Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Lower fuel ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

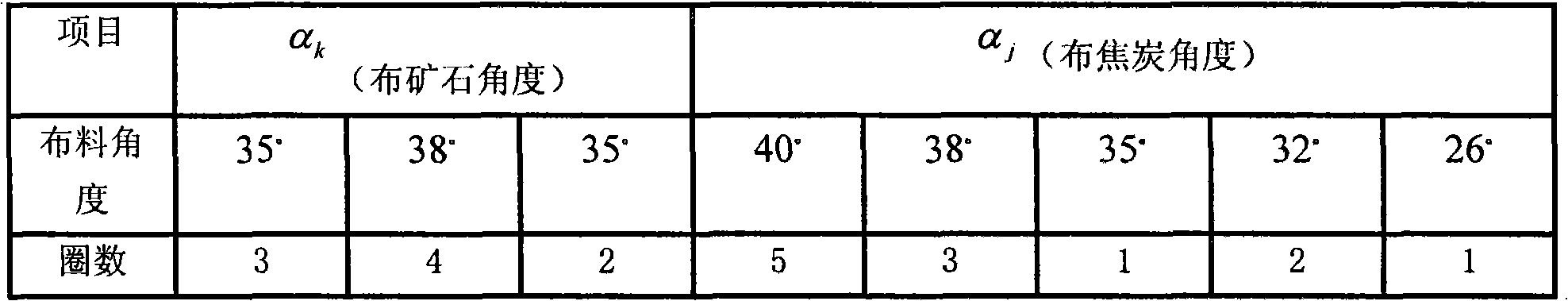

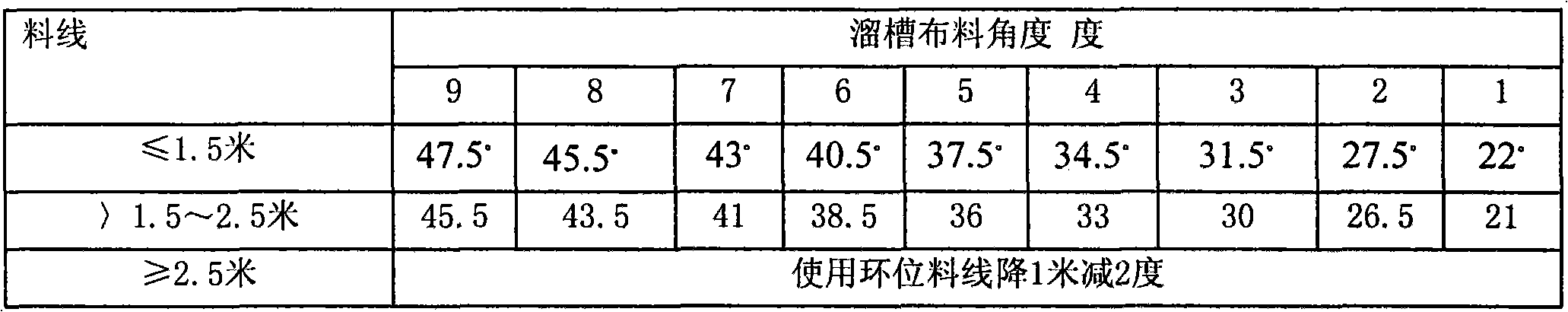

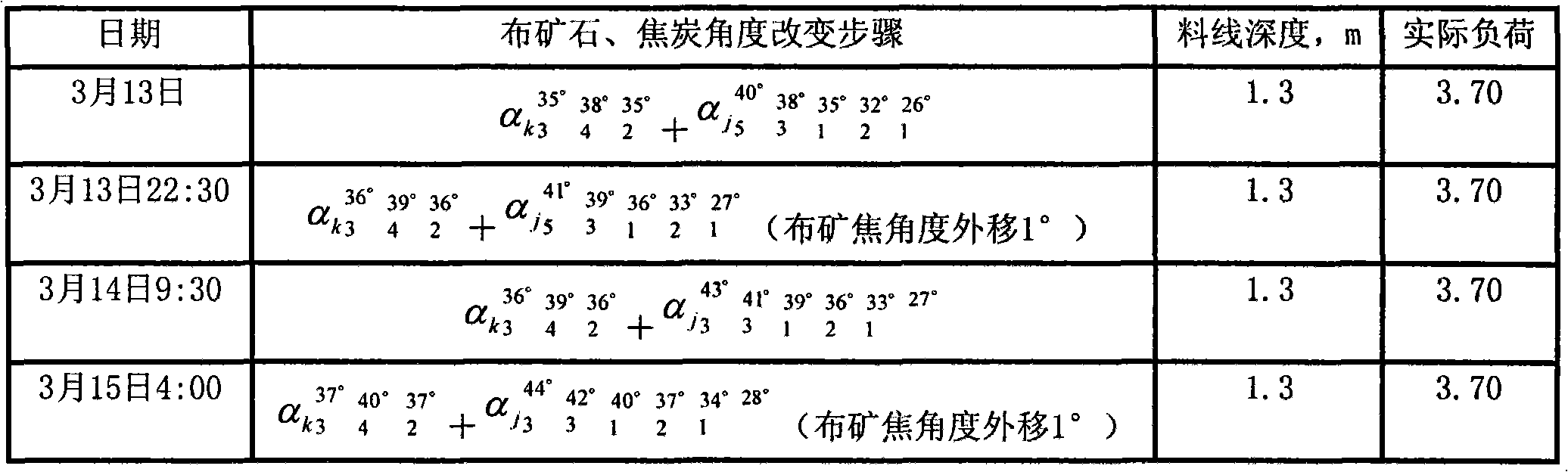

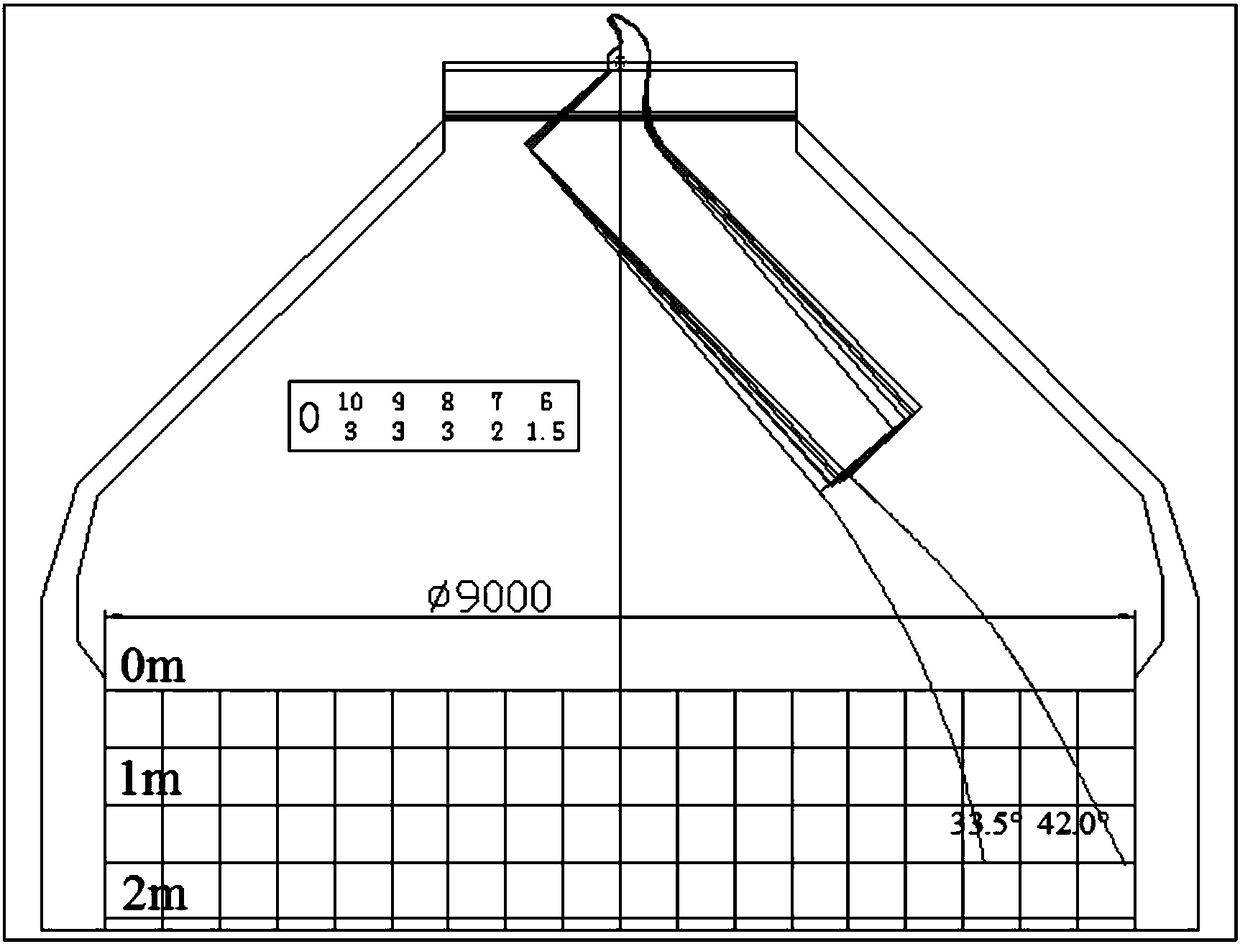

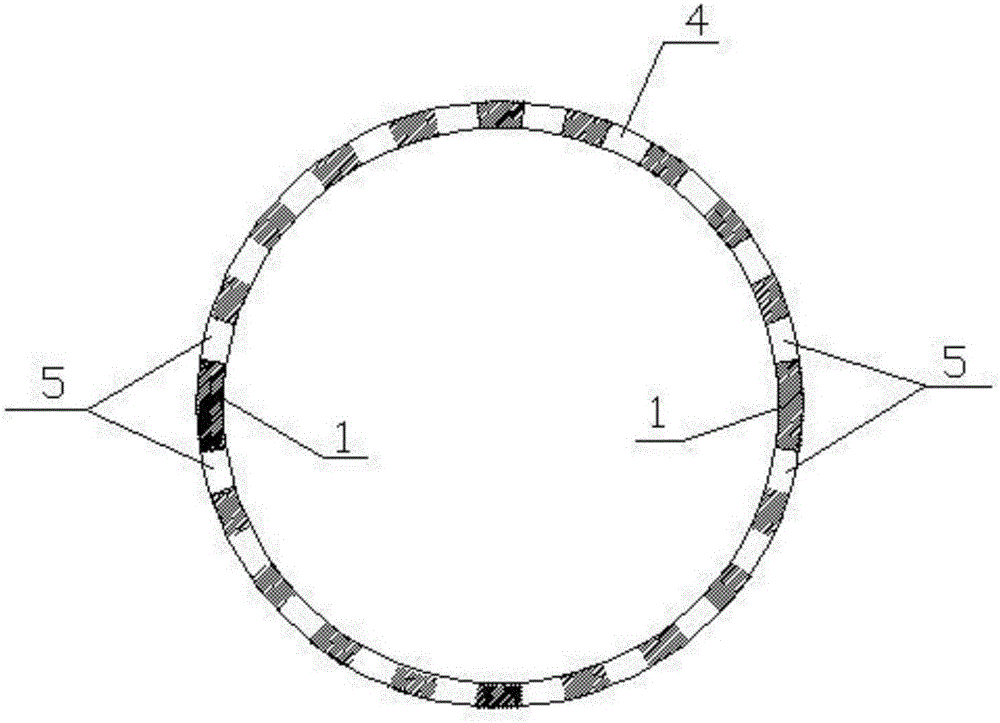

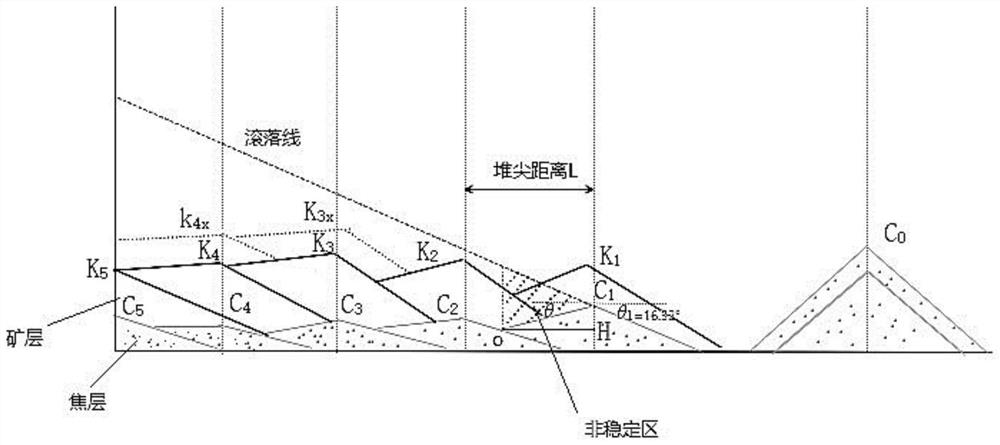

Multi-ring matrix burden distribution process for bell-less top of blast furnace

InactiveCN101845528AThe reduction is not obvious or even reverse regulationLower fuel ratioBlast furnace componentsBlast furnace detailsDistribution matrixThroat

The invention relates to a multi-ring matrix burden distribution process for a bell-less top of a blast furnace, belonging to the technical field of burden distribution of blast furnaces. A multi-ring burden distribution process is combined with a burden distribution matrix, and the burden distribution matrix is set according to 9-11 ring sites; generally, 4-6 ring sites are selected for distributing coke, and 3-5 ring sites are selected for distributing ore; the number of turns on each ring site for distributing coke is selected preferably to enable the coke to be laid horizontally; the number of turns on each ring site for distributing ore is selected to control the ore coke ratio on the furnace throat radius, thereby controlling radial distribution of coal gas flow; and the number of turns for distributing coke and distributing ore is generally controlled to be 10-14 turns. The invention can obtain furnace throat coal gas distribution in which coal gas at edges has certain passages and coal gas in the center develops, and the burden distribution is flexible and adjustable, thereby keeping stable and smooth operation of the blast furnace, realizing the purposes of opening the center and stabilizing the edges, improving the utilization ratio of coal gas, reducing the fuel ratio of the blast furnace, and further reducing the production cost.

