Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Meet braking requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper-based powder metallurgy friction material for high-speed train braking and preparation method thereof

ActiveCN105063459AGood comprehensive mechanical propertiesStable friction and wear performancePowder metallurgyChromium

The invention provides a copper-based powder metallurgy friction material for high-speed train braking. The copper-based powder metallurgy friction material comprises, by weight percentage, 40%-60% of copper, 7%-20% of iron, 3%-5% of chromium, 5%-10% of zirconite, 3%-6% of aluminum oxide, 2%-5% of tin, 2%-4% of manganese, 5%-10% of graphite, 2%-5% of molybdenum disulfide and 1%-5% of ferrochromium. A preparation method of the copper-based powder metallurgy friction material comprises the steps of proportioning, mixing, pressing, sintering and the like. The copper-based powder metallurgy friction material has excellent friction performance and stable and safe braking performance, and can meet the braking requirement of a 380 km / h high-speed train. The preparation method is simple and environmentally friendly, and has a good market prospect.

Owner:GUANGXI UNIV FOR NATITIES

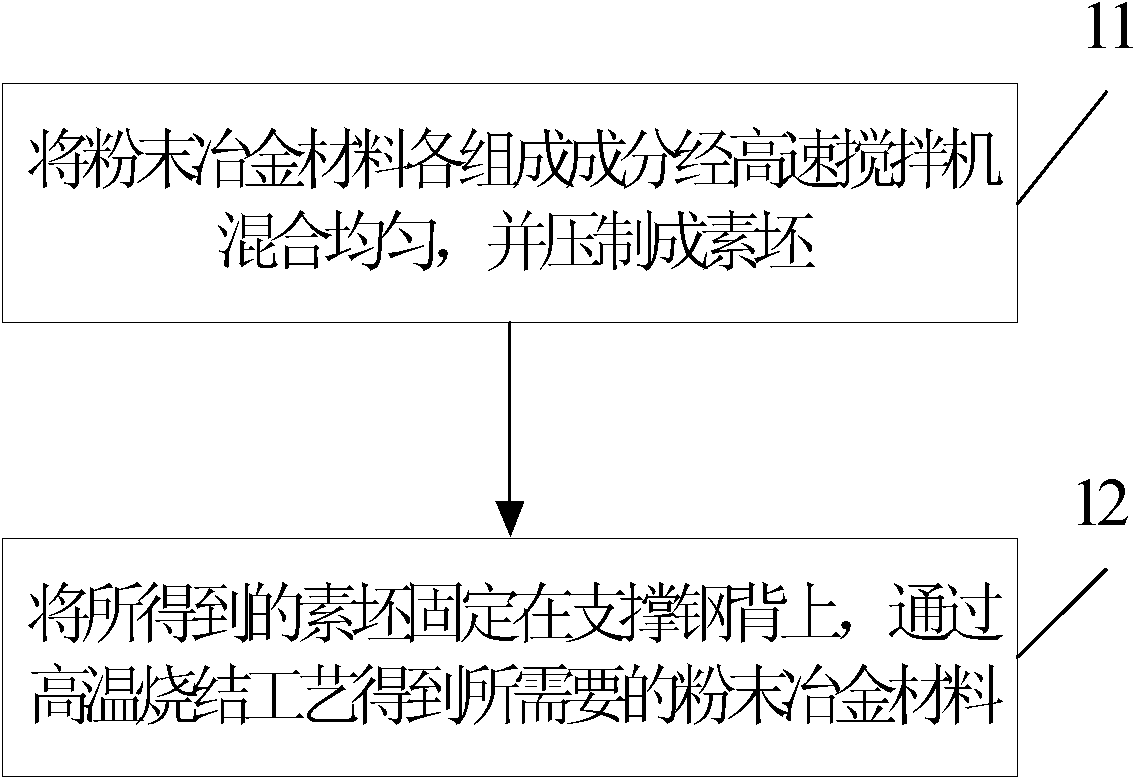

Preparation method of powder metallurgy material for train brake pad

The embodiment of the invention provides a preparation method of a powder metallurgy material for a train brake pad. The powder metallurgy material comprises the following components by weight percent: 40-50% of copper powder, 10-25% of iron powder, 8-15% of ferro-manganese ore powder, 2-7% of silica, 5-9% of molybdenum disulfide, 2-8% of aluminum oxide, 1-5% of boron nitride, 15-25% of graphite and 0.2-1% of polyacrylonitrile fiber. In the preparation method, the components are evenly mixed by a high speed stirrer and then pressed into a biscuit; and the biscuit is fixed on a support steel back, and the required powder metallurgy material is obtained by a high temperature sintering technology. The powder metallurgy material obtained by implementation of the technical scheme has the advantages of over 125 MPa of compressive strength, excellent friction stability and heat resistance, thus the compressive strength and braking performance of the brake pad can meet the braking requirements of a high-speed train with a speed of 300km / h or beyond.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

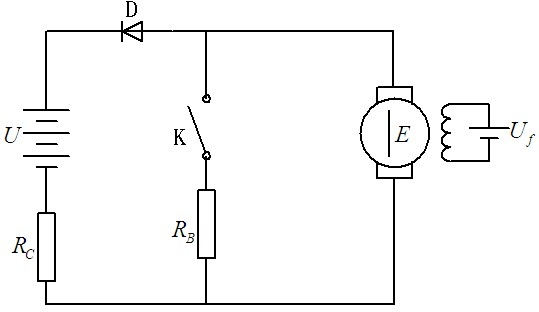

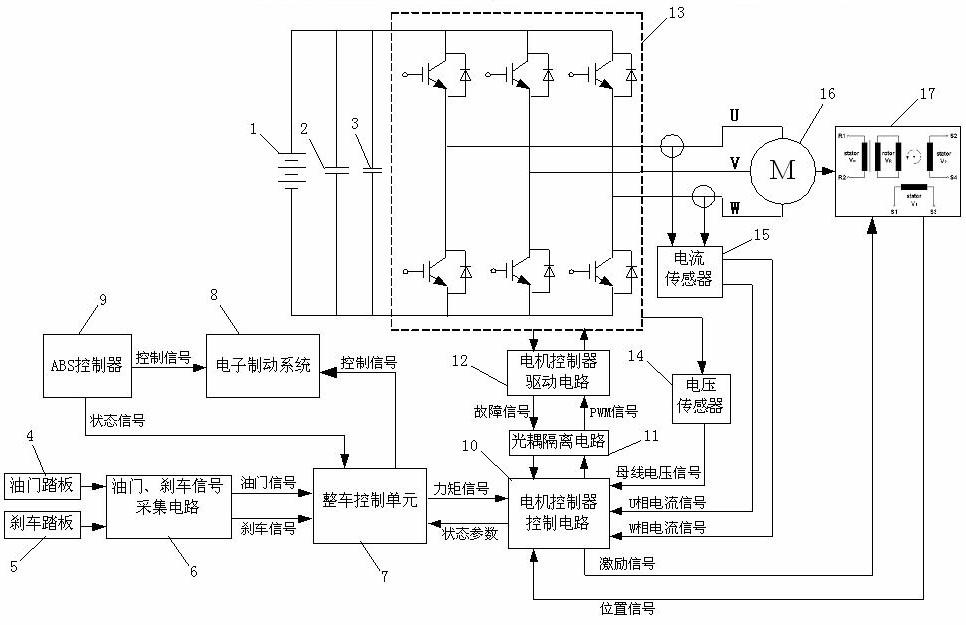

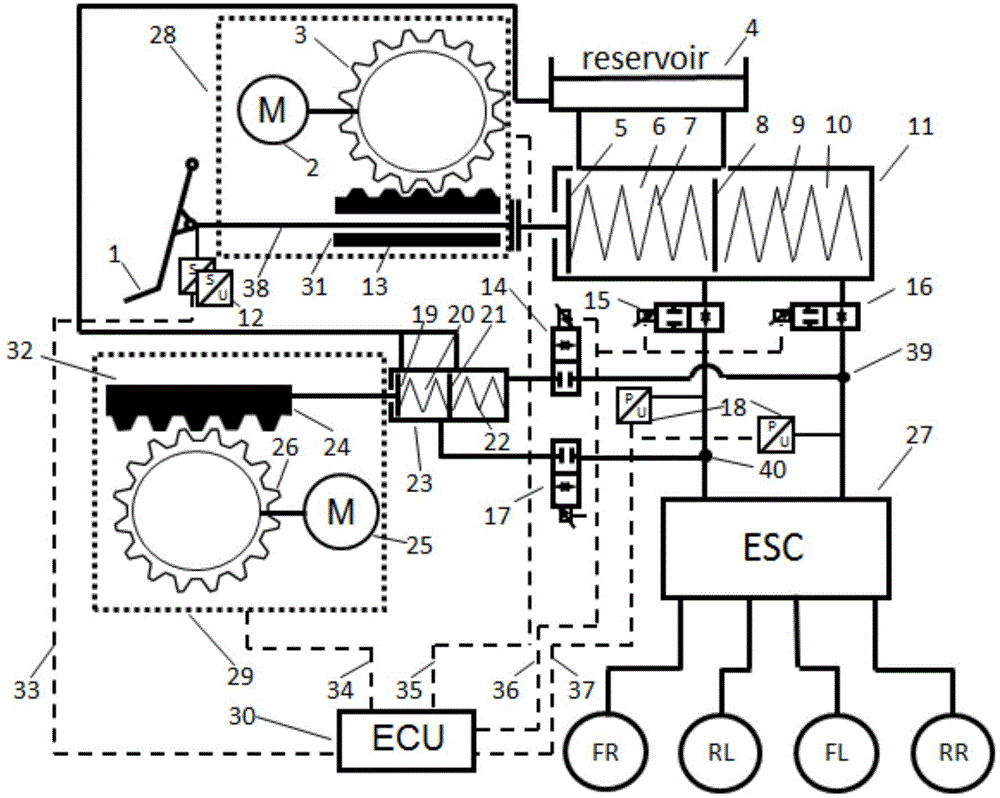

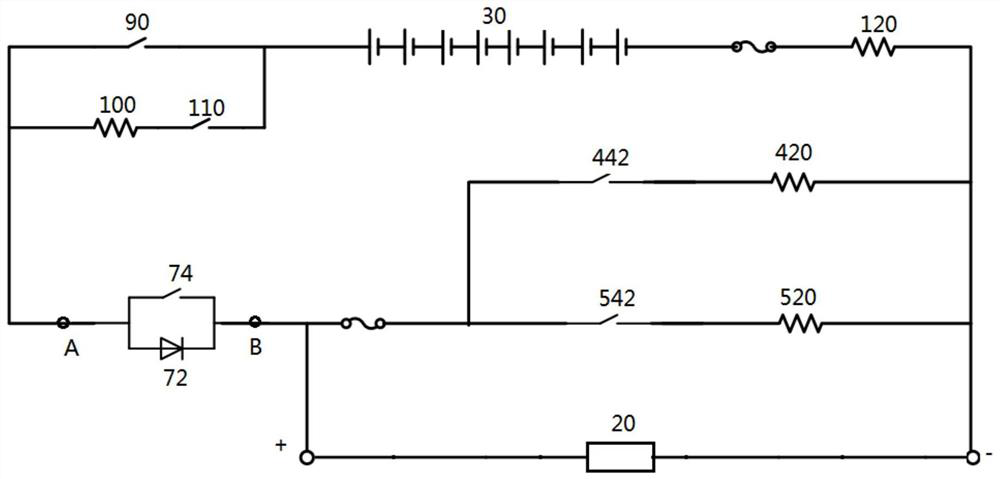

Brake energy feedback control system of pure electric automobile

InactiveCN102166962AAchieve recyclingMeet braking requirementsElectric devicesElectrodynamic brake systemsElectric machineryAutomotive engineering

