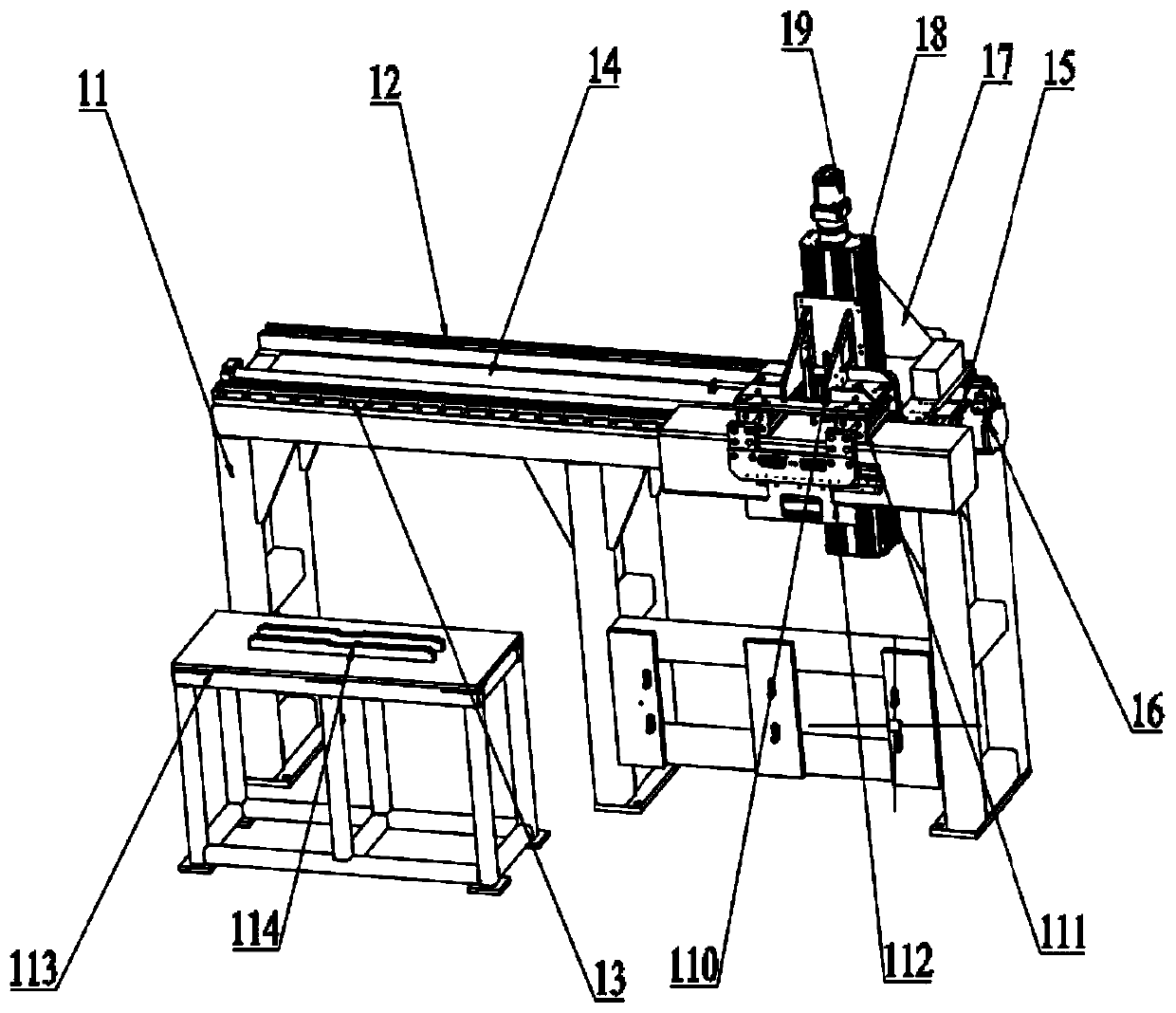

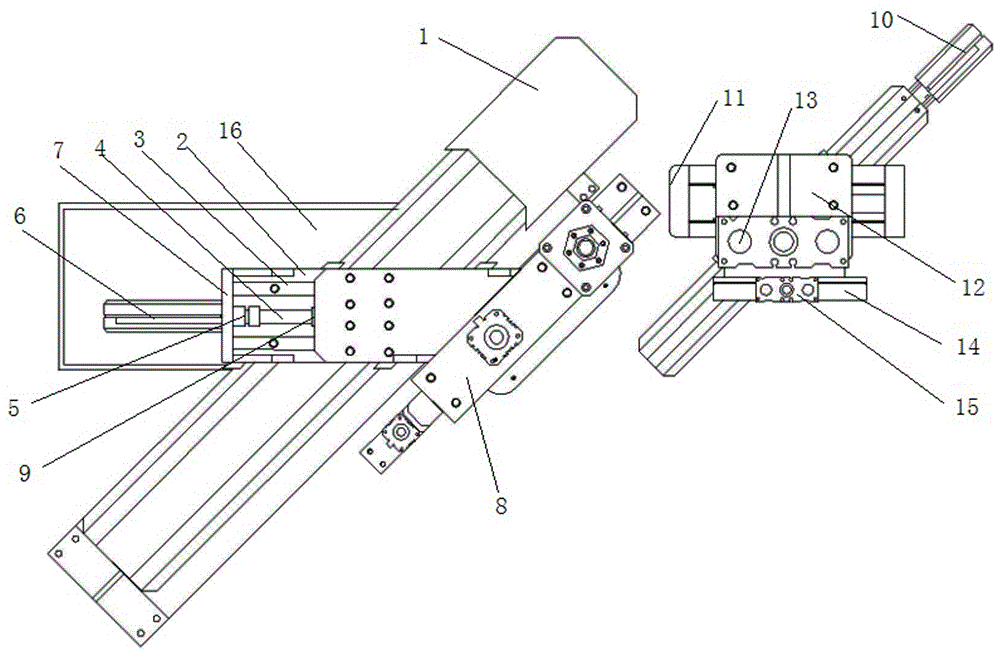

Automatic welding device for optical cable longitudinally wrapped steel belt or aluminum belt connection

ActiveCN106624814AImprove qualityImprove equipment capacityOther manufacturing equipments/toolsProduction lineControl system

The invention discloses an automatic welding device for optical cable longitudinally wrapped steel belt or aluminum belt connection. The automatic welding device is characterized by comprising an operation platform, a belt tail positioning device, a belt head positioning and clamping device, an oblique moving device, a shearing device, a tailing recycling device a welding device body and a control system. According to the automatic welding device, through control and combination of a pre-shearing profiling mold, an air cylinder and an electric cylinder, positioning and clamping of belt ends (the belt head and the belt tail) are achieved, the effect that oblique overlapped joints stably pass through an embossing and longitudinal wrapping device is guaranteed in the 45-degree belt end shearing and welding mode, control over the belt stacking width and the number of rows of weld spots is achieved through the oblique moving device, and a quality guarantee is provided for automatic belt stacking welding. Through the automatic welding device, the automation degree of the sheath production line is improved, the problem that the labor cost is high can be effectively solved, production can be conducted incessantly for 24 hours, the dependence on number of workers is eliminated fundamentally, labor cost is reduced, and the enterprise competitiveness is improved.

