Method for producing molten iron by adding scrap steel into blast furnace

A technology for scrap steel and molten iron, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as complex components, achieve the effects of strengthening air permeability and liquid permeability, increasing temperature, and increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

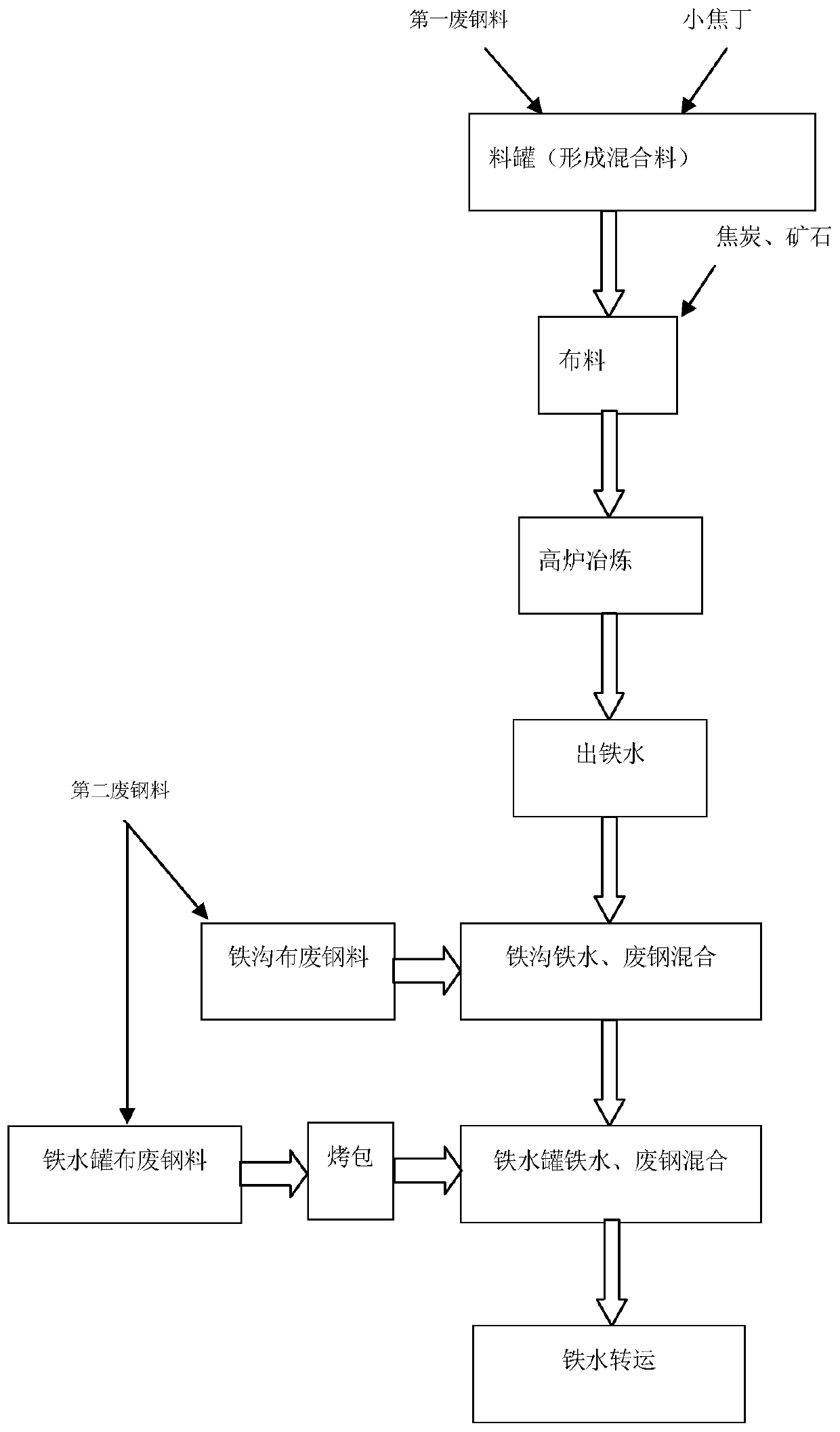

[0037] A method for adding steel scrap to a blast furnace to produce molten iron, comprising the steps of:

[0038](1) Ingredients: the massive steel scrap in the first steel scrap material is crushed by a crushing machine and then screened, and the light and thin steel scrap in the first steel scrap material is screened after being pressed, and is respectively screened into 9-12mm, 5-8mm, and less than 5mm (grains greater than 15mm return to re-crushing), wherein the first steel scrap material less than 5mm is re-agglomerated and screened for use. The first scrap material is a mixture of 18 parts by weight of social scrap and 70 parts by weight of factory scrap.

[0039] After crushing and pressing the first steel scrap with an equivalent diameter of 9-12mm and small cokes with a diameter of 5-10mm are mixed according to the weight ratio of 58:16, the lower layer in the first material tank is the first steel scrap The upper layer is mixed with small cokes to obtain the first...

