Hot-pressing processing technology for curved glass

A processing technology, a technology of curved glass, applied in glass forming, glass re-forming, glass manufacturing equipment and other directions, can solve the problems of poor cooling effect, inability to soften flat glass, energy waste, etc., to improve heat dissipation, The effect of reducing heat loss and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

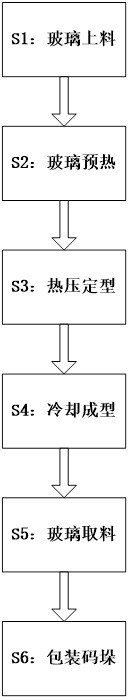

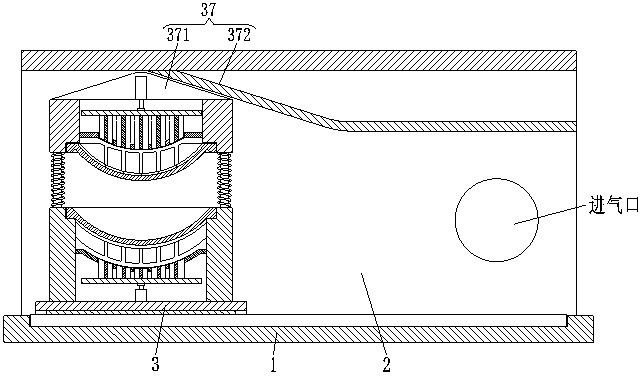

[0041] Such as Figure 1 to Figure 9 As shown, a curved glass hot-pressing processing technology, the curved glass hot-pressing processing technology adopts the following processing equipment, the processing equipment includes a bottom frame 1, a fixed frame 2 and a hot-pressing assembly 3, and the upper end of the bottom frame 1 is installed with The fixed frame 2 has an electric heating grid uniformly arranged on the left side of the inner wall of the fixed frame 2. The cross section of the fixed frame 2 is a U-shaped structure.

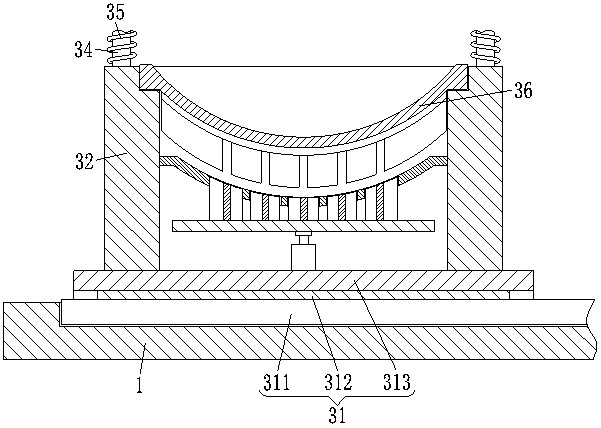

[0042]The hot pressing assembly 3 includes a moving unit 31, a lower mold frame 32, an upper mold frame 33, a connecting rod 34, a connecting spring 35, a heating unit 36 and a guiding unit 37, and the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com