The invention discloses a brake energy feedback control system of a pure electric automobile. The system in the invention combines electric brake and mechanical brake, wherein the electric brake is realized by controlling a motor to work in a generating state; and the mechanical brake is realized by an electronic brake system. An entire automobile control unit is a core control unit of the brake energy feedback control system; and the entire automobile control unit is used for calculating brake torque needed by the motor and the brake force needed by the electronic brake system, and respectively transmitting control commands to a motor controller control circuit and the electronic brake system. The brake energy feedback control system in the invention not only meets the brake requirements of the automobile under various work conditions, but also ensures the stability of the automobile during driving and the smoothness of automobile brake speed reduction; and furthermore, the system is capable of effectively recovering the brake energy and improving the use efficiency of the entire automobile energy.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

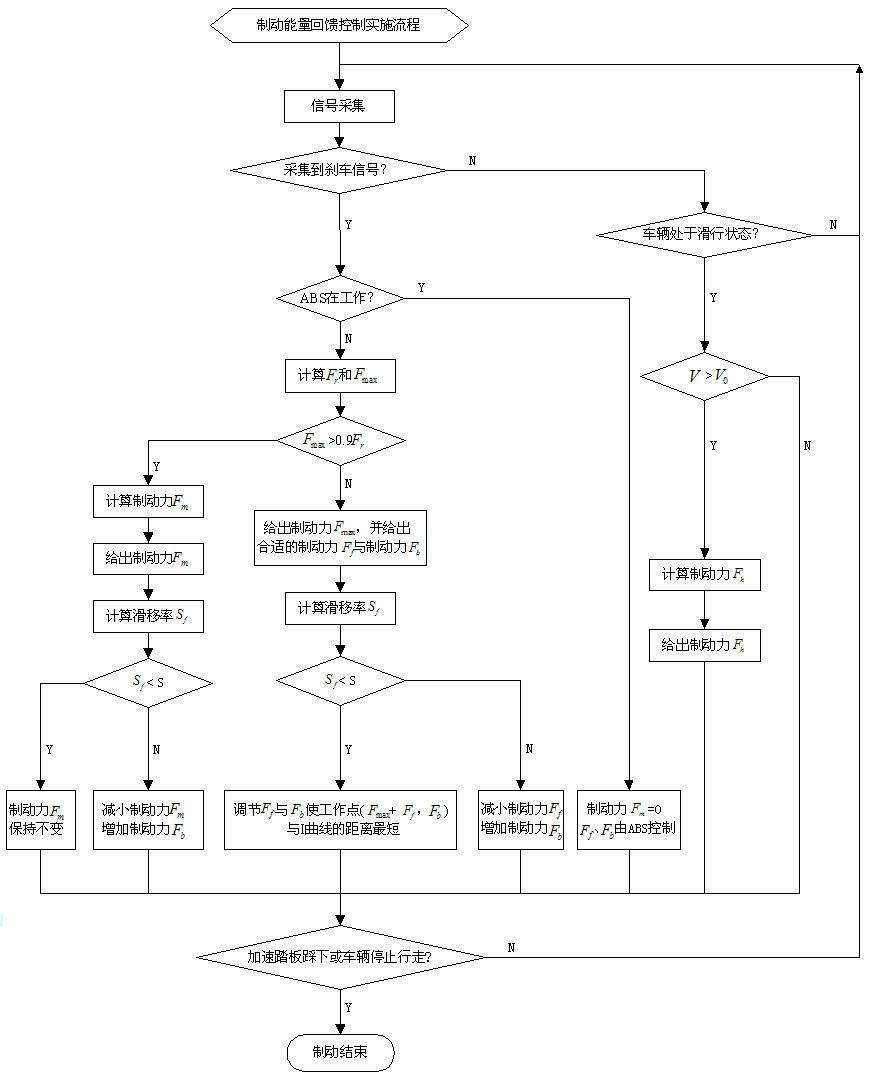

Brake energy feedback control method of pure electric automobile

InactiveCN102166963AMeet braking requirementsGuaranteed stabilityElectrodynamic brake systemsElectric machineBraking system

The invention discloses a brake energy feedback control method of a pure electric automobile. The method comprises the following steps of: judging whether a brake signal exists, if so, judging whether an ABS (antilock braking system) works, and if the ABS works, enabling a brake force Fm of a motor to be 0, enabling the front axle brake force Ff and the rear axle brake force Fb to be controlled by the ABS; if the ABS dose not work, adjusting based on the fact whether the maximum brake force Fmax provided by the motor currently meets the brake threshold value F, the sliding rate threshold value S of the front axle wheels and other factors required by a driver; if no brake signal exits, judging whether the automobile is in a sliding state, if so, judging whether a current speed V is greater than the sliding speed threshold value V0, if V is greater than V0, controlling the motor to provide the brake force Fh needed by over-speed sliding of the automobile, and if V is less than or equal to V0, requiring no braking for the automobile; and repeating the steps till the driver steps on an acceleration pedal or the automobile stops moving, ending the brake. By the method in the invention, the use efficiency of the entire automobile energy can be increased.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Hydraulic double-motor driving electronic hydraulic braking system

InactiveCN103950445ALow powerExtend your lifeBraking action transmissionMotor driveLiquid storage tank

A hydraulic double-motor driving electronic hydraulic braking system comprises a braking pedal, a braking master cylinder, a secondary master cylinder, a liquid storage tank, a pedal displacement sensor, a hydraulic pressure sensor, an electronic control unit ECU, a first electronic control linear moving module and a second electronic control linear moving module for performing active control on hydraulic braking force and pedal force of the system, an electronic stability control module ESC for regulating the hydraulic braking force of each wheel cylinder, a tee joint for connecting hydraulic pipelines between the braking master cylinder and the inlet of the electronic stability control (ESC) module as well as between the secondary master cylinder and the inlet of the ESC module. According to the invention, the pedal force of a driver can be utilized for pressure establishing, the active control on the pedal force is realized while a pedal force simulator with a complex structure is omitted, braking pedal feel is ensured, the braking intention of the driver can be correctly reflected, the active control on hydraulic pressure is realized, the braking requirement of a vehicle is met, maximum braking energy recycling can be realized, the control is precise, and the response speed is high.

Owner:TONGJI UNIV

Copper-base powder metallurgy brake pad for high-power wind turbine generator sets and preparation technique thereof

ActiveCN101876011AImprove uniformityImprove adhesionTurbinesOther manufacturing equipments/toolsPowder metallurgyFerrosilicon

The invention relates to a copper-base powder metallurgy brake pad which is composed of copper, graphite, sea sand, ferrochromium, tin and ferrosilicon. The preparation technique comprises the following steps: weighing the powder components according to the proportion, incorporating zinc stearate and aviation kerosene, and evenly mixing; pressing into a pressed compact; and putting the pressed compact on a steel backing of which the surface is plated with copper, covering a graphite plate on the surface of the pressed compact, pressure-sintering in a sintering furnace in a gradient-temperature gradient-pressure mode, cooling in a water-cooling hood to room temperature, and discharging to obtain the copper-base powder metallurgy brake pad blank. The invention has the advantages of reasonable component proportioning, convenient manufacture, favorable wearability and long service life; the service life and braking performance of the brake pad can meet the braking requirements for a high speed shaft in the wind turbine generator set of which the power is greater than 2.5 MW; and the brake pad can be industrially produced, and has wide industrialization prospects.

