Brake shoe external arc surface accuracy measuring instrument for automobile brakes

A technology of precision measurement and brake shoe, applied in the direction of angle/taper measurement, mechanical counter/curvature measurement, measuring device, etc., can solve the problem of not meeting the requirements of precision measurement of brake shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

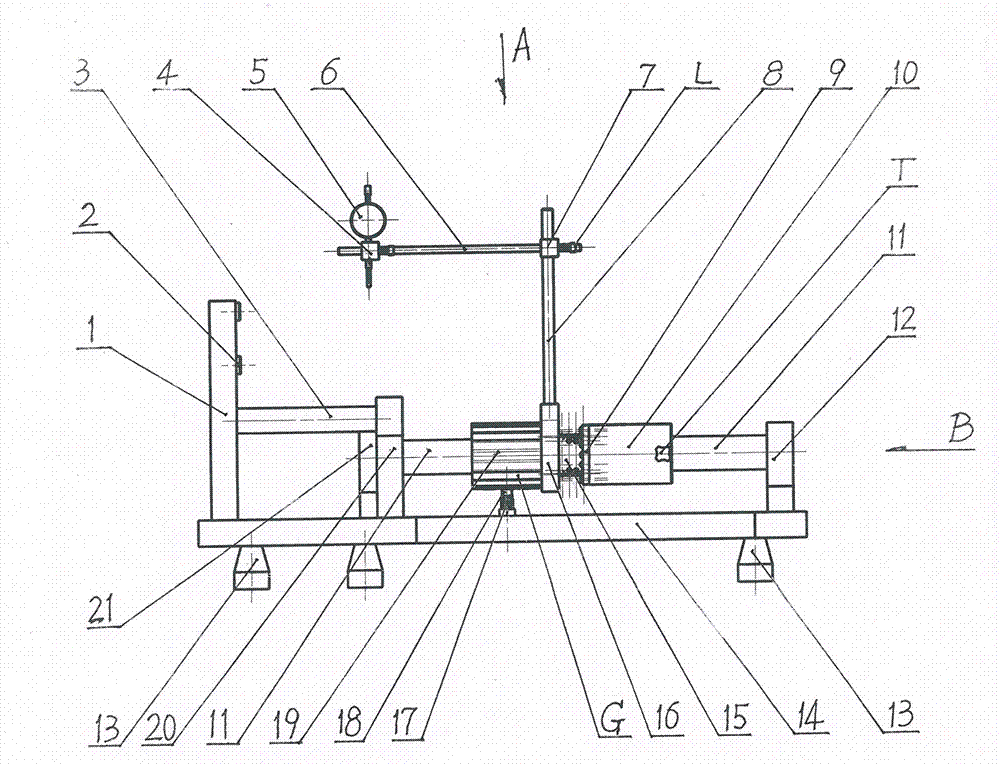

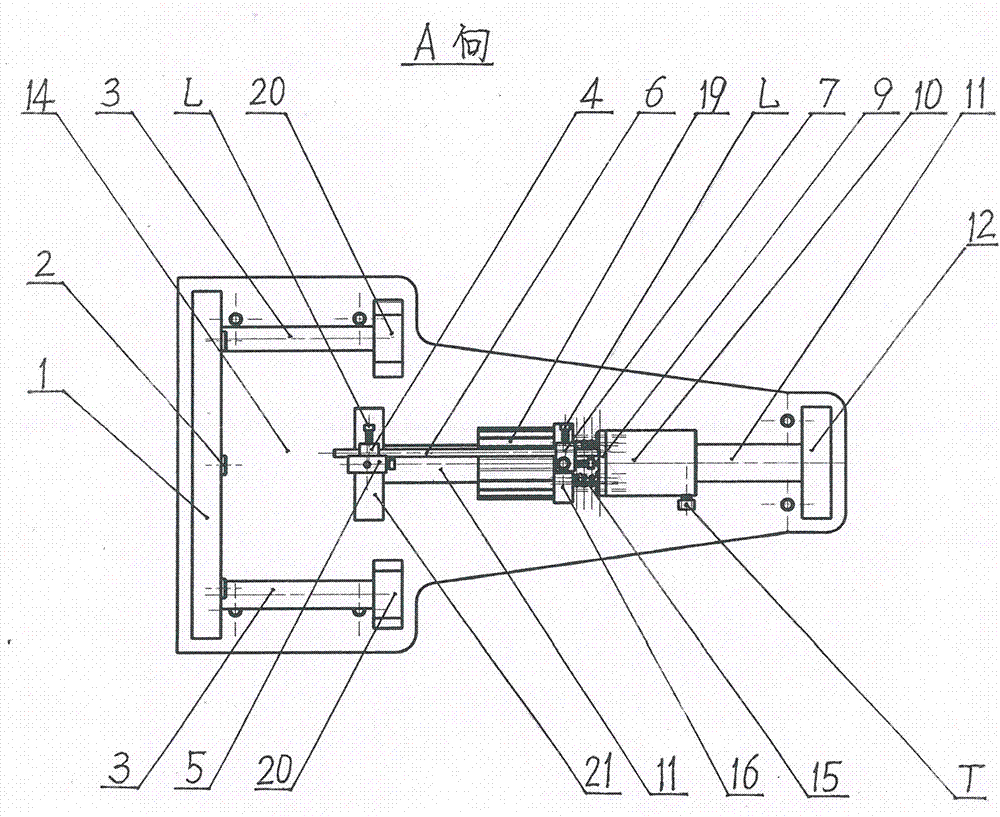

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention is composed of a base part, a measuring mechanism, and a workpiece positioning mechanism. The base part includes a bottom plate 14, a vertical plate 1, a support nail 2, and a foot 13. The measuring mechanism includes a dial indicator 5, a horizontal gauge rod 6, and a vertical gauge rod 8. , table seat 16, sliding seat 19, sliding seat bushing 15, axial positioning sleeve 10, guide rod 11, guide rod tailstock 12, guide rod front seat 21, workpiece positioning mechanism includes workpiece positioning rod 3, positioning rod support 20 , sliding seat limiting rod 17, sliding seat limiting steel ball 18, the base plate 14 of the base part is a flat plate made of thick steel plate, and there are some square holes on the base plate 14, which can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com