System for recovering ammonia from rare earth separation waste liquor

A technology for separating waste liquid and recovering ammonia, which is applied in the preparation/separation of ammonia, ammonia compounds, inorganic chemistry, etc. It can solve the problems of high processing cost, environmental pollution, high energy consumption of processing, etc., achieve efficient and thorough recovery, and save steam , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

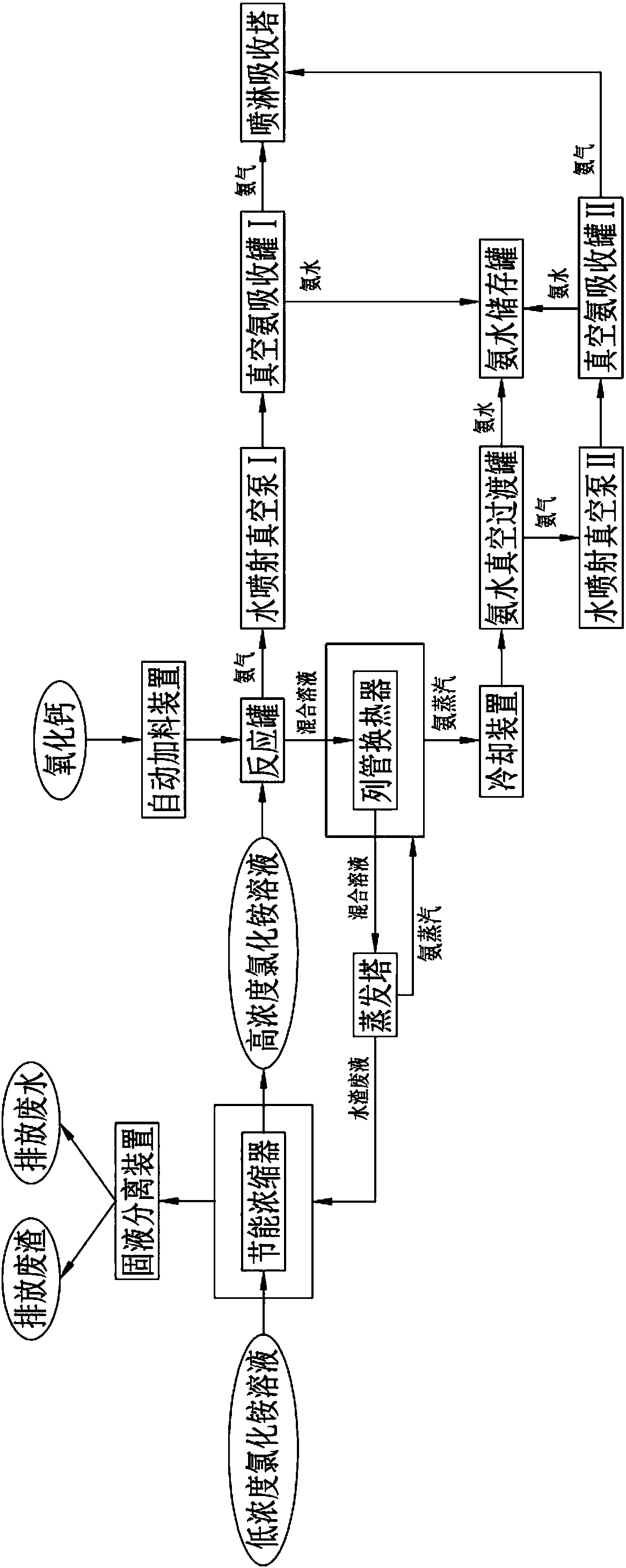

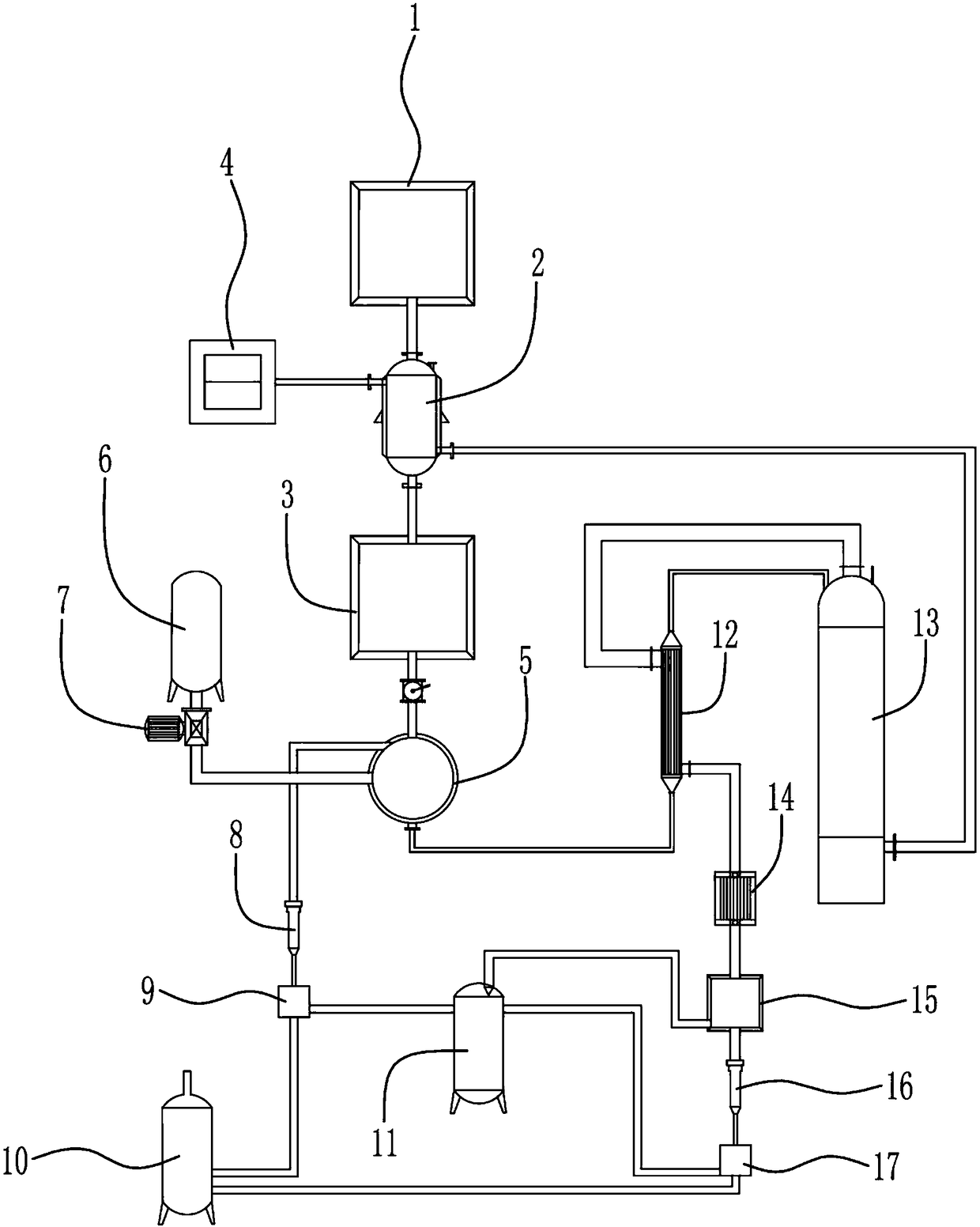

[0045] A method for recovering ammonia from rare earth separation waste liquid, such as figure 1 as shown, figure 1 Be the process flow diagram of this embodiment, concrete steps are:

[0046]Step 1, stir evenly; put the ammonium chloride wastewater discharged in the rare earth processing and extraction production with a concentration range of 1.7-2.1mol / L and an acidity range of 0.2-0.3mol / L in the solution pool I1 and stir evenly to obtain the concentration and A solution with a consistent pH.

[0047] Step 2, heating and concentrating; pump the low-concentration ammonium chloride solution obtained in step 1 into the energy-saving concentrator 2 and heat and concentrate it to obtain a high-concentration ammonium chloride solution and place it in the solution pool II3. The concentration of ammonium chloride in the high-concentration ammonium chloride solution is controlled at 3.6mol / L.

[0048] Step 3, replacement reaction; the high-concentration ammonium chloride solution...

Embodiment 2

[0053] A method for recovering ammonia from rare earth separation waste liquid, such as figure 1 as shown, figure 1 Be the process flow diagram of this embodiment, concrete steps are:

[0054] Step 1. Stir evenly; combine ammonium chloride wastewater with a concentration range of 1.8-2.3mol / L and an acidity range of 0.2-2.3mol / L discharged from the rare earth processing and extraction production with a concentration range of 0.4-1.0 discharged from the precipitation production mol / L, neutral to weakly alkaline ammonium chloride wastewater is placed in the solution pool Ⅰ1 and stirred evenly to obtain a solution with the same concentration and pH. The concentration of ammonium chloride wastewater after stirring is 1.9±0.1mol / L , The acidity is 0.3±0.05mol / L.

[0055] Step 2, heating and concentrating; pump the low-concentration ammonium chloride solution obtained in step 1 into the energy-saving concentrator 2 and heat and concentrate it to obtain a high-concentration ammoniu...

Embodiment 3

[0061] A method for recovering ammonia from rare earth separation waste liquid, such as figure 1 as shown, figure 1 Be the process flow diagram of this embodiment, concrete steps are:

[0062] Step 1. Stir evenly; put the ammonium chloride wastewater discharged from the rare earth processing and precipitation production with a concentration range of 0.4-1.0mol / L and a neutral to slightly alkaline acidity in the solution pool I1 and stir evenly to obtain the concentration and pH consistent solution.

[0063] Step 2, heating and concentrating; pump the low-concentration ammonium chloride solution obtained in step 1 into the energy-saving concentrator 2 and heat and concentrate it to obtain a high-concentration ammonium chloride solution and place it in the solution pool II3. The concentration of ammonium chloride in the high-concentration ammonium chloride solution is controlled at 2.6mol / L.

[0064] Step 3, replacement reaction; the high-concentration ammonium chloride solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com