Medium-titanium high-strength sintered ore and preparation method thereof

A sinter and high-strength technology, which is applied in the field of medium-titanium high-strength sinter and its preparation, can solve the problems of poor strength, high return rate of medium-titanium sinter, and low yield, so as to improve the granulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0029] Examples 1 to 3: The medium-titanium-type high-strength sinter adopts the following preparation process.

[0030] The medium-titanium-type high-strength sintered ore is produced by the above method. The specific implementation is described as follows: Table 1 shows the particle size of the raw materials in the embodiment, Table 2 shows the raw material ratio of the embodiment, and Table 3 shows the process parameters and technical and economic indicators of the embodiment.

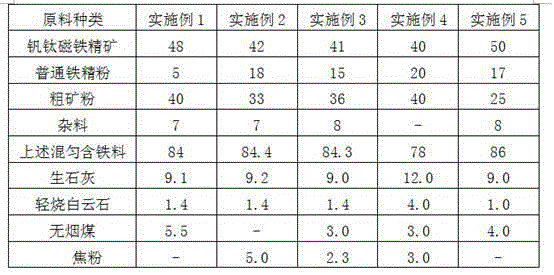

[0031] Table 1: Example raw material particle size (wt%)

[0032]

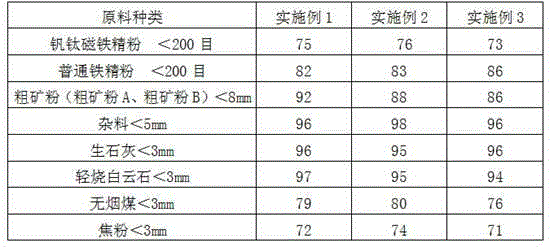

[0033] Table 2: Examples of raw material ratio (wt%)

[0034]

[0035] Table 3: Example process parameters and technical and economic indicators

[0036] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com