Owner:四川天府江东科技有限公司

Quenching process for bearing steel shaft pin parts

InactiveCN103924056AImprove equipment capacityReduce production energy consumptionFurnace typesHeat treatment furnacesHardnessHeating furnace

The invention relates to a quenching process for bearing steel shaft pin parts. As a blank, bearing steel is machined into shaft pin parts, the quenching process comprises the following steps: (1) checking whether the spheroidizing annealed structure of the parts is qualified, if yes, performing the step (2); (2) putting the parts in a heating furnace, and controlling the heating temperature to be 875-885DEG C, carbon potential to be 0.6-0.7%, and heating time to be 40-50min; (3) enabling the parts to fall in an oil tank for quenching at the quenching oil temperature of 60-80DEG C, wherein the quenching cooling time is 5-10min; and (4) tempering, wherein when the hardness of the parts is required for 61-65HRC, the tempering temperature is at 165-185DEG C, and the tempering time is 2.5-3h, and when the hardness of the parts is required for 58-62HRC, the tempering temperature is at 200-215DEG C, and the tempering time is 2.5-3h. By strictly controlling the spheroidizing annealed structure of the parts and changing the heating temperature, furnace carbon potential Cp and other thermal treatment technological parameters, the time per hour is shortened by 10-15min compared with the conventional treatment time, and on the premise that guaranteeing the quality index of quenching thermal treatment is guaranteed, the purposes of obviously improving the equipment productivity, and decreasing the production energy consumption can be achieved.

