Low-cost blast furnace smelting method

A smelting method and blast furnace smelting technology, applied in the field of low-cost blast furnace smelting, can solve the problems of poor air permeability, high blast furnace smelting cost, and large consumption, and achieve the effects of improving air permeability, increasing blast furnace smelting intensity, and reducing fuel ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A low-cost blast furnace smelting method, the smelting method comprising:

[0036] Upper adjustment: add coke with a particle size range of 8 to 20 mm into vanadium-titanium sintered ore, vanadium-titanium sintered ore, vanadium-titanium pellets and pig iron, and mix uniformly to form an ore layer; the vanadium-titanium sintered ore, the The mass ratio of the vanadium-titanium sinter ore, the vanadium-titanium pellets and the pig iron is 31:50:27:20, and the coke and the ore layers are alternately distributed into the blast furnace to form the ore-forming stone layer And the alternate layered structure of the coke layer, the coke is composed of high-strength coke and low-strength coke, the high-strength coke includes CDQ; the coke composition is composed of high-strength coke 70wt% and low-strength coke 25wt%. The CDQ accounted for 49.2wt% of the high strength coke.

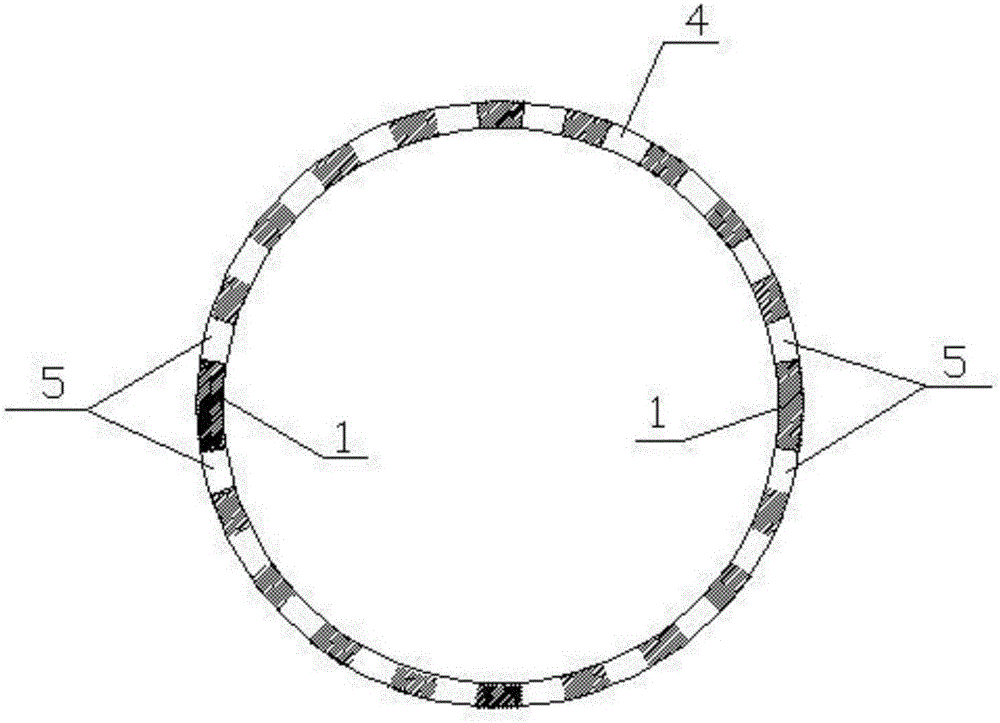

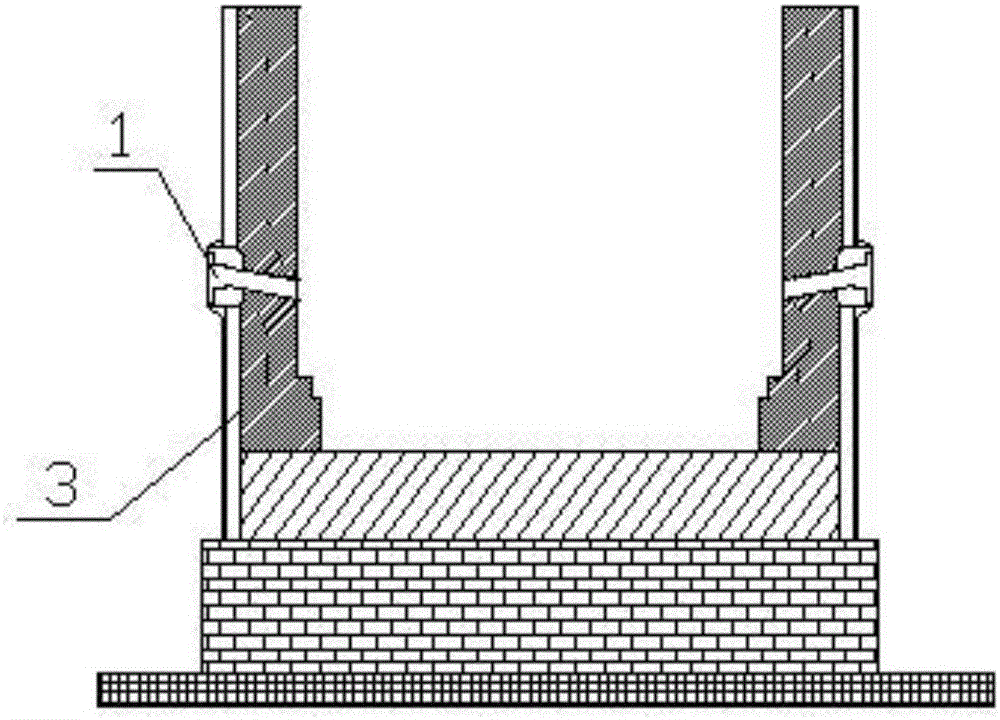

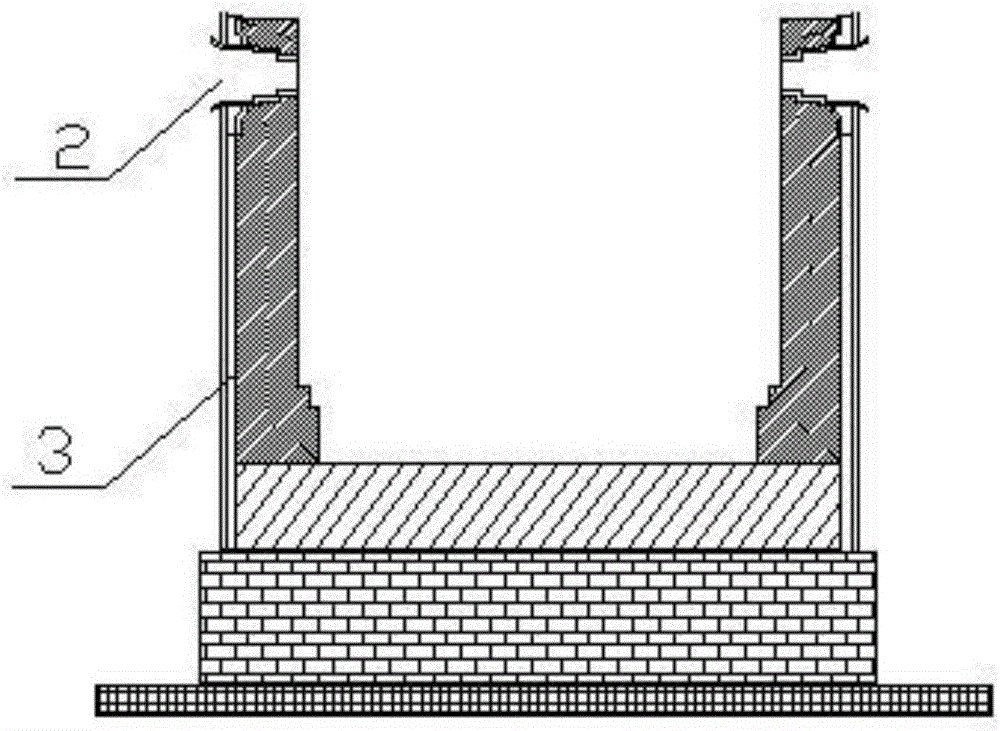

[0037] Do not adjust: if Figure 1 ~ Figure 3 As shown, the blast furnace hearth includes 20 tuyeres ...

Embodiment 2

[0041] A low-cost blast furnace smelting method, the smelting method comprising:

