Method and device for determining thickness change of slag crust of copper cooling wall of blast furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

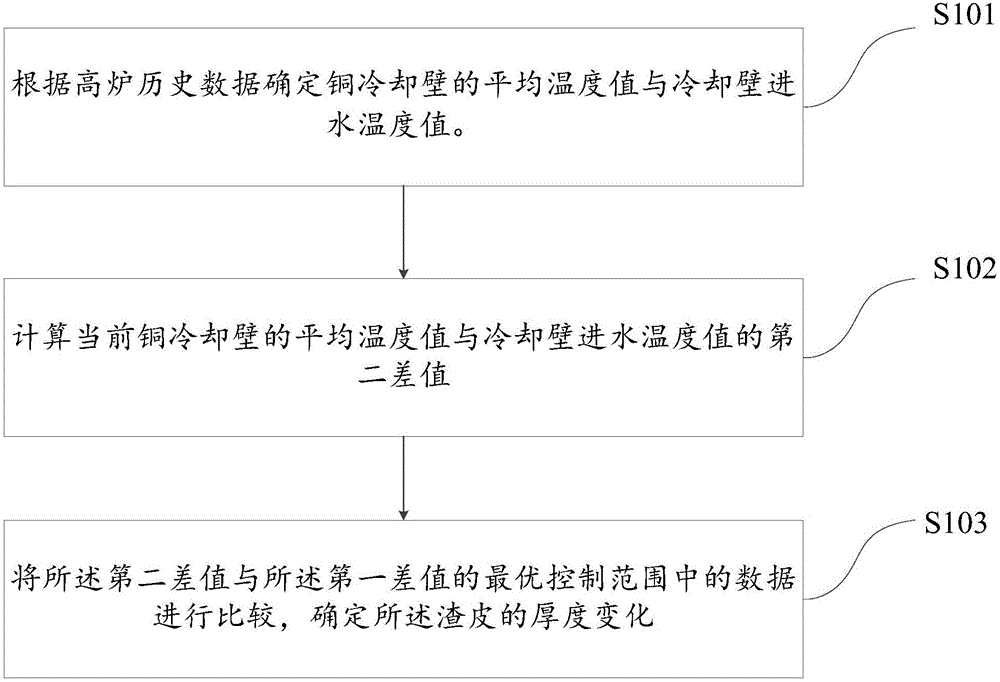

[0040] This embodiment provides a method for determining the thickness variation of blast furnace copper stave slag skin, see figure 1 , the method includes:

[0041] S101. Determine the average temperature value of the copper stave and the temperature value of the water entering the stave according to the historical data of the blast furnace.

[0042] In this step, the historical data of blast furnace production is obtained, the average temperature value of each section of copper stave is calculated, and then the first difference between the average temperature value of copper stave and the inlet water temperature value of stave is calculated; and according to the blast furnace economic index Determine the optimal control range of the first difference between the average temperature of the copper stave and the inlet water temperature of the stave.

[0043] Here, the economic indicators of the blast furnace may include: gas utilization rate, iron tapping amount of the blast f...

Embodiment 2

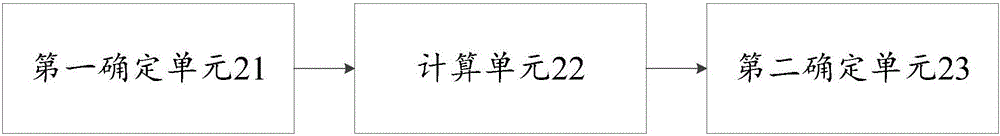

[0054] Corresponding to Embodiment 1, this embodiment also provides a device for determining the thickness variation of blast furnace copper stave slag skin, see figure 2 , the device includes: a first determination unit 21, a calculation unit 22 and a second determination unit 23; wherein,

[0055] The first determination unit 21 is used to determine the average temperature value of the copper stave and the temperature value of the water entering the stave according to the historical data of the blast furnace. Specifically, after the first determination unit 21 obtains the historical data of blast furnace production, calculates the average temperature value of each copper stave, and then calculates the first value between the average temperature value of the copper stave and the inlet water temperature value of the stave. After the difference; and determine the optimal control range of the first difference between the average temperature of the copper stave and the inlet wat...

Embodiment 3

[0066] In practical application, when utilizing the method that embodiment one provides and the device that embodiment two provides to determine certain 4000m3 level blast furnace copper stave slag skin thickness, specifically as follows:

[0067] Copper staves are used in the blast furnace bosh, furnace waist, and the bottom 6 to 9 sections of the furnace shaft in this embodiment. The historical data of blast furnace production are obtained, and the average temperature values of the copper staves in each section are calculated, and then the average temperature of the copper staves is calculated. The first difference between the temperature value and the inlet water temperature of the stave; and determine the optimal control range of the first difference between the average temperature of the copper stave and the inlet water temperature of the stave according to the economic index of the blast furnace. Here, the economic indicators of the blast furnace may include: gas utiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com