Owner:鑫光热处理工业(昆山)有限公司

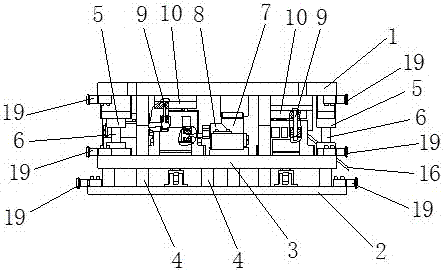

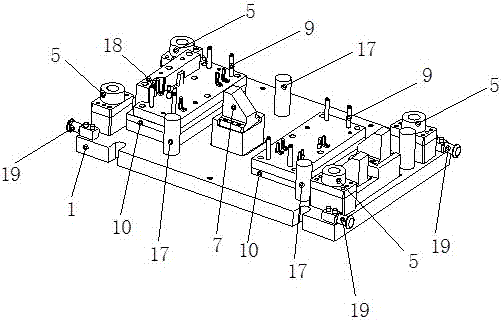

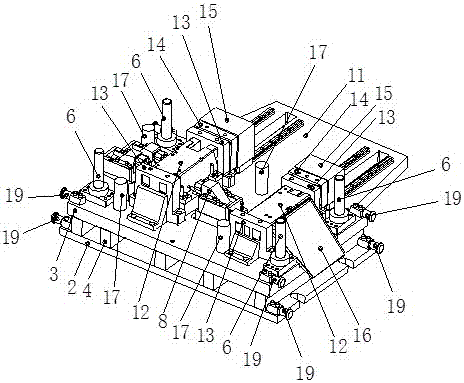

Energy-absorbing box punching mold

ActiveCN106001246BCompact and efficientHigh dimensional accuracyPerforating toolsMetal-working feeding devicesPunchingEngineering

Owner:辉泰(太仓)汽配有限公司

A kind of method and system for continuous production of 2,5-dichlorophenol

ActiveCN105384610BShort reaction timeLess side effectsOrganic chemistryOrganic compound preparationDichlorophenolAniline

The present invention provides a method and system for continuously producing 2,5-dichlorophenol. The method comprises an aniline salt diazotization process and a diazo solution hydrolysis process. The aniline salt diazotization process comprises the steps of continuously feeding aniline salt and nitrite into a diazo intensive mixing apparatus; performing a diazotization reaction under intensive mixing; feeding a diazo solution generated by the reaction into a diazo solution storing tank; back-mixing a part of the diazo solution in the diazo solution storing tank after cooling and feeding the part of the diazo solution into the diazo intensive mixing apparatus; removing all or a part of heat generated in the diazotization reaction by using the back-mixed cryogenic diazo solution; and directly performing continuous hydrolysis on the other part of the diazo solution. According to the method provided by the present invention, by adopting an intensive mixing process and a back-mixing process, mass and heat transfer during the diazotization reaction and the hydrolysis reaction can be quickly performed; heat can be taken away or given in time; a reaction time is shortened; the side reaction is reduced; the heat utilization rate is improved; the costs are lowered; and a safety factor and the device production capacity are improved.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Semiconductor laser tube socket for PD die bonding

InactiveCN110943364AIncrease productivityImprove equipment utilizationLaser detailsSemiconductor lasersPhysicsErbium lasers

The invention relates to a semiconductor laser tube socket for PD die bonding. The tube socket comprises a main body, a tube tongue arranged on the upper surface of the main body, a PD area and PINs arranged on the lower surface of the main body. The tube tongue and the PD area are both of a strip-shaped structure. The length direction of the tube tongue is perpendicular to the upper surface of the main body, and the length direction of the PD area is parallel to the upper surface of the main body; the left side face and the right side face of the PD area are each of a slope structure. The tube socket can effectively solve the problems of PD failure and equipment stop due to excessive abnormity caused by poor glue amount control; the output rate and the equipment utilization rate are effectively improved, and the marking characteristics of PR recognition are provided for automatic equipment.

Owner:潍坊华光光电子有限公司

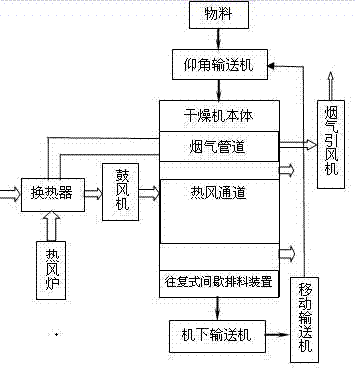

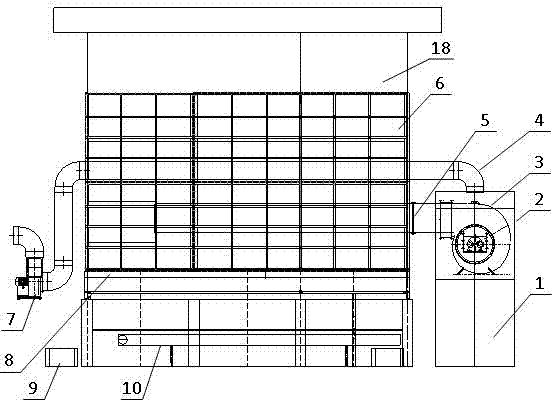

Circulating drying machine capable of automatically breaking material bridge and process system of machine

ActiveCN107062887AGuaranteed unloading phenomenonPrevent bridgingDrying gas arrangementsDrying solid materialsProcess systemsProcess engineering