Owner:CENT SOUTH UNIV

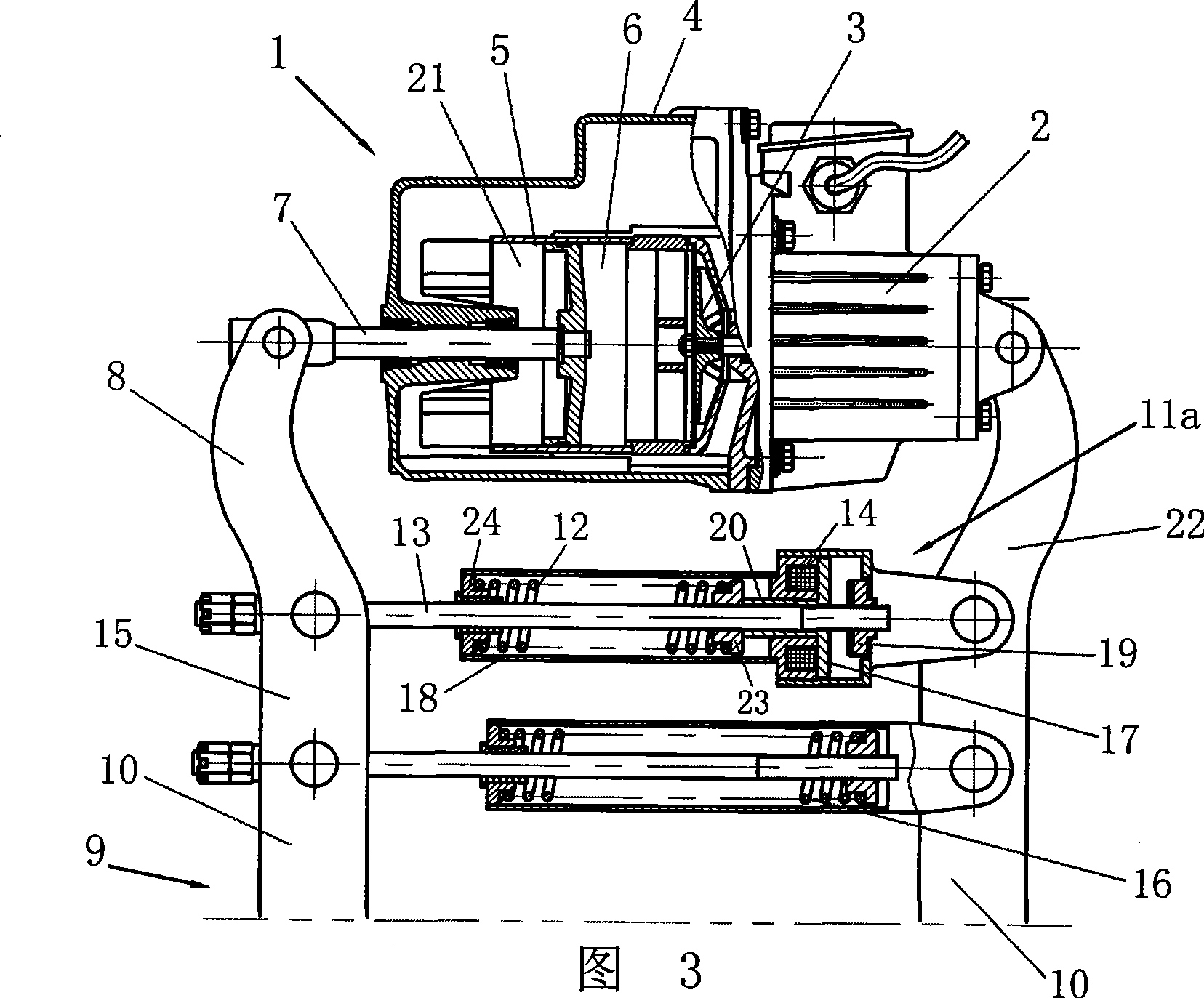

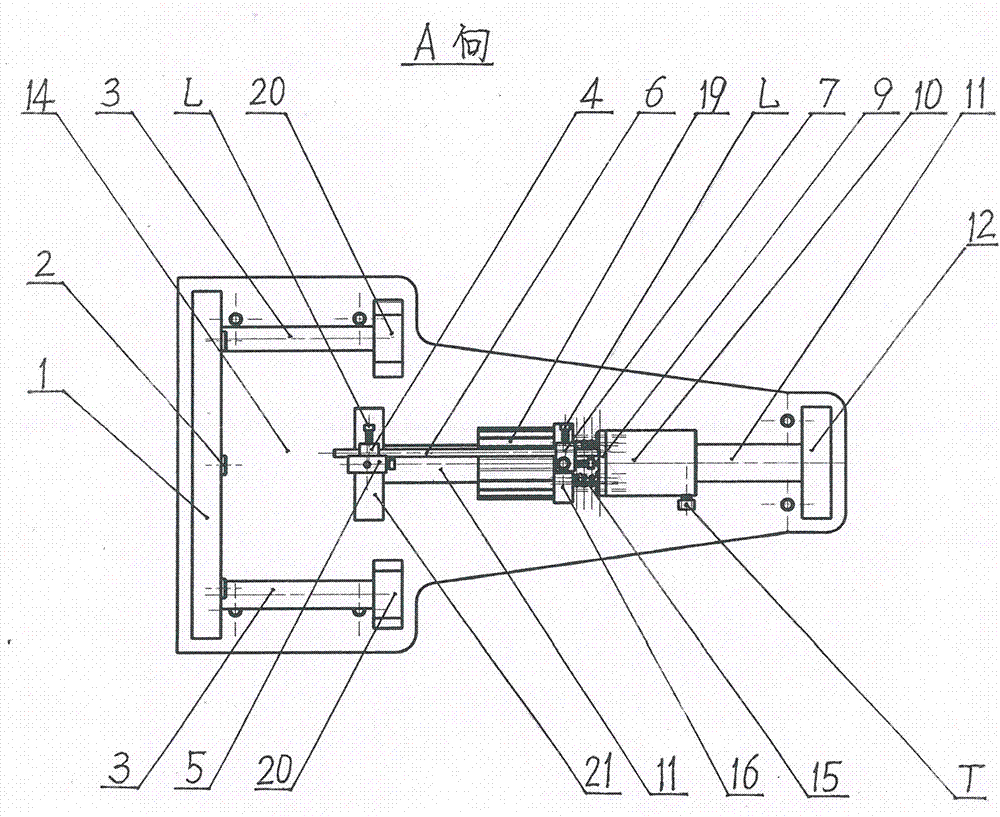

Stacked braking thrust unit of normally closed brake

InactiveCN101463874AReliable brakingMeet braking requirementsDrum brakesBrake actuating mechanismsAutomotive engineeringHinge angle

A superimposed braking driver of a normally closed type brake comprises a driver (1), the external end of a push rod (7) is used for connecting a driving arm (8) in a braking part by hinge shaft so as to act on the braking part (9), a superimposed braking mechanism which can lead the braking part to realize superimposed braking is arranged, and the superimposed braking mechanism acts on the braking arm (10) in the braking part (9) by a corresponding component; the superimposed braking mechanism can adopt a plurality of structures like a superimposed braking mechanism (11a) or a superimposed braking mechanism (11b) or a superimposed braking mechanism (11c). By operating the driver (1) individually, the openness and restoration of the normally closed brake can be realized, and according to requirement, the superimposed braking mechanism can be operated individually to realize the superimposed brake; and the working process of the openness and restoration of the normally closed brake can be applied to a working condition with frequent braking individually to lead the normally closed brake and the superimposed brake to be in a working process of a braking mode, and can be applied to a more stable and reliable braking.

Owner:谢兴云

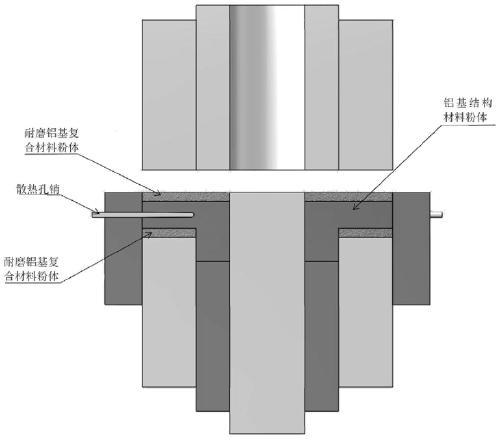

Light wear-resistant aluminum-based powder metallurgical composite material automobile brake disc and preparation method thereof

ActiveCN111442039AMeet braking requirementsReduce weightBraking discsActuatorsWear resistanceCast iron

The invention discloses a light wear-resistant aluminum-based powder metallurgical composite material automobile brake disc and a preparation method thereof. A disc body of the automobile brake disc is made of an aluminum-based structural material, and a frictional surface is made of a wear-resistant aluminum-based composite material. According to the preparation method, the automobile brake discis prepared by using wear-resistant aluminum-based composite material mixed powder, aluminum-based structural material mixed powder and other raw materials through regional reinforcement and integrated ''near-net-shaping'' technologies according to the principle of powder metallurgy. The prepared aluminum-based powder metallurgical composite material automobile brake disc has a series of advantages of being free of damage, free of defects, good in compactness, high in strength and the like and can well meet the requirements for braking and wear resistance of the automobile brake disc; meanwhile, compared with a traditional cast iron brake disc, the weight is reduced by more than 55%, so that energy consumption is greatly lowered, and the national requirements for energy conservation and emission reduction are met; and the preparation method is easy and convenient to use, low in cost and high in finished product rate and can be used for preparing automobile brake discs of various dimensions and structures, thereby meeting the requirement for industrial mass continuous production.

Owner:HUNAN JINTIAN ALUMINUM HI TECH CO LTD

Powder metallurgy brake lining for high speed train and preparing method thereof

InactiveCN106351993AIncrease coefficient of frictionImprove smoothnessOther chemical processesTransportation and packagingBoron nitrideBrake lining

The invention discloses a powder metallurgy brake lining fora high speed train and a preparing method thereof, belonging to the technical field of a brake. The preparing method comprises the steps of raw material treating, burdening, mixing, compression moulding, molding and sintering, machining, rivet processing and so on. The power is prepared from, by weight, 50-70 parts of copper powder, 3-10 parts of iron powder, 10-20 parts of graphite, 5-10 parts of silicon carbide, 2-6 parts of quartz sand, 0.5-3 parts of nickel powder, 1-7 parts of tungsten carbide, 0.5-2 parts of molybdenum oxide, 1-4 parts of zirconite, 2-6 parts of tin powder and 0.5-2 parts of boron nitride. The technical scheme takes the copper as the base component; the base is reinforced by adding iron powder, nickel powder, tin powder and the like; the friction coefficient of the car brake block is increased by adding silicon carbide, zirconite, quartz sand and the like, and the brake pad with stable brake, log service life and capability of meeting the brake requirement of the high-speed train.