Owner:SHOUGANG CORPORATION

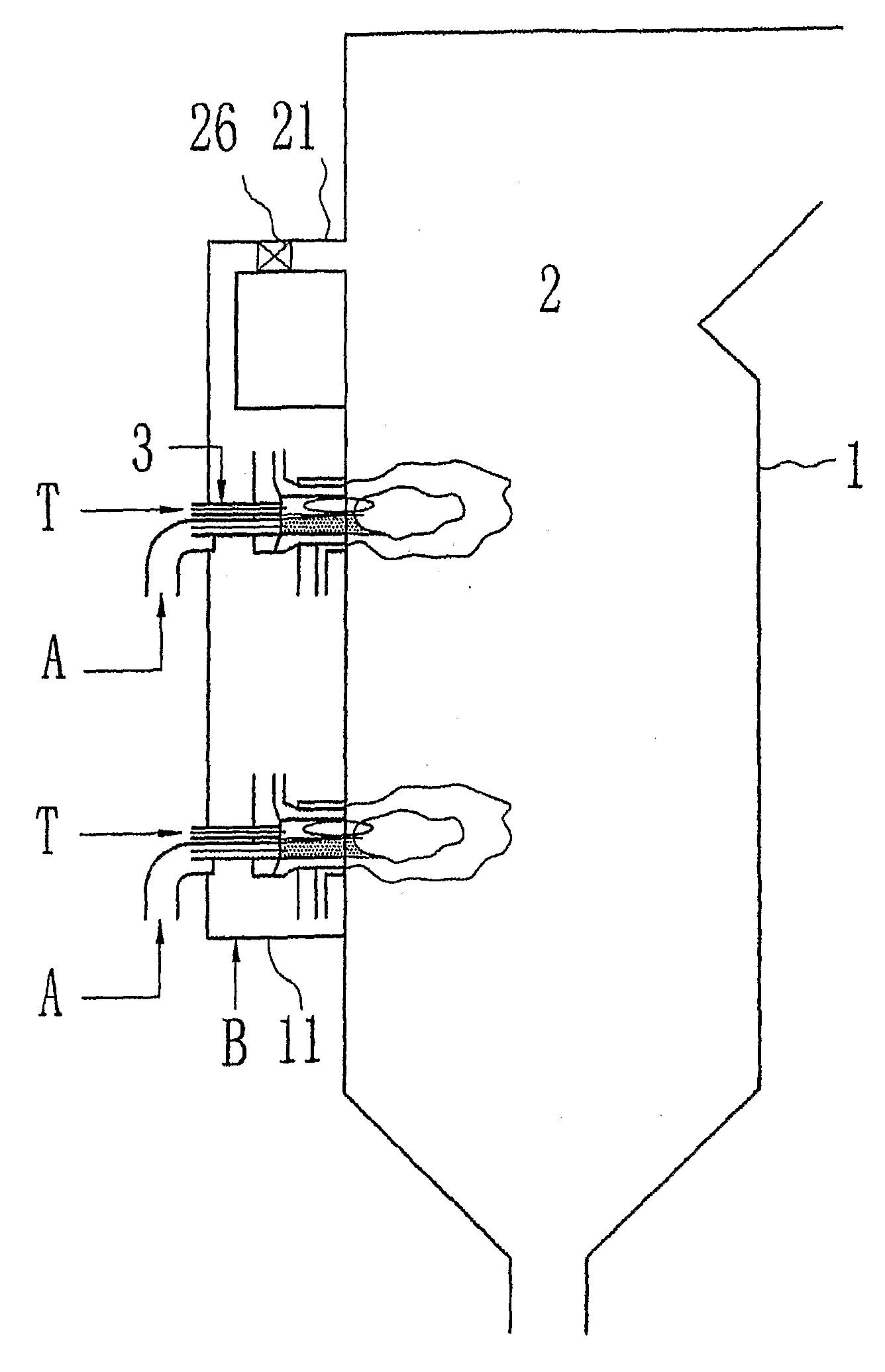

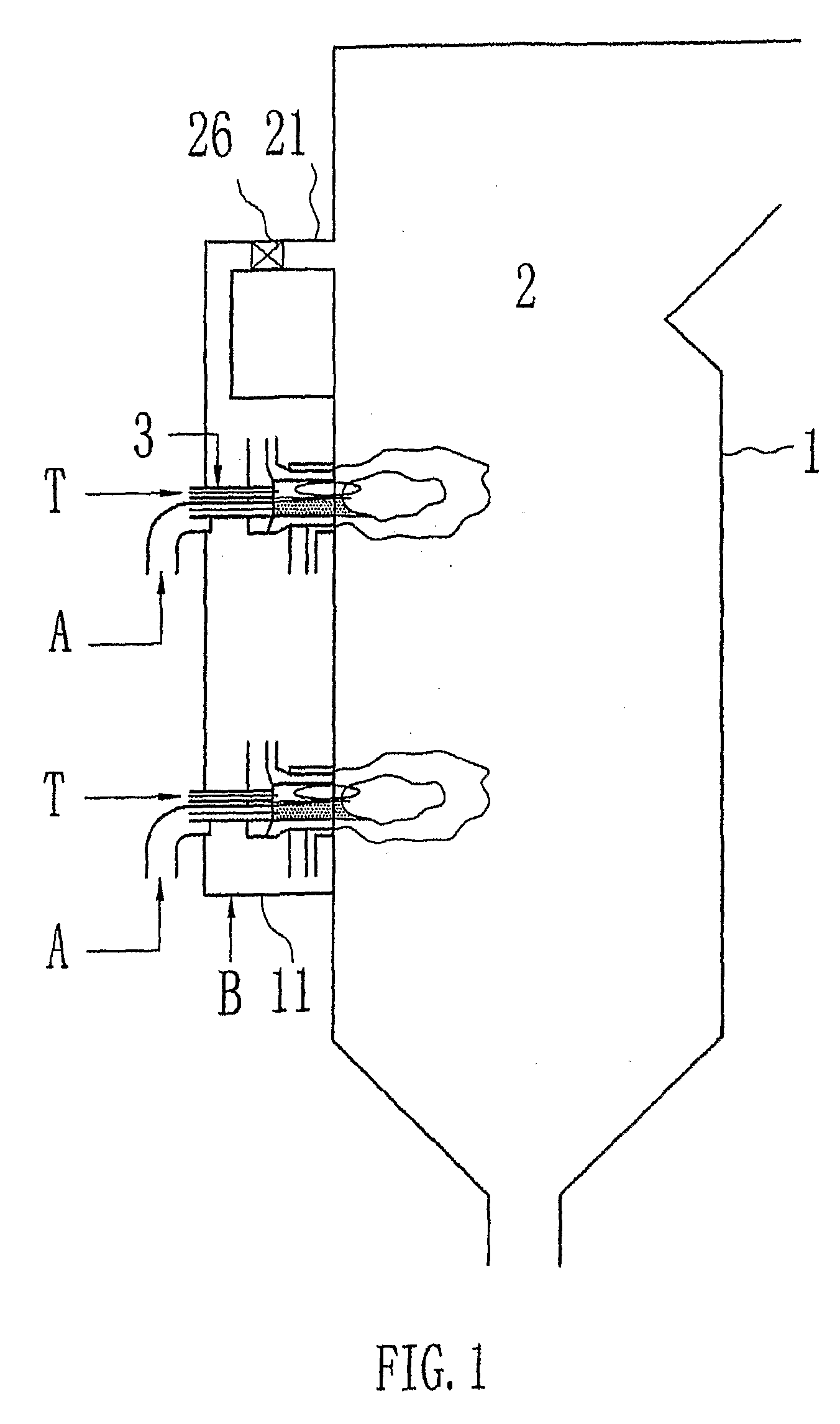

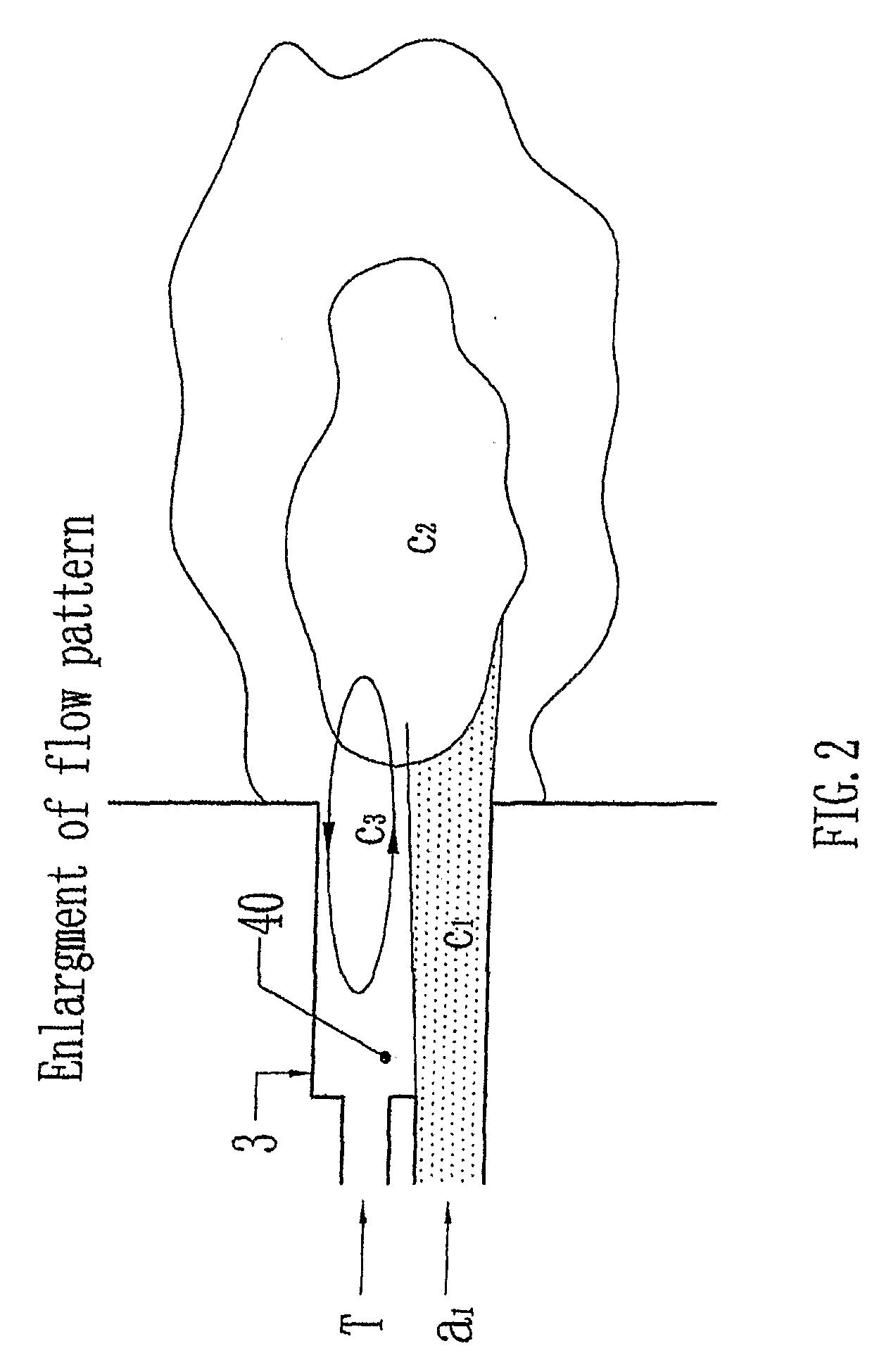

Combustion Method and System

InactiveUS20080264310A1Reduce the differenceReduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

A method of combustion for pulverized hydro-carbonaceous fuel includes the steps of injecting an oxidant / fuel stream into a burner, causing a low-pressure zone; directing a flow of a high-temperature combustion gas from a combustion chamber into the low-pressure zone in the burner; mixing the high-temperature combustion gas with the injected oxidant / fuel stream to heat the injected oxidant / fuel stream, and injecting the heated oxidant / fuel stream from the burner to the combustion chamber, wherein the oxidant / fuel stream is rapidly devolatilized and combusted in a flame that has a high temperature; sensing a combustion parameter; and based on the sensed combustion parameter, controlling combustion to achieve at least one of a desired NOx reduction and a desired distance from the burner to a flame front.

Owner:CLEAN COMBUSTION TECH

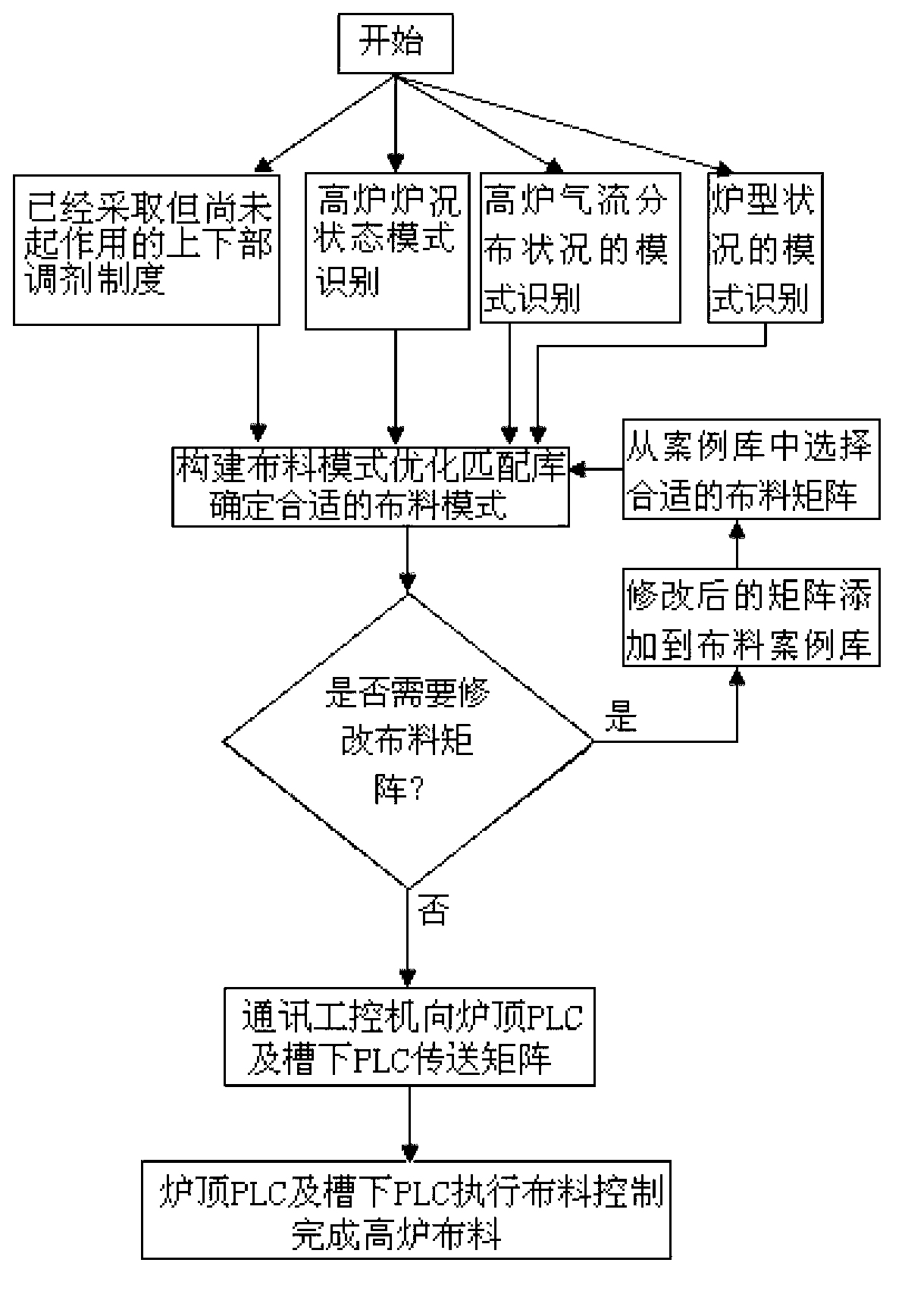

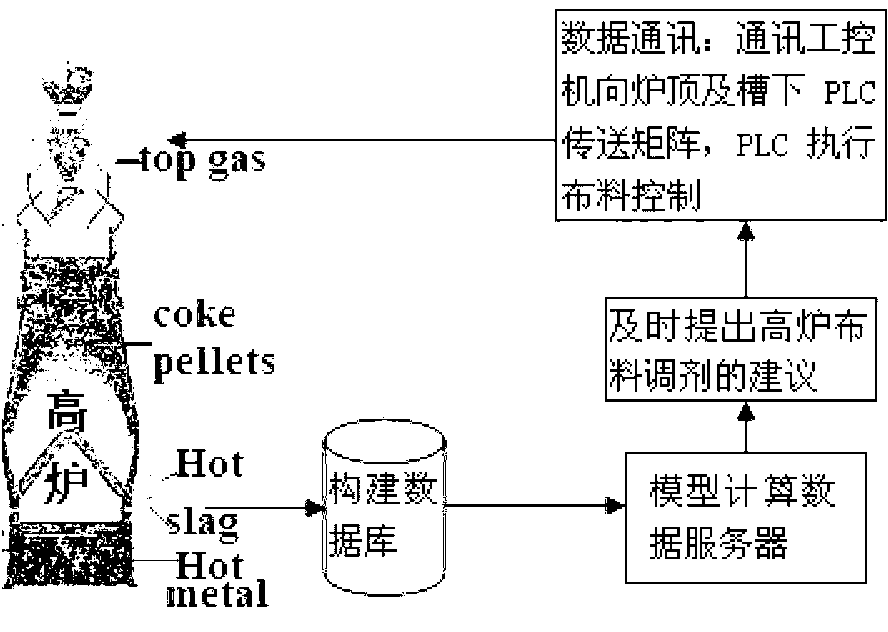

Blast furnace burden distribution optimization method based on mode recognition and expert system as well as system

ActiveCN103014204AAvoid big ups and downsLower fuel ratioBlast furnace detailsDistribution matrixDistribution control

The invention relates to blast furnace process control, in particular to a blast furnace burden distribution optimization method based on mode recognition and an expert system as well as a corresponding system. The method comprises the following steps: firstly, establishing a condition case base: establishing the mode recognition of air distribution state in a blast furnace, the mode recognition of furnace profile variation state and the mode recognition of furnace condition state of the blast furnace, secondly, establishing a burden distribution case base: establishing a burden distribution case base, thirdly, establishing a burden distribution mode optimization matching base; selecting one burden distribution matrix with matched conditions, fourthly, judging whether the burden distribution matrix is reasonable for current furnace condition burden distribution measures, utilizing the burden distribution matrix if the burden distribution matrix is reasonable, or adjusting the burden distribution matrix till the burden distribution matrix is reasonable, and fifthly, ensuring that a communication industrial computer transmits the matrix to a furnace top PLC (Programmable Logic Controller) and a PLC below a groove, and ensuring that the two PLCs carry out burden distribution control, so as to accomplish blast furnace burden distribution. The method and the system reduce the fuel ratio of the blast furnace, and greatly improve the production efficiency and the productivity of the blast furnace.