A circulating drying machine capable of automatically breaking a material bridge comprises a hot-blast stove (1), a heat exchanger (2), an air blower (3), a smoke induced draft fan (7), a drying machine body (6), a feeding port (18), a smoke pipeline (4), a hot air passage (5), a flow distributor (15), a reciprocating intermittent discharging device (8), a lower conveyor (10), a moving conveyor (9) and an elevation conveyor (11). With the drying machine, the bridge phenomenon of dry materials in the prior art is effectively eliminated, the materials completely depend on the dead weight to alternate, stagger and flow at the differential speed in the drying machine, the machine is suitable for bulk materials with the relatively good liquidity and also meets the requirement for smooth and intermittent flow of materials having the relatively high holding resistance, the universality of the drying machine is substantially improved, the drying machine is simple in structure, convenient to operate and wide in application range, the drying energy consumption is reduced, the cost of equipment is reduced, and the drying efficiency and the productivity of the equipment are increased.

Owner:SOUTH CHINA AGRI UNIV

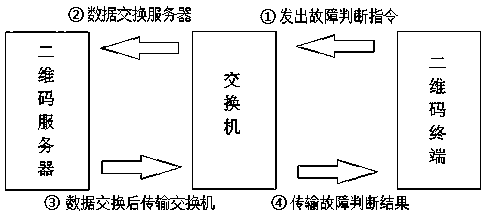

System for tracing and positioning network fault position of production line through QR code

InactiveCN111064615AReduce parking timeImprove equipment capacityData switching networksEmbedded systemData transmission

The invention discloses a system for tracing and positioning a network fault position of a production line through a QR code, and belongs to the technical field of communication. The system comprisesa QR code terminal, a switch and a QR code server; the working process of the system comprises the following steps that the QR code terminal sends a fault judgment instruction to the switch; the switch transmits data to the QR code server; the QR code server judges a network fault point and transmits data to the switch; and the switch transmits the data to the QR code terminal to display a judgment result. According to the system, the network fault point can be rapidly and accurately judged, the assembly line parking time is shortened, and the equipment productivity is improved.

Owner:华北制药集团动物保健品有限责任公司

Thin film transistor array substrate and manufacturing method thereof

ActiveCN102629590BLow costReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsActive layer

Disclosed are a thin film transistor array substrate and a producing method thereof in the embodiments of the present invention, the producing method comprising: forming an active layer thin film and a conductive layer thin film on a substrate; depositing a source / drain electrode layer thin film on the conductive layer thin film, treating the conductive layer thin film and the source / drain electrode layer thin film using gray tone or half tone masking process, to form at least two data lines, a pixel electrode and source / drain electrodes of the thin film transistor (TFT); after depositing an insulating layer thin film covered the active layer thin film, the source / drain electrodes, the data lines and the pixel electrode, forming a through hole and a gate insulating layer of the TFT on the insulating layer, to form an active layer of the TFT; forming a gate electrode of the TFT and at least two gate scanning lines cross with the data wires.