Embodiment 2

[0049] A method for adding steel scrap to a blast furnace to produce molten iron, comprising the steps of:

[0050] (1) Batching: the massive steel scrap in the first steel scrap material is screened after crushing by a crushing machine, and the light and thin steel scrap in the first steel scrap material is screened after being pressed, and is respectively screened into 8-15mm, 5- 8mm and not including 8mm, and less than 5mm (in which the particles larger than 15mm are returned to be broken again), wherein the first steel scrap particles smaller than 5mm are re-agglomerated and then sieved for use. After crushing and pressing the first steel scrap with an equivalent diameter of 8-15mm and small cokes with a diameter of 5-10mm are mixed according to the weight ratio of 56:20, the lower layer in the first material tank is the first steel scrap The upper layer is mixed with small coke to obtain the first mixture; the equivalent diameter after crushing and pressing is 5-8mm and d...

Embodiment 3

[0059] A method for adding steel scrap to a blast furnace to produce molten iron, comprising the steps of:

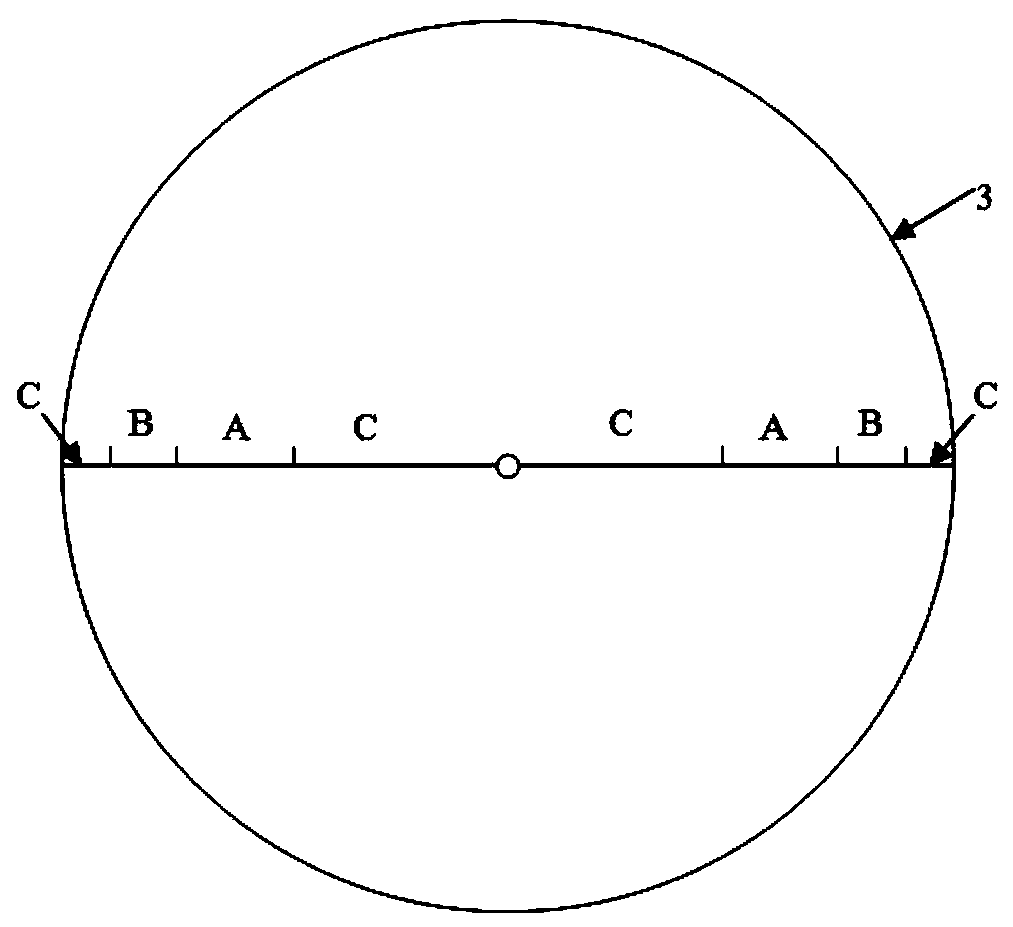

[0060] (1) Batching: After crushing and pressing the first steel scrap material with an equivalent diameter of 8-15mm and small cokes with a diameter of 5-10mm according to the weight ratio of 59:29, the following layer in the first material tank The first mixed material is obtained by mixing the upper layer of the first steel scrap with small cokes; the crushed and pressed first steel scrap with an equivalent diameter of 5-8mm and the small cokes with a diameter of 5-10mm are obtained in parts by weight 63:28 After batching, in the second material tank, the lower layer is the first steel scrap and the upper layer is small coke, and then the second mixture is obtained. The first scrap material is a mixture of 22 parts by weight of social scrap and 75 parts by weight of factory scrap.

[0061] (2) cloth: the second mixture obtained in step 1 is distributed along the mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com