System for tracing and positioning network fault position of production line through QR code

A network fault and two-dimensional code technology, applied in the field of communication, can solve problems such as safety hazards of automated production equipment, various mechanical or electrical faults, and impact on production efficiency, and achieve the effects of shortened parking time, high cost performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

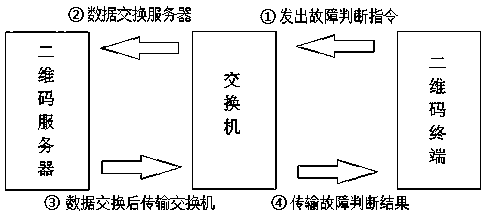

[0019] as attached figure 1 As shown in the schematic diagram, the present invention provides a system for retroactively locating the fault location of the production line network through a two-dimensional code, including a two-dimensional code terminal, a switch and a two-dimensional code server;

[0020] The working process of the system for retroactively locating the fault location of the production line network through the two-dimensional code includes the following steps,

[0021] 1) The two-dimensional code terminal sends a fault judgment command to the switch;

[0022] 2) The switch transmits data to the QR code server;

[0023] 3) The two-dimensional code server judges the network failure point and transmits the data to the switch;

[0024] 4) The switch transmits the data to the QR code terminal to display the judgment result.

[0025] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com