Owner:武汉钢铁有限公司

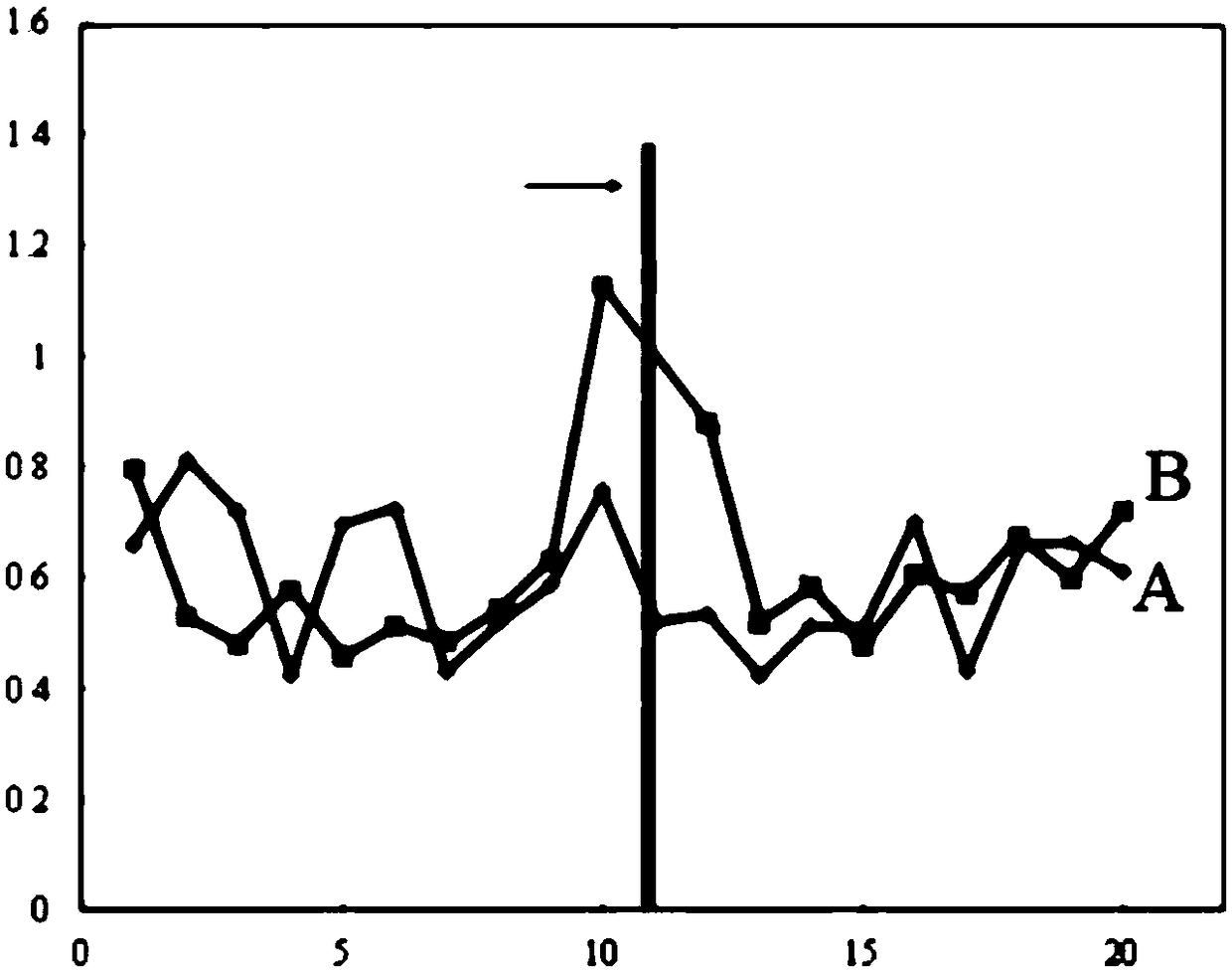

Detecting method for air flow distribution of blast furnace

ActiveCN104212924AExtended service lifeLower fuel ratioBlast furnace detailsCooling devicesDistribution systemEngineering

The invention provides a detecting method for air flow distribution of a blast furnace. The heat exchange between an air flow and a solid material bed is considered; the distribution of a material layer structure in the radial direction of the blast furnace influences the air permeability of the blast furnace in the radial direction so as to influence the form of the air flow distribution; and the material layer structure in the radial direction of the blast furnace and the air flow distribution are calculated by combining a cross-shaped temperature measuring gun and other main operation parameters of the blast furnace. According to the detecting method provided by the invention, a blast furnace operator can timely and accurately speculate the material layer structure in the radial direction of the furnace throat part and the change direction of the air flow distribution according to the variation of the radial air flow temperature distribution at present, so that the direction is provided for the adjustment of the distribution system, the stable and smooth operation of the blast furnace is guaranteed, the service life is prolonged, the fuel ratio is reduced, and other expensive detecting instruments are not needed.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

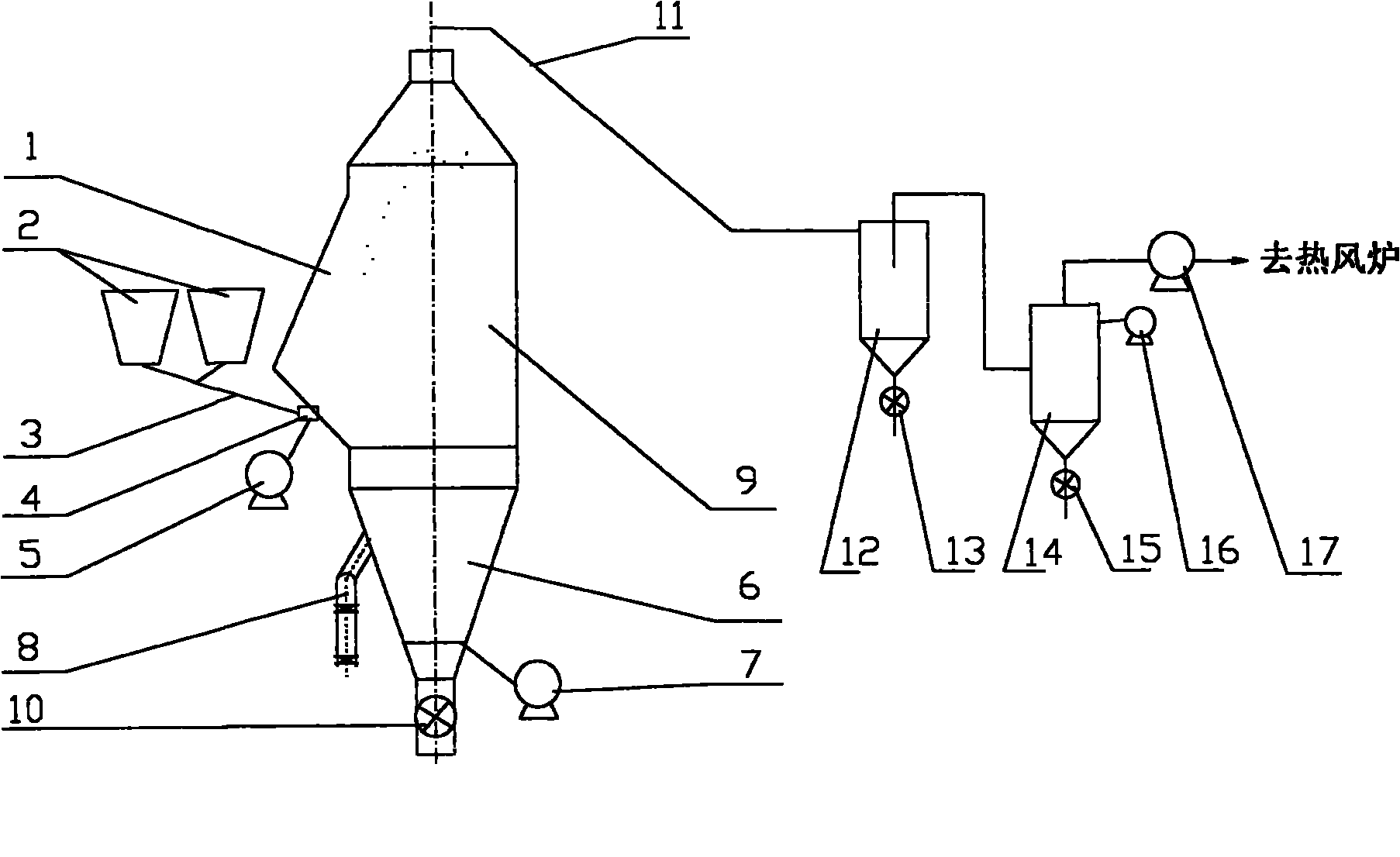

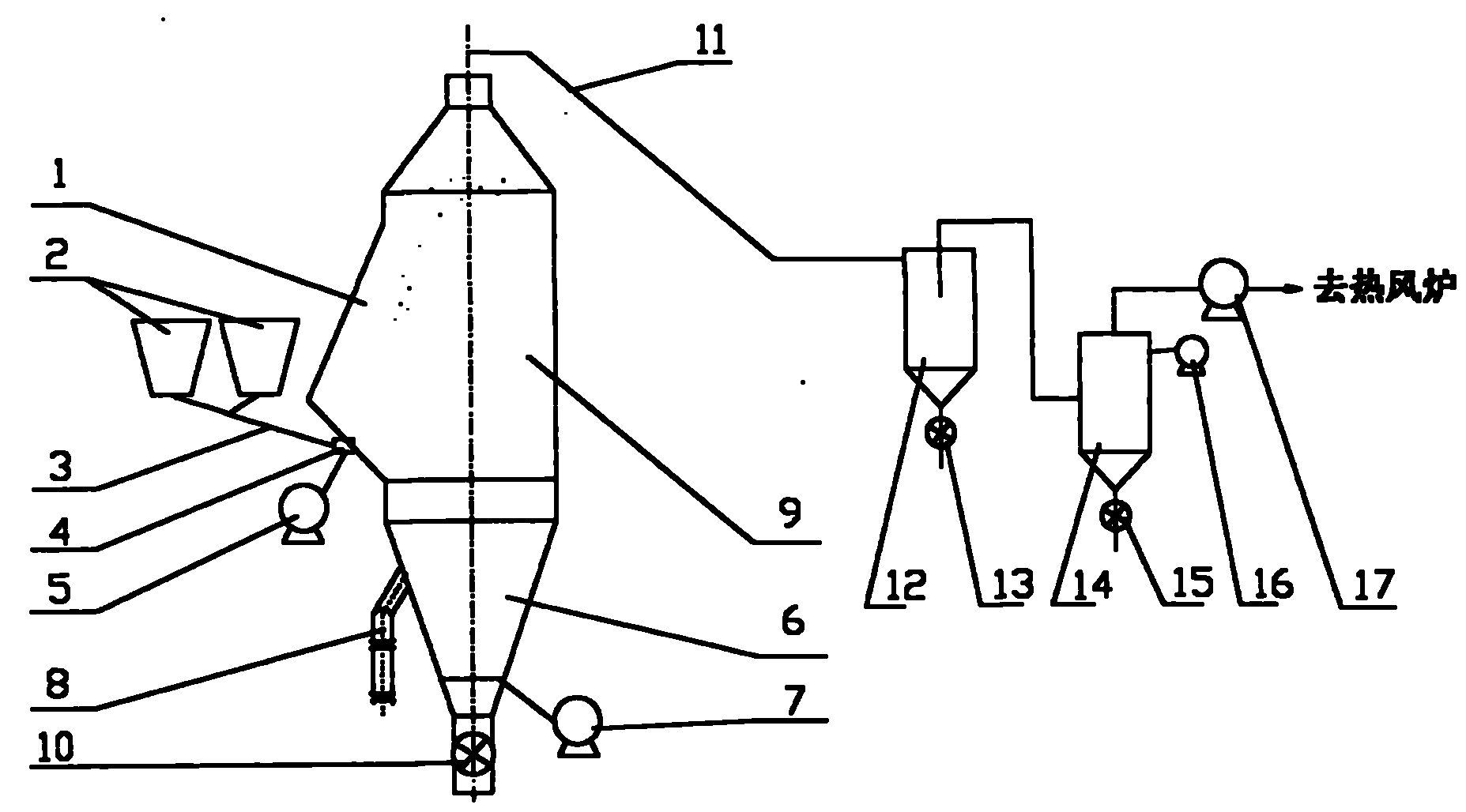

Method for raising air temperature of hot blast stove by recovering sensible heat of blast furnace slag

InactiveCN101864504AIncrease valueReduced expected payback periodBlast furnace detailsRecycling and recovery technologiesCombustionRecovery period

The invention discloses a method for raising the air temperature of a hot blast stove by recovering the sensible heat of blast furnace slag. In the invention, the high-temperature air resulting from a drying process is subjected to a secondary dust removal and a pressurization processing and then used as high-temperature combustion-supporting air for the hot blast stove to raise the temperature of the hot air of the hot blast stove to 1250-1270 DEG C, which is 100-120 DEG C higher than that of the hot air of the hot blast stove using blast furnace gas only. As the economic benefit brought by the raising of air temperature to blast furnace iron making is far higher than that brought by the production of steam by a waste heat boiler, and the step of converting high-temperature air to steam and the corresponding investment in waste heat boiler are saved, the method greatly improves the recovery value of the sensible heat of blast furnace slag and shortens investment recovery periods of corresponding projects.

Owner:北京睿德趋势量化咨询有限公司

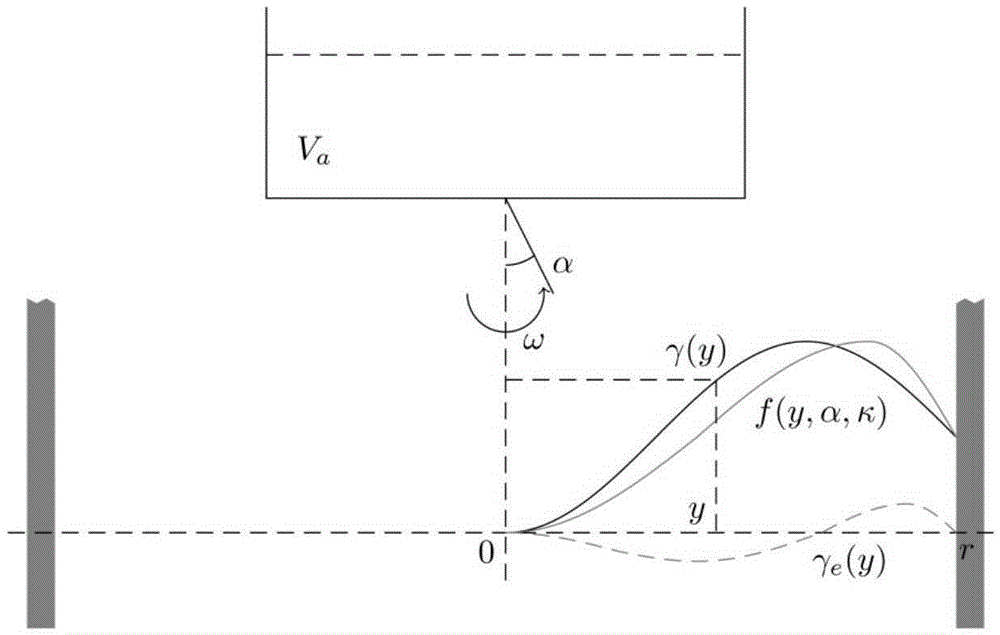

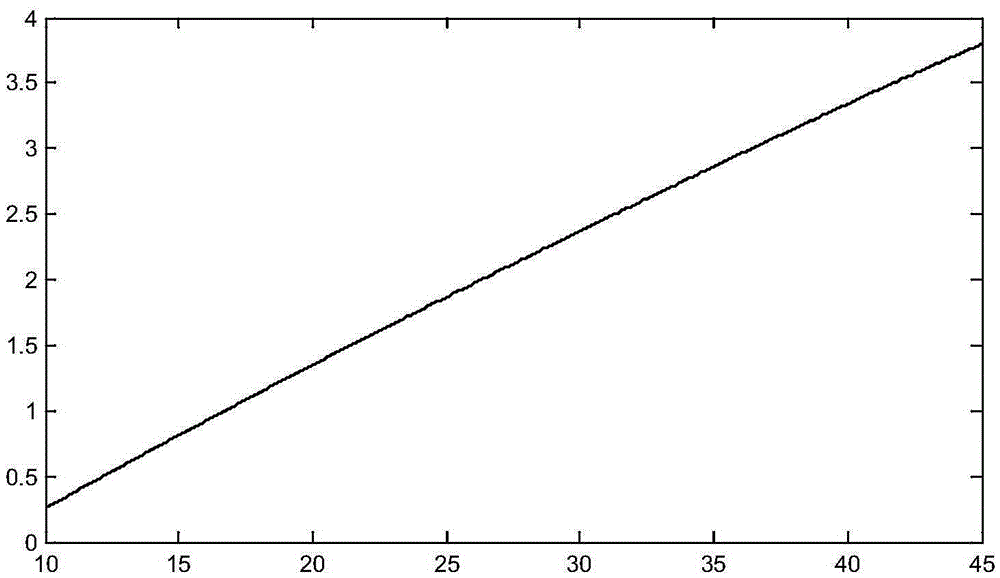

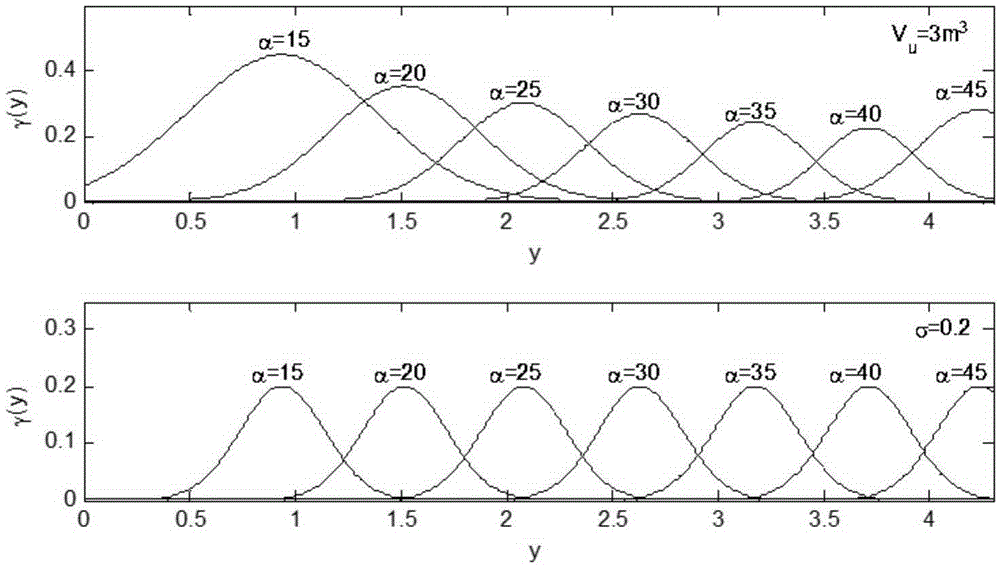

Method for modeling material surface output shape in material layout process in blast furnace

ActiveCN105243190ARealize dynamic distributed controlSimple methodSpecial data processing applicationsDistribution controlSmelting process