[0042] Upper adjustment: add coke with a particle size range of 8 to 20 mm into vanadium-titanium sintered ore, vanadium-titanium sintered ore, vanadium-titanium pellets and pig iron, and mix uniformly to form an ore layer; the vanadium-titanium sintered ore, the The mass ratio of the vanadium-titanium sinter ore, the vanadium-titanium pellets and the pig iron is 31:50:27:20, and the coke and the ore layers are alternately distributed into the blast furnace to form the ore-forming stone layer And the alternate layered structure of the coke layer, the coke is composed of high-strength coke and low-strength coke, and the high-strength coke includes CDQ; the coke composition is composed of high-strength coke 73wt% and low-strength coke 27wt%. The CDQ accounted for 49.2wt% of the high strength coke.

[0043] Lower adjustment: such as Figure 1 ~ Figure 3As shown, the blast furnace hearth includes ...

Embodiment 3

[0047] A low-cost blast furnace smelting method, the smelting method comprising:

[0048] Upper adjustment: add coke with a particle size range of 8 to 20 mm into vanadium-titanium sintered ore, vanadium-titanium sintered ore, vanadium-titanium pellets and pig iron, and mix uniformly to form an ore layer; the vanadium-titanium sintered ore, the The mass ratio of the vanadium-titanium sinter ore, the vanadium-titanium pellets and the pig iron is 31:50:27:20, and the coke and the ore layers are alternately distributed into the blast furnace to form the ore-forming stone layer and the alternate layered structure of the coke layer, the coke is composed of high-strength coke and low-strength coke, the high-strength coke includes CDQ; the coke composition is composed of high-strength coke 75wt% and low-strength coke 30wt%, so The CDQ accounted for 49.2wt% of the high-strength coke.

[0049] Lower adjustment: such as Figure 1 ~ Figure 3 As shown, the blast furnace hearth includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com