Owner:贵州新安航空机械有限责任公司

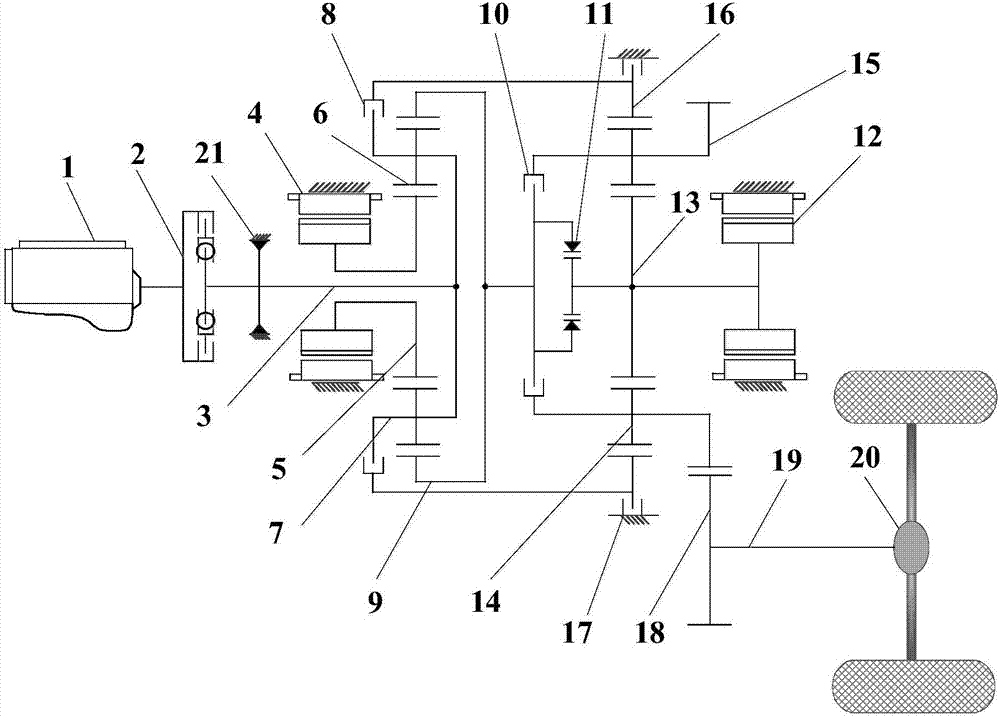

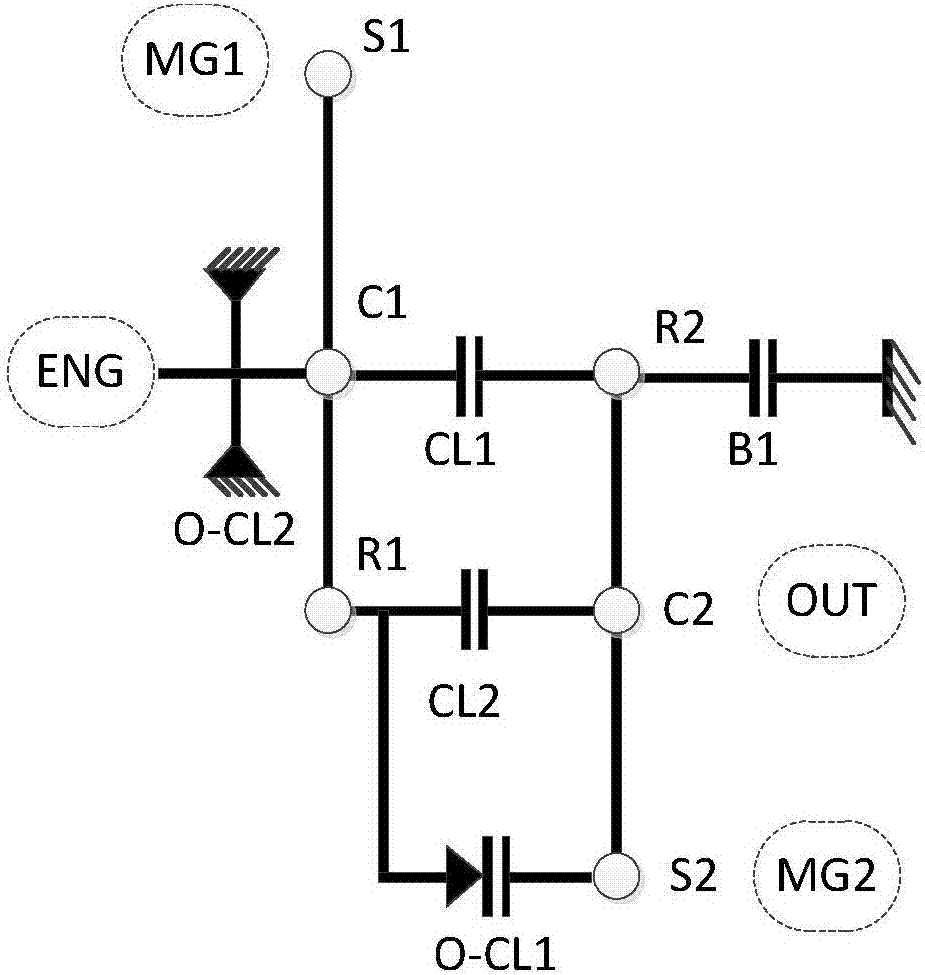

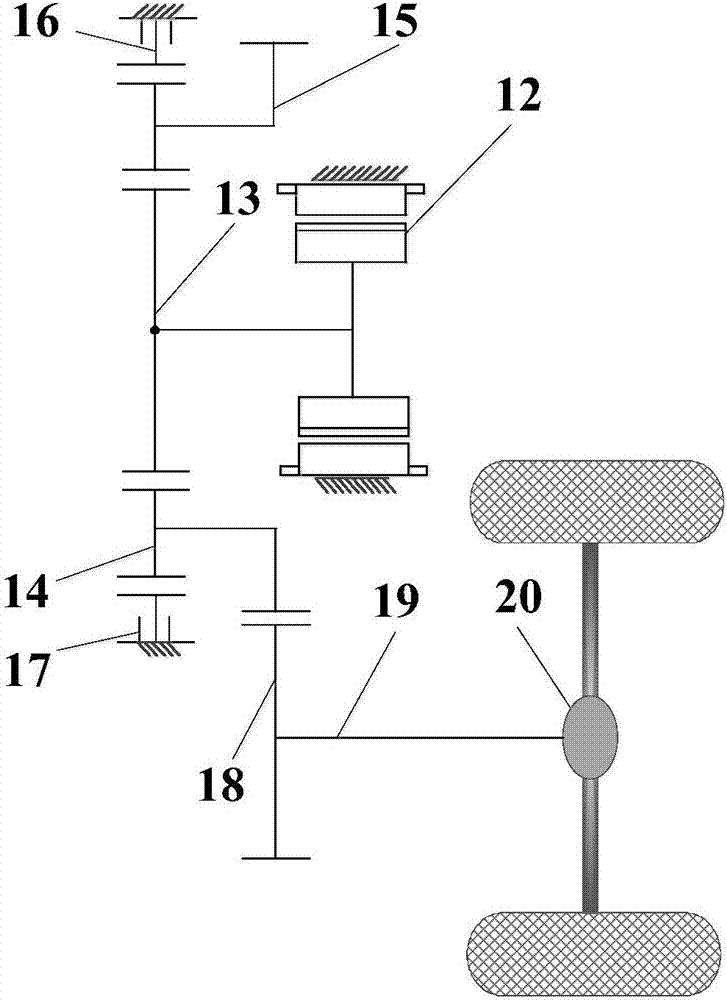

Planetary gear series-parallel twin-mode hybrid vehicle drive system

InactiveCN106976390AEliminate idle fuel consumptionImprove fuel economyHybrid vehiclesGas pressure propulsion mountingLow speedElectric machine

The invention discloses a planetary gear series-parallel twin-mode hybrid vehicle drive system and relates to the technical field of vehicles. The system comprises an engine, a front planetary gear train, a rear planetary gear train, a first clutch, a second clutch, an overrun clutch, a backstop, a brake, a first motor and a second motor. Conversion among different working modes can be achieved through combination and separation of the clutches and the brake. The system is compact in structural design, the power grades of the motors are effectively decreased, the sizes of the motors are reduced, the slope climbing performance of the vehicle in a pure electric mode is improved, and the low-speed performance of the vehicle in the pure electric mode is improved; the defect that parasitic power is generated when the vehicle travels in a high-speed area is overcome, the high-efficiency range of a hybrid power system is enlarged, and the economic efficiency of the vehicle is improved; and the problems that the acceleration performance of the vehicle is poor and the slope climbing capability is limited in a low-speed area are solved, and the dynamic property and the economic efficiency of the vehicle are improved.

Owner:JILIN UNIV

Brake power-assisted system based on ECU (electric control unit) auxiliary control and control method of brake power-assisted system

InactiveCN104325970AMeet braking requirementsDoes not affect the requirement of low idle speedBraking action transmissionEngine controllersIdle speedElectric control

The invention relates to a brake power-assisted system based on ECU (electric control unit) auxiliary control and a control method of the brake power-assisted system. The brake power-assisted system comprises a brake power-assisted vacuum pump, an engine intake manifold and an ECU, wherein the brake power-assisted vacuum pump is connected with the engine intake manifold through a pipeline, the engine intake manifold is connected with the engine and is used for forming vacuum degree for the brake power-assisted vacuum pump, the engine intake manifold is provided with an intake manifold pressure sensor, the intake manifold pressure sensor is connected and communicated with the ECU, and is used for sending signals to the ECU, and the ECU is used for controlling the engine to control the vacuum degree of the engine intake manifold which is connected with the engine. The ECU is used as the auxiliary controller of the brake power-assisted system, so as to identify the brake action, and a control strategy algorithm is adopted to enable the vacuum degree of the manifold to meet the brake requirement. The influence on the requirement of oil consumption on low idle rotation speed is avoided, and the manifold is guaranteed to have certain vacuum degree to meet the brake requirement. The control method and the control method are innovatively developed. The brake power-assisted system has the advantages that the brake auxiliary control is realized by the ECU, the system is simple, the purpose is realized, and the cost is not increased.

Owner:CHERY AUTOMOBILE CO LTD

A braking method and a braking device of a gear rail car

InactiveCN109017826AMeet braking requirementsRailway braking systemsRack railwaysGround slopeAutomotive engineering

The invention discloses a braking method of a gear rail car, On the basis of adhering a brake device to the belt brake device, the gear rail car first receives a the brake command, the ground gradientof the line running on the gear-rail car is acquired first, the line is the gear-rail line is judged according to the ground gradient, if it is, the adhesive brake and the belt brake are started, ifnot, the adhesive brake is started. In the prior art, the braking mode of the gear-rail car is only adhesive braking, and the braking mode cannot meet the braking requirements when the gear-rail car is traveling on the ramp. The invention adopts the combination of adhesive braking and belt braking on the gear track to complete the braking. The belt braking is more suitable for ramp braking than adhesive braking, and the gear track car can reach the braking requirement on the ramp. The braking mode is selected by the ground slope of the running track, so that the gear-rail car can meet the braking requirements both on the straight road and on the ramp. The invention also discloses a braking device of a gear rail car, which has the beneficial effects.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

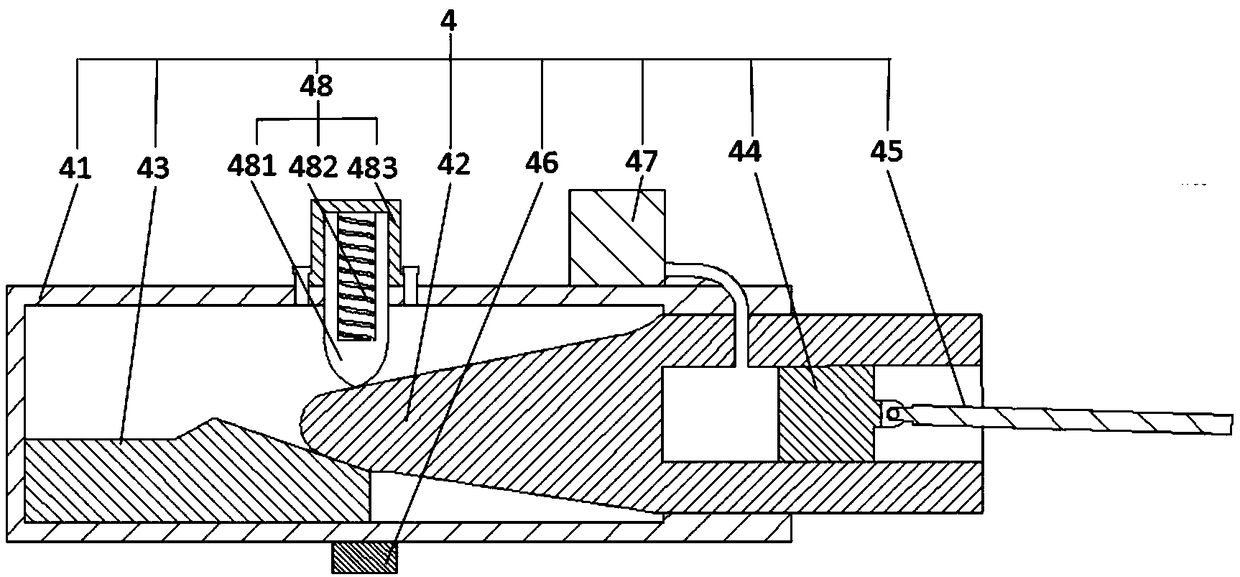

Vehicle electronic mechanical brake actuator

InactiveCN104806669AReduce volumeCompact structureBrake actuating mechanismsActuatorsBall screwReducer

The invention discloses a vehicle electronic mechanical brake actuator. The vehicle electronic mechanical brake actuator comprises the structure that a motor shell is connected with a harmonic gear reducer rigid gear and a bracket through fastening screws; the bracket is fixedly connected with a brake caliper body through a locking nut; power of a motor is transmitted to a harmonic gear reducer through a motor shaft; flexible wheel gears at the two ends of a long shaft are inserted into harmonic gear reducer rigid gear grooves; a flexible gear is connected with a screw nut of a ball screw through a fastening screw to transmit torque; a groove is formed in the screw nut; a bump on the bracket is embedded into the groove and is in clearance fit with the groove; a guide key is arranged between the ball screw and the bracket; the bracket is contacted with the left end of the ball screw; the ball screw is sequentially connected with a linear pushing block, a brake friction block and a brake disc; a brake friction sheet is arranged in a clamping groove of the brake caliper body; a brake disc is fixed to a wheel hub; the linear pushing block is arranged in a cavity of the brake caliper body. The vehicle electronic mechanical brake actuator is simple and compact in structure and good in brake performance.