The present application discloses a method for modeling a material surface output shape in a material layout process in blast furnace. The method comprises: setting a chute inclination vector and a material layout laps vector of a material layout matrix; setting a function of the material surface output shape in the material layout process; taking a horizontal plane of the material bottom output shape as a reference to construct an integral constraint of the function of the material surface output shape; setting a base function of a unique lap material surface output of the material layout to construct a material layout output function with different ring bits; and determining a final material surface output shape according to the material layout output function with a last ring bit. According to the method of the present application, an entire outline of the material surface shape output by the material layout matrix can be conveniently and accurately obtained, and image visualization of the material surface output shape in the blast furnace material layout matrix can be realized, so as to reduce a fuel consumption ratio, save energy consumption, ensure stable and smooth in blast furnace conditions, stable in blast furnace yield, and prolonged in blast furnace life, avoid failures such as stuffiness, difficult operation, collapse, material collapse, and the like, and facilitate realization of dynamic distribution control of the blast furnace material output shape, and automation of the whole smelting process of the blast furnace.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

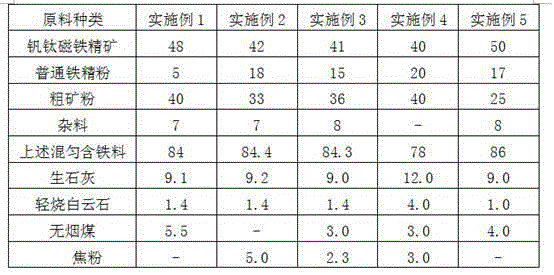

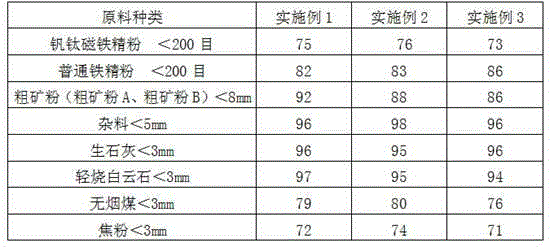

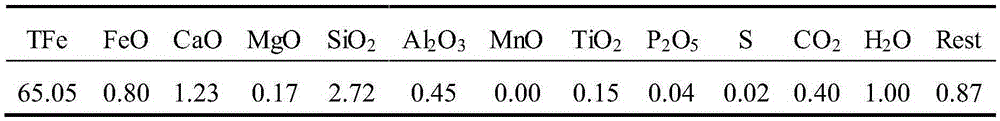

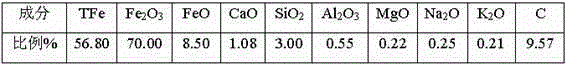

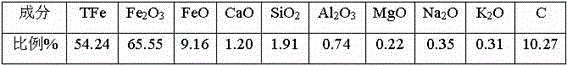

Medium-titanium high-strength sintered ore and preparation method thereof

The invention discloses a medium-titanium high-strength sintered ore which is formed by sintering the following ingredients by weight percentage: 78-86% of iron-bearing material, 9-12% of quicklime, 1-4% of lightly fired dolomite and 4-6% of fuel, wherein the iron-bearing material comprises the following components by weight percentage: 40-50% of vanadium titanium magnetite concentrate, 5-20% of common fine iron powder, 25-40% of coarse ore powder and 0-8% of miscellaneous material. The sintered ore is produced by taking a vanadium titanium magnetite and the vanadium titanium magnetite concentrate as main raw materials; the pelletizing performance of a mixture is improved by reasonably preparing and adding other iron ore powder and fluxes; component and phase composition of the sintered ore is controlled; an influence of higher TiO2 content in the sintered ore on the quality of the sintered ore is reduced; a tumbler index of the sintered ore reaches above 77% when the medium-titanium sintered ore is produced; the sintered ore is high in cold strength and low in return rate; and the sintered ore is smelted via a blast furnace, so that a fuel ratio is reduced and a utilization coefficient is increased.

Owner:HEBEI IRON AND STEEL

High-reducibility pellet and preparation method thereof

The invention relates to a preparation method of a high-reducibility pellet. In the method, hematite concentrate, dehydrated molten iron-smelting sludge, a magnesium-containing additive and a binding agent are mixed according to a mass percentage of 88-95%:1-8%:2.5-5.5%:0.7-1.5%. When the raw materials are uniformly mixed, moisture of the mixed raw materials is controlled to be 4-9%. A wet-grinding process is carried out for 2-9 min, and then a finished product of the high-reducibility pellet is obtained successively through a pelletizing process, a drying process, a pre-heating process and a roasting process after the wet-grinding process finished. The high-reducibility pellet is not less than 60% in TFe, is 1.0-3.0% in MgO content and is 0.8-1.4 in a ratio of CaO to SiO2. By means of the method, not only are problems, such as high temperature during pre-heating and roasting process, a long time and a low strength of the finished product of the high-reducibility pellet and the like, during preparation of an oxidizing pellet by the hematite concentrate are solved effectively, but also the pellet is significantly enhanced in reducing performance, thereby achieving energy conservation and emission reduction during iron smelting.

Owner:BAOSHAN IRON & STEEL CO LTD

Smelting reduction iron-making device and method for avoiding re-oxidation of pre-reduction ores

The invention discloses a smelting reduction iron-making device and method for avoiding re-oxidation of pre-reduction ores, and belongs to the technical field of smelting reduction iron making. The smelting reduction iron-making device adopts an existing shaft furnace and an iron bath furnace as reduction reactors and also comprises a feed port which is used for conveying pre-reduction ores generated by the shaft furnace to the furnace body side surface of the iron bath furnace by adopting a pre-reduction furnace charge descending passage, the furnace charge is further pressed into a slag blanket of the iron bath furnace to avoid the pre-reduction ores from contacting with gas in a free space in the upper part of the iron bath furnace and generating re-oxidation, thereby ensuring that the secondary combustion rate of the gas in the free space is not limited. Three layers of spray guns are arranged on the furnace body of the iron bath furnace, and the secondary combustion rate and the temperature of the gas in the furnace can be adjusted by adjusting the oxygen blowing ratio and the coal injection ratio as well as the total oxygen blowing quantity and the total coal injection quantity of the three layers of the spray guns, thereby providing sufficient heat for a melting bath in the iron bath furnace.