Owner:BOE TECH GRP CO LTD

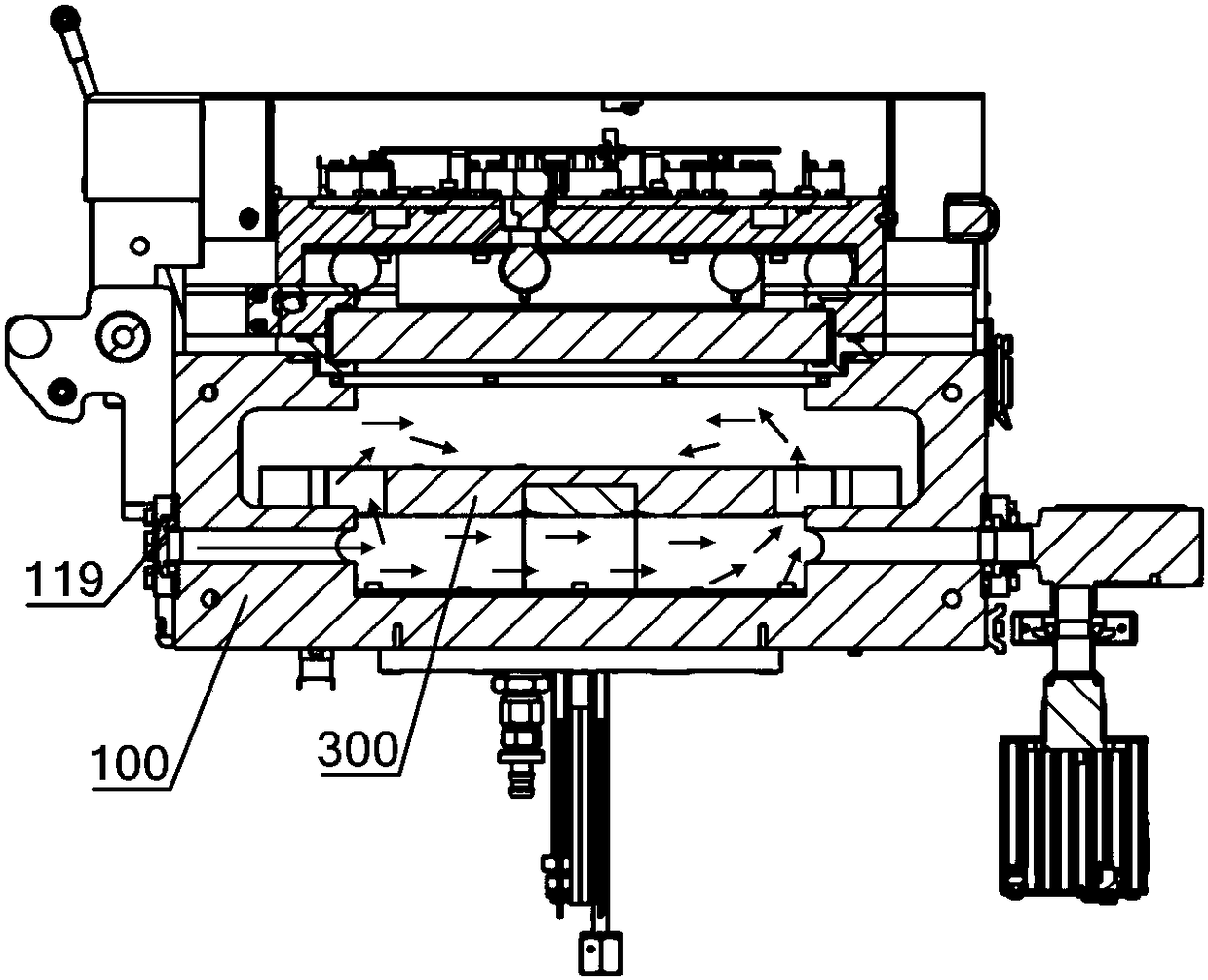

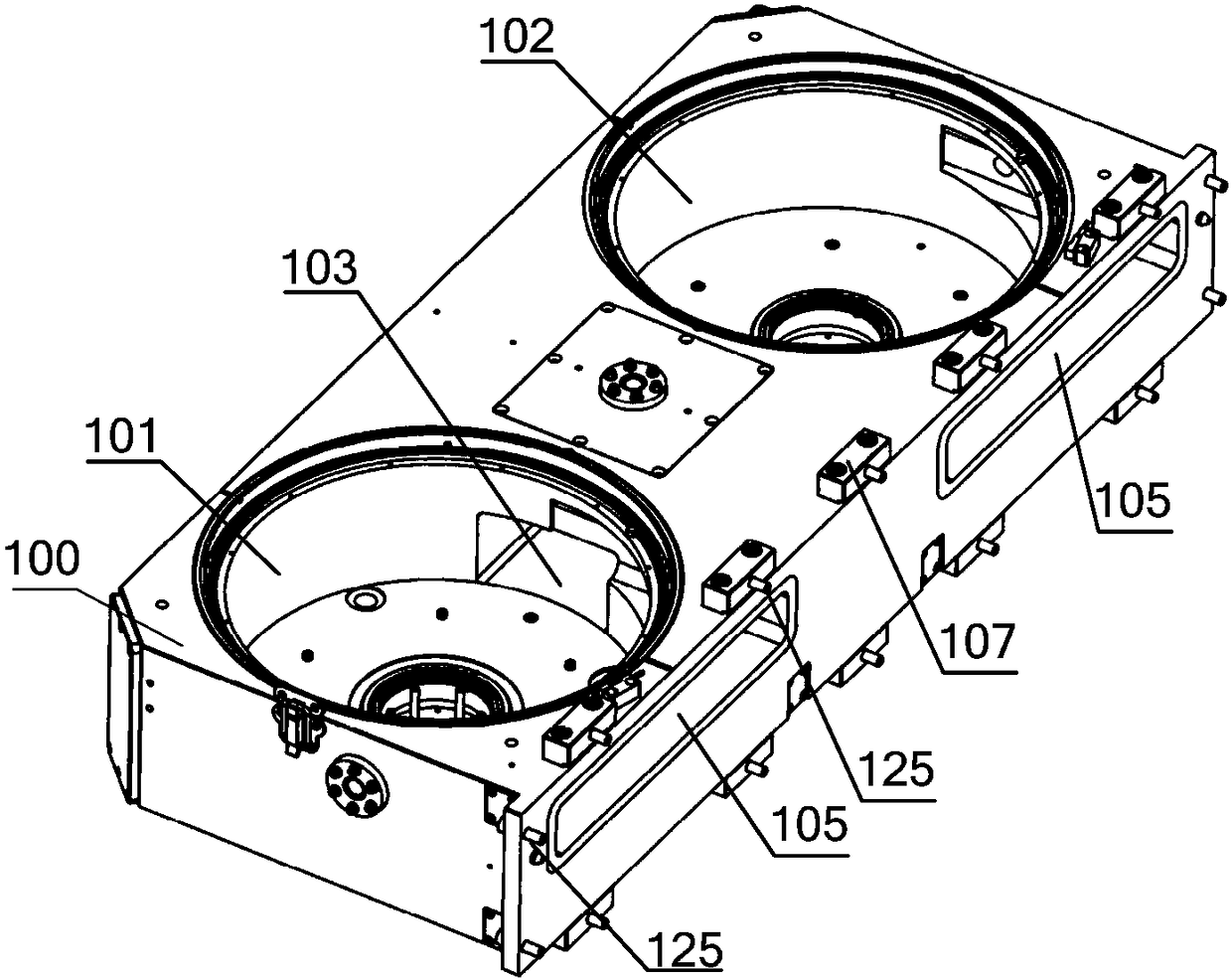

Process chamber

ActiveCN108091587AReduce processing timeImprove processing efficiencySemiconductor/solid-state device manufacturingEngineeringTransmission time

The invention provides a process chamber. A first chamber and a second chamber which are identical in structure and symmetrically arranged are arranged on the chamber body, and a connecting cavity forhorizontally connecting the first chamber and the second chamber is arranged on the chamber body so that two wafers can be simultaneously transmitted into the first chamber and the second chamber, and thus half of the wafer transmission time can be shortened and the wafer transmission efficiency and the equipment productivity can be enhanced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