Owner:JILIN UNIV

Brake control device for a brake system of a rail vehicle, brake system, rail vehicle and method for operating a brake control device

InactiveCN103781676ADrive control realizationRealization of drive controlBraking action transmissionRail brake actuationBraking systemAutomotive engineering

The invention relates to a brake control device (24) for a brake system (10) of a rail vehicle, said device being designed to detect strain during a braking process on at least one friction brake device (14, 16; 15, 17) actuated during the braking process, the brake control device (24) being further designed to store wear data based on the detected strain in a memory device. The invention further relates to a brake system (10) for a rail vehicle comprising such a brake control device (24), and to a rail vehicle comprising such a brake system (10) and / or such a brake control device (24). The invention also relates to a method for operating a brake control device (24) for a brake system (10) of a rail vehicle.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

Lithium battery system and overhead working truck

ActiveCN112259829AAvoid the risk of lithium analysisReduce the probability of lithium analysisCell temperature controlSecondary cells charging/dischargingControl theoryElectric current flow

The invention relates to the technical field of engineering machinery, and discloses a lithium battery system and an overhead working truck. The lithium battery system comprises a battery and a feedback current control device, wherein the feedback current control device comprises a plurality of current capture module groups, each module group comprises a heating module matched with the position ofa battery module and used for capturing feedback current, a first switch module used for conducting a current capture branch where the switch module is located, and a control module used for receiving a first voltage and a second voltage on a main circuit and the average temperature of the battery, controlling the first switch module in each current capture module group to switch on the current capture branch in which the first switch module is located when the difference between the first voltage and the second voltage is greater than a preset voltage and the average temperature of the battery is less than or equal to a preset temperature, and converting the feedback current into heat energy by the heating module to heat the corresponding module. According to the invention, the probability of lithium precipitation of the battery and the risk of thermal runaway of the battery can be greatly reduced.

Owner:ZOOMLION INTELLIGENT ACCESS MASCH CO LTD

Silane coupling agent modified artificial graphite resin-based brake pad and manufacturing method thereof

InactiveCN104613113ALow costStable coefficient of frictionOther chemical processesFriction liningPhenol formaldehyde resinGraphite

The invention discloses a silane coupling agent modified artificial graphite resin-based brake pad and a manufacturing method of the silane coupling agent modified artificial graphite resin-based brake pad. Materials comprise phenolic resin, rubber and organic friction powder, short cut steel fibers, red copper fibers, aramid fibers, high-aluminum ceramic fibers, mineral fibers, silane coupling agents, graphite, composite fillers and the like. The manufacturing method of the silane coupling agent modified artificial graphite resin-based brake pad includes the steps that the silane coupling agents are used for modifying the artificial graphite first, the materials are weighed in sequence and added into a high-speed mixer to be uniformly mixed, pressing and heat curing treatment are conducted according to the dry method one-shot forming method for traditional resin-based friction materials, and finally machining, ceramic treatment and inspecting packaging are carried out. The silane coupling agent modified artificial graphite resin-based brake pad manufactured according to the method has the advantages of being large in braking torque, comfortable and stable in emergency braking, free of obvious degeneration and noise and less in dust fall. The production method is simple and environmentally friendly. The silane coupling agent modified artificial graphite resin-based brake pad is especially suitable for urban bus air disk brakes and has broad market prospects.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS

A kind of brake pad with high friction coefficient and preparation method thereof

ActiveCN106238722BIncrease coefficient of frictionSmall fluctuationOther chemical processesFriction liningSulfideSilicon dioxide

The invention provides a brake pad with high friction coefficients and a preparation method of the brake pad. A raw material formula of the brake pad comprises components as follows: a copper source, eutectoid steel ground powder, copper-coated graphite powder, ferrous sulfide, a nickel source, silicon dioxide and molybdenum oxide; the components of raw materials are sufficiently mixed, pressed and formed, a blank body is subjected to hot pressed sintering and constant-temperature cooling, and the brake pad is prepared. Through adoption of the reasonable proportion of the raw materials, strict control of heating temperature and proper constant-temperature cooling treatment, the density of the produced material can be substantially improved, the texture and the structure of the materials are more stable, and the brake pad can adapt to the high-temperature condition produced during braking of a high-speed train and also always has stable high friction coefficient and low wear in the use process. The brake pad prepared with the method has the advantages of high friction coefficients, little wear, stable friction performance, long service life and the like under the high-speed braking condition.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Automatic braking device of gardening tool

ActiveCN103168567AMeet braking requirementsImprove braking effectHarvestersAutomatic brakingBrake pad

An automatic braking device of a gardening tool comprises a fixing plate, wherein a motor and an output shaft are arranged on the fixing plate. A big belt wheel is fixed on the output shaft. The lower end of a shaft of the motor stretches out of the fixing plate and a small belt wheel is fixed on the lower end of the shaft of the motor. The big belt wheel is connected with the small belt wheel in a transmission mode through a transmission belt. A friction ring sleeved on the output shaft and stretching into the big belt wheel is fixed on the fixing plate. A spring and a braking block are arranged in an inner cavity of the big belt wheel. One end of the braking block is movably connected with the big belt wheel. The other end of the braking block is matched with the spring in an abutting mode. A check slope is further arranged in the inner cavity of the big belt wheel. A protrusion is arranged on the braking block and is capable of sliding on the check slope. The automatic braking device of the gardening tool has the advantages of being simple in structure, high in safety, good in braking effect, low in production cost, long in service life, stable and reliable in working, and the like.

Owner:ZHEJIANG SAFUN IND

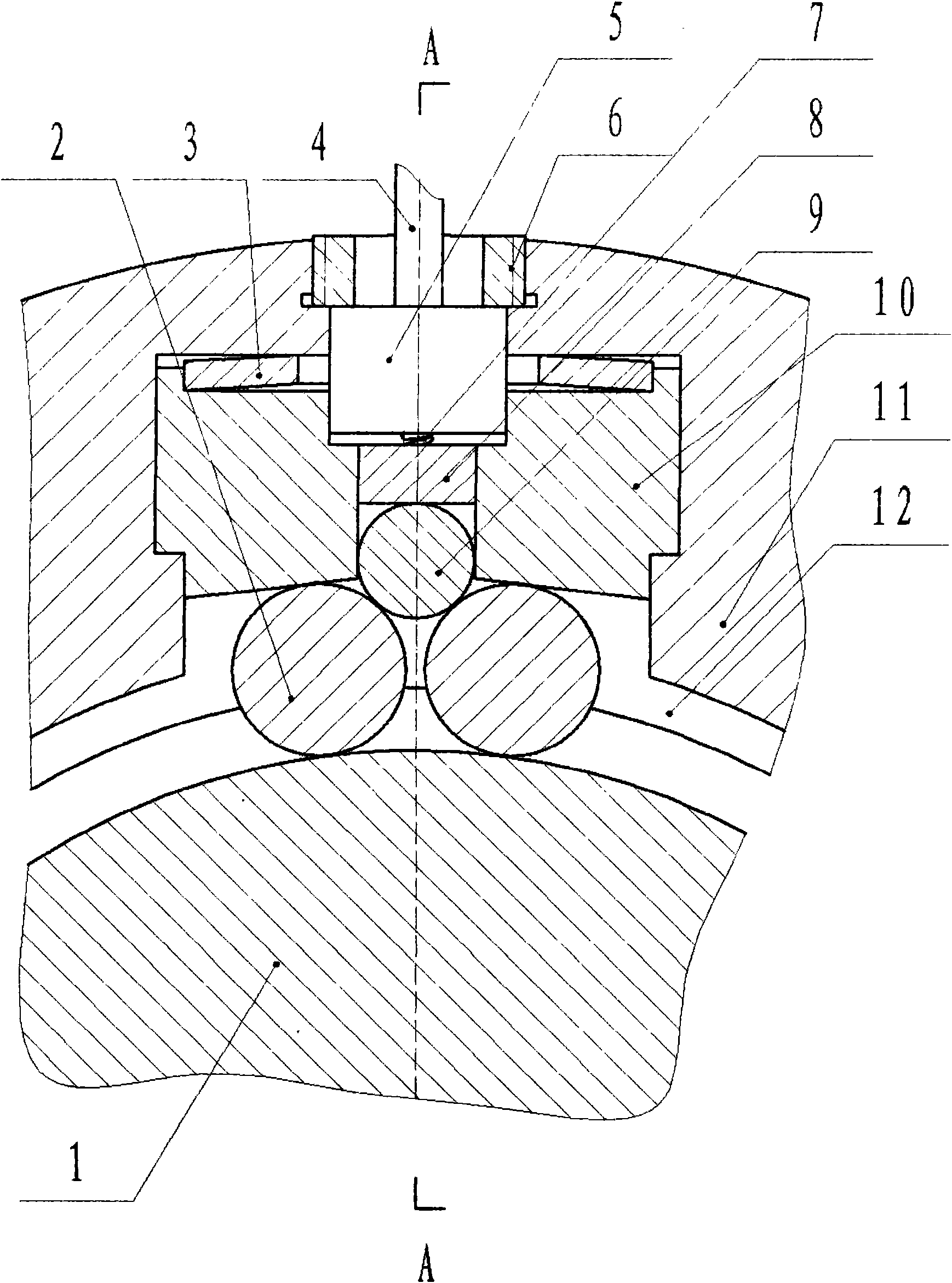

Roller type mechanical brake

The invention relates to a roller type mechanical brake belonging to the field of mechanical brakes and provided with a roller type overrunning clutch mechanism having a star wheel as an outer star wheel. The roller type mechanical brake is characterized in that a spring lifting pin mechanism installed on the outer star wheel (11) in the roller type overrunning clutch mechanism having the star wheel as the outer star wheel is removed and is replaced by a cylindrical roller lifting post (9) installed nearby the original spring lifting pin mechanism, wherein the cylindrical roller lifting post (9) can do constrained motion along the radial direction of the outer star wheel (11), lift a roller (2) in the mechanism on a working position under the action of operational external force and be separated from the roller (2) under the action of the operational external force.