Owner:NORTHEASTERN UNIV

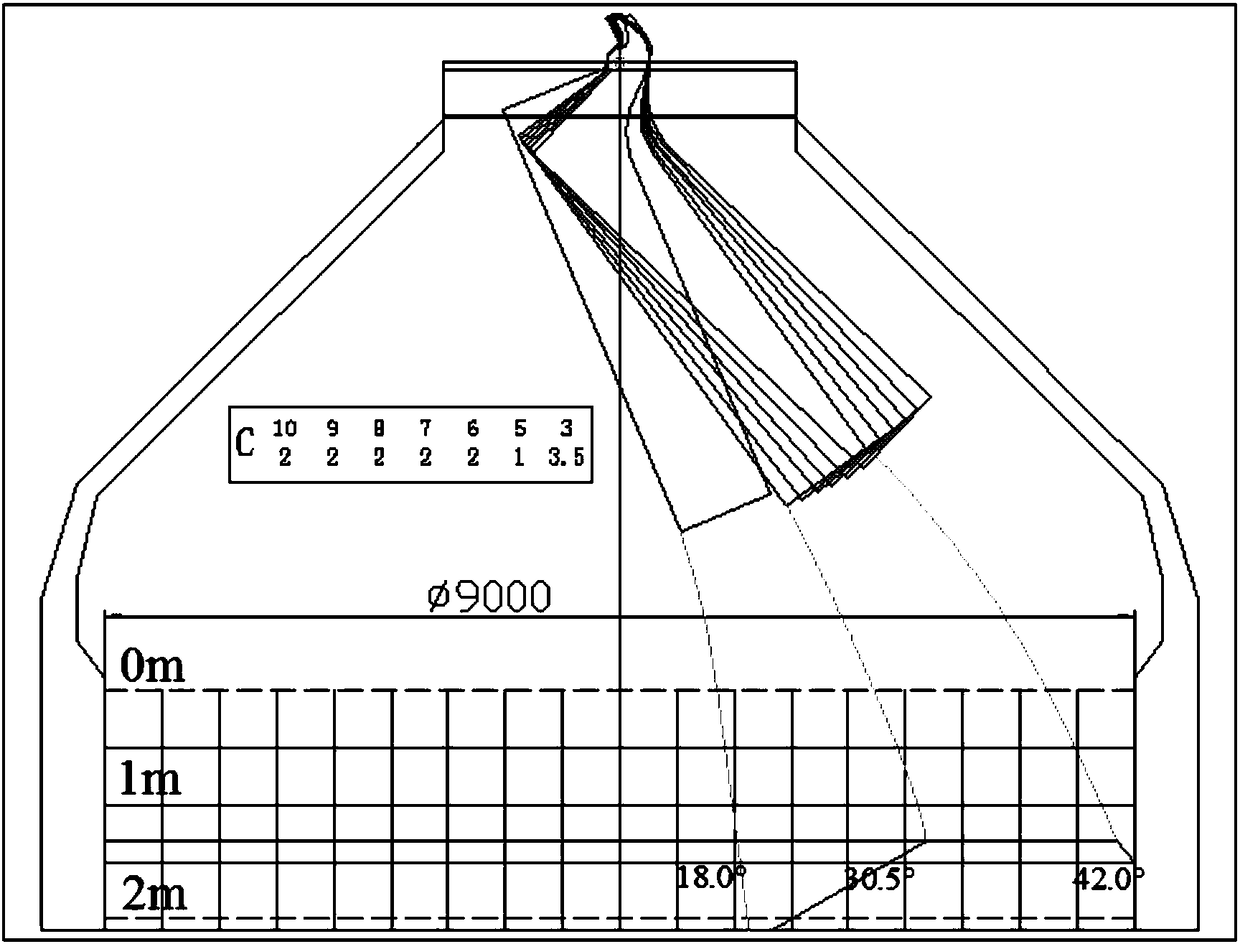

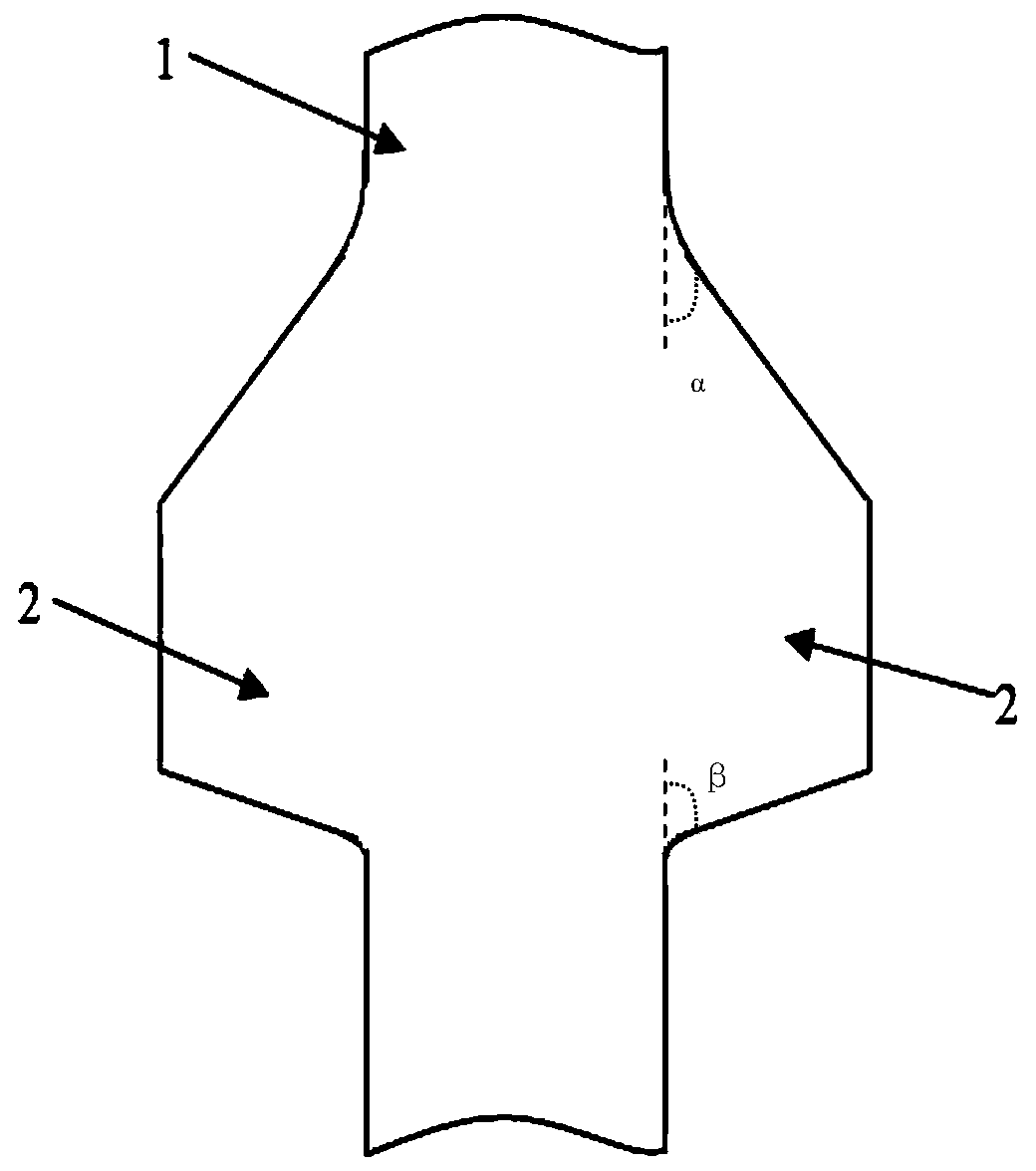

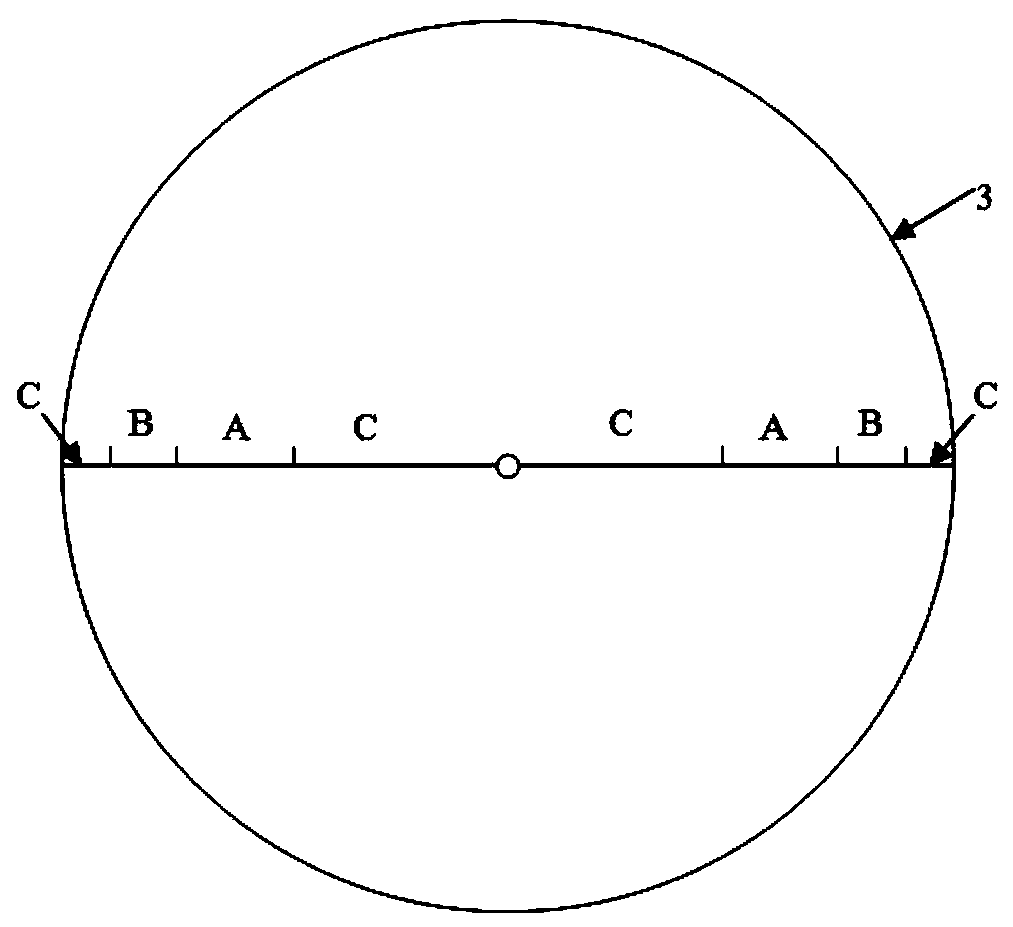

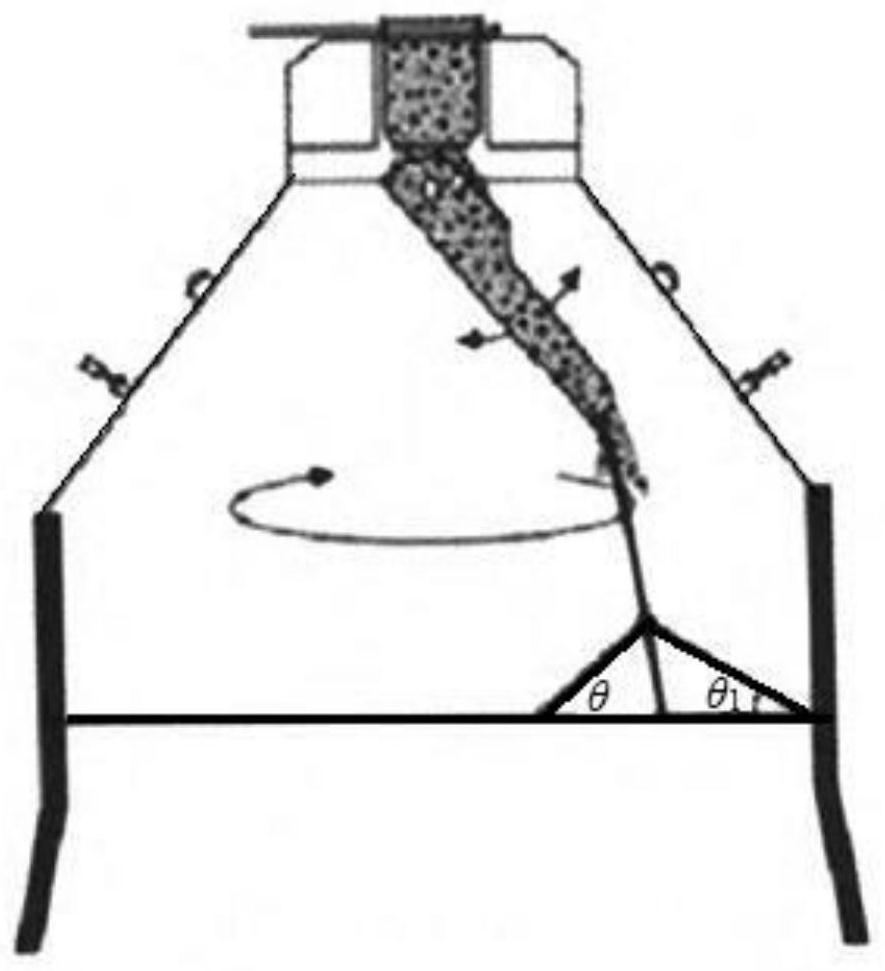

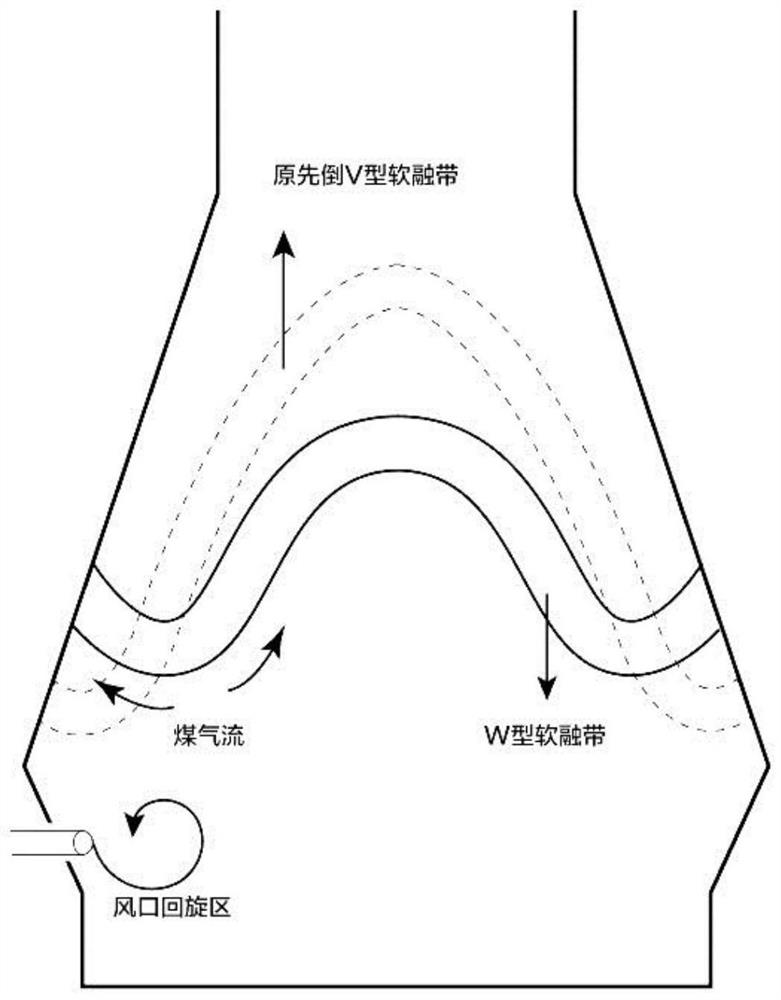

Distribution matrix designing method for increasing utilizing rate of large blast furnace gas

InactiveCN108085444AIncrease profitLower fuel ratioBell-and-hopper arrangementBlast furnace detailsDistribution matrixEngineering

The invention relates to the field of blast furnaces, in particular to a distribution matrix designing method for increasing the utilizing rate of large blast furnace gas. According to the distribution mode, in the blast furnace material loading process, by changing the tilting angle of a chute, the distribution ring number and the opening degree of a throttle valve, distribution of ore and coke in a surface is changed; and distribution of the coal gas at the edge and in the center is controlled, a coal gas flow is made to be reasonably distributed, the furnace condition is stabilized, the utilization rate of carbon monoxide is increased, and fuel consumption is reduced. Through the distribution mode adopting a platform with the proper width and the funnel depth, the utilizing rate of theblast furnace carbon monoxide is greatly increased while meeting blast furnace performance, the fuel ratio is remarkably decreased, and the production cost is reduced; and therefore, the problems of ore coke drop point positions and the ore coke numbers of all the positions are solved, the reasonably distributed and stable coal gas flow is achieved, and the furnace condition is stably performed.

Owner:BENGANG STEEL PLATES

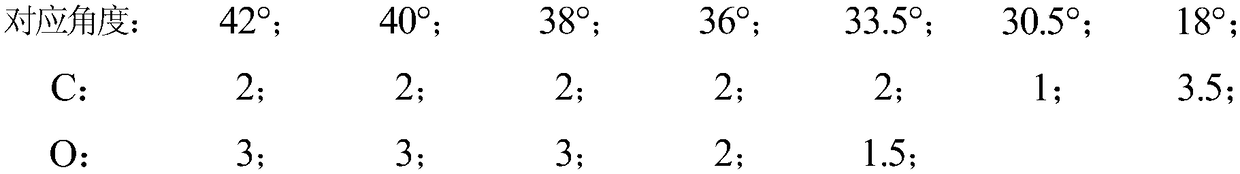

Blasting belt-type sintering machine and method, for producing sinter, of blasting belt-type sintering machine

InactiveCN103542724AIncrease productionIncreasing the thicknessFurnace typesElectricityRoom temperature

The invention provides a blasting belt-type sintering machine and a method, for producing sinter, of the blasting belt-type sintering machine. A material distribution mechanism I, an igniter, a material distribution mechanism II, an air draft and dust-removal flue and a discharging device are sequentially arranged on an upper-layer sintering cart way from a machine head to a machine tail, wherein the lower portion of the igniter is communicated with an air draft ignition pipeline through a wind box, the lower portion of the air draft and dust-removal flue is connected with a sealing cover, the sealing cover is arranged on the upper-layer sintering cart way, the sealing cover is communicated with a sintering blasting pipeline through the wind box at the lower portion of a cart, and a dust-falling pipe is arranged at the lower portion of the sintering blasting pipeline. According to the sintering machine, through two times of feeding, the thickness of a material layer can be improved to about 1-1.5m, fuel is combusted thoroughly through blasting sintering, the electricity-saving effect is obvious, and the electricity is saved by three fourths when air draft is changed into blasting. In the air draft process, the cart and grate bars make direct contact with sintering high-temperature smoke, the temperature is high, and the cart and the grate bars are deformed and damaged easily. After air draft is changed into blasting, the cart and the grate bars make contact with room-temperature blasting air, the temperature is low, and therefore the cart and the grate bars are not damaged easily.

Owner:林州市马氏炼铁技术研究开发有限公司

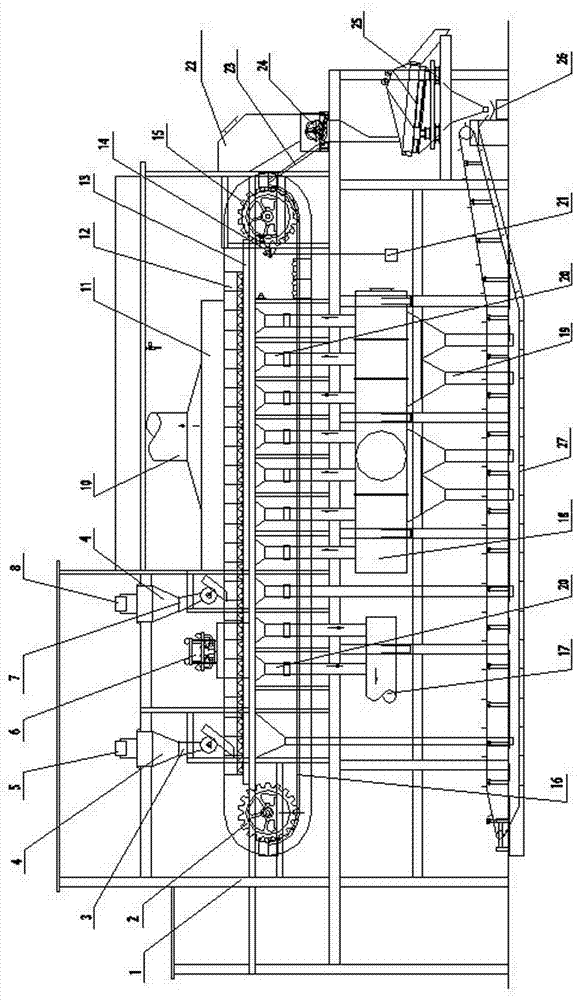

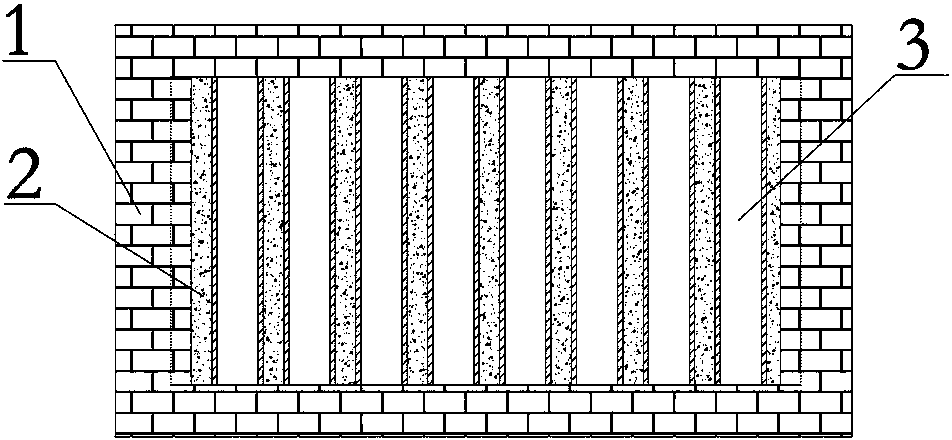

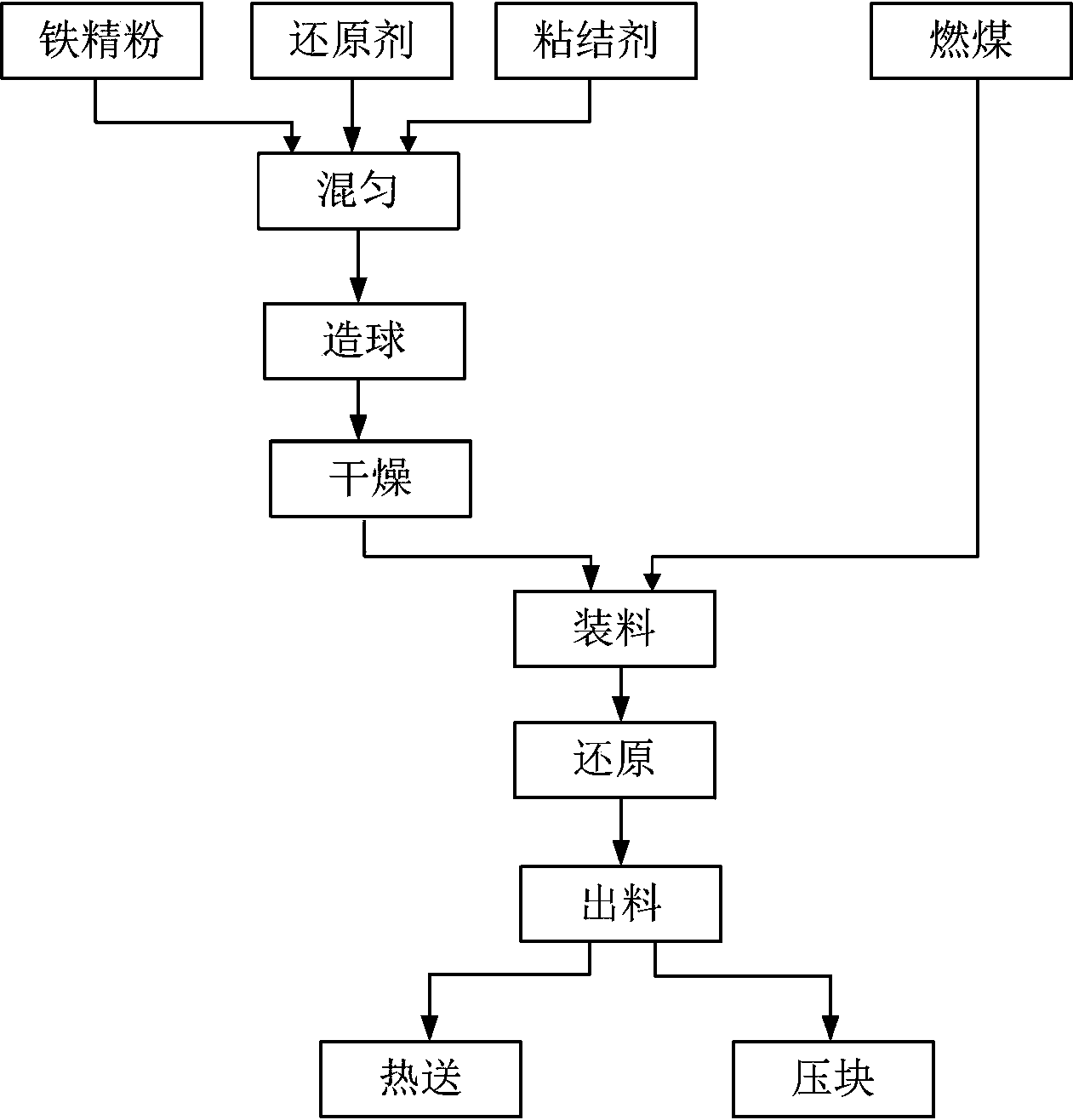

Reducing furnace, and technology for directly reducing coal-containing pellets through preheating outside coal base

InactiveCN103352097AAvoid the fatal flaw of small restoration capacityEvenly heatedFluidised-bed furnacesSteelmakingThermodynamics

The invention provides a reducing furnace. The reducing furnace comprises a furnace wall, at least one reducing tank and at least one combustion tank, and the at least one reducing tank and the at least one combustion tank are alternately arranged. The top of each reducing tank is connected with a raw material feeding device, and the bottom of each reducing tank is provided with a material outlet. The top of each combustion tank is connected with a fuel feeding device, and the bottom of each combustion tank is provided with an ash outlet. The invention also provides a technology for directly heating coal-containing pellets through preheating outside a coal base. The technology comprises the following steps: 1, mixing and pelletizing an iron-containing raw material, coal dust and a binder to obtain coal pellets; and 2, providing the reducing furnace, adding the pellets to the reducing tank(s) through the raw material feeding device(s), adding fire coal to the combustion tank(s) through the fuel feeding device(s), allowing the pellets and the fire coal to independently move from top to bottom, heating and reducing the pellets to form spongy iron, and discharging the spongy iron. The reducing furnace and the reducing technology have the advantages of high shaft furnace productivity, adoption of non-coking coal as a reducing agent in coal base reduction, adoption of cheap coal as a heat source, and production of the direct reduction iron for steel making.

Owner:WISDRI ENG & RES INC LTD

Method for blast furnace smelting of vanadium titanium magnetite

InactiveCN104060007AIncrease profitImprove propertiesBlast furnace detailsGas emission reductionMagnetiteBlast furnace smelting

The invention discloses a method for blast furnace smelting of a vanadium titanium magnetite, and is characterized in that the method comprises the steps: in the process of blast furnace smelting of the vanadium titanium magnetite, spraying and blowing a fuel and a fluorite powder into a blast furnace through an air port. With adopting of the method for blast furnace smelting of the vanadium titanium magnetite, the content of iron in slag iron can be significantly reduced, and the total fuel ratio can be reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Method for increasing combustion rate of coal powder by adding furnace-front dust of blast furnace to injection coal

ActiveCN105112583AGuaranteed GranularityMake sure the ratioBlast furnace detailsThermodynamicsCombustion

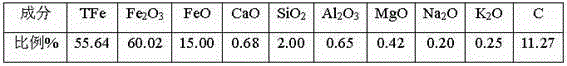

The invention discloses a method for increasing the combustion rate of coal powder by adding furnace-front dust of a blast furnace to injection coal. The method comprises steps as follows: step (1), the furnace-front dust of the blast furnace is collected and transported to an injection coal grinding workshop; step (2), 1.0%-.4.0% of the furnace-front dust of the blast furnace is added to the injection coal, the mixture is transported to a coal grinding machine through a belt conveyor to be prepared to form mixed coal powder, and the mixed coal powder is collected by a bag type powder collector; step (3), the mixed coal powder is conveyed to a blast furnace injection station through compressed air via a pipeline, then conveyed to a blast furnace distributor through an injection tank, distributed to coal injection lances and sprayed into the blast furnace to be combusted from a blast furnace tuyere finally. The furnace-front dust of the blast furnace is added to the injection coal, so that the amount of ore and coke required for smelting of each ton of iron is reduced; the combustion rate of the coal powder is increased due to addition of a proper amount of Fe2O3 to the coal powder, and the comprehensive fuel ratio of the blast furnace is reduced due to the increase of the combustion rate; SiO2 in the furnace-front dust of the blast furnace t performs the function of an abrasive, and the yield of the coal powder is increased.