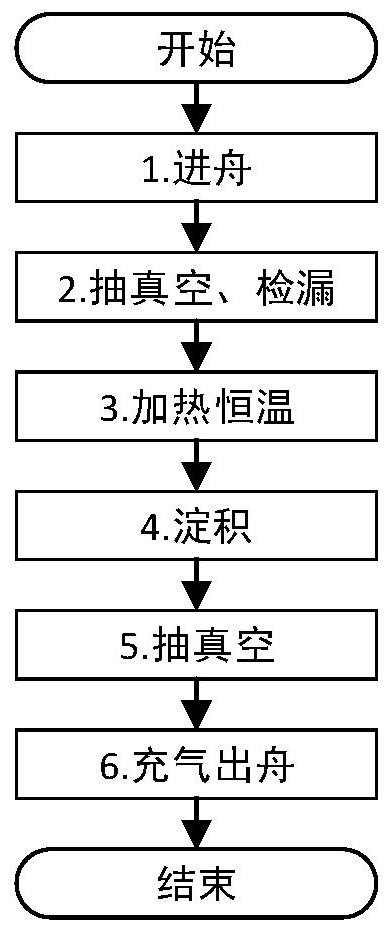

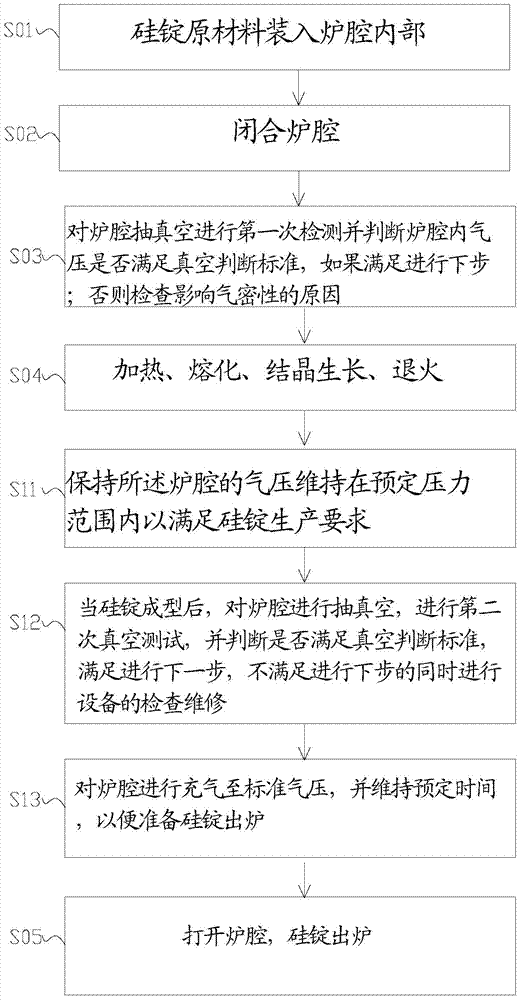

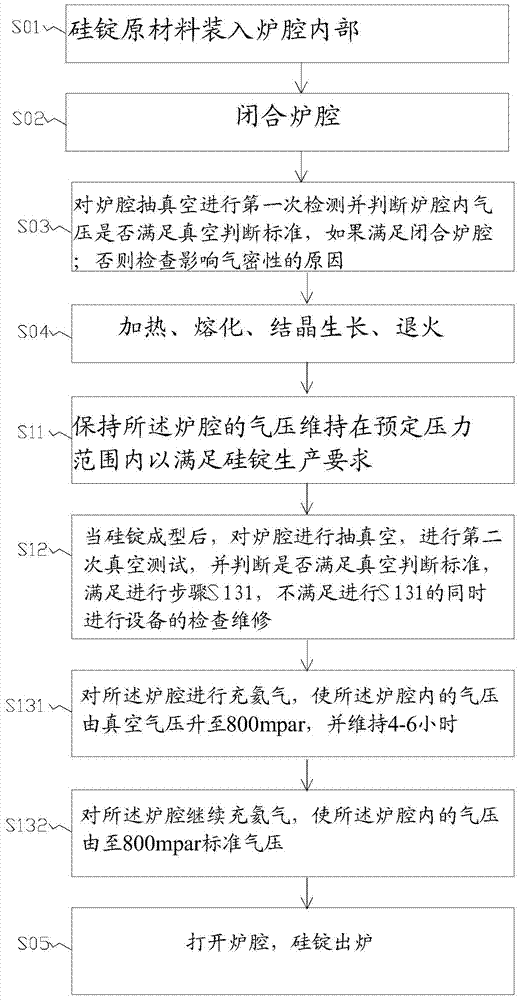

A method for detecting the airtightness of polycrystalline ingot furnace equipment

InactiveCN103981571BGuarantee product qualityIncreased air tightnessPolycrystalline material growthSingle crystal growth detailsIngotAir tightness

The invention discloses a method for detecting the air tightness of a polycrystalline ingot furnace. The method particularly comprises the steps of vacuumizing the furnace chamber to carry out a first vacuum test before the silicon ingot raw materials are charged and the furnace chamber of the polycrystalline ingot furnace apparatus is closed to produce silicon ingots; after the silicon ingots are formed and before the furnace chamber is opened, vacuumizing the furnace chamber to carry out a second vacuum test, wherein whether the first vacuum test is directly carried out or not is determined according to the second vacuum test results of the previous production cycle. According to the method, since the step of the furnace chamber vacuum test is increased in the silicon ingot procedure running production process, the air tightness of the device within the current production cycle is beneficial to be known timely and factors for affecting the air tightness are checked timely to guarantee the production quality of the silicon ingot. Furthermore, the tightness inspection of the device is increased under the premise that no additional production time is brought for the polycrystalline ingot furnace, and thus problems existing in the device can be found and timely maintained before the first vacuum test for the next cycle is carried out.