Owner:陈伯恒

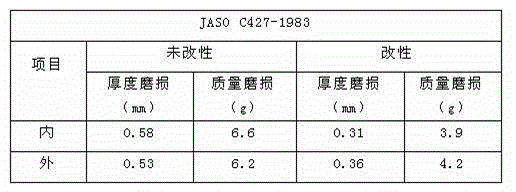

Brake shoe body preparation material for railway high-power locomotive synthetic brake shoes and preparation method thereof

The invention relates to a railway locomotive synthetic brake shoe preparation technique, particularly a brake shoe body preparation material which is prepared from the following components in parts by weight: 9-10 parts of nitrile-butadiene rubber, 4-5 parts of phenol aldehyde resin, 8-10 parts of meerschaum, 21-23 parts of iron powder, 3-4 parts of steel wool fiber, 0.3-0.8 part of bauxite, 11.5-12.5 parts of composition fiber, 15-17 parts of barium sulfate, 14-15.5 parts of graphite, 5-6 parts of potash feldspar, 0.2-0.7 part of accelerator, 0.1-0.5 part of zinc oxide, 0.1-0.5 part of stearic acid and 0.5-1 part of sulfur. The invention develops the friction material for Chinese railway HXD2 locomotives and forms the manufacturing technique of the friction material for Chinese CRH locomotives. The novel brake shoe can substitute imported products to satisfy the braking requirements of Chinese railway high-power locomotives.

Owner:山西铁路装备制造集团机车车辆有限公司

Main shaft brake lining of wind-driven generator and preparation method thereof

ActiveCN105422702AStable coefficient of frictionStrong wear resistanceFriction liningActuatorsWind drivenBrake lining

The invention discloses a main shaft brake lining of a wind-driven generator. The brake lining is composed of, by weight, electrolytic copper powder of 55-65%, atomization tin powder of 1-8%, reduced iron powder of 5-15%, flake graphite of 5-12%, granular graphite of 5-10%, aluminum hydroxide of 5-15% and chromium powder of 8-15%. The invention further discloses a preparation method of the main shaft brake lining of the wind-driven generator. The brake lining is obtained through the steps of material proportioning, material mixing, cold blank compression forming, high temperature sintering in an elevator furnace, furnace cooling and final machining. The brake lining manufactured through the method is stable in friction coefficient, high in wear resistance, free of sparks in braking, long in service life and small in wear to mating plates, and can fully meet the braking requirement of a main shaft of the wind-driven generator.

Owner:JIANGXI HUAWU BRAKE

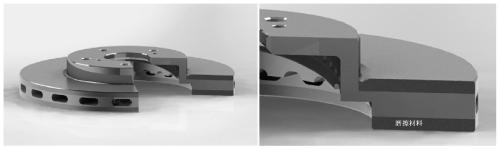

Light weight wear-resistant aluminum-based powder metallurgy composite material rail traffic brake disc and preparation method thereof

ActiveCN111250698AReduce weightGood wear resistance and braking performanceMetal-working apparatusBraking discsPowder metallurgyCast iron

The invention discloses a light weight wear-resistant aluminum-based powder metallurgy composite material rail traffic brake disc and a preparation method thereof. The rail traffic brake disc is prepared from an aluminum-based powder metallurgy composite material through cold press molding, sintering and integrated hot pressing shaping processes. The prepared rail traffic brake disc has a series of advantages of no damage, no defect, good compactness, high strength and the like, and can meet braking and wear-resisting demands of the rail traffic brake disc well. Meanwhile, compared with a conventional cast iron brake disc, the weight is reduced by 40-60%, so that energy consumption is saved greatly, and the demand on energy conservation and emission reduction in China is met. The rail traffic brake disc is simple in preparation method, low in cost and high in rate of finished products. The preparation method can be used for preparing rail traffic brake discs of various dimensions and structures, and meet the industrial continuous production demand on a large scale.

Owner:湖南湘投轻材科技股份有限公司

Carbon-ceramic brake disc with wear-resistant and anti-oxidation coating and preparation method of carbon-ceramic brake disc

ActiveCN113277869AHigh bonding strengthUniform compositionBraking discsFriction liningOxidation resistantCarbon composites

The invention discloses a carbon-ceramic brake disc with a wear-resistant and anti-oxidation coating and a preparation method of the carbon-ceramic brake disc. The preparation method comprises the following steps that grooving treatment is conducted on the upper surface and the lower surface of a carbon / carbon composite material disc body, then coating slurry is brushed in a groove in the upper surface till the groove in the upper surface is filled with the coating slurry, and then the carbon / carbon composite material disc body is turned over, the groove in the lower surface is coated with the coating slurry till the groove in the lower surface is filled with the coating slurry, thus the carbon / carbon composite material disc body containing the coating slurry is obtained, curing, carbonization and ceramization treatment are sequentially conducted, and the carbon-ceramic brake disc is obtained. The preparation process of the wear-resistant and oxidation-resistant coating is simple, large-scale industrial mass production is easy to realize, the coating is bright and smooth in appearance, the bonding strength between the coating and the disc body is high, the size precision is easy to accurately control, and the problem that the size is easy to control inaccurately when the ceramic brake disc is subjected to machining treatment can be effectively solved.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

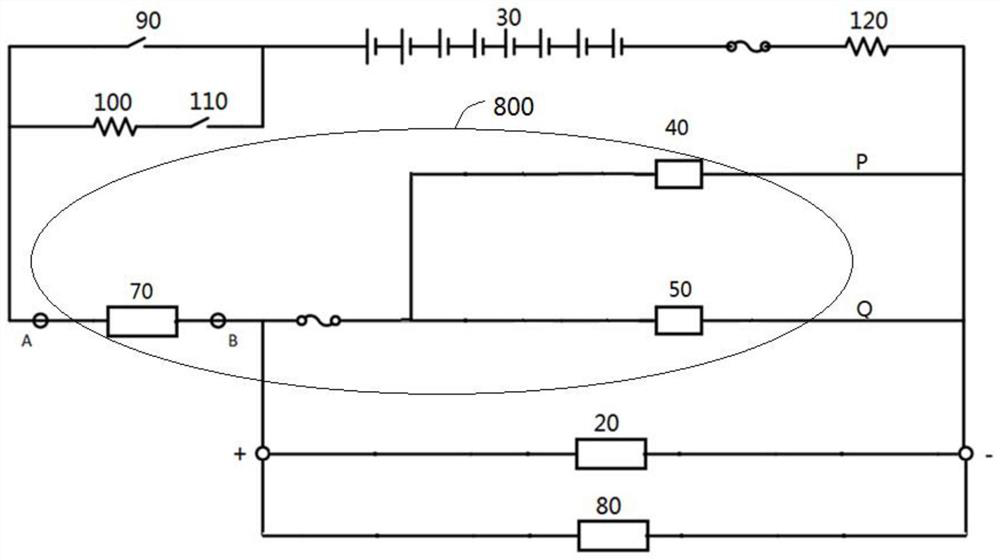

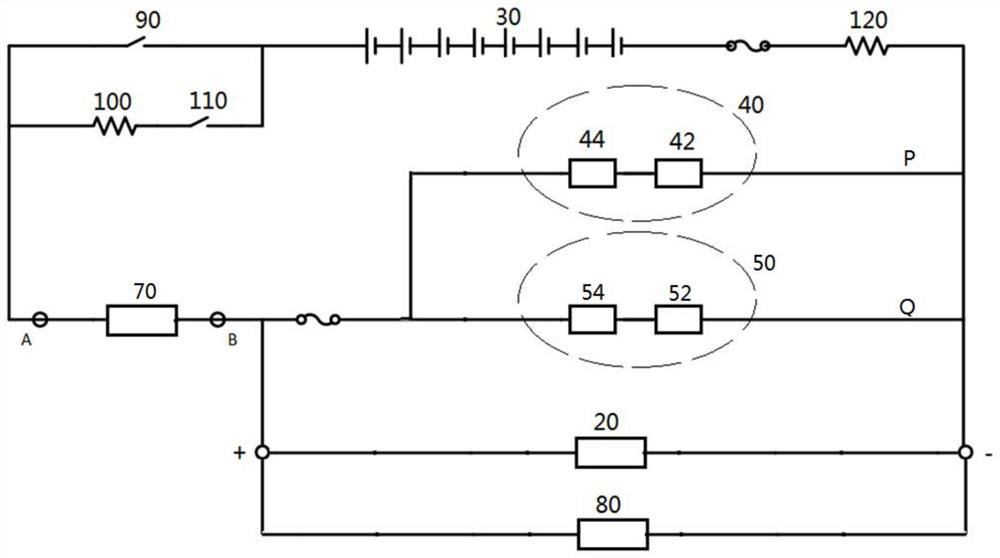

Braking energy feedback system of full electric vehicle based on data redundancy dual controllers

ActiveCN103692926AImprove smoothnessImprove experienceElectric vehicle charging technologyVehicular energy storageArea networkControl theory

The invention relates to a braking energy feedback system of a full electric vehicle based on data redundancy dual controllers. The system comprises a vehicle controller as well as an energy management system, an energy storage system and a data redundancy system which are controlled by the vehicle controller, wherein the data redundancy system consists of an ABS (Anti-skid Brake System) controller and a motor controller which are connected with each other through a data interaction channel CAN (Controller Area Network) bus, and are simultaneously connected with the vehicle controller through the CAN bus. Regenerated braking force and frictional braking force in a braking process are operated by the ABS controller and the motor controller, and data interaction and optimization between the two controllers is carried out to increase the speed, so that data is prevented from being transmitted from the vehicle controller to the brake controller and the ABS controller, therefore, the deficiency that the best opportunity of brake is always missing caused by too low response speed in a conventional braking process is overcome, the braking energy recycling effect is improved and the response speed and the driving range of the full electric vehicle are increased.

Owner:WM MOTOR TECH GRP CO LTD

Brake shoe external arc surface accuracy measuring instrument for automobile brakes

PendingCN107401969AGuaranteed quality effectMeet braking requirementsAngles/taper measurementsMechanical counters/curvatures measurementsControl theoryBrake shoe

The invention relates to a brake shoe external arc surface accuracy measuring instrument for automobile brakes. The brake shoe external arc surface accuracy measuring instrument comprises a base body part, a measuring mechanism and a workpiece positioning mechanism; three support pins, distributed along the inner edge of the arc periphery of an upright plate of the base body part, are arranged on the upright plate of the base body part; the sliding seat bushing of the measuring mechanism sleeves a guide rod; a sliding seat sleeves the sliding seat bushing; the sliding seat is sleeved with a meter stand; the meter stand is provided with a dial indicator; the dial indicator can synchronously rotate or move axially with the sliding seat; an axial positioning sleeve sleeves the guide rod; the guide rod is mounted on a guide rod tail seat and a guide rod front seat; the positioning rod supporting seats of the workpiece positioning mechanism are provided with workpiece positioning rods; and a bottom plate is provided with a sliding seat limiting rod which limits the axial movement of the sliding seat when the sliding seat rotates, and limits the rotation of the sliding seat when the sliding seat axially slides. With the brake shoe external arc surface accuracy measuring instrument adopted, the use condition of a brake shoe on an automobile can be simulated; and the circularity of the outer arc surface of a brake shoe panel (M) and the axial straightness of the brake shoe panel (M) can be measured conveniently and accurately.