Owner:WUKUN STEEL

Vanadium titanium magnetite smelting method

ActiveCN106755670APrevent distribution imbalanceImprove smelting efficiencyBlast furnace detailsDistribution systemBlast furnace smelting

The invention discloses a vanadium titanium magnetite smelting method. The smelting method is characterized in that a burden distribution system is J333313293272202 and K312293272262, wherein J represents coke, K represents mineral, the inclined angle of a burden distribution chute is divided into a sixth gear, a fifth gear, a fourth gear, a third gear, a second gear and a first gear, number superscripts represent corresponding angles, and number subscripts correspond to number of rings of corresponding gears. The smelting method is even in burden distribution, gas flow distribution is reasonable, the gas using rate is improved, the blast furnace smelting intensity is improved, and furnace wall scaffolding is prevented.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Charging material for blast-furnace smelting and blast-furnace smelting method

InactiveCN107586903AHigh degree of reductionReduce return rateBlast furnace detailsAlkalinityIron powder

The invention discloses a charging material for blast-furnace smelting and a blast-furnace smelting method. The charging material for blast-furnace smelting comprises components in parts by weight asfollows: 60-85 parts of alkaline sintered ore, 10-20 parts of acid pellets and 0-5 parts of geological minerals, wherein alkalinity of the alkaline sintered ore is 2.2-2.3, and alkalinity of the acidpellets is 0.2-0.4; the alkaline sintered ore is prepared from 40-50 parts by weight of vanadium bearing titanomagnetite, 5-10 parts by weight of common fine iron powder, 5-15 parts by weight of boron-bearing iron ore powder, 1-5 parts by weight of SiC powder and 6-10 parts by weight of CaO as raw materials through sintering; the acid pellets are prepared from 50-60 parts by weight of the vanadiumbearing titanomagnetite, 5-10 parts by weight of common fine iron powder, 1-2 parts by weight of magnesite, 3-5 parts by weight of dolomite and 1-2 parts by weight of bentonite as raw materials through sintering. According to the blast-furnace smelting method adopting the charging material for blast-furnace smelting, liquidity of iron slag can be guaranteed, a slag charge structure is changed, slag basicity is reduced, effective availability of the charging material for blast-furnace smelting is improved, blast-furnace smelting efficiency is improved, and smelting cost is reduced.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Blast furnace oxygen adding coal injection method and apparatus thereof

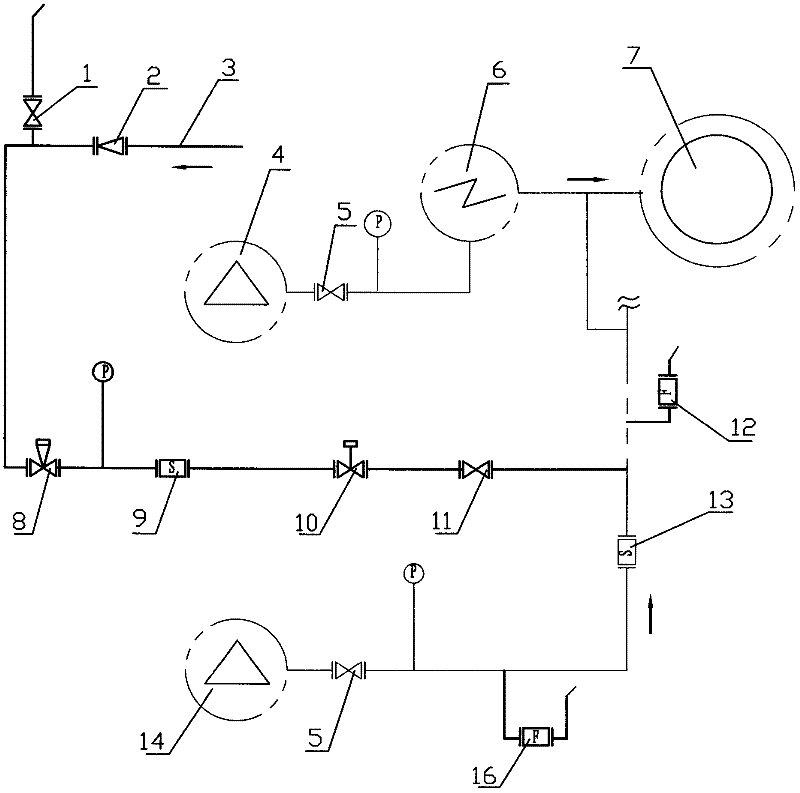

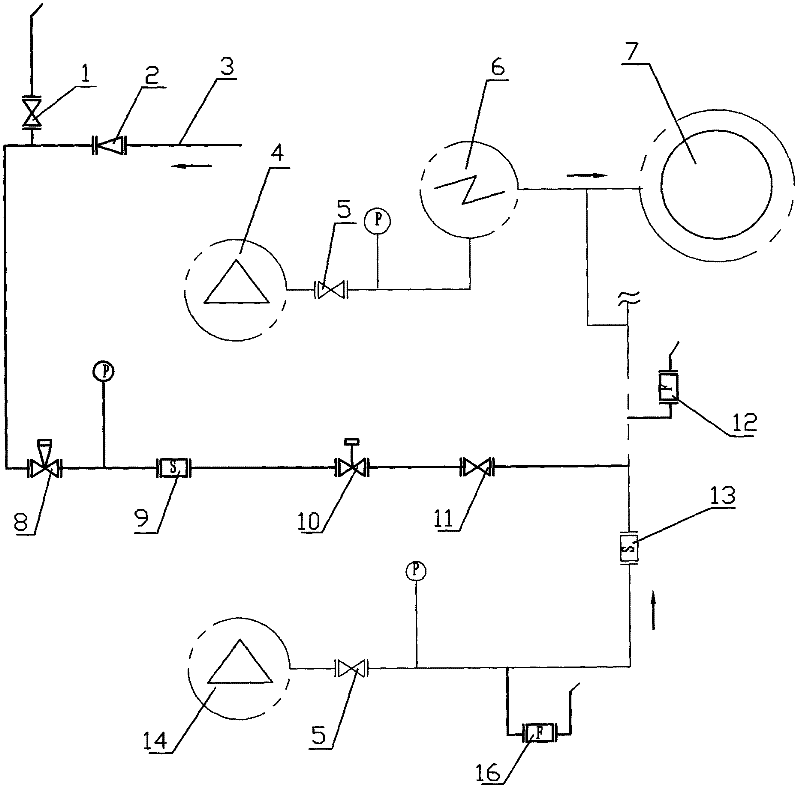

InactiveCN102409122AHigh economic valueThe economic value is higher than one coke ratioBlast furnace componentsBlast furnace detailsHigh pressure oxygenHigh pressure

The invention discloses a blast furnace oxygen adding coal injection method and an apparatus thereof, and relates to a blast furnace coal injection method. According to the apparatus, a pressure stabilizing nitrogen tank is communicated with a blowing tank by a manual nitrogen valve; the blowing tank is communicated with the blast furnace by a blowing pipe; an air feeding nitrogen tank is communicated with an air feeding total pipe by the manual nitrogen valve and a nitrogen flow meter; the air feeding total pipe is communicated with the blowing pipe. The apparatus is characterized in that: a high pressure oxygen pipe is additionally arranged, and is communicated with the air feeding total pipe sequentially by a check valve, a fast switch electromagnetic valve, an oxygen flow meter, an electromagnetic regulating valve and a manual oxygen valve; the air feeding total pipe forms a bypass communication with an oxygen analyzer for oxygen amount detection; the pipeline between the manual nitrogen valve and the nitrogen flow meter forms a bypass communication with an oxygen analyzer for inverted fleeing oxygen detection; the information output ends of the two flow meters and the two oxygen analyzers are respectively communicated with the input end of a PLC central processing unit; the output end of the PLC central processing unit is connected with the information input ends of the electromagnetic regulating valve and the fast switch electromagnetic valve. With the present invention, the coke ratio and the fuel ratio are substantially reduced, and the burning rate of the coal fines is significantly improved.

Owner:福建三钢闽光股份有限公司 +1

Method for improving desulphurization efficiency of blast-furnace slag

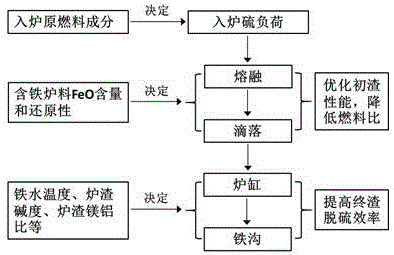

InactiveCN106702051AImprove desulfurization efficiencyImprovement ingredientsBlast furnace detailsAlkalinitySulfur

The invention discloses a method for improving desulphurization efficiency of blast-furnace slag. The technology is that during the desulphurization process of blast-furnace smelting, the temperature of blast-furnace melted iron is controlled to be 1450 DEG C to 1550 DEG C, the content of Si in melted iron is 0.2 wt% to 0.8 wt%, binary basicity of slag is 1.0 to 1.3, ternary basicity of slag is 1.3 to 1.6, and the content of MgO in slag is 5 wt% to 12 wt%. According to the method, the slag desulphurization efficiency in zones above a hearth can be improved, desulphurization burden in the hearth zone is reduced, the energy utilization efficiency is improved, and fuel ratio is decreased; when the load of sulfur entering the furnace is increased, the slag desulphurization efficiency is improved and stable and smooth operation of a blast furnace is guaranteed through optimization of components and performances of iron-bearing raw materials and improvement of the slagging process of the blast furnace; selection ranges of coke and coal dust can be further expanded, and the purchase cost is reduced; and the method has the characteristics of being high in operability, simple in technology and easy to achieve.

Owner:TANGSHAN IRON & STEEL GROUP +1

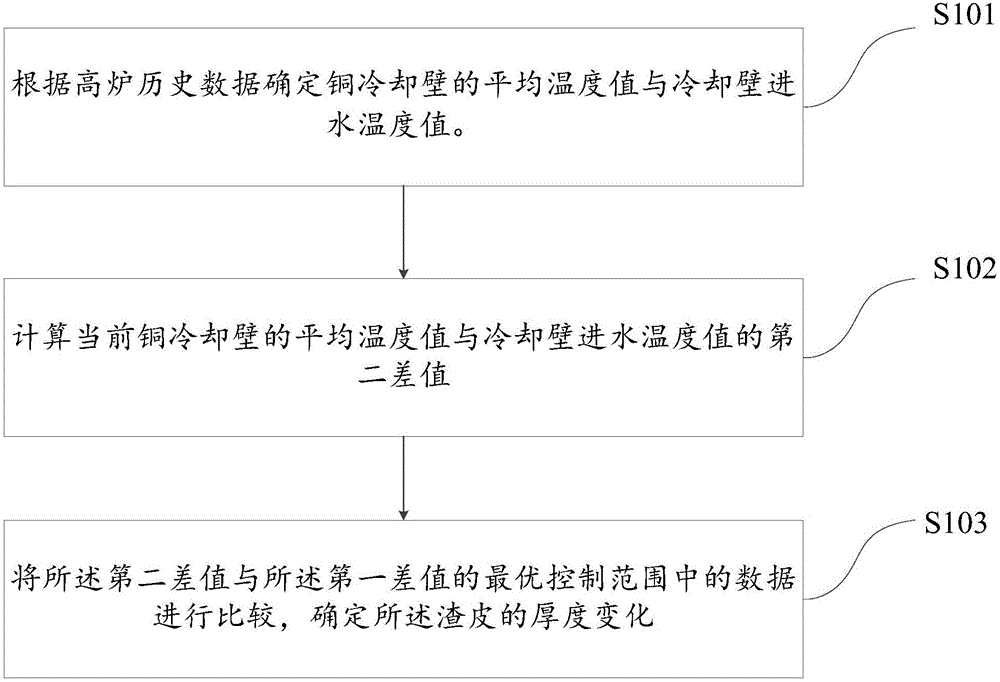

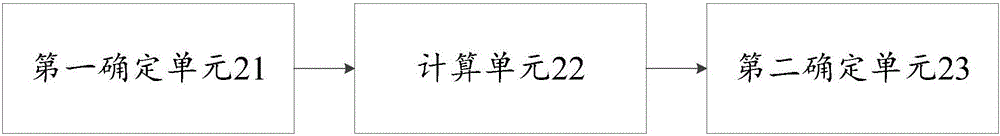

Method and device for determining thickness change of slag crust of copper cooling wall of blast furnace

The invention provides a method and a device for determining thickness change of slag crust of a copper cooling wall of a blast furnace. The method comprises steps of according to historical data of the blast furnace, determining a first difference value of an average temperature value of each segment of the copper cooling wall and the water charging temperature value of the cooling wall; determining an optimal control range of the first difference value, wherein the first difference value has the inversely proportional relationship with the thickness of the slag crust; calculating a second difference value of the average temperature value of each segment of the copper cooling wall and the water charging temperature value of the cooling wall; and comparing the second difference value with data in the optimal control range of the first difference value so as to obtain thickness change of the slag crust. In this way, when the thickness change of the slag crust is determined, the temperature of the cooling wall and the water charging temperature of the cooling wall are comprehensively considered, so the first difference value can be largely regarded as the temperature gradient from a temperature measurement point to the interior of a cooling water pipe. By using the difference value of the temperature to judge the thickness of the slag crust, judgment precision is improved, gas utilization rate is improved and fuel ratio is reduced, thereby improving stability of the furnace condition of the blast furnace.

Owner:武汉钢铁有限公司

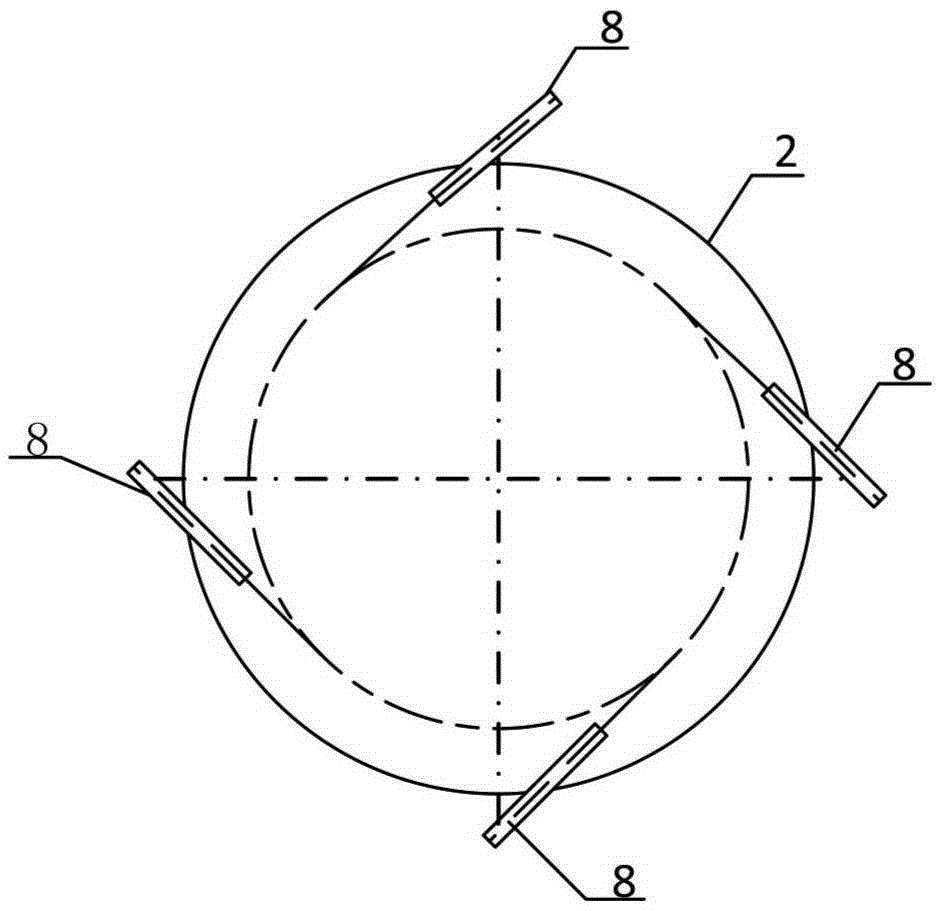

Low-cost blast furnace smelting method

InactiveCN106591524AQuality improvementAvoid pollutionTuyeresBlast furnace detailsGranularityBlast furnace smelting

The invention discloses a low-cost blast furnace smelting method. The low-cost blast furnace smelting method comprises the steps that coke nut with the particle sizes ranging from 8 mm to 20 mm is added to sintered vanadium-titanium ores, small sintered vanadium-titanium ore cubes, vanadium-titanium pellets and pig iron, and an ore layer is formed through uniform mixing; and the coke and the ore layers are alternately fed into a blast furnace, so that an alternate layering structure of the ore layers and the coke layers is formed, wherein the coke is composed of high-strength coke and low-strength coke, and the high-strength coke comprises dry quenched coke. A hearth of the blast furnace comprises multiple tuyeres and two iron notches, wherein the two iron notches are symmetrical about the center axis of the hearth, the tuyeres are arranged above the iron notches and distributed circumferentially, the diameters of the tuyeres which are symmetrical about the center axis of the hearth are identical, and the diameters of the tuyeres located on the two sides of the iron notches are smaller than or equal to the diameters of the other tuyeres on the circumference. By the adoption of the low-cost blast furnace smelting method, the ventilation performance of blast furnace smelting is improved, the intensity of blast furnace smelting is improved, the fuel ratio is lowered, and the cost is lowered.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Production technique for improving heat exchange efficiency of heat pipe type preheater of hot air furnace

ActiveCN105018665AImprove heat transfer efficiencyDoes not affect normal productionBlast furnace detailsHeating stovesEnvironmental resistanceEngineering

The invention relates to a production technique for improving the heat exchange efficiency of a heat pipe type preheater of a hot air furnace. The production technique for improving the heat exchange efficiency of the heat pipe type preheater of the hot air furnace comprises the technological steps that firstly, the reason for the reduction of the heat exchange effect is found out; secondly, the reduction of the heat exchange efficiency is confirmed; thirdly, the operation condition of working media in a heat pipe is confirmed; fourthly, a large amount of non-condensable gas in the heat pipe is exhausted; fifthly, fluid working media are supplemented; and finally, the maintenance effect is evaluated. According to the production technique, the operation is easy and convenient; the investment is small; the high benefits can be achieved continuously; the environment friendliness, equipment and wind temperature quality are not affected; the highly-efficient application of the preheater can be prolonged; and the investment for replacing the heat pipe or the whole preheater equipment is reduced.

