Method for producing aluminum oxide with high-alumina fly ash

A high-aluminum fly ash, alumina technology, applied in chemical instruments and methods, alkali metal aluminate/alumina/aluminum hydroxide preparation, aluminum compounds, etc., can solve the problem of uncertain process reliability, acid method The problems of high equipment investment and difficulty in large-scale equipment can achieve the effect of reducing production costs and construction investment, easy and feasible industrialization, and realizing comprehensive recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

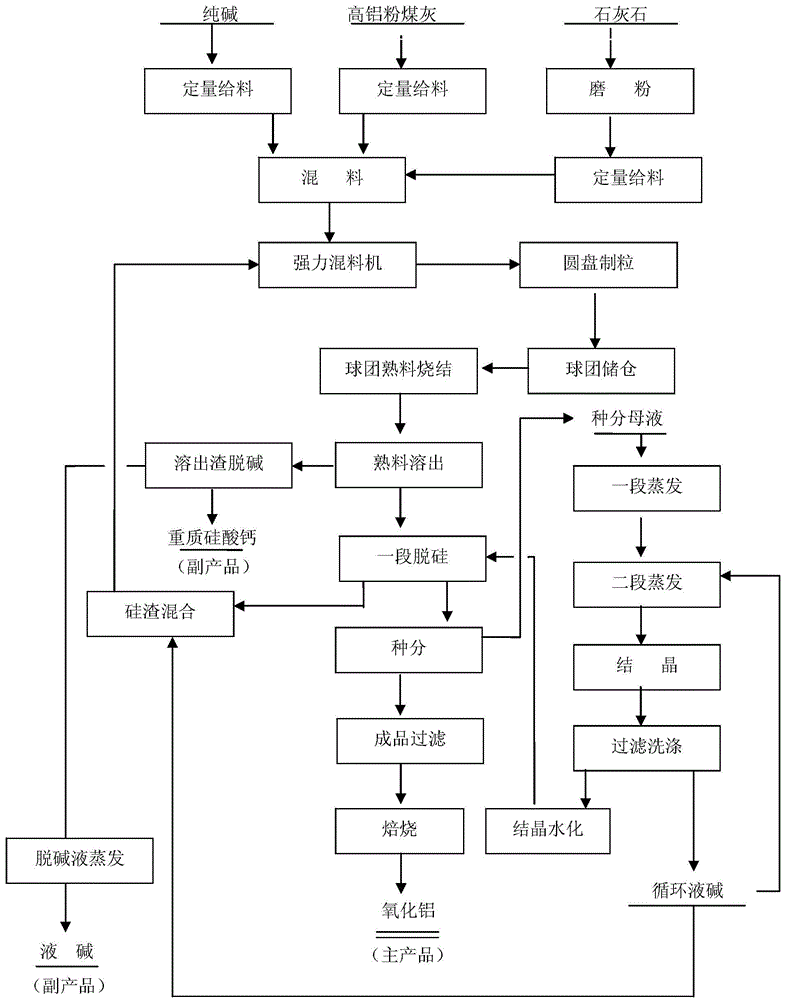

Method used

Image

Examples

Embodiment 1

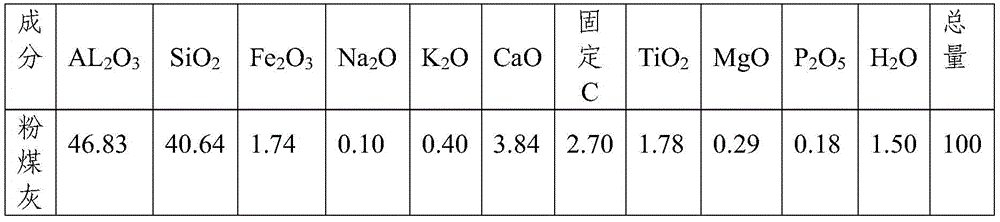

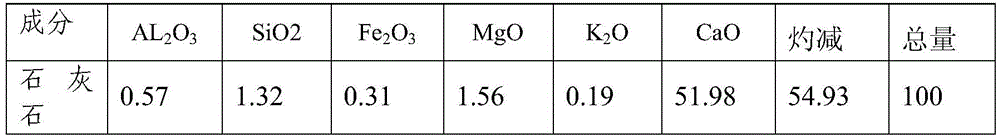

[0041]First, the limestone whose composition is shown in Table 2 is crushed to 2-5 mm, and then the ore powder is ground until the particle size is -0.074 mm, accounting for more than 85%. Then add the fly ash and soda ash powder of composition such as table 1 and fully mix, and fly ash, limestone, soda ash are respectively 38 parts by weight, 32 parts by weight and 20 parts by weight, then add lye (the circulating mother liquor that crystallization obtains), Divide the prepared lye into two parts in a ratio of 87:13. The concentration of lye is Na 2 O550g / L, αk=14. The batching index is: moisture 26%, alkali ratio 1, calcium ratio 1.

[0042] Add the prepared material together with 87% lye into a powerful mixer for thorough mixing, and then use a disc pelletizer to make pellets. 8 ~ 12mm, compressive strength greater than 10N.

[0043] The finished pellets are sintered into sintered pellets through five stages of drying, drying, preheating, sintering and cooling. The temp...

Embodiment 2

[0053] First, the limestone whose composition is shown in Table 2 is crushed to 2-5 mm, and then the ore powder is ground until the particle size is -0.074 mm, accounting for more than 85%. Then add the fly ash and soda ash powder of composition such as table 1 and fully mix, 40 parts by weight of fly ash, 35 parts by weight of limestone, 25 parts by weight of soda ash, then add lye, concentration is Na 2 O580g / L, αk=20. Ingredients control index, moisture 25%, alkali ratio 1, calcium ratio 1.

[0054] Add the prepared materials together into a powerful mixer for thorough mixing, and then use a disc pelletizer to make pellets. The amount of liquid added to the pellets is lye (volume is 15% of the previous step), and the particle size of the pellets is 16. ~20mm, compressive strength greater than 10N.

[0055] The finished pellets are sintered into sintered pellets through five stages of drying, drying, preheating, sintering and cooling, in which the temperature is controlled...

Embodiment 3

[0062] First, the limestone whose composition is shown in Table 2 is crushed to 2-5 mm, and then the ore powder is ground until the particle size is -0.074 mm, accounting for more than 85%. Then add the fly ash and soda ash powder of composition such as table 1 and fully mix, 43 parts by weight of fly ash, 37 parts by weight of limestone, 25 parts by weight of soda ash, then add lye, concentration is Na 2 O600g / L, αk=30. Ingredients control index, moisture 23%. , the alkali ratio is 1, and the calcium ratio is 1. Divide the prepared lye into two parts by volume, and divide it in a ratio of 87:13.

[0063] Add the prepared material together with 87% lye into a strong mixer for thorough mixing, and then use a disc pelletizer to make pellets. 20mm, the compressive strength is greater than 10N.

[0064] The finished pellets are sintered into sintered pellets through five stages of drying, drying, preheating, sintering and cooling, in which the temperature is controlled at 130°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com