Owner:山东力得汽车科技股份有限公司

Synthetic friction material suitable for high braking energy and preparation method of synthetic friction material

The invention provides a synthetic friction material suitable for high braking energy. The synthetic friction material comprises the following components in percentages by mass: 8-11% of carboxylatednitrile rubber, 8-10% of nano montmorillonite modified phenolic resin, 5-8% of an iron sulfide mineral, 8-10% of diatomite, 3-4% of steel fibers, 9-11% of inorganic mineral fibers, 3-4% of foam iron powder, 3-4% of potassium feldspar powder, 40-51% of nano precipitated barium silicate, 0.05-0.15% of granulating sulphur, 0.06-0.20% of stearic acid, 0.06-0.20% of an accelerant CZ, and 0.05-0.15% ofzinc oxide. According to the synthetic friction material provided by the invention, the carboxylated nitrile rubber and the nano montmorillonite modified phenolic resin are used as binders, a synergistic effect of the carboxylated nitrile rubber and the nano montmorillonite modified phenolic resin is fully played, and the heat insulation efficiency and thermal stability of the synthetic friction material are significantly improved.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +3

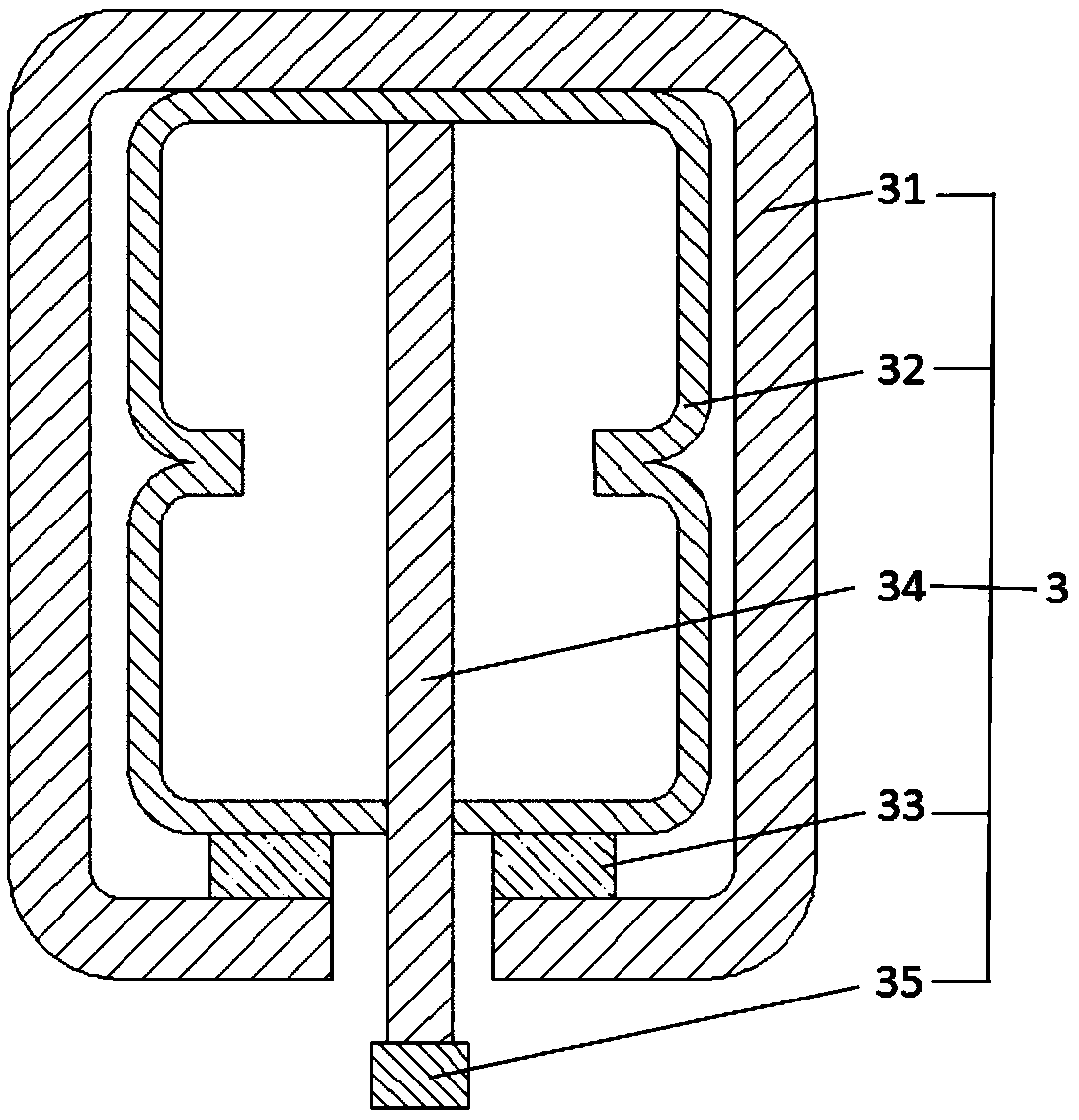

Rail eddy current brake

PendingCN108860208AAvoid deformationGuaranteed reliabilityTrack-braking member co-operationBogieEngineering

The invention belongs to the field of rail train braking and particularly relates to a rail eddy current brake. The rail eddy current brake comprises connecting beams and a pair of excitation units and is characterized in that the pair of excitation units are parallelly arranged on two sides of the connecting beams, the excitation units are mounted on a turning rack, and each excitation unit comprises a magnet yoke beam and a plurality of excitation windings; a lifting system and an air gap adjusting system are respectively arranged at the front end and the rear end of each excitation unit, the lifting is located on the inner side of the air gap adjusting system, and the air gap adjusting system is used for adjusting the distance between the excitation unit and a rail. The rail eddy current brake has the advantages that by the rail eddy current brake, the braking effect and operation stability of a rail train can be increased; the distance measuring sensors of the air gap adjusting systems measure air gaps air, and air cylinder air feeding or discharging is performed through air pumps to automatically adjust the air gaps so as to satisfy braking requirements.