Owner:SGIS SONGSHAN CO LTD

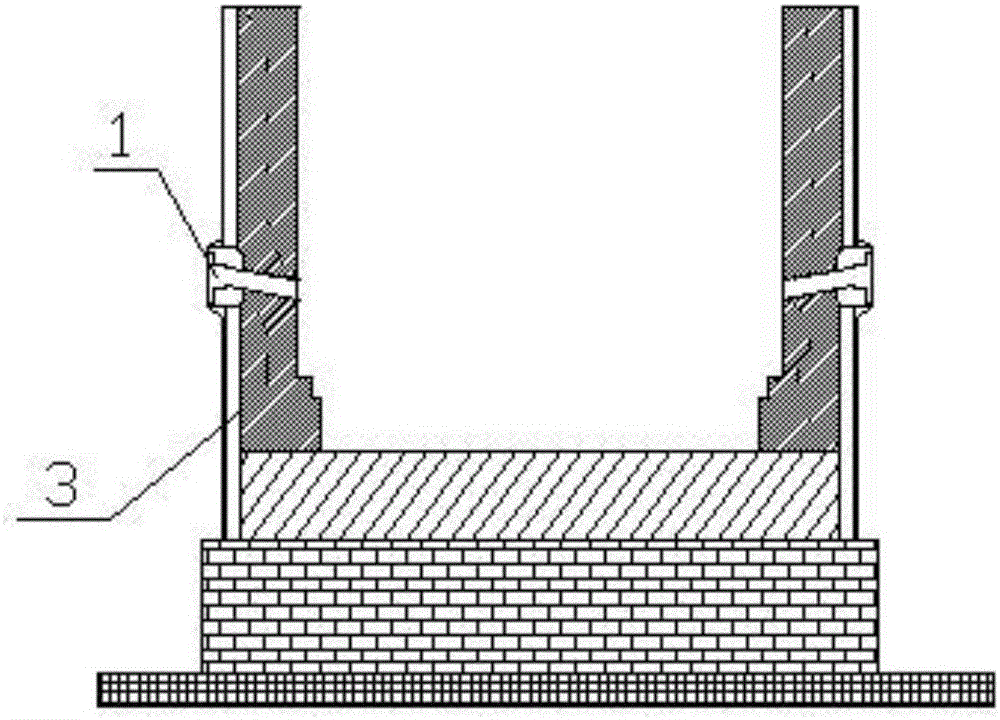

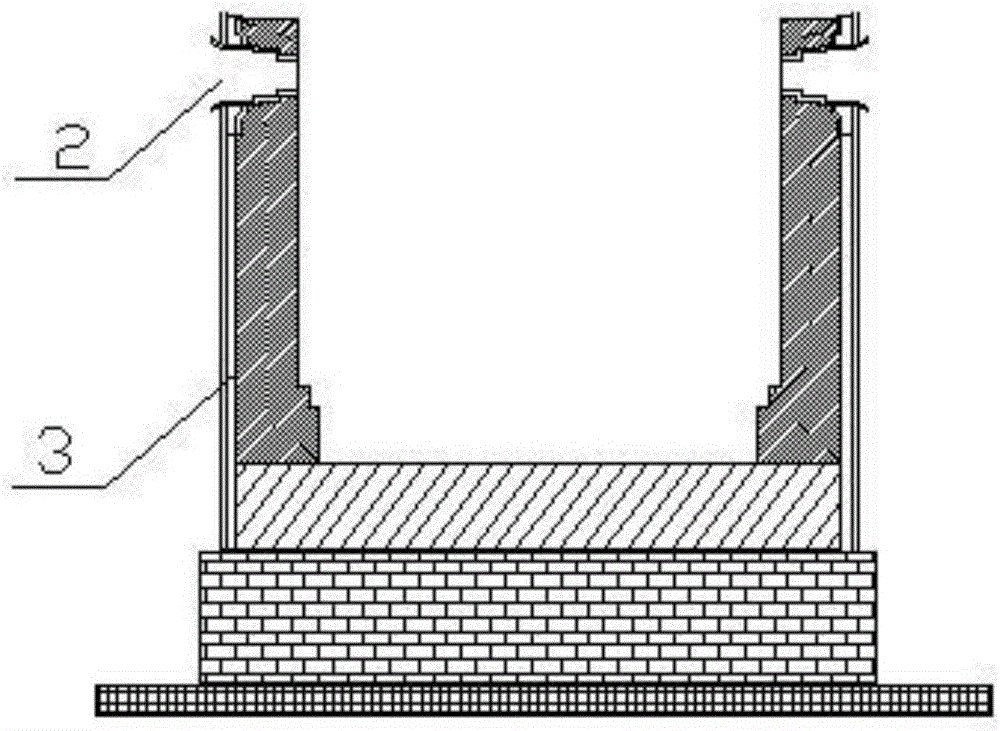

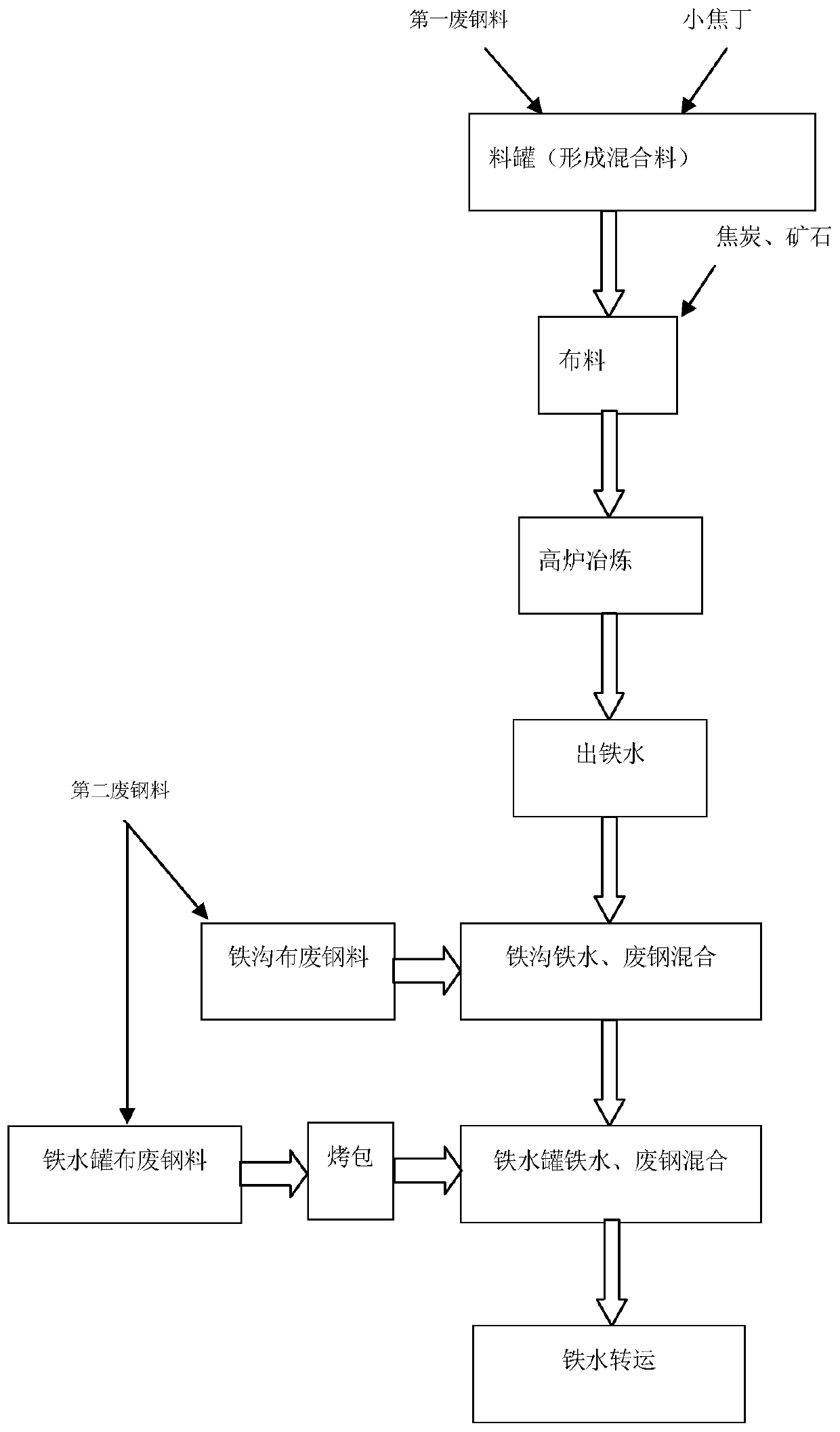

Method for producing molten iron by adding scrap steel into blast furnace

ActiveCN110129499AImprove productivityIncrease temperatureBlast furnace detailsDischarge devicesSocial benefitsEconomic benefits

The invention relates to a method for producing molten iron by adding scrap steel into a blast furnace. The method mainly comprises the steps of mixing, distributing, smelting, iron runner modification, iron runner distribution, molten iron ladle distribution, molten iron ladle baking and tapping and the like. According to the method, the scrap steel is added in different modes in different opportunities in a blast furnace smelting process, so that the technical effects that the overall smelting time is shortened, the tapping amount is improved, the utilization amount of the coke is greatly saved, and the downstream degree of the blast furnace and the like are improved. According to the method, the utilization rate of scarp steel can be greatly improved, more industry and domestic scarp steel can be digested, energy consumption can be reduced, emission of harmful substances is reduced, the development requirements of environmental protection and energy conservation are met, and important social benefits are achieved while the blast furnace economic benefits are increased.

Owner:德龙钢铁有限公司 +1

Gasoline detergent and preparation method thereof

InactiveCN108441271AReduce consumption rateStable storage and transportation statusLiquid carbonaceous fuelsFuel additivesNew energyOxygen

The invention provides a gasoline detergent. The gasoline detergent is prepared from aliphatic alcohols, aliphatic carboxylates, solvent oil, dimethyl carbonate, aliphatic nitrogen-containing compounds, peroxides and anti-corrosion and anti-dissolution compounds. The gasoline detergent can supply enough oxygen and enough micro detonating agents; synchronous full combustion of gasoline and the gasoline detergent is accelerated; the combustion is stable; the heating value is high; the generation of poisonous and harmful gas is reduced; components of tail gas are changed; the detergency of the gasoline is improved; the environment friendliness is improved; original deposited carbon is effectively removed; when the gasoline is continuously used, the deposited carbon is not generated; is effectively saved, and the pollution of automobile tail gas to the air is effectively reduced, so that the blue sky is protected; acid rain and haze are reduced; green mountains and rivers are indirectly protected; the gasoline detergent has the effects of saving energy, protecting environment and reducing emission, also has good environmental protection benefits and social benefits, and is used as green new energy which is urgently needed by people.

Owner:汪青

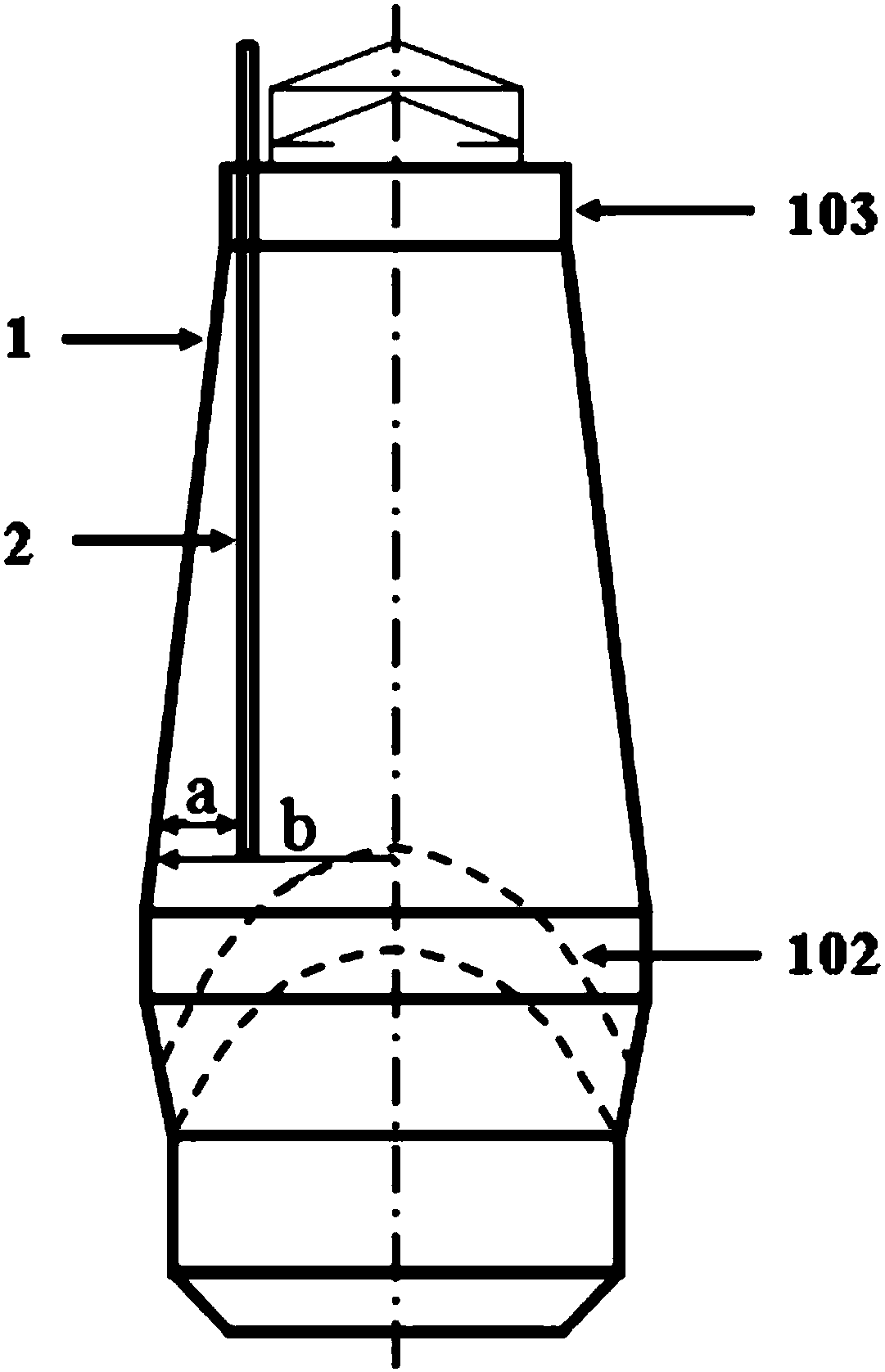

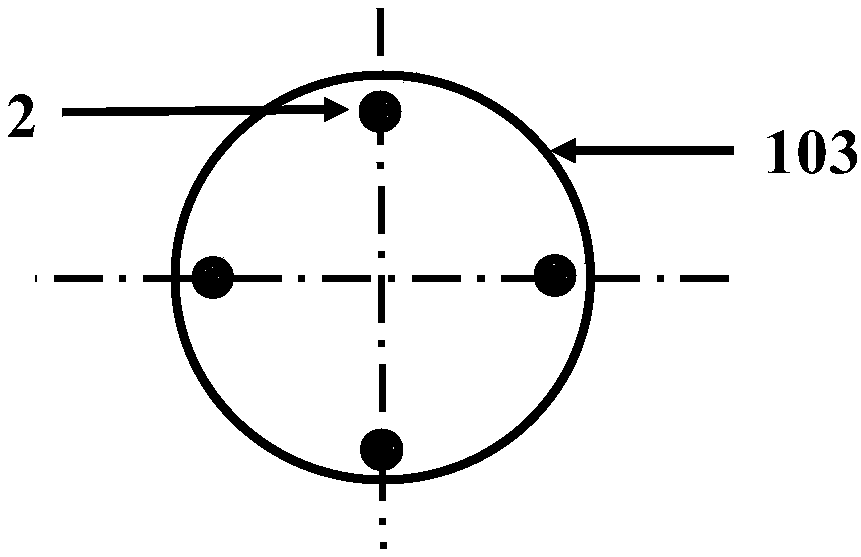

Vertical device for improving coal flow distribution in blast furnace

ActiveCN108265146AReduce total differential pressureImprove breathabilityInternal formsAir volumeEngineering

The invention belongs to the technical field of blast furnace iron making, and in particular, relates to a vertical device for improving coal flow distribution in a blast furnace. The vertical devicecomprises a furnace body, and multiple ventilation pieces arranged in the furnace body; the multiple vertical ventilation pieces are all solid columnar structural bodies; and the multiple vertical ventilation pieces are distributed at the top of the blast furnace in an array form, extend from top to bottom, and are inserted in a material column in the blast furnace by a period of distance. The vertical device for improving coal flow distribution in the blast furnace can improve the breathability of the material column of the blast furnace and reduce total pressure difference of the blast furnace to solve such problems as coal flow distribution and breathability of the material column, and improves the air blowing quantity and the yield under the precondition of guaranteeing invariable pressure difference of the material column to achieve the beneficial effect of improving the production benefit.