Owner:YINGLI ENERGY CHINA

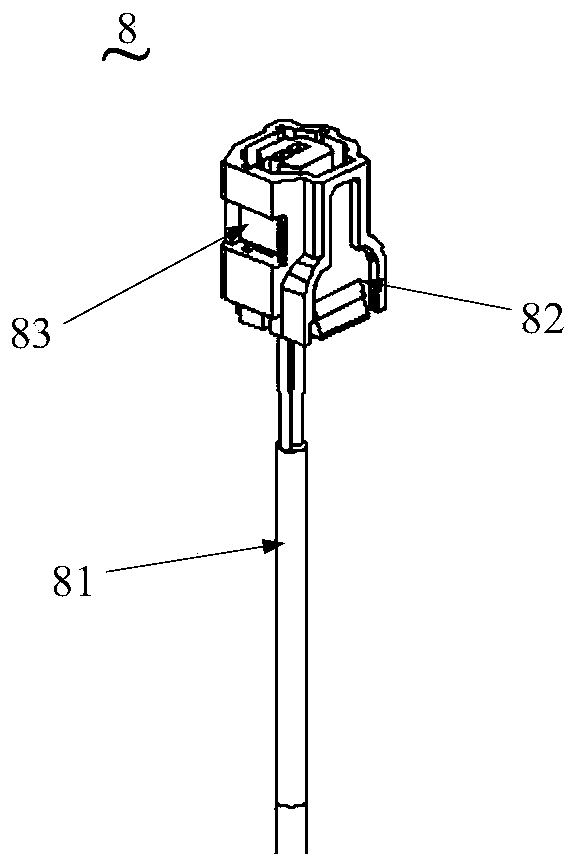

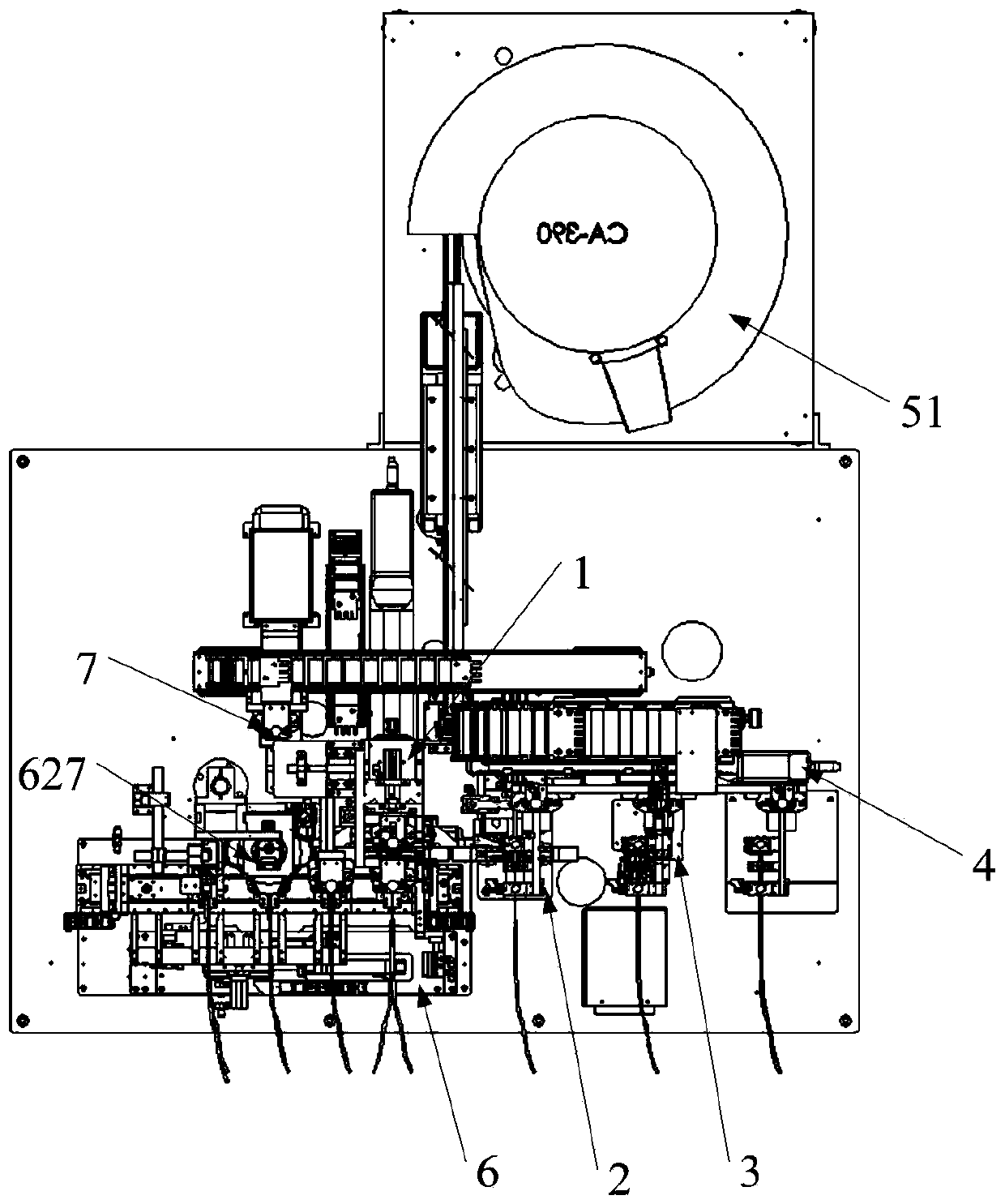

Automatic assembling and detection equipment for wire harness connector

ActiveCN111438501AReduce labor costsImprove equipment capacityContact member assembly/disassemblyMaterial strength using tensile/compressive forcesManipulatorElectrical and Electronics engineering

The invention discloses automatic assembling and detection equipment for a wire harness connector. The equipment comprises a matched assembling device, a tension testing device, a conduction testing device, a linkage transfer manipulator, a connector supply device used for loading connectors and a wire harness supply device used for loading wire harnesses, wherein the matched assembling device ismatched with the wire harness supply device to insert a terminal of a wire harness into the connector to complete assembling; the tension testing device is arranged between the matched assembling device and the conduction testing device, and the linkage transfer manipulator is used for transferring finished products on the matched assembling device, the tension testing device and the conduction testing device; and the tension testing device is used for performing tension testing on the finished products, and the conduction testing device is used for checking whether the terminal of the wire harness is normally connected with the connector. The automatic equipment integrates loading, assembling and detection, the manual cost is greatly reduced, and the efficiency and the production capacityof the equipment are improved.

Owner:宇山自动化技术(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com