Owner:扬州华铁机电集团有限公司

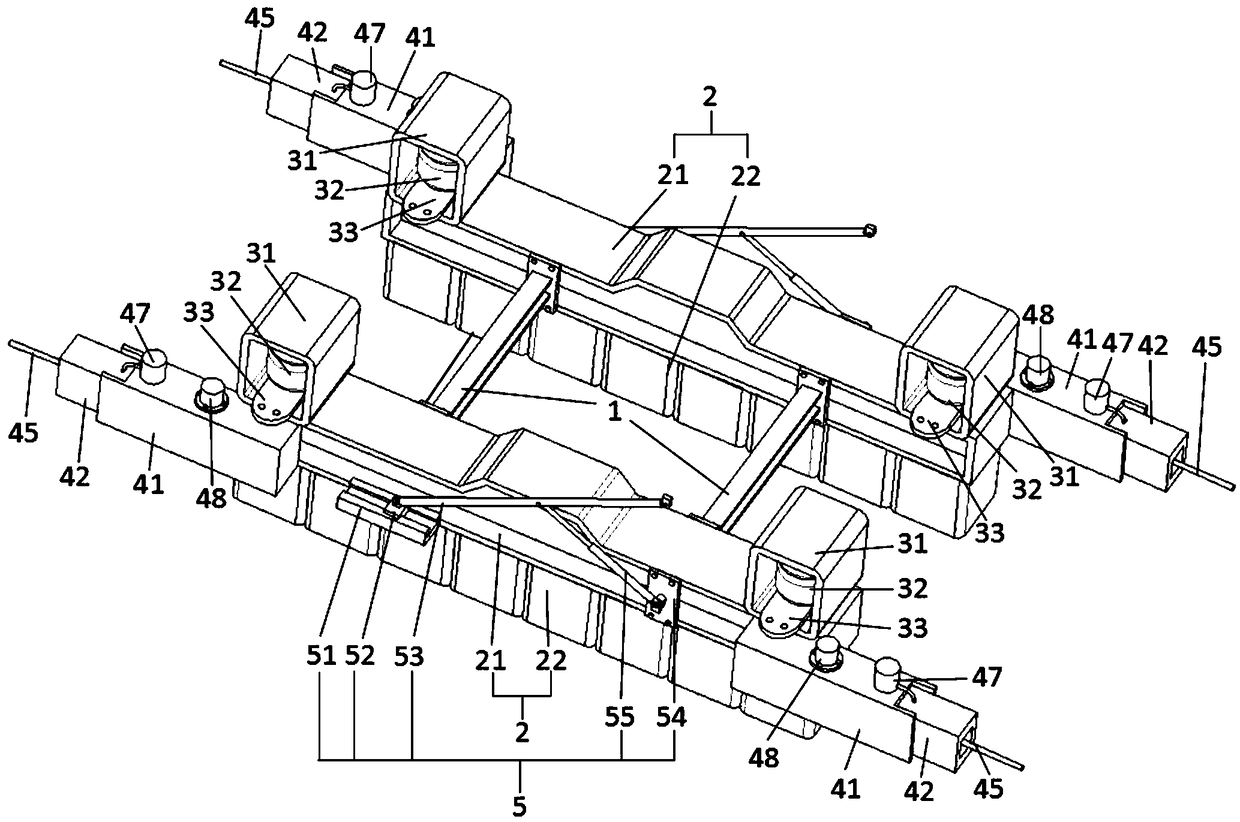

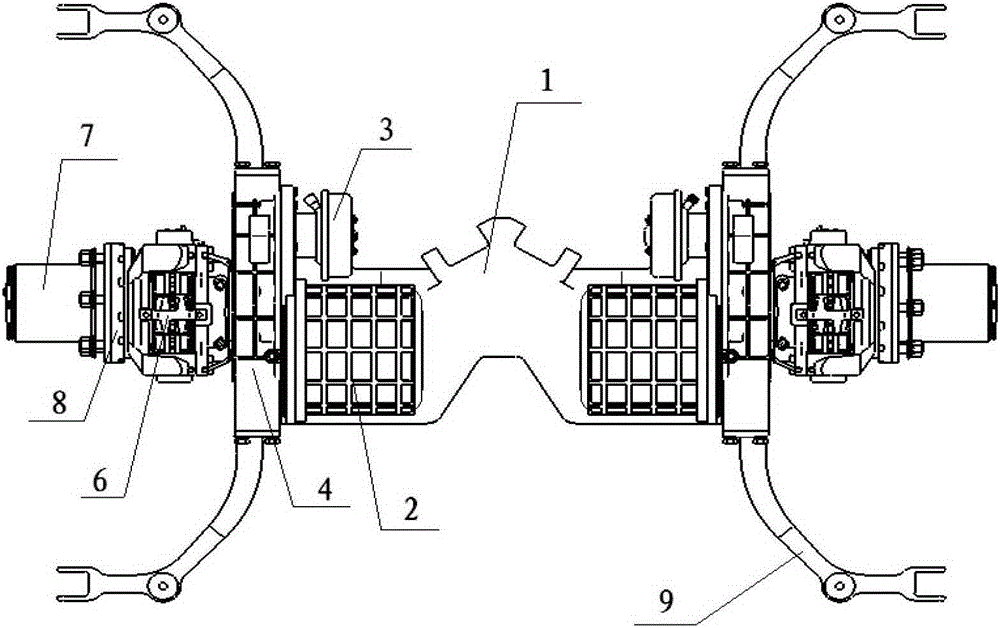

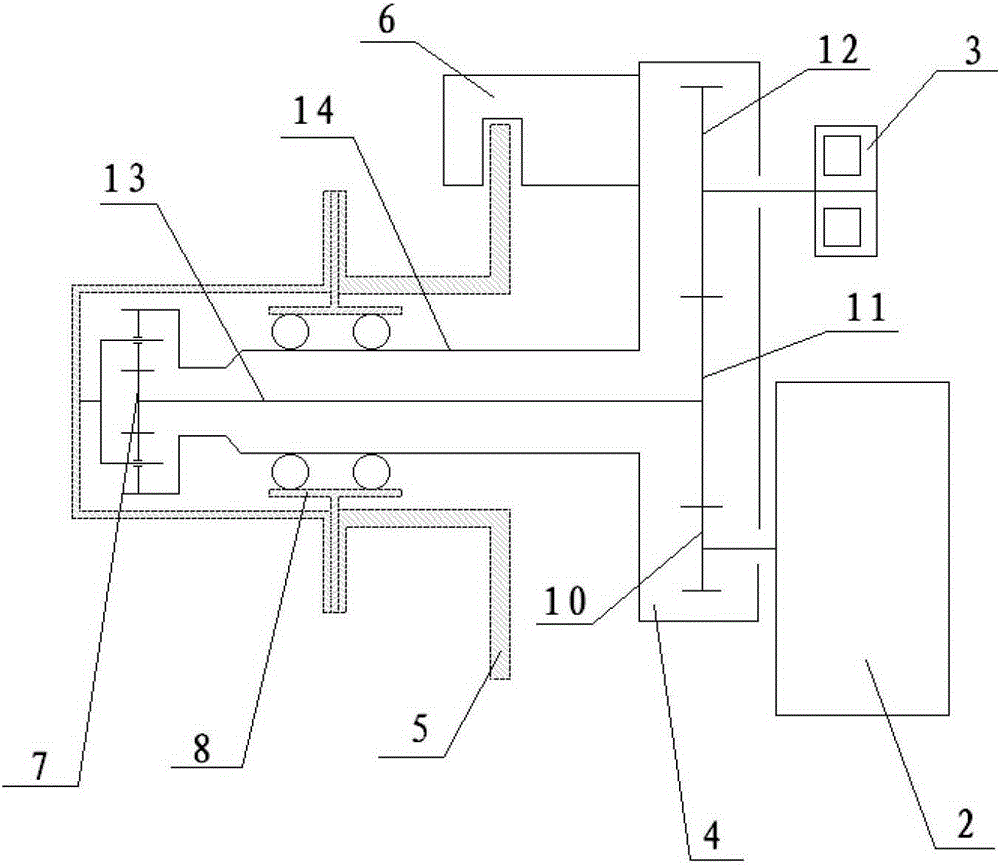

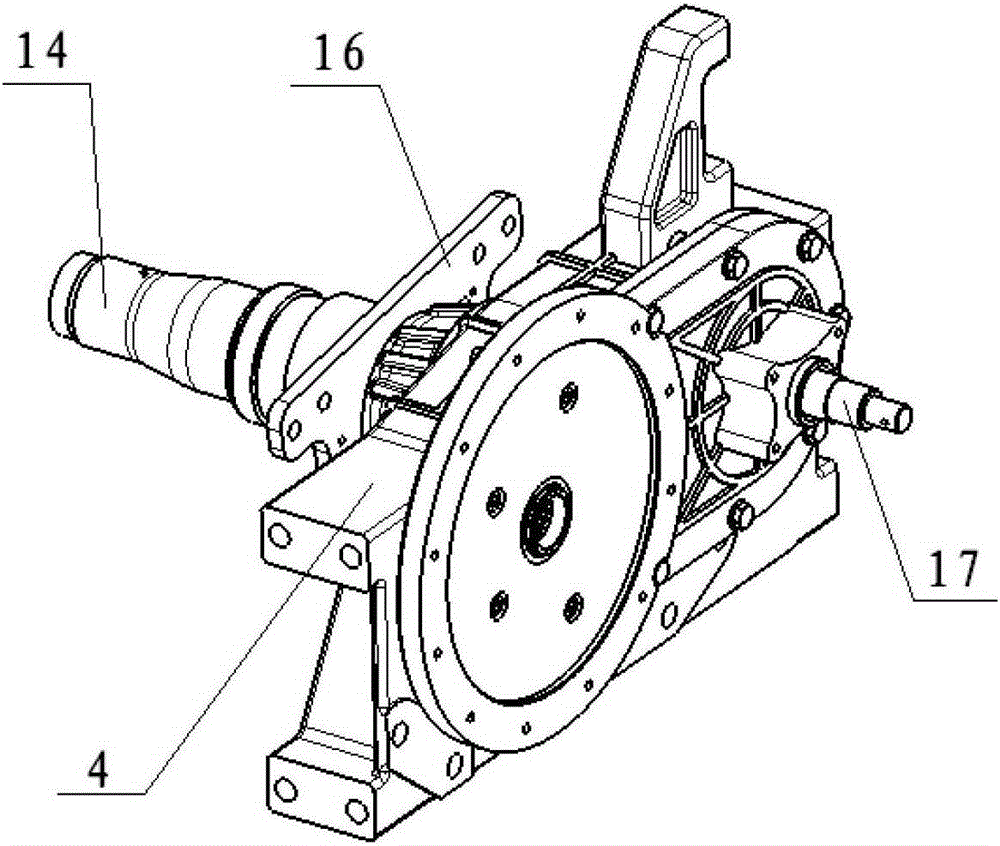

A new energy vehicle wheel side motor drive axle

ActiveCN104290721BImprove braking effectCompact structureBraking element arrangementsMotor driveNew energy

The invention relates to the field of new energy automobiles, in particular to a wheel motor drive axle of a new energy automobile. The wheel motor drive axle comprises a cross beam assembly, and wheel motor driving systems horizontally and symmetrically arranged at the two sides of the cross beam assembly, wherein each wheel motor driving system comprises a driving motor assembly, a first-stage speed reducer assembly, a second-stage speed reducer assembly, a wheel hub assembly, a hydraulic brake assembly and a parking brake assembly; and hydraulic brakes are arranged on shells or axle shaft sleeves of the first-stage speed reducer assemblies of the wheel motor driving systems and fit brake discs arranged on wheel hubs for realizing hydraulic braking of the wheel hubs, so that the braking response is quick and the braking noise is low. Thus, the wheel motor drive axle can satisfy the braking requirements of a light top-grade passenger car. A hydraulic braking mode is adopted, so that the whole drive axle is compact in structure and is small in occupied space.

Owner:JASMIN INT AUTO RES ANDDEV BEIJING CO LTD

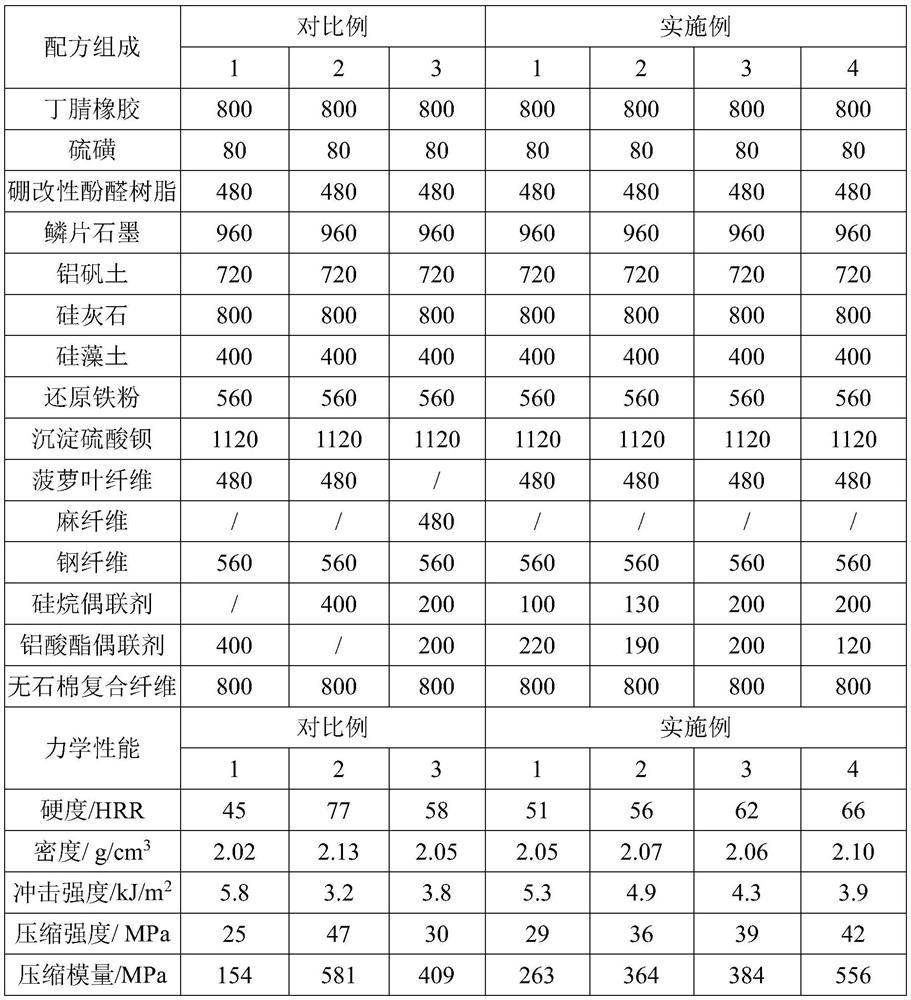

Synthetic friction material and preparation method and application thereof

ActiveCN113388173AImprove mechanical propertiesReduce coefficient of frictionNitrile rubberPhysical chemistry

The invention provides a synthetic friction material and a preparation method and application thereof. The synthetic friction material comprises the following components in percentage by mass: 8-10% of nitrile rubber, 0.9-3% of sulfur, 5-7% of boron modified phenolic resin, 10-14% of crystalline flake graphite, 8-10% of bauxite, 8-10% of wollastonite, 3-5% of diatomite, 6-7% of reduced iron powder, 12-15% of precipitated barium sulphate, 5-7% of pineapple leaf fibers, 6-8% of steel fibers, 2-4% of a coupling agent combination agent and 7-10% of inorganic mineral fibers. The sum of the mass percentages of all the components is 100%. The coupling agent combination agent comprises a silane coupling agent and an aluminate coupling agent. The invention further provides application of the synthetic friction material in synthetic friction materials for urban rail vehicles. The synthetic friction material provided by the invention has the advantages of environmental protection, high mechanical strength, low compression modulus, small dual wear, low abrasion and the like.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com