Owner:NORTHEASTERN UNIV LIAONING

Metallized charge for treating blast furnace hearth accumulation and using method thereof

ActiveCN110305999AOptimizing smelting process parametersEasy to removeBlast furnace detailsProcess efficiency improvementHot blastScrap

The invention discloses a metallized charge for treating blast furnace hearth accumulation and a using method of the metallized charge. The metallized charge is prepared from, by mass, 10-20% of HBI,5-35% of metallized pellets, 10-20% of scrap steel, 0-5% of lump ore and the balance sinter. The using method of the metallized charge comprises the steps that after accumulation of a blast furnace hearth is detected, stopping of the furnace is not needed, the metallized charge is directly adopted for blast furnace ironmaking, after the accumulation of the hearth does not exist, conventional charge is selected for smelting, and the whole process does not reduce production or reduces little production. The furnace charge structure is optimized and matched with a corresponding processes, so thatthe coke ratio of the blast furnace can be reduced by 20-45%, the burden of direct reduction at the lower part of the blast furnace can be obviously reduced, the furnace charge structure can be usedas a furnace condition seasoning of the blast furnace, when the accumulation of the blast furnace hearth occurs, a certain yield is maintained through the use of the metallized charge, and meanwhile,the hearth melt has higher carbon capacity due to the lower carbon content of the metallized charge, and removal of accumulation is accelerated.

Owner:SHANDONG IRON & STEEL CO LTD +1

Enhanced marine engine lubricating oil

InactiveCN106590860AReduce oil consumptionLower oil to fuel ratioLubricant compositionFuel oilEngineering

The invention belongs to the technical field of lubricating oil research and development, and particularly relates to enhanced marine engine lubricating oil which comprises, by weight, 40-45 parts of 150N base oil, 30-34 parts of 500N base oil, 10 parts of PAO 6 base oil, 13-13.5 parts of composite additives, 1.36-1.60 parts of alkali value reinforcing agents, 0.70-0.78 parts of thickening agent and 5-10*10<6> parts of anti-foaming agents. The enhanced marine engine lubricating oil can improve suitable alkali value, and the alkali value ranges from 12.5 to 13.0. The enhanced marine engine lubricating oil can greatly reduce engine oil consumption of oil products, fuel oil rate of engine oil and consumption rate of the engine oil, cost is saved for users, and economic benefits are improved.

Owner:广西北海玉柴马石油高级润滑油有限公司

Efficient center coke adding matrix setting method based on charge level iteration

ActiveCN113136467AImprove flatnessReduce thicknessSteel manufacturing process aspectsBlast furnace detailsPhysical chemistryCoke

The invention relates to the technical field of coke and ore grade and dip angle setting in a blast furnace top charging system, in particular to an efficient center coke adding matrix setting method based on charge level iteration. The method specifically comprises the following steps of 1) setting the radius ratio of a barren area to a furnace throat to be 40%-45%, and calculating the distance from an innermost ring coke drop point to the center of the furnace throat; 2) calculating the effective distance of a chute; (3) calculating the final velocity V<2> after furnace burden leaves the chute; 4) calculating a minimum coke angle alpha<coke min> according to L<min>; 5) calculating the dip angle of each grade of coke; (7) calculating the minimum dip angle alpha<ore min> of ore; 8) calculating other tilting angles of the ore; (9) determining the number of turns of material distribution of each ring position of the coke; and (10) determining the number of turns of material distribution of each ring position of the ore; According to the method, collapse layers formed by ores close to the ring position of the barren area in the material distribution process onto the coke can be avoided, then the air permeability and liquid permeability of a center material column are improved, and the proportion of center coke can be greatly decreased to 15%; and the gas utilization rate is increased, and the fuel ratio is decreased.

Owner:ANGANG STEEL CO LTD

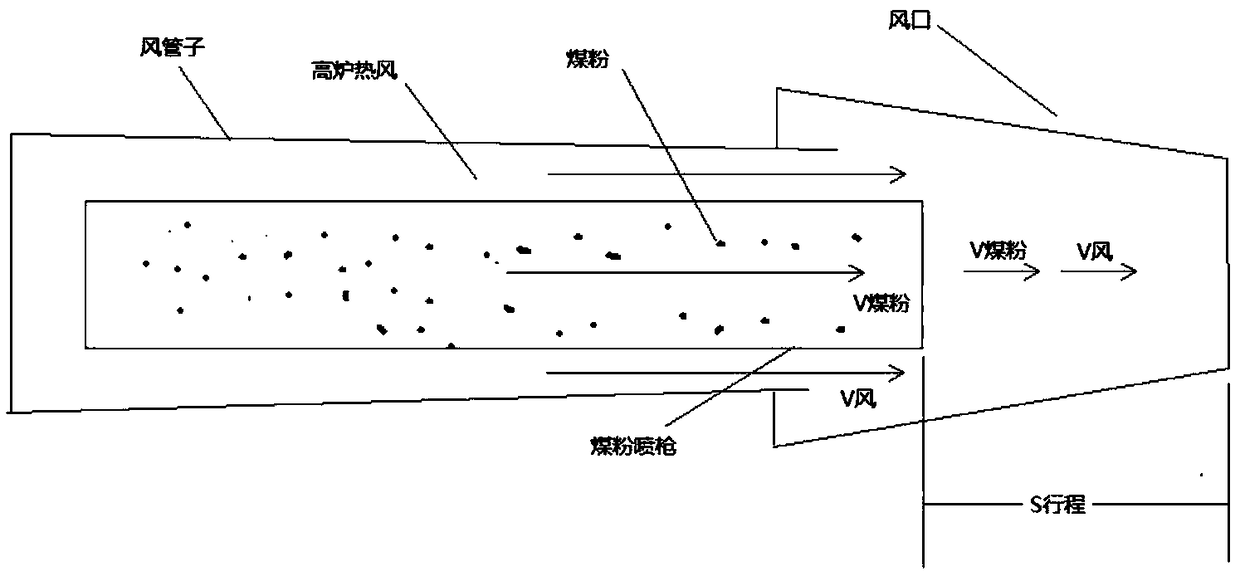

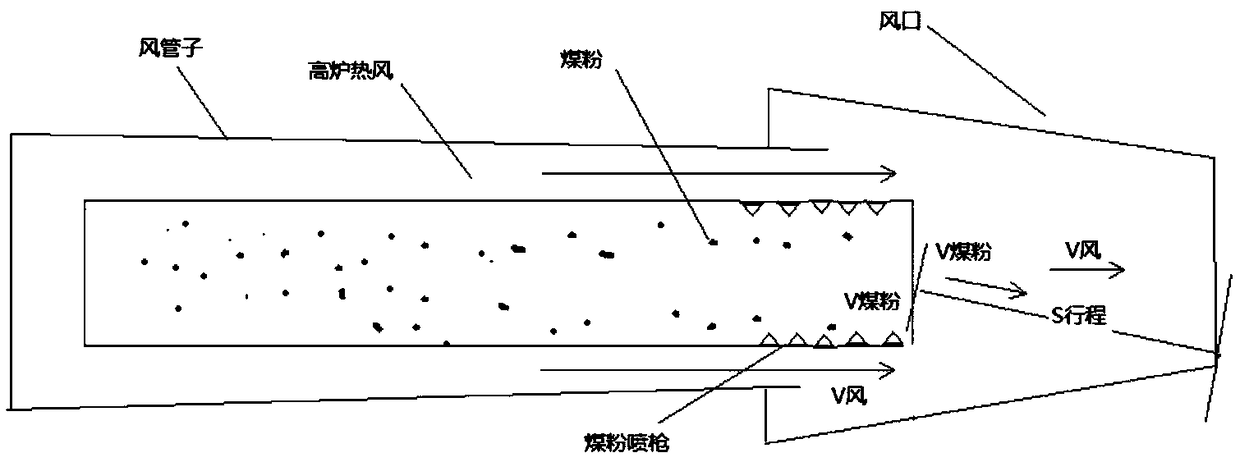

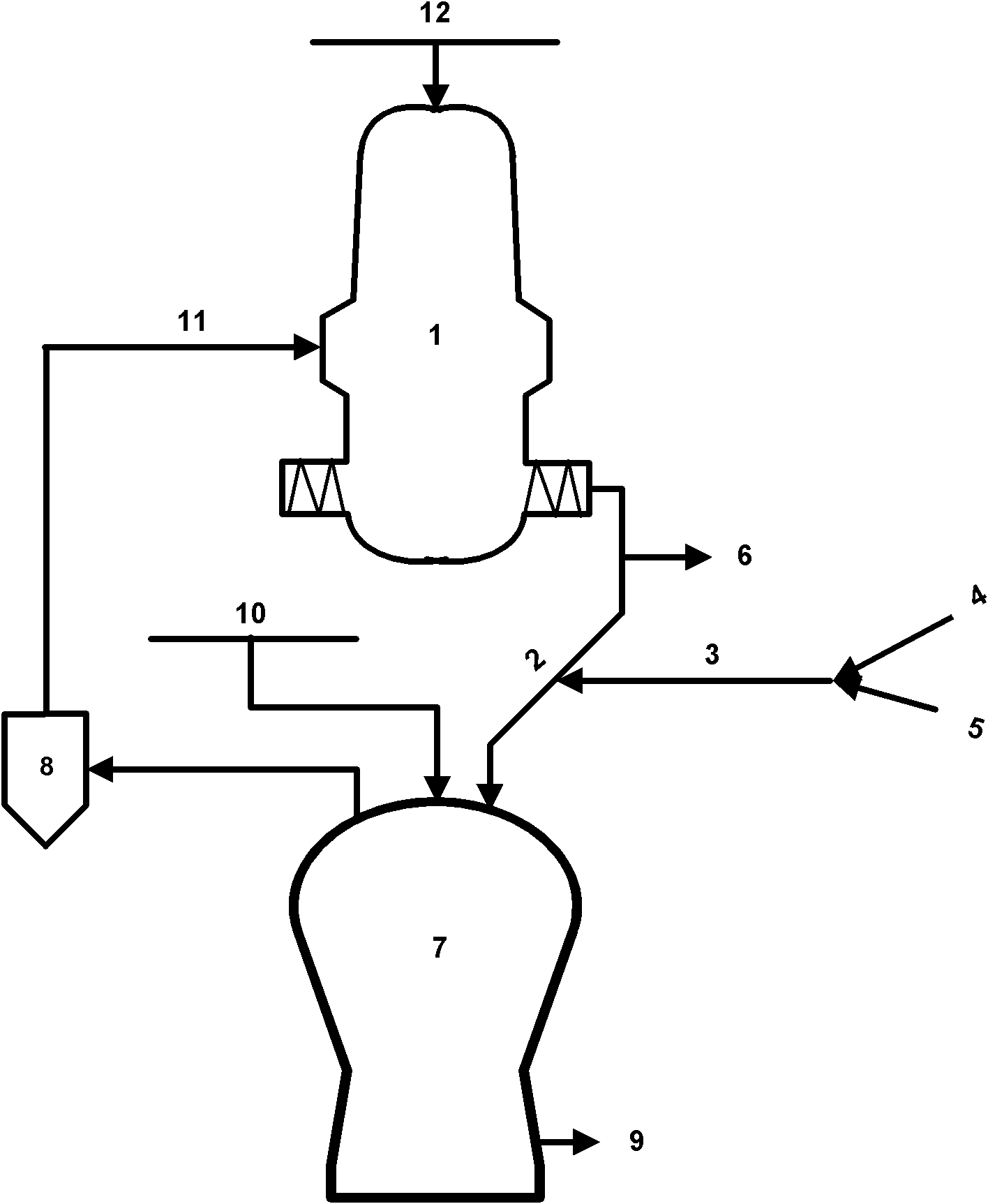

Injection method for improving pulverized coal combustion efficiency

InactiveCN109055635AReduce the ratioLower fuel ratioBlast furnace componentsBlast furnace detailsCoalFlue gas

The invention relates to the technical field of iron making, in particular to an injection method for improving the pulverized coal combustion efficiency. The injection method comprises the steps thatpulverized coal in a pulverized coal bin is loaded into an injection tank in an injection system, the pulverized coal in the injection tank is delivered to coal guns located in front of an air port through a delivering medium, and the pulverized coal is injected into a blast furnace through the coal guns. The injection method further comprises the following steps that (1), flue gas preheating isconducted on the pulverized coal discharged from the injection tank; (2), compressed air is adopted as the delivering medium for the pulverized coal; and (3), the crossed spiral casing pipe coal gunsare adopted and each comprise an inner channel and an outer channel, the outer channels adopt an oxygen cooling mode, the inner channels are used for delivering the pulverized coal, the inner side ofeach coal gun outlet adopts a spiral lining, the angle that the pulverized coal is injected out from the coal guns is changed to 45-degree inclination rotation from the horizontal direction, the component velocity V of the pulverized coal in the horizontal direction is decreased by 13.4%, and the walking route S of the pulverized coal in the air port is increased by 1.414 times. The two coal gunsare adopted and arranged at the front end of the air port in a crossed mode. According to the injection method for improving the pulverized coal combustion efficiency, the pulverized coal combustion efficiency can be improved, and energy conservation and environment protection are achieved.

Owner:ANGANG STEEL CO LTD

Method for controlling gas backflow in melting reduction smelting

InactiveCN103184301AEvenly distributedReduce the chance of enrichmentShaft furnaceDifferential pressureNitrogen

The invention relates to a method for controlling gas backflow in melting reduction smelting. Each DRI downcomer connected with a shaft furnace is mounted with a cold gas and nitrogen adding pipe which is provided with a control valve. The DRI downcomer is mounted with a temperature detection galvanic couple to detect gas temperature in the downcomer. Through inputting cold gas or nitrogen to the DRI downcomer, the temperature of the backflow gas in the DRI downcomer is controlled at 650-750 DEG C. The high temperature backflow gas which does harm to shaft furnace running is transformed into normally used reduction gas, which participates in reduction inside the shaft furnace to achieve control of the gas backflow. Conventional practice of suppressing backflow gas is changed by the present invention, adding powder to shaft furnace center is cancelled, and the backflow gas is dredged and used. Cold gas / nitrogen is fed into the DRI downcomer to reduce the temperature of backflow gas, improve dust distribution and enrichment condition in the shaft furnace, reduce shaft furnace differential pressure, improve gas utilization, prolong shaft furnace emptying cycle, reduce downcomer blockage frequency and damping down time, and improve operation rate and yield.

Owner:CHINA BAOWU STEEL GRP CORP LTD

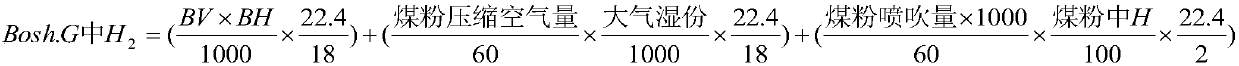

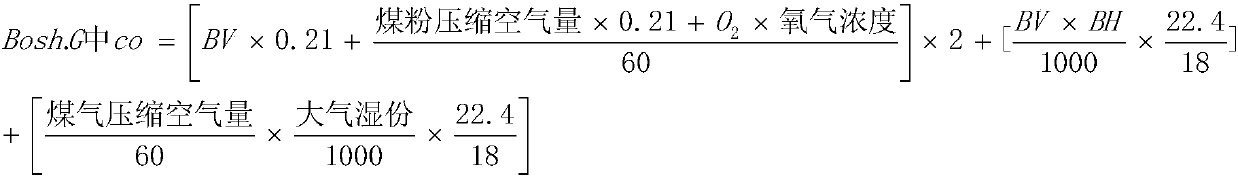

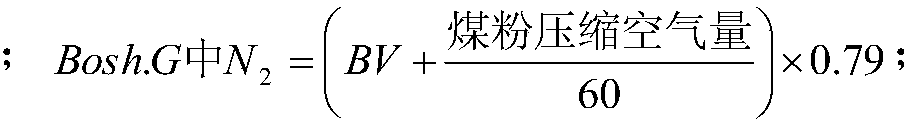

Method for determining ore batches and furnace top pressure according to blast furnace bosh gas volume indexes

ActiveCN107119157AIncrease production capacityImprove economyBlast furnace detailsLower limitMetallurgy

The invention provides a method for determining ore batches and furnace top pressure according to blast furnace bosh gas volume indexes, and belongs to the field of blast furnace ironmaking safe operation. The method is characterized in that the ore batches are equal to the sum of -46.71, the product of 2.65 and the bosh gas volume indexes, and a number ranging from 5 to 15, wherein the unit is t; the furnace top pressure is equal to the sum of 12.73, the product of 3.69 and the bosh gas volume indexes, and a number ranging from 15 to 30, wherein the unit is KPa; and for large blast furnaces of the grade ranging from 3500 m<3> to 5000 m<3>, upper limit values are taken, and for small blast furnaces of the grade ranging from 1500 m<3> to 3500 m<3>, lower limit values are taken. By means of the method, positioning of the ore batches and the furnace top pressure under the different bosh gas volume indexes in the normal production process of the blast furnaces is accurate; and the way of increasing the ore batches and the furnace top pressure, decreasing fuel ratios and controlling the bosh gas volume indexes within a certain range is the main way for achieving high-utilization-